Specialist recommendations

To avoid defects and errors during the work, you need to familiarize yourself with the recommendations from the masters.

- When preparing a grouting composition on your own, it is necessary to use sieved components so that they do not contain large fractions.

- After preparing the solution, it should be allowed to settle for 10-15 minutes, and then mixed again to improve plasticity.

- When grouting, avoid applying mortar to bricks.

- If the solution gets on the decorative finish, it must be removed immediately, avoiding drying out.

SNiP indicates that the thickness of the seam should be up to 1 cm, and therefore it is recommended to make small gaps between the bricks themselves, adjusting the value depending on the climatic conditions at the place of work. You do not need to start grouting on hot days, as the solution will quickly harden, which can lead to a disruption in the technological process. And also it is worth refusing to carry out work in wet weather. The solution must be mixed in small portions in order to quickly produce it and not allow it to solidify.

As you can see, grouting is a responsible, but effective way to improve the appearance of a ceramic or other coating after finishing work, and it will also make it possible to create completeness of the work. A professionally produced grout will improve the appearance of the substrate and protect the wall from damage. In addition, it will increase the thermal insulation properties of the masonry, which will allow it to stand for a long time and not require annual repairs. To do this, you only need to complete all the work in accordance with the recommendations and rules.

You can see an example of grouting in the video below.

How to erase them?

For high-quality processing of the seam, it is necessary to study the instructions on the packaging of the grouting material, and also prepare for work. You will need tools and materials:

- mixer;

- spatula / gun;

- kneading drill;

- sponge;

- rags or rags;

- gloves;

- mixing container.

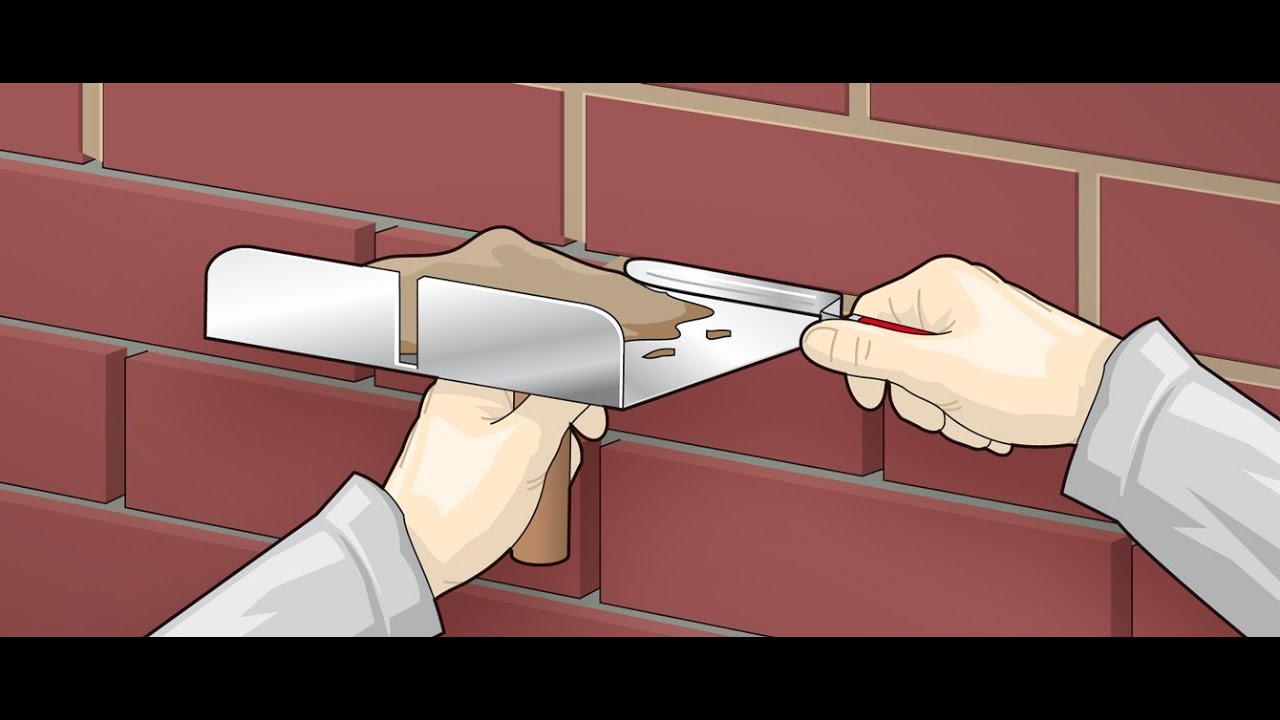

Regardless of the purpose of the grout, it is applied with a gun or trowel / spatula.

