Foam block

Specifications

Photo of the foam block

This type of aerated concrete appeared on the construction market a long time ago and immediately gained popularity. This was achieved thanks to good properties, which we will talk about below.

Foam concrete is made from simple components, which are cement mortar, sand and some water. To impart the desired qualities and structure, a foaming agent is added to the final product.

Production workshop for the production of foam blocks

Some types of foam concrete also contain additional ingredients such as clay, fiber and even ash. These components are designed to add to the quality indicators of the foam block also the characteristics of the brick.

To give a competent answer to the question of which is better: a foam block, building brick or aerated concrete, you need to consider the advantages and disadvantages of each of these products.

Let's start with the properties of the foam block:

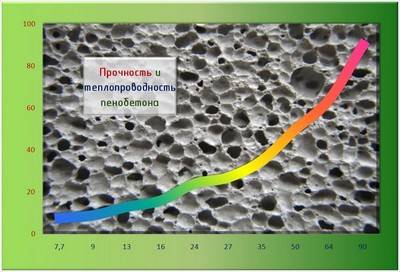

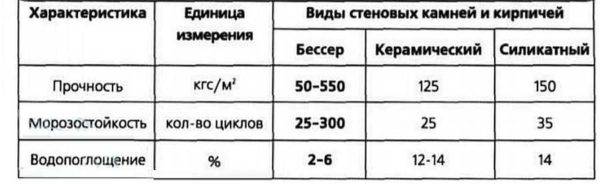

Comparative characteristics of some materials

- Environmental friendliness. These products are completely safe for health, as they are created from natural ingredients.

- Moisture resistance. The foam block is rather mediocre in resisting moisture.

- Durability. The service life is calculated in many tens of years.

- Density. This value is equal to 700 kg / m. cub.

- The thermal conductivity coefficient is 0.18. This is a low figure that allows you to keep warm in the room.

- The weight. The foam block is very light. The mass of a square meter of a wall made of this material is 700 kg.

- Fire resistance. This product is classified as non-flammable.

- Price. The price of aerated concrete is acceptable and less than that of many building materials.

Application

Foam block masonry

The foam block is quite common in construction. It is used both by private developers for the construction of country houses and in urban construction. Quite often, foam concrete is used for monolithic pouring, where it turns into blocks right at the construction site.

The relative cheapness of this building material and good quality indicators expand the scope of its use. The only restrictions on its use are basements and foundations. This is due to the poor moisture resistance of foam concrete.

Preparation for work

Before starting the zero cycle and laying the foundation for the gazebo, we recommend drawing up a draft of the future structure. For example, decide on the shape, size, and design. Since our material is non-combustible, we recommend setting aside a place for a barbecue or making a built-in barbecue.

Are the walls closed or open? In the first case, when you have three blank walls, the roof is set up on elevations of blocks. In the open version, a metal or wooden frame is erected. A roof is erected on it, after which 1-2 walls of foam blocks are erected.

Gazebo made of open-type foam blocks with a wooden fence

Gazebo made of open-type foam blocks with a wooden fence

- Drawing. You can draw it yourself or download the finished project online.

- List of materials, tools.

- Calculation of the budget.

- Plan for conducting electrical wires (if necessary), pipes for water supply.

In a word, the concept of construction should be thought out in as much detail as possible. And then it took shape on paper.

DIY aerated block production

Technology at home requires the master to adhere to certain rules. This process consists of several stages.

The required set of equipment and materials

Before making aerated concrete, you need to prepare materials and tools. Concrete is made from a mixture of the following materials:

- Sand. It is recommended to give preference to quartz sand, which is pre-washed and dried.

- Cement. High-strength material is obtained using cement, which has a grade of over 400.

- Clean water.

- Quicklime.

- Aluminum powder, caustic soda, sodium sulfate.

Forms

Before aerated concrete is made, the forms are prepared. You can buy finished products in hardware stores. To save money, they are created independently. Initially, a pencil case is made of wooden boards. Jumpers are inserted into it, with the help of which the frame is divided into compartments. Molds can be made from moisture-proof plywood. In order to fix the boards, cuts must first be made in them.

The dimensions of the cells must match the dimensions that the finished block must have in accordance with the project. In order to speed up the production process, it is recommended to carry out the simultaneous construction of several forms. In order to exclude the possibility of adhesion of the solution to the forms, they must first be lubricated with a special agent. At home, it is recommended to use waste engine oil, which is diluted with water in a ratio of 1: 3.

