Peculiarities

Tytan, part of the Polish company Selena, specializes in the production of various building compounds: polyurethane Titan with high moisture resistance, adhesives with a wide range of uses, polyurethane foam and much more. In the article we will dwell in more detail on liquid nails from the above manufacturer.

Most of all adhesives are universal products that are used both for household repairs and for large-scale work. Excellent performance indicators of products are provided due to special additives in the composition. All goods are manufactured abroad and end up in Russia through official distributors.

How to apply the composition?

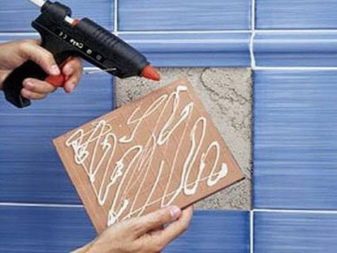

To apply liquid nails, you must follow the step-by-step instructions.

- The work surface must be washed, dried and, if necessary, degreased.

- It is not necessary to apply the composition to the entire substrate. A stripe or dotted line should be sufficient.

- For more convenience, a special pistol is used.

- To protect indoor furniture and other items, use film, thick fabric or newspaper.

- Remember that the setting process takes a second, so the job must be done quickly. After that, you need to securely connect the parts and hold them for about two minutes, pressing firmly against each other.

- The complete hardening process takes about a day. During this time, it is recommended not to load the connected elements.

Construction adhesive 601 (Liquid nails)

Rubber glue Tytan No. 601 is produced in cylinders with fastening for a mounting gun. The main advantage of liquid nails over other formats is the ability to glue slightly spaced surfaces (that is, it does not require full adhesion). Titanium 601 will easily replace nails and screws.

The composition does not lose its properties in the temperature range from -30 to 60 ° C. It is applied in a thick layer over the entire surface, initial hardening takes 5-10 minutes, complete drying - 24 hours.

Titanium liquid nails are perfect for bonding metal, glass, ceramics, wood, PVC, polyurethane and thermal insulation materials. They cope with heavy building materials, structures and decorative elements.

For gluing heavy structures in the Tytan line there is a heavy-duty adhesive No. 901.

Range

The catalog of Tytan products is varied. Let's dwell on three types of product in more detail.

Installation product Classic Fix

Glue Classic Fix ("Classic Fix") has versatility. Due to what the composition can be used indoors and outdoors. For the manufacture of a transparent composition, the manufacturer used synthetic rubber.

Specifications:

- full curing process - two days;

- product consumption is from 150 to 300 grams per square meter;

- resistance to temperatures from - 30 to +60 degrees Celsius;

- shelf life - 1 year.

Peculiarities:

- increased strength;

- excellent adhesion to most materials;

- resistance to moisture and frost.

Usage:

- work with materials such as wood, metal, PVC, polycarbonate, ABS, glass;

- installation of decorative elements and various items (mirrors, shelves, hooks and much more);

- connection of structures made of light and heavy metals.

Super strong compound No. 901

A rubber compound with excellent durability is used for indoor and outdoor work. In the process of work, a moisture-resistant, durable and elastic seam is formed.

Technical specifications:

- the glue dries completely in 24 hours;

- composition color - beige;

- material consumption from 200 to 400 grams per m²;

- glue can withstand temperatures from 30 degrees below zero to 60 degrees Celsius;

- the shelf life of the glue is a year.

Peculiarities:

- the composition does not contain toluene;

- durable and reliable seams;

- resistance to weathering.

Usage:

- installation of structures made of materials such as plaster, plastic, stone, ceramics, glass, wood, plywood;

- connection of elements and panels.

Special glue No. 915

The water-based composition is specially designed for use in rooms with high humidity. Liquid nails are ideal for bonding various building materials to porous surfaces.

Performance characteristics:

- glue color - white;

- the minimum temperature indicator maintained by the composition is 20 degrees below zero, the maximum is 60 degrees Celsius;

- the material hardens in two days;

- product shelf life - 12 months;

- the consumption volume ranges from 200 to 400 grams per square meter.

Peculiarities:

- excellent resistance to steam, moisture and dampness;

- the glue is not susceptible to the formation of mold and mildew;

- fast adhesion.

Usage: joining elements made of plastic, stone, natural wood, polystyrene and gypsum.

See below for more details.

Tytan Professional liquid nails: features and application

When renovating, interior decoration or interior decoration, there is often a need for reliable gluing of materials. An indispensable assistant in this matter can be a specialized glue - liquid nails. Such compositions appeared on the market relatively recently, but they have already gained popularity among builders due to their numerous advantages.