Let's consider how to properly fill and grind the joint joints when laying stone cladding. Work progress when sealing seams:

- Surface preparation - clean the cladding, allow to dry.

- Knead a small amount of grout to prevent the excess from hardening.

- Treat the seams in one of the ways - from a pistol or a spatula, apply the mixture, tamp into the suture gap. The excess must be wiped off immediately.

- Let the solution set.

- Treat it with a fixative.

Important

Each mixture has its own instructions for use. On average, dry formulations are prepared in proportions of 1 kg per 200 ml of water

The mass is stirred until homogeneous, the grout has the best characteristics in the first three hours, then it begins to thicken and loses its elasticity. It is recommended not to use a stale mortar, as this will lead to a loss of waterproofing and if the seam is repaired with such a tool, microcracks may appear.

We recommend watching a video on how to grind the seams on decorative brick:

Jointing

Jointing of seams is the final stage of surface facing. It is necessary for fixing the facing elements, completing the composition, additional processing of the gaps between the elements from various influences (temperature, dirt, moisture).

For planing, the following materials and tools must be prepared:

- grout for joints;

- foam sponge;

- several containers: for water and fugue breeding;

- trowel spatula;

- masking tape;

- rubber gloves.

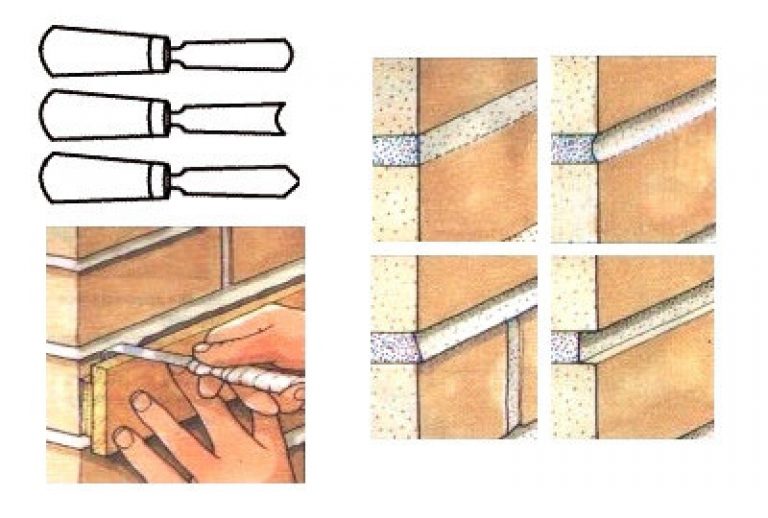

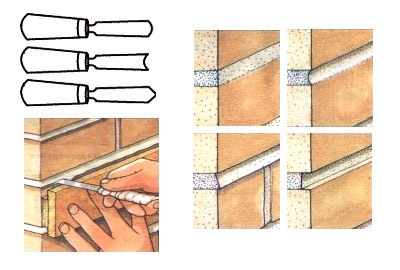

For jointing, you need to purchase a special grouting gun or rubber trowel. The latter is a small plate with a handle. Tools made from different materials are selected depending on the process in which it is used. To apply and press grout into the gap between decorative stones, spatulas with a springy rubber surface with a narrow blade are used.

Advice

Rubbing with a spatula is faster than using a pistol, but this requires skill in execution.

Before work, the stone can be covered with masking tape so as not to get dirty and not wipe it off again. For the final cleaning of surfaces from contamination with a grout and its residues, special synthetic-cellulose or foam sponges are used. But a soft cloth moistened with warm water may also work if it does not spoil the stone (it is better to check beforehand).

After work, it is better not to store the remnants of the diluted fugue: after use, it dries up, loses its elasticity.

You can familiarize yourself with the options and principles of finishing the corridor, hall, bedroom, area near the TV, balcony, doorways, arches and columns with decorative stone.