In order to speed up the production of aerated concrete, you can use mobile installations, which consist of a compressor, mixer and connecting hoses. Devices are preliminarily prepared with the help of which excess concrete is removed.

Preparation of the solution

The process of making aerated concrete at home begins with the preparation of a solution. The number of components used depends on the density of the material the user wants to obtain. Consider the option of preparing a solution for aerated concrete, with a density of 1600 kilograms per cubic meter. This will require 1100 kilograms of sand and 400 kilograms of cement. The components are thoroughly mixed. To them you need to add 5 kg of lime. Additives such as caustic soda, aluminum powder, and sodium sulfate are also added to the solution.

After thorough mixing of all dry components, they are filled with 189 liters of water. After mixing the composition until smooth, it can be used for pouring.

Fill

After lubricating the molds with a special composition, a solution is poured into them. In this case, care must be taken that the forms are not poured to the brim, since when the mixture hardens, it swells and the excess will be licked out. Forms need to be filled in half. After pouring the material, the appearance of a gas formation process is observed. The next step is to remove excess mixture using metal strings. The procedure is carried out 5-6 hours after pouring.

After 18 hours after pouring, the products can be stripped. In order for the aerated concrete blocks to move away better, you need to knock a little on the forms. After a month, aerated concrete will acquire technical strength. Solidification of blocks is observed not only indoors, but also in open areas.

Production profitability

A variety of factors affect the profitability of block manufacturing. It depends on:

- The cost of raw materials;

- Investments for the purchase of equipment;

- The amount of industrial waste;

- Desired volume;

- Production goals.

Experts carried out calculations in accordance with the indicators, according to which it was found that making aerated concrete blocks with your own hands is more expensive than purchasing ready-made material. In addition, this process is labor-intensive and time-consuming.

Aerated concrete blocks are a versatile building material that is widely used for the construction of buildings. You can buy it at factories and in hardware stores. You can also make blocks with your own hands, having previously calculated the profitability of this process.

Foam block: pros and cons

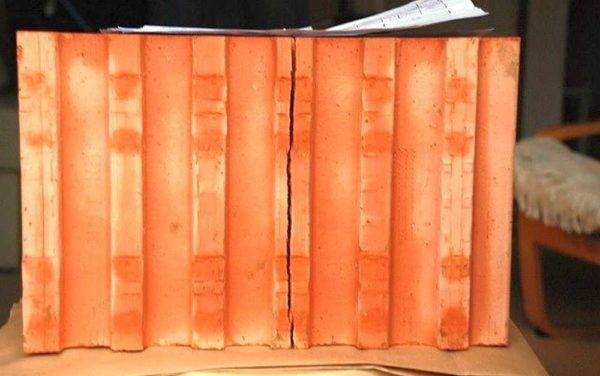

Foam blocks are made of concrete dough mixed with pre-prepared technical foam.The entire thickness of the product is saturated with small closed spherical pores (0.2–2 mm).

The process of making foam concrete involves:

- Cement binder;

- Foam generator;

- M special mixer;

- Foaming agent (modified waste from other industries or a specially synthesized substance).

Information. Foam concrete is made on a cement binder, therefore it continues to gain strength for a long time.

Features of foam concrete (is it possible to build a bath from foam blocks)?

Foam concrete is warmer and lighter than brick, ordinary concrete. A frame bath is warmer and lighter than a foam block bath: its masonry conducts heat better than a frame wall.

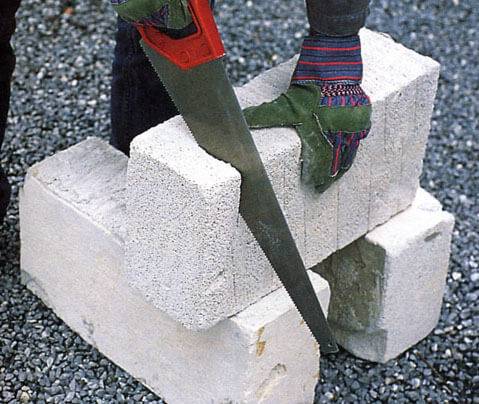

In processing, the foam block is almost as light as wood - it can be sawed, drilled.