The products of this brand are of high quality and favorable cost.

Varieties and area of use

Tytan Professional liquid nails come in several types. By purpose, they are divided into two types.

- Universal. Such compositions are suitable for gluing any materials.

- Special purpose products. These adhesives can be used for certain types of materials. On the packaging of special-purpose adhesives, the manufacturer indicates information about the purpose for which they are intended. These can be compounds for bonding heavy structures or metal parts, for outdoor work, for mirrors, glass, for installing foam panels.

Liquid nails also vary in composition. Adhesives can be made on the basis of rubber or acrylic. The first are polyurethane materials with an unpleasant odor caused by synthetic components. These products are suitable for bonding heavy materials.

A respirator and protective gloves are required to work with such nails. It is recommended to use rubber adhesives in well-ventilated areas.

Acrylic (water-based) compositions do not contain toxic substances, due to which they do not have a smell. Such nails are cheaper than rubber ones, but they do not have increased strength.

Depending on the composition, liquid nails are used for the installation of window sills, cornices, brick structures, various panels, plasterboard products, glass, aluminum, solid wood. The glue is not recommended for working with damp wood and for setting up aquariums.

Advantages and disadvantages

Tytan Professional liquid nails, like other assembly adhesives, have both advantages and disadvantages. Therefore, before purchasing, you should carefully read all the characteristics. The composition has more advantages.

- High levels of adhesion strength. The nails are capable of withstanding loads from 20 to 80 kg / cm2.

- Resistant to rust formation.

- Ease of use. For convenience, you can use special pistols.

- A "clean" process of joining parts, in which there is no dirt or dust.

- Fast adhesion of the materials to be glued (within 30 seconds).

- Suitable for use on uneven surfaces.

- Fire resistance.

- Affordable price and economical consumption.

The disadvantages of liquid nails include only their unpleasant odor and the possible occurrence of difficulties when working with the material for the first time.

Range

There are many varieties of liquid nails from the manufacturer Tytan Professional on the construction market. The company produces a wide range of products for construction and finishing works.

There are several types of the most popular brand liquid nails.

- Classic Fix. It is a transparent rubber assembly adhesive that can be used both indoors and outdoors. It is distinguished by high adhesion, moisture and frost resistance. When hardened, the product forms a transparent seam.

- Heavy-duty glue No. 901. The material, made on the basis of rubber, is suitable for outdoor and indoor use. Due to its improved composition, the product can withstand increased loads. The composition is recommended for gluing heavy structures, forms a waterproof seam.

- Liquid nails for bathrooms and bathrooms No. 915. This is a water-based composition, characterized by increased resistance to high humidity, high temperatures and steam effects.

- Mirror glue No. 930. It is recommended for fixing mirrors to various substrates (concrete, wood, ceramic). The product has a high initial bond strength.

- Adhesive for moldings and panels No. 910. This is a water-based composition intended for gluing elements made of wood or plastic. It is highly resistant to mold and other biological damage. The product has a high initial adhesion, resistance to adverse climatic conditions. The composition can withstand temperatures from -20 ° C to + 60 ° C.

Thanks to a wide range of products, everyone will be able to choose the composition suitable for specific types of work.

Tytan Professional Sealants

Titan Professional offers quality sealants for any task: silicone and silicate sealants, acrylic, polymer, polyurethane (PU), bitumen and rubber sealants. In addition to universal and multi-purpose compounds, the brand offers specialized sealants (roofing, for example).

Silicone sealant

Titanium silicone sealants have proven themselves well in professional circles. They have a high level of adhesion to most materials and are resistant to various weather conditions. A universal sealant is used not only for sealing seams and sealing joints, but also for sealing wires and protecting polyurethane foam from ultraviolet radiation. Withstands 1 freeze cycle.

In addition to the versatile range of Tytan silicone sealants, there are sanitary sealant, glass sealant, kitchen and bathroom sealant, marble, window, door and siding sealant, acrylic bath sealant, high temperature sealant, and more.

Multipurpose sealant

Tytan Multi Purpose Sealant (Hybrid) can be used for bonding and sealing even on wet surfaces. The composition is odorless and does not contain solvents, therefore, after drying it can be painted.

This sealant is practically non-aging and retains its elasticity.

Like the entire Titanium range, the multi-purpose sealant is suitable for most building materials: ceramics, glass, concrete, cement, stone, metal, wood, polycarbonate, PVC, etc. The sealant is excellent for roofing work.