Instruments

Sewing seams can be done either with ready-made devices purchased in the store or with homemade ones. Moreover, some master masons make their own hand tools of various configurations in order to obtain irregular seams.

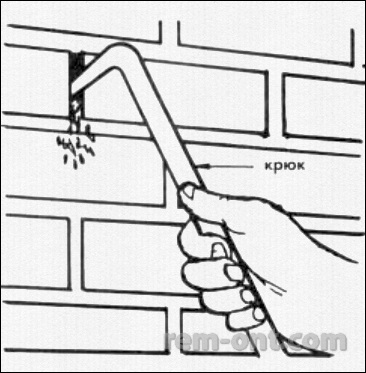

But the use of joints alone is not enough. Depending on the state of your brick wall, you may need:

- Sharpened chisel and hammer or hammer to remove old mortar from the joint.

- Drill with mixer attachment for grout preparation. If the volume of work is large, it makes sense to use a concrete mixer.

- Triangular trowel and falcon - for gentle application of the mixture and removal of excess from the masonry.

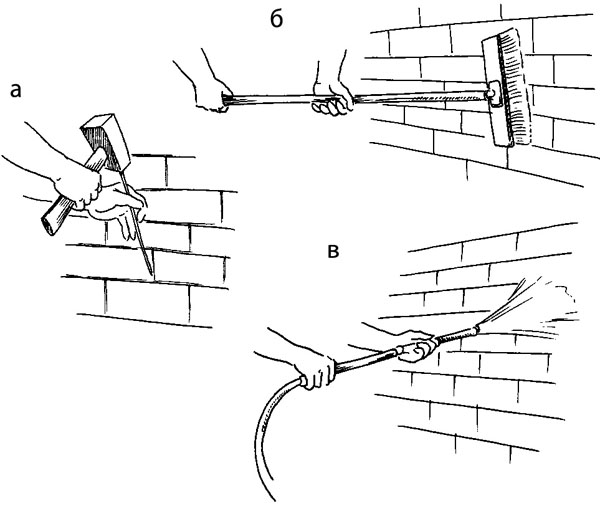

- Stiff brush and brushed - will easily clean the surface of stones when grouting and grouting are finished.

- A soft flute brush or roller is needed to wet the surfaces.

- A wooden lath about a meter long - it is convenient to support the tool on it when joining horizontal seams.

Also, do not forget that to prepare the grout, you will need a special container - deep, but not wide, so that the solution in it does not set so quickly.

Truly working legal way to save money. Everyone needs to know this!

Grouting brickwork

This procedure may be required if you need to restore the properties of old walls or make a jointing of the same color. Indeed, often the mixture in different parts of the masonry differs markedly in shade. First of all, it is necessary to cut the surface of the dry mortar to a depth of 1-1.5 cm (with a hammer and chisel) and remove its remnants. Cleaning is carried out not only at the seams, but also throughout the masonry - the brick wall must be completely cleaned of dirt and dust before grouting. To simplify the task, you can use a compressor unit to blow out even the smallest chipped particles from the cracks and ensure the best adhesion of the fresh joint.

Also, a reliable and well-sharpened tool is needed to accurately prepare for joining. Only with its help can excess mortar be removed so that the brickwork does not suffer. After that, you need to moisten the seams with water and get to work. Do not moisten the entire surface at once - limit yourself to a small area that you will be working on in the next hour.

Brick grout is sold ready-made or dry. It can come with the addition of pigments and plasticizing additives. But the main thing in any selected composition for seams is its basis. Today, there are two options for embroidering walls:

- cement (Quick-Mix, Mixonite);

- epoxy resin (Litokol Litochrom, Mapei).

But you can make an inexpensive mixture yourself.The simplest grout for masonry consists of two parts of lime and cement, taken equally, and 10 hours of fine sand. Such a solution has a pot life of about 90-120 minutes, so it is not worth kneading a large volume for joining immediately.

Another recipe: for one part of the cement, they take the same amount of ground volcanic track and 5 hours of sand as an aggregate. This grout should be used if the brick wall "pleases" the eye with efflorescence and whitish smudges from the seams. A purchased or independently prepared jointing solution is stirred to the consistency of liquid sour cream: it should not spread, but should be kept on an inverted trowel in a lump.