Foamed cement paste stone does not burn or rot. The foaming agent does not reduce the ecological purity of the cement-sand stone (not to be confused with expanded polystyrene concrete, in which the pores are filled with poisonous and flammable polystyrene).

Is it possible to make a sauna from foam blocks? The vapor permeability of the foam block is good for softening the microclimate in the bath, but it needs to be limited due to the presence of capillary pores.

Is it possible to make a sauna from foam blocks? The vapor permeability of the foam block is good for softening the microclimate in the bath, but it needs to be limited due to the presence of capillary pores.

It is very important to protect cellular materials from contact with water, in particular the lining, since they are permeable to water.

Lightweight concrete grades for water permeability: W0.4; W0.6; W0.8; W1; W1.2.

Is it possible to build a sauna from foam blocks and immediately revet it?

Alas, foam concrete masonry gives significant shrinkage, you will have to wait a little with finishing.

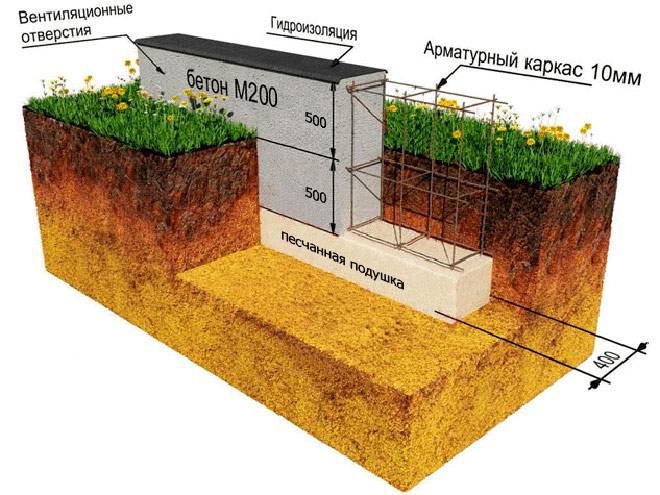

Which foundation should you choose?

Foam blocks require a reliable foundation. For example, tape. When the soil is unstable, you will have to fill in a solid slab.

We recommend a foundation tape. It is quite possible to build it in a day on your own and you do not have to wait a month until the material hardens, the gazebo is a rather small building and the weight of the walls folded from the foam block is incomparably less.

When the monolithic option is selected, formwork is installed in the coated trench. It is covered with polyethylene. The frame is laid on the bottom, and concrete is poured from above.

Since we are building a gazebo, not a house, you can do without excessive deepening of the monolithic tape. Especially if the groundwater is deep enough, and everything is in order with the ground itself.

What should be the height of the support? 35 cm is enough for the head (20 cm deep). We dig a trench to a depth of 40 cm

It is very important that the width of the foundation matches the wall material. If we make it five centimeters wider, we get a small protruding base.

A combined version of the foundation is also possible

For a building with a terrace, specialists make concrete tape for the walls and point supports (pillars) for the frame.

Of course, each type has its own advantages, disadvantages and construction technology. You can always find the necessary instruction with a photo on our website.

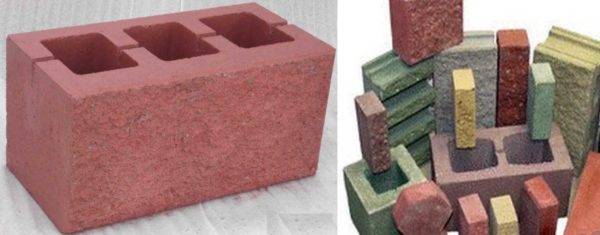

Pressed cement blocks from sand concrete (besser-blocks)

Another type of hollow building block is made from sand concrete. Full-bodied ones are made using the same technology, but they have low thermal efficiency. But the wall is practically a monolith, it is difficult to break through it, the bearing capacity is high. But such a house, in order to be warm, will have very thick walls, which will increase the cost of the foundation.

Which blocks are the best for building a house? If strong walls are a priority, then vibropressed walls are out of competition

The process of forming vibropressed blocks is as follows: a mixture of cement and sand are diluted with water... The solution is poured into molds, which are then processed on a vibrocompression table. That is, the solution is simultaneously subjected to vibration and pressure. This gives it increased strength and allows you to make the walls thin, and the voids significant.All this makes it possible to reduce weight, as well as increase the thermal performance. This technology has been used in America for a long time. Budget houses are built from such a building block. It is called the Besser-block.