Acrylic sealant

The brand's acrylic sealant has a high level of adhesion to porous materials, it can be applied to damp surfaces, and can also be painted after drying. The sealant quickly forms a film that can be removed until completely cured, then only a mechanical method will help.

Advantages and disadvantages

First, let's dwell on the advantages of liquid nail formulations.

- Space and ease of use.

- Excellent adhesion to a wide variety of materials.

- Connection reliability. The layer easily transfers loads up to 80 kilograms per square centimeter.

- The product is not susceptible to rust formation.

- When working with construction adhesive, dust and dirt do not form. And also there is no noise.

- The composition sets quickly, literally in seconds.

- Liquid nails can be used on surfaces that have imperfections. The product greatly simplifies the process of laying material on curved substrates.

- Unlike standard fasteners, the adhesive maintains the integrity of the surface without destroying it.

- The compositions offered by modern manufacturers are safe for health due to the non-toxicity of the elements.

- A quality product is not afraid of increased moisture. Some formulations can withstand low temperatures.

- Excellent fire resistance.

- Favorable consumption.

Experts assure that the products have no significant drawbacks. Unless some formulations have a pungent and unpleasant odor.

Description and features of Titan glue

Adhesives of the Russian brand "Titan" have been produced since 1992 and have a wide range of effects, are considered universal. With their help, it is possible to connect homogeneous and dissimilar materials - the adhesion force in any case will be high. Adhesives "Titan" are used to connect:

- wood;

- linoleum;

- laminate and parquet;

- wallpaper;

- paper and cardboard;

- foam;

- plastic;

- metal;

- concrete;

- ceramics;

- gypsum;

- skin;

- fabrics;

- aerated concrete;

- ceiling tiles.

"Titan" will be able to replace a whole range of adhesives for construction purposes: tile glue, compositions for the laying of porcelain stoneware, tile blocks. Mounting foam of this brand is used for installing PVC windows, liquid nails and universal glue - for fixing mirrors, cabinets, for repairing any household products. Titan sealants help to process seams, joints in the bathroom, in the kitchen.

The composition of "Titan" does not spoil materials, is suitable even for different types of plastics, is environmentally friendly and does not harm humans. Adhesives fit For interior and exterior use, they are waterproof, do not deteriorate from temperature extremes, ultraviolet radiation. After drying, the glue seam becomes plastic, elastic, frost-resistant, has a heat resistance of more than +100 degrees.

Tytan Professional liquid nails: features and application

When renovating, interior decoration or interior decoration, there is often a need for reliable gluing of materials. An indispensable assistant in this matter can be a specialized glue - liquid nails. Such compositions appeared on the market relatively recently, but they have already gained popularity among builders due to their numerous advantages.

The products of this brand are of high quality and favorable cost.

Varieties and area of use

Tytan Professional liquid nails come in several types. By purpose, they are divided into two types.

- Universal. Such compositions are suitable for gluing any materials.

- Special purpose products. These adhesives can be used for certain types of materials. On the packaging of special-purpose adhesives, the manufacturer indicates information about the purpose for which they are intended. These can be compounds for bonding heavy structures or metal parts, for outdoor work, for mirrors, glass, for installing foam panels.

Liquid nails also vary in composition. Adhesives can be made on the basis of rubber or acrylic. The first are polyurethane materials with an unpleasant odor caused by synthetic components. These products are suitable for bonding heavy materials.

A respirator and protective gloves are required to work with such nails. It is recommended to use rubber adhesives in well-ventilated areas.

Acrylic (water-based) compositions do not contain toxic substances, due to which they do not have a smell. Such nails are cheaper than rubber ones, but they do not have increased strength.

Depending on the composition, liquid nails are used for the installation of window sills, cornices, brick structures, various panels, plasterboard products, glass, aluminum, solid wood.The glue is not recommended for working with damp wood and for setting up aquariums.

Titan glue varieties

The most popular types of glue are found on sale everywhere in construction and hardware stores, supermarkets. There are also a number of specialized formulations that are much more difficult to find, for example:

- Titan Professional EV W (professional winter chemical anchor) is a two-component composition for use at subzero temperatures (up to -18 degrees);

- "Titan PVA D3" - PVA construction glue with increased moisture resistance;

- Titan Thermospray - sprayed polyurethane insulation;

- Power Flex adhesive sealant is a silicone sealant with increased strength.