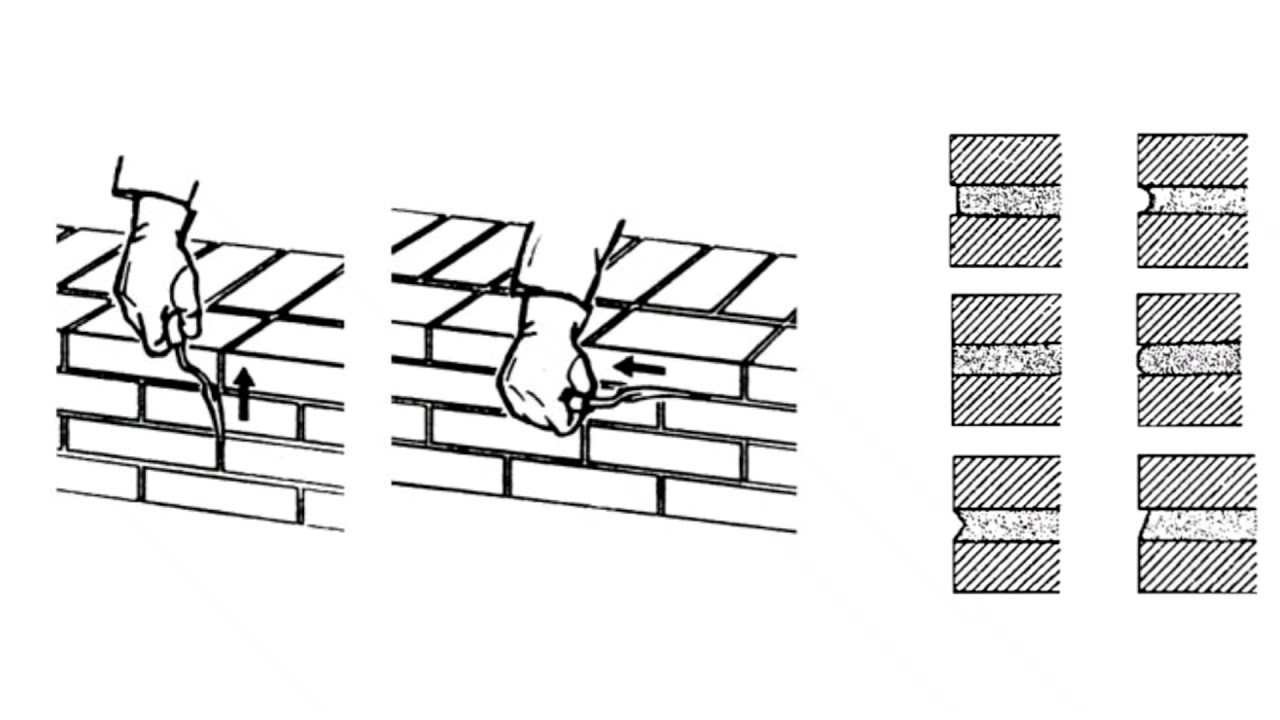

Having prepared the grout according to the instructions on the package, you can proceed to the vertical seams. The composition should be soft and plastic, so that it is easier to work with it, but at the same time not liquid, otherwise the solution will not keep its shape and will simply flow over the masonry. After all the preparations, the jointing is performed using the following technology:

1. Apply the ready-made grout with a trowel - a little more than needed to fill the joint. In order not to stain the bricks of the lower row, you can substitute a plaster falcon.

2. Remove excess mixture with an edge and smooth the surface with a suitable hand tool. Each seam is pressed with force so that there are no voids between the old grout and the grout.

3. After filling in, the actual jointing takes place, that is, giving them a shape. To work in horizontal rows, it is more convenient to use a straight rail - under it, as under a ruler, it will turn out to draw a straight line.

When the jointing of the brickwork is completed, the front side of it is cleaned of traces of mortar with a stiff brush. Then you need to give the mixture to finally gain strength, not allowing the seams to dry out, or vice versa - get wet in the rain.

List of sources

- .

- .

- .