Advantages and disadvantages of vibropressed blocks

The main advantage of this technology is vibration treatment with simultaneous pressure. The concrete stone is very strong and homogeneous. There are no voids, irregularities, characteristics and properties are stable, the walls are even and smooth. And also such processing makes it possible to control the size. Of all the blocks that are poured into molds, this one has the best geometry.

Sand concrete blocks: the main characteristics of corpulent

Further according to properties: high frost resistance - from 50 cycles (up to 300), strength - M100 or higher. The thermal conductivity of hollow blocks is 0.9 W / m², which is much lower than required, so either the wall must be thick, or it must be insulated. It absorbs moisture, but in small quantities, it is not afraid of getting wet. There is no data on the thermal conductivity of the solid block. You have to understand that they are extremely disappointing.

When constructing walls from hollow vibroblocks, reinforcement is recommended. And they do both vertical and horizontal. For the vertical, rods are used, which would be good to connect with the outlets from the foundation. And the horizontal reinforcement is a metal mesh. This is not a requirement, but stronger walls are obtained this way.

Which blocks are the best for building a house? By their beauty - these

Of the "pure" disadvantages - a fairly large weight and small size of the stone. This is when compared with lightweight concrete blocks. Accordingly, a foundation for a large weight needs a more powerful one, which leads to an increase in its costs.

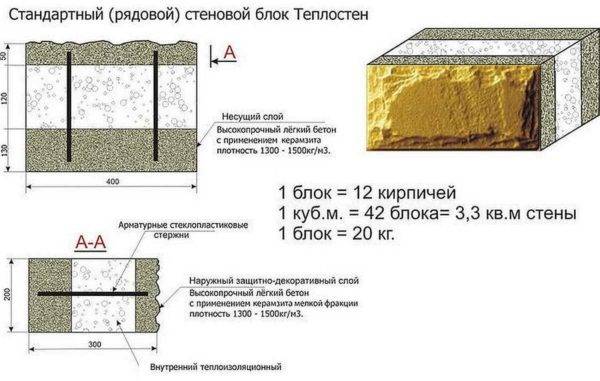

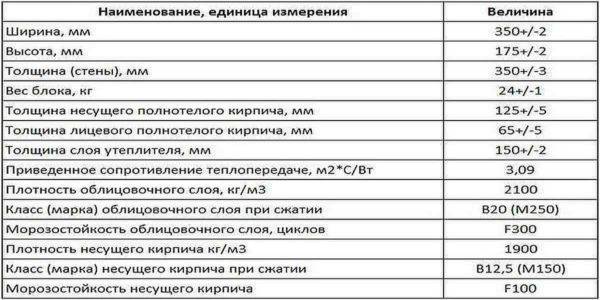

Heat block

A heat block was made on the basis of vibrocompression technology. This is a multi-layer structure, in the middle of which there is polystyrene, and on the sides there is a cement-sand vibropressed composition. Moreover, one side is front, painted in bulk and, as a rule, textured, and the other is a solid building stone that bears the load. To increase reliability, the structure is fastened with reinforcing rods.

Perhaps the most energy efficient option. That's just until it's too popular.

That is, the heat block is a three-in-one material. Immediately, the wall is being erected, and its thermal insulation and decoration. The idea is very interesting and tempting. But, as usual, the novelty raises concerns - how will such a cake behave over time? How reliable are such walls? In general, while people are in no hurry, although these blocks are better for quickly building a house.

It is not so difficult to find the characteristics here. Apparently, because thermal conductivity pleases

What is better to use for construction

To determine the question of which material is better to give preference to when erecting various buildings, it is worth considering the scope of their application.

Namely:

- Autoclaved gas blocks are most often used for the construction of load-bearing structures and internal walls and partitions in private construction. They are also actively used to fill frames when creating a monolithic house. They can be used in the construction of multi-storey buildings and the construction of high-rise structures.

- The gas block, which was dried in natural conditions, has more limited applications. It is less dense and durable, the dimensions are not so clear. It is often used to create an insulating layer, as well as a foam block.

- The area of application of foam blocks is as follows: the construction of internal walls and partitions, external load-bearing walls up to 3 floors, the creation of fences. They are also used for the construction of industrial buildings, thermal insulation of walls, floors, ceilings in non-residential premises.