Universal adhesive

Polymeric universal Titan SM ("Titan CM") and "Titan Wild Premium" - adhesives that have a wide range of applications. They are sold in translucent plastic bottles, conveniently applied through a dispenser. After drying, the seam turns out to be completely transparent, therefore the scope of use of adhesives is not limited to the color of the surface. Most often, funds are purchased for gluing such materials:

- wood;

- PVC;

- polystyrene;

- wood-shaving materials;

- carpet;

- glaze and ceramics;

- leather.

How long does universal glue dry? Enough 1 hour for the composition to dry completely, and the product can be used (without serious mechanical stress). The seam remains flexible and does not deteriorate from vibration, it is moisture resistant, heat resistant, but acquires full properties after 24 hours.

Glue-foam "Titan"

Several types of glue-foam are produced under the brand name "Titan" - "Titan Professional 65 Uni" (Professional 65 Uni), Titan Professional Euro for masonry blocks, "Titan 60 seconds", etc. Such products are characterized by high adhesion to mineral substrates, economical in consumption, perfectly fill cracks, pits. The maximum level of adhesion to surfaces is observed after 2 hours. You can work with the compositions at temperatures from -10 degrees. They are used for installation:

- thermal insulation;

- foam silicate blocks;

- ceramic tiles;

- silicate brick;

- gas silicate blocks.

Glue-mastic

Mastic "Titan" is intended for work with tiles, natural and artificial stone, glass, plywood, brick, plaster. It can also be used to glue ceiling tiles, baseboards and decorative elements, plasterboard sheets, chipboard and fiberboard. Mastic can be used for leveling bases, sealing any defects.

The composition is frost-resistant, heat-resistant, lasts a long time, does not deteriorate. You can work with it at temperatures from +8 degrees. Despite the fact that the mastic sets in 20 seconds, it will not be possible to quickly dry the glue joint completely, it takes 12 hours. The glue consists only of safe components, there are no solvents in it.

Liquid Nails

Among analogues (such as "Moment", "Epoxy-Titan 6 BL" and others), liquid nails of the "Titan" brand stand out for their high degree of adhesion, economical consumption, and moderate cost. They are available in tubes of 200-310 ml, and the large package is additionally equipped with a glue gun. The most popular adhesives in this series are:

- "Titanium rubber glue for roofing" - a roofing compound that reliably holds together metal sheets, tiles, tiles, PVC gutters;

- assembly Classic Fix ("Classic Fix") - a rubber-based product for any interior and exterior work;

- assembly Hydro Fix - a water-based general construction adhesive used in interior work and for gluing porous materials;

- assembly Heavy Duty is a universal tool for finishing works in construction.

The adhesion to surfaces of liquid nails is so strong that they can be an excellent alternative to metal nails, screws. They are used for fixing tiles and stone, polystyrene and polyurethane, gypsum, cement, brick, cork and other materials. The compositions cannot be applied only to products made of polyethylene, polypropylene and on damp substrates, although after drying the glue line will be moisture resistant.

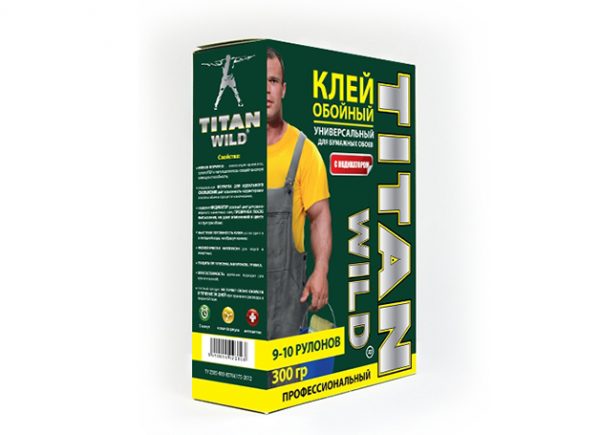

Powder

Dry powder is understood as adhesives "Titan" for wallpaper, which include three types - for paper, non-woven, vinyl. Instructions for use contains all the necessary data on the dilution of funds. They can be easily dissolved in water according to the indicated proportions, mixed and used as directed after 5 minutes. The composition contains additives from fungus and mold, as well as special components that facilitate the adjustment of the position of the canvases on the wall.

Compositional classification

Adhesives of the Titan brand are subdivided depending on the basic composition. Each glue has advantages and disadvantages, and also differs from others in the specifics of application, although the difference in the scope of use is small. The main types of adhesives are:

- Rubber. This includes the line of "Titan Professional" products, which are convenient to use for wood, particle boards, gluing tiles, skirting boards, baguettes. The adhesives are resistant to pressure and temperature changes and have excellent elasticity. The same line includes the so-called "metal liquid nails", which are used to glue mirrors and glass only indoors. Rubber in the composition also contains universal liquid nails "Titan 601", intended for finishing and insulating materials, cornices, sockets, panels.

