In everyday life, almost everything that we may need is at the height accessible to us. However, despite the fact that for the most part household items are adjusted to fit a person, sometimes natural growth may not be enough.

In such cases, to compensate for the lack of height, additional support points are used, which most often are assembly ladders.

Portable mobile ladders are mainly used when carrying out construction or installation work, since it is there that their working potential is fully realized. Since, in most cases, the reconstructed structures have a sufficiently high height, one cannot do without additional equipment.

There are several types of portable ladders that have significant differences in structure - the most suitable analogue is selected based on the available circumstances, in each, separately taken case. This article will describe the products of the attachment type, which are most often used for various types of installation work.

Extension ladders

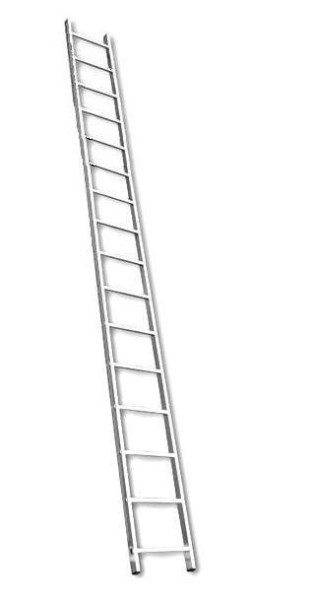

Ladders of this design have the most traditional texture, which is familiar to us from childhood - in view of the simplified structure, it was most often used as an example for making it with our own hands from scrap materials (wood, pipes). Today, wood is not the optimal material for the manufacture of products of this type - manufacturers most often use fiberglass or aluminum alloys as raw materials.

The structure of the attached analogs consists of two crossbeams running parallel to each other, which are interconnected by means of intermediate step elements. Their location is determined by ease of use and corresponds to the optimal value of the step width of the average person. In factory production, the steps are cut strictly perpendicular to each of the guides.

Installation of ladders is carried out by resting the upper part of the section on a horizontally laid surface and implies the obligatory presence of a fulcrum in the form of a wall, a column, etc. A correctly installed section should be at an angle of at least 50 and no more than 75 degrees to the surface of the retaining wall. The most optimal value is 60 degrees to the horizon.

Dignity

- Strength. Since the ladder is a one-piece structure, the load is distributed evenly along its entire length, while in folding counterparts, most of the weight falls on the connecting elements;

- Efficiency. The length of the attached analogs can be up to 5 meters - this significantly increases the area of their application in comparison with other modifications;

- Price. Since there are no connecting parts and other side elements in stairs of this type, therefore the cost of this product is an order of magnitude lower than folding counterparts;

disadvantages

- The presence of support. A ladder without fail implies the presence of a fulcrum in the form of a wall or a similar surface and cannot be used as an independent structure;

- Low stability. Since the upper crossbar rests on the wall without the use of additional clamps, there is a possibility of its slipping;

Note! Some manufacturers produce hinged counterparts, in which there are clamps on the top of the stairs - with their help, the last drawback ceases to be relevant.

Composite constructions

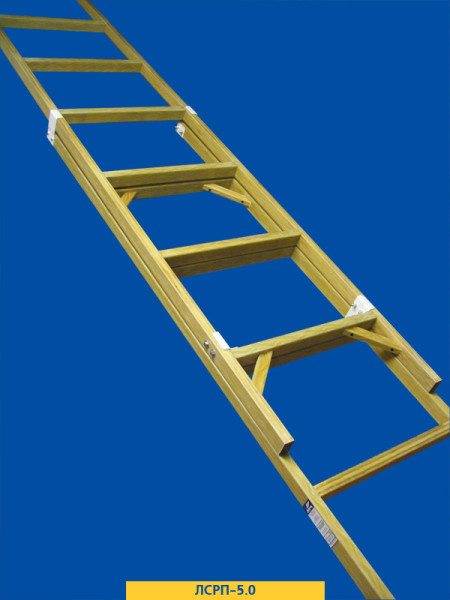

Prefabricated ladders, which are used for installation on high-rise buildings, deserve a separate discussion. Products of this type consist of several sections, each of which is an independent element and can be operated independently of the others as a regular staircase. However, when assembled, the process of its operation is somewhat different from the traditional method.

The sections are connected to each other by means of an intermediate channel, in which both leaves are fixed by means of bolts. The advantage of this design is the ease of installation - the assembly instructions are not complicated and can be produced without any special skills.

Since the structure of this type has a rather long length, its safety is especially important. Each of the steps has an anti-slip coating that will prevent the sole from slipping during the climb. Also, the material from which it is made has dielectric properties, which allows you to use it when working with conductive equipment.

As mentioned above, composite erection ladders are operated according to a slightly different principle than solid counterparts. Each section contains in its design special fasteners, by means of which the assembled ladder can be securely fixed in an upright position. This allows it to be used for work on power line supports or other high-rise structures.

Note! In addition to the above-described structure, there are also composite ladders, the structure of which allows them to be operated in a traditional way.