For home

For the construction of buildings with 2-3 floors, a private house, guest houses and permanent residence, gas blocks are often used.

For garage

Buildings from gas blocks are durable, they serve for a long time. But if you look at the cost, it is more economical to choose foam concrete. It is also actively used in the construction of non-residential buildings.

The walls of the garage are subject to such requirements as strength, reliability, resistance to mechanical stress. The choice of material can only depend on the personal preferences of the owners.

It is easier for beginners to work with gas blocks that have fixed dimensions, and there is no need to adjust them.

For a bath

Unlike foam concrete, gas silicate blocks are afraid of water, easily absorb it and take a long time to dry. They provide excellent heat and sound insulation, but it is not recommended to use them for the construction of a bath.

Foam blocks can be used to build walls in places with high levels of humidity. This allows you to build baths out of them. Its advantages are also frost resistance and good thermal protection.

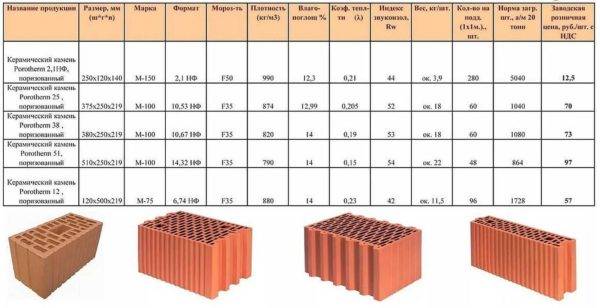

Ceramic block or porous warm ceramic

This porous ceramic block is produced using the same technology as bricks and from the same materials. The only difference is that the "body" of the material is not solid, but consists of voids and ceramic bridges. Such a structure is effective: for central Russia, a wall made of porous ceramics should be 50 cm. The same wall thickness is needed from aerated concrete. And additional insulation with such a thickness is not required. That is, the wall will be single-layer, which is much better than multi-layer. And the finish can be made from facing bricks or clinker. Ceramics will make friends with ceramics without any problems. But not everything is so rosy.

Hollow blocks for walls made of ceramics could be considered the best option, if not for a high percentage of battle and difficulty with fasteners

Advantages and disadvantages of ceramic blocks

The main advantages were listed - good thermal performance and low (compared to ordinary or even hollow brick) weight. But ceramics is fragile. And thin partitions break and break easily. When transporting, you can get about 10% of the battle. In addition, cutting off a ceramic block is not so easy. The saw will not help here. Other, more serious equipment is required. Another disadvantage is that special fasteners are required, since only he can hold on to thin walls.

| Pros of ceramic blocks | Cons of hollow ceramic blocks |

|---|---|

| Good thermal insulation performance | Fragile material that easily splits and breaks |

| High level of sound insulation | Special tool required to cut blocks |

| Average water absorption | Requires special fasteners |

| Steam permeability | The blocks are not as big when compared to lightweight concrete |

| Decent frost resistance | Imperfect geometry, high cost for ground, which have stable dimensions |

| High strength | |

| The presence of a corrugated surface, which increases the thermal resistance of the masonry. | |

| High heat absorption. It works like a large heat storage, but it is bad for building houses with periodical heating. |

Other advantages are the same as for bricks: natural ceramics, average water absorption, frost resistance from 30 to 80 cycles, good sound insulation properties - up to 55 dB, which is a very good indicator. In addition, there is such a thing as heat capacity. It shows how much heat a material can accumulate in itself. The more heat it "takes" into itself, the longer it will then give it away. For houses with permanent residence, it is materials with a high heat capacity that are more comfortable. And for ceramics it is rather big. Such a wall is a kind of heat accumulator. For a home of permanent residence, this is good, but for a summer residence, which is visited in winter only from time to time, it is bad. It takes a lot of fuel and time to warm up. So this building block is not the best for summer cottages or baths.

It should also be added that today the cost of a cube of a porous ceramic block and the cost of autoclaved aerated concrete are practically the same. In some places, aerated concrete is even more expensive.But the dimensions of the blocks made of aerated concrete are larger, the consumption of glue and the time required are less. Time can be argued, since for ceramics the presence of armored belts is not necessary, but it will not be superfluous. And you can't argue with the size of the blocks. And with the precision of geometry. No, there are grinded ceramic blocks that can be customized. They can be installed with a minimum layer of adhesive. But such blocks are much more expensive. Nevertheless, taking into account all the facts, it is worth saying that we all know ceramics. So, all other things being equal, it is more reasonable to choose it.