- Polyurethane. Styro 753 glue, which has polyurethane in its composition, is a representative of this group of adhesives. It can glue almost any material, even bitumen, mineral wool, and is often used for fastening thermal insulation boards, roofing. Polyurethane glue has antiseptic properties and prevents fungus and mold from multiplying.

- Acrylic. Glue "Titan Express" is an excellent means for gluing stone, wood, ceramics, glass, it hardens very quickly, therefore it is used for urgent work. Glue "Stucco Decor" also refers to acrylic, has excellent quality characteristics, is suitable for cork, glass, can glue any decor in the interior.

- Polymeric. The area of application of such a tool is extensive, but more often it is used for unusual materials that it does not harm - amalgams, alloys, fiberglass, etc. No less well, this tool fixes different types of insulation, ceramic tiles, moldings. The adhesive has powerful sealing properties and is not exposed to sunlight.

Also, funds are divided according to the form of release. They can be packaged in metal buckets, plastic buckets, tubes with a nozzle-nozzle or dispenser, which are used with a glue gun. Titan is also sold in plastic bottles and small tubes with a screw cap.

Foam assembly STD

One-component polyurethane foam Tytan STD is used to fill and seal joints, crevices and other gaps. Most often used in the installation of windows and doors. Ideal for wood, stone, concrete and metal.

Benefits of STD Foam:

- does not require additional equipment (the bottle is equipped with a special applicator);

- noise isolation up to 62 dB;

- thermal insulation;

- ergonomic packaging;

- can be used within 2 months;

- fast hardening;

- prevents the appearance of mold and mildew.

Mode of application: shake the can thoroughly before use and then keep it upside down. Apply the foam to a clean, degreased and damp surface using the applicator. When solidified, the composition doubles.

Characteristics of Titan glue

For each type, the technical characteristics are individual, they depend on the constituent substances. The most popular is transparent universal glue, the parameters of which look like this:

- adhesive layer thickness - up to 4 mm;

- weight of 1 m2 of glue - 4.5 kg;

- breaking force in the transverse / longitudinal direction - 600/400 N;

- heat resistance - up to +140 degrees.

The properties of the glue allow the finished joint to withstand significant mechanical loads, after drying it does not become brittle, and does not deteriorate over time. Means of the "Titan" brand can be used in rooms with any humidity, they can withstand even intermittent direct contact with water.

Instructions for use

First you need to find the right glue so that it perfectly matches the materials used. The easiest way is to use polyurethane glue, it dries faster, and it is easy to apply. When working with glue, it is necessary to provide good ventilation, but without drafts - the latter violate the quality of adhesion and change the drying rate of the composition.

You need to work with glue like this:

- Perform high-quality preparation of the base. All dirt and dust must be removed from the wall, ceiling, and other surfaces. Remove the falling off pieces of the old coating, apply plaster, cover all holes and defects as well. Products made of metal, plastic should be sanded, degreased. Use a primer if possible. The substrate must be absolutely dry immediately before applying the adhesive.

- Apply Titan glue to one side (for complex or large surfaces, all surfaces to be glued must be processed, for tiles - apply glue with a snake). Firmly press the materials together, do not tear off your hands or the fixing device for at least a minute (if we are talking about a ceiling tile, you need to hold it with your hand for 60 seconds, then you can release it). Leave the products alone until the glue is completely dry.

Glue-mastic is applied with a spatula pointwise or by a continuous method, if the product has a significant weight. "Liquid nails" are applied with a glue gun in strips, waves in a thick layer, they can be used to finish surfaces with differences and defects.

Dried glue stains are noticeable in bright light, so it is recommended to remove them immediately. Expanded polystyrene, other soft substrates can be cleaned with a damp cloth if the glue has not yet hardened. After drying, the glue is removed from solid substrates by picking it up with a sharp spatula and tearing it off with your hands. You can also use organic solvents for cleaning surfaces - acetone, white spirit.

How to dilute the glue

It happens that the glue dries up and becomes more viscous. If it has thickened, you can dilute the composition by simple steps. It is necessary to take ordinary medical alcohol, add it to the glue in a small volume, shake well. The diluted product dries a little longer, but it penetrates better into the smallest cracks, pits. How to dilute the glue in tubes when thickening? It will not be possible to restore the normal consistency of such a product due to the tightness of the package, but it can become too viscous only after the expiration date.