Types of jointing and their main characteristics

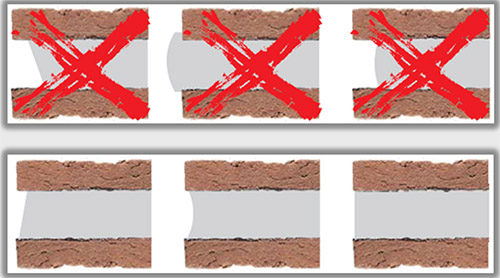

Before starting joining work, you need to get acquainted with the main methods of sealing joints. You can often find the following types of joining:

- flush. A simple and common type of jointing. The technological process is as follows: it is necessary to cut off the excess mortar from the wall surface; this can be done using a construction trowel. Next, using a brush, you should process the gaps between the bricks. The result of processing is clearly marked white seams;

- recessed rectangular. Usually this type is used as a decorative finish. This option is more time consuming. If the brickwork is constantly exposed to atmospheric precipitation, then this method of processing should not be used. Joining technology: it is necessary to remove the mortar from the joints to a depth of 5 mm. Next, a new mortar should be compacted and smoothed, this can be done using a construction tool called a rounded dowel;

- concave. An equally popular option that is used for grouting. This method assumes using a prepared tool called "jointing". Such grouting implies the following: cut off the excess solution and process the resulting white seams with a semicircular jointing along the entire length;

- beveled. This type of jointing has become widespread in regions with harsh climatic conditions. A prerequisite is a carefully sharpened trowel. Grouting is carried out in the following way: cut off the excess mortar with a sharpened trowel, which must be held at an acute angle. It is recommended to deepen the tool by 3-4 mm.

Restoration of brickwork seams

Sealing joints with lime mortar

To stop the pouring out of the joints between the bricks, first of all, we remove all the rotten mortar with a metal brush, reaching its solid state. Then, with an ordinary broom brush, we remove all the dust that remains in the seams between the bricks.

Prepare a solution of slaked lime.Quicklime, when solidified, will swell and try to crawl out without giving a tightening effect. Sand is added to lime in the proportion: 1 part of lime + 3 parts of sand, mixing with water. It is better to take river sand, washed, since the gully sand contains clay particles, which will give the seams a yellow color.

Before the process of filling with lime mortar, the problem areas are moistened with water and, with the help of jointing, push the solution into the damaged areas. After the mortar has hardened, the seams are cleaned with sandpaper.

Repairing cracks in a brick wall

If cracks up to 5 - 8 mm in size appear in the brick wall of your house, you need to proceed as follows. To clean the seams in the places where the destruction is spreading perpendicular to the cracks so that reinforcing rods with a diameter of 6 - 8 mm can be inserted into these places of the seams, and in some cases it can be thicker, depending on the width of the seam. Then the places where the reinforcement is laid are sealed with a concrete solution.

Metal screed along the perimeter of the wall

It happens that this method does not give positive results, then they resort to a method of repairing brickwork, using a wall screed along the perimeter using metal profiles. In other words, depending on the size of the entire wall, using electric welding, a frame is constructed from a large metal corner in the range of 63 - 110 mm, which adjoins the corners of the house and is pulled together (welded) together in several places along the perimeter of the wall with a metal strip. In "several places" it is above, in the middle and below. After the screed is installed, you need to repeat the elimination of cracks with reinforcement.

If the dimensions of the cracks reach more than 10 mm, experienced craftsmen recommend disassembling the old masonry in these places and laying out a new one.

Note: all work to eliminate defects must be carried out after the cracks reach their maximum size and stop growing.

Benefits of grouting

The embroidery is both decorative and practical.

The decorative properties include:

- emphasizing the texture of lines;

- highlighting a brick pattern;

- unification of all lines that have been laid out both horizontally and vertically;

- giving the facade austerity and clarity.

The practical characteristics are as follows:

- sound insulation increases with joining;

- it protects against excess moisture;

- keeps warm in the building;

- service life increases;

- tightness appears;

- small cracks are closed.

The grout overlaps the previous layer of cement, but in this way it is impossible to completely remove errors in the form of excess cement in the wall, its curvature and unevenness of the masonry.

There are several well-known and common methods of making do-it-yourself grout. Let's consider some examples in more detail.

What are grout made of

Depending on the bonding element, there are different types of grout for decorative stone: epoxy, cement, latex. The materials also contain polymer additives that improve their properties. Depending on the main component, the grout is:

- Plaster. The mixture is suitable for sealing joints between decorative stones indoors.

- Epoxy. It has a high level of moisture resistance. Thanks to special additives, it becomes immune to aggressive substances. This grout polymerizes quickly and is therefore not easy to apply.