Lightweight blocks for construction made of porous ceramics have good characteristics, but they can be cracked, which do not contradict GOST. Some manufacturers change such material without problems. Others don't see it as a marriage.

Everything is true, but there is one setback. A ceramic block is a type of brick. And according to GOST, non-through cracks are allowed in the brick, if they do not affect the strength. Solid bricks do. The presence of small cracks on one side is not considered a marriage and does not affect the quality of the masonry in any way. But if there is a crack in one of the edges of the ceramic block, it will clearly not be as strong. Second. When one of the faces is torn, it diverges, the sides are no longer parallel. It is hardly worth using such a block in masonry, although technically this is not a marriage.

Consider the advantages and disadvantages of each of the materials

Each of the blocks has its own characteristics. Their analysis will make it possible to make the right choice of the material used in wall construction for the construction of the required facility.

Which is stronger

Since the blocks have a porous structure, the question arises which is stronger. This indicator directly depends on the density of the material.

For foam concrete it is 700 kg / m³, and for aerated concrete - 450 kg / m³. Foam concrete is a more durable product, but with proper installation, the strength of buildings made of aerated concrete and foam concrete is approximately the same.

Which is easier

Due to the porous structure, the products are lightweight, which allows them to be used in the construction of any facilities. The foam block has less weight due to the foam structure. Small pores are not filled with moisture. And its counterpart changes weight depending on the humidity of the environment around.

Which is warmer

An important factor when building a house is warm walls. Frost resistance of materials is almost the same when properly installed using special glue and mixtures. But according to technical indicators, the foam block is a more frost-resistant material. Here it is worth considering production indicators: brand, block thickness.

The foam block is a warm material, it retains heat. However, the thermal resistance of the gas block is much higher.

Water absorption

The gas silicate block quickly absorbs water. This is due to its structure. Foam concrete is moisture resistant, but both materials require additional insulation. Correct surface treatment prevents the risk of deterioration due to exposure to water and the formation of mold.

.

Convenience in construction

The materials are convenient in the process of construction work. Their indicators are approximately equal. Both materials are used in the construction of walls for both low and multi-storey structures. What are their advantages:

- high strength foundation is not required, since the materials are lightweight;

- a high thermal insulation index allows you to save on heating;

- a flat surface allows you not to carry out complex finishing work.

The cellular structure of the foam block does not allow it to be used for the construction of buildings above 2 floors, with the exception of using it as a heater for brick structures.

The gas block is stronger and has a wider scope. It is used for masonry partitions, load-bearing walls, fences, floors.

What is more natural

The composition of gas and foam concrete includes environmentally friendly materials. Despite the fact that aluminum paste is included in the raw material for the manufacture of gas silicate, it is safe. A solution of aluminum is extremely harmful in a concentrated state, however, during the production of concrete, it volatilizes during the reaction.

Foam concrete construction.

Foam concrete construction.

What sizes

Manufacturers present a whole line of concrete materials. The most popular block has indicators of 625x25 mm, the thickness varies depending on the purpose: 10 mm, 15 mm, 20 mm - for partitions and insulation, 25-60 mm - for the construction of walls.

Durability

Manufacturers claim that foam and aerated concrete have a 50-year warranty, but it only lasts if all installation and operating conditions are met.

What is the price of materials

Due to the complex production technology, a gas silicate block is much more expensive than a foam block. However, when calculating the construction estimate, it is worth considering other manipulations. So, for example, in order to achieve the required thermal insulation effect, you will need a larger amount of foam block. In addition, an uneven surface requires a larger volume of binder solution.

For building a house with your own hands from lightweight concrete, both a foam block and a gas silicate block are suitable. The main condition is to select high-quality material.

Aerated concrete balcony

Gas silicate and aerated concrete blocks are used in the construction or insulation of balconies and loggias. The advantages of these materials are:

- ease;

- high compressive strength;

- thermal insulation properties;

- sound insulation due to the porous structure;

- not susceptible to fire;

- ecological cleanliness;

- no harmful additives in the composition.

For arranging a balcony from aerated concrete blocks, it is recommended to use glue-cement, which will provide strength and prevent the appearance of cold bridges.