- Cement. It happens coarse and fine-grained. The first type creates a pronounced textured surface. The composition looks natural. The specified material is prone to cracking, but the problem can be quickly fixed. Do not use it on marble or glossy veneers.

- Polyurethane. The composition has a great price, but it is resistant to fading, moisture, staining.Since the material does not dry very quickly, it is not difficult to work with it.

- Silicone. It is flexible and provides a high level of tightness. Among the technical characteristics, resistance to negative temperatures and moisture is distinguished.

- Latex. It has good parameters of adhesion to the base, as it penetrates deep into the seam. Cracks do not form on it yet.

- Rubber. This type of grout is resistant to moisture and easy to apply. It is expensive, so finishing large areas is impractical. It is more suitable for interior walls in rooms with high humidity.

The technology for applying the material depends on the type of composition.

Instruments

Sewing seams can be done either with ready-made devices purchased in the store or with homemade ones. Moreover, some master masons make their own hand tools of various configurations in order to obtain irregular seams.

But the use of joints alone is not enough. Depending on the state of your brick wall, you may need:

- Sharpened chisel and hammer or hammer to remove old mortar from the joint.

- Drill with mixer attachment for grout preparation. If the volume of work is large, it makes sense to use a concrete mixer.

- Triangular trowel and falcon - for gentle application of the mixture and removal of excess from the masonry.

- Stiff brush and brushed - will easily clean the surface of stones when grouting and grouting are finished.

- A soft flute brush or roller is needed to wet the surfaces.

- A wooden lath about a meter long - it is convenient to support the tool on it when joining horizontal seams.

Also, do not forget that to prepare the grout, you will need a special container - deep, but not wide, so that the solution in it does not set so quickly.

Truly working legal way to save money. Everyone needs to know this!

Grouting brickwork

This procedure may be required if you need to restore the properties of old walls or make a jointing of the same color. Indeed, often the mixture in different parts of the masonry differs markedly in shade. First of all, it is necessary to cut the surface of the dry mortar to a depth of 1-1.5 cm (with a hammer and chisel) and remove its remnants. Cleaning is carried out not only at the seams, but also throughout the masonry - the brick wall must be completely cleaned of dirt and dust before grouting. To simplify the task, you can use a compressor unit to blow out even the smallest chipped particles from the cracks and ensure the best adhesion of the fresh joint.

Also, a reliable and well-sharpened tool is needed to accurately prepare for joining. Only with its help can excess mortar be removed so that the brickwork does not suffer. After that, you need to moisten the seams with water and get to work. Do not moisten the entire surface at once - limit yourself to a small area that you will be working on in the next hour.

Brick grout is sold ready-made or dry. It can come with the addition of pigments and plasticizing additives. But the main thing in any selected composition for seams is its basis. Today, there are two options for embroidering walls:

- cement (Quick-Mix, Mixonite);

- epoxy resin (Litokol Litochrom, Mapei).

But you can make an inexpensive mixture yourself. The simplest grout for masonry consists of two parts of lime and cement, taken equally, and 10 hours of fine sand. Such a solution has a pot life of about 90-120 minutes, so it is not worth kneading a large volume for joining immediately.

Another recipe: for one part of the cement, they take the same amount of ground volcanic track and 5 hours of sand as an aggregate. This grout should be used if the brick wall "pleases" the eye with efflorescence and whitish smudges from the seams.A purchased or independently prepared jointing solution is stirred to the consistency of liquid sour cream: it should not spread, but should be kept on an inverted trowel in a lump.

Having prepared the grout according to the instructions on the package, you can proceed to the vertical seams. The composition should be soft and plastic, so that it is easier to work with it, but at the same time not liquid, otherwise the solution will not keep its shape and will simply flow over the masonry. After all the preparations, the jointing is performed using the following technology:

1. Apply the ready-made grout with a trowel - a little more than needed to fill the joint. In order not to stain the bricks of the lower row, you can substitute a plaster falcon.

2. Remove excess mixture with an edge and smooth the surface with a suitable hand tool. Each seam is pressed with force so that there are no voids between the old grout and the grout.

3. After filling in, the actual jointing takes place, that is, giving them a shape. To work in horizontal rows, it is more convenient to use a straight rail - under it, as under a ruler, it will turn out to draw a straight line.