Most often, blocks with dimensions of 30 x 20 x 10 centimeters are used. In terms of density, the material must correspond to grades D400-D500.

As in the previous cases, first of all, you need to make the markup.

In this case, it is important that the middle of the support masonry is located under the upper attachment points of the future window frame - approximately five centimeters from the edge of the upper reinforced concrete floor slab

Preparing the cement mortar

When laying the first row, a generous use of adhesive is required. After firmly pressing the block to the floor surface, the excess glue should be at least two to three centimeters. All other rows of gas blocks must be laid at intervals.

If there are pipes on the balcony, they must be bypassed by cutting off excess sections from the blocks. To fill the voids that are formed as a result of this, ordinary polyurethane foam is suitable. It must be used in minimal quantities, since swelling, it can cause cracking of the gas block.

When all the rows are laid, you need to wipe the seams with a special compound that will fill all the voids.

How to lay out a parapet on a balcony made of aerated concrete

For laying a parapet from aerated concrete you will need:

- gas blocks of the required size;

- glue for aerated concrete blocks;

- perforated metal mounting tape;

- guide profile;

- dowels or fittings;

- metal masonry mesh.

The work should be carried out in the following order:

- Determine the location of the future parapet.

- Mark the floor.

- Install the guide profile on the base of the floor using self-tapping screws and dowels.

- Insert the blocks with adhesive on the back into the profile and firmly attach to each other.

- Spread out the second row and check the correctness of the vertical using the level and markings on the wall.

- In a similar way, lay out all subsequent rows, not forgetting to grind each gas block to each other.

In order for the parapet to be stable and strong, it needs reinforcement. The easiest way to do it is with a perforated metal tape. It must be laid on top of the finished parapet and fastened with self-tapping screws. Additionally, you can lay the tape on each row of gas blocks from the inside.

Securing the parapet masonry with reinforcement

Thermal insulation of the balcony with aerated concrete blocks

To insulate a balcony, it is better to use gas blocks with a thickness of about 10-12 centimeters, so as not to greatly reduce the usable space. To do this, cut the standard material with a regular hacksaw.

The styling process is simple. Apply the required amount of cement glue from the lower edge of the wall and press firmly. After filling the first row, lay out all subsequent ones in a checkerboard pattern. Cut off the excess pieces of the gas block with a hacksaw.

Cut off the excess part of the foam block

We build a brazier from blocks

Not only the presence of leftover material pushes people to make a brazier with their own hands. Purchased or off-the-shelf models are a trade-off that is probably convenient for many. But an individual project will take into account all the features you need and you will not need to pay for unnecessary items. The appearance is also original.

Block advantage

The quality of modern blocks is such that after finishing it is difficult to find differences with brickwork. What are the advantages of this material for the barbecue:

- Lightweight construction does not require a heavy foundation;

- Blocks are easy to handle;

- Some options have a ribbed surface, which saves masonry mixture;

- There are no restrictions on any type of finish;

- Low thermal conductivity;

- High frost resistance;

- Sufficient strength;

- Where there is no thermal stress, increased service life compared to brick.

Several types are available:

- Foam blocks;

- Cinder blocks;

- Gas blocks.

Foam blocks

These blocks are made from a mixture of sand, cement, water and synthetic foam. After solidification, a fine-celled structure is obtained. The blocks are produced in different brands, but only from D500 to D900 are suitable for the barbecue.

In addition to the advantages, there are also disadvantages:

- Significant shrinkage;

- High hygroscopicity;

- Brittle on impact, especially on edges;

- For fasteners, you will have to use embedded parts (the material does not hold nails or screws).

We recommend using special glue for masonry, although a cement mixture or oven mortar will also work.

Gas blocks

They are made mainly of cement, but there are also gypsum or lime. For gassing, aluminum powder is used. Gas blocks are not subject to shrinkage and hold fasteners well. Through voids will require more masonry mortar.

Cinder block

Cinder block masonry can be left without finishing, which will give the barbecue a special look. Such blocks are made from a cement mixture with a high proportion of filler:

- Ash;

- Tyrsa;

- Slag;

- Shell rock.

There are options with or without voids. Such material is durable.

What to choose

Street barbecue - the building is not particularly responsible. In the sense that she does not need to withstand the load. And to create it, it is rational to take the cheapest material. Cinder blocks are just right here. But taking into account environmental safety, durability and attractiveness, we recommend a gas block or foam block.