When the jointing of the brickwork is completed, the front side of it is cleaned of traces of mortar with a stiff brush. Then you need to give the mixture to finally gain strength, not allowing the seams to dry out, or vice versa - get wet in the rain.

Benefits of grouting

- Improving the appearance of the building facade. The grout is rich in color palette. Using contrasting colors, you can emphasize the slenderness of the masonry.

- Protection from moisture not only the seams, but also the walls of the house, which increases their service life.

- The sound and heat insulation data of the floors are significantly increased.

It is not always possible to observe buildings with a similar finish. If the masonry is to be plastering or facing in the future, grouting is not required. During the subsequent decoration of the seams for masonry, it is necessary to use exclusively intact and flawless material, and the seams should be the same in thickness. There are craftsmen who make horizontal seams somewhat thicker relative to vertical ones. This is a design decision.

Types of syringe pistols

The devices are used to fill and grind seams. They differ from each other. But in fact, there are only two varieties of them:

- Pistols that work with stone.

- For work with ceramic tiles.

They are equipped with a special mechanism that squeezes out a specially prepared mixture, like in a syringe. But different models may differ from each other in the following characteristics:

- The material from which all components of the gun are made.

- Body color.

- Variable volume of mortar cylinders.

- Availability of additional components.

Models with a large cylinder have a reinforced casing that can hold a lot of pressure inside. Usually all elements are galvanized.

That is, the larger the volume of the cylinder, the more the parts wear out. This is also due to the fact that some objects have to work in an accelerated mode. This is reflected in the operation of the gun.

Varieties of material and methods

For interior decoration, epoxy-based compositions are used.

For interior decoration, epoxy-based compositions are used.

Masonry joints must be treated with special compounds. Several different types of grout can be used for these purposes. However, in Russia with frosty winters, only 2 types are widely used:

- cement-based mixture;

- composition made from epoxy resin.

The first is mainly used for treating external walls, the second - internal, since it is much easier to wash and clean. The color of the composition is determined depending on the desire of the owner and is achieved by mixing with the color scheme.

In addition, you can use chemical components that will prevent the formation of mold and mildew, as well as increasing resistance to sudden changes in temperature conditions.

The appearance of the wall will depend on the chosen grouting method.The final result will depend on which tool will be used to perform the work. While some of the grouting joints can be applied with a spatula, more complex compositions will require a special appliance.

To a greater extent, jointing is done in the following ways:

To a greater extent, jointing is done in the following ways:

- Flush, in this case, the composition is placed inside the seam, and the excess is removed with a spatula. After that, the brick is cleaned with a brush.

- A convex seam is applied in a similar way, but the excess is not removed with a spatula, but, on the contrary, a special arcuate device is drawn along them, after which a neat trace is formed. Thus, the processing of horizontal masonry is carried out, the vertical seams must be passed after the first partially hardened.

There are many ways to lay the jointing. The most common ones are presented below.

When performing work, you need to strongly press the composition into the seams between the masonry. This will create a high-quality and durable surface.

What can you do with your own hands?

Budgetary, but no less high-quality - making a fugue (grouting mixture) yourself. Initially, you need to know the main types of grouting components:

Budgetary, but no less high-quality - making a fugue (grouting mixture) yourself. Initially, you need to know the main types of grouting components:

- Cement mixtures are simple, easy to prepare, cheap, but high quality material. To make a fugue, you will need to mix a cement mixture in equal proportions (white cement can be used), sand and water. The sand is selected in the smallest fraction. A dye or color scheme of the decor required in color is added to the mixture.

- Gypsum fugue - such a composition requires skill, since the gypsum sets quickly. The mixture is made in small portions, which will not have time to harden during work. Gypsum is diluted to a semi-liquid state, slaked lime or 2% of any glue of animal origin is added for strength. Such substances will replace the plasticizer, make the fugue less brittle, and increase the setting time.

- Alabaster mix is a type of gypsum, only after additional heat treatment. Alabaster powder is diluted with water to a semi-liquid, thick state, you can add a dye. In use, it is similar to plaster composition.

- Clay grout - a fugu from such a material is made from a clay mass with the addition of a small amount of slaked lime and cement. The mixture will be very strong when hardened.

Advice

You can buy a ready-made grout mixture and modify it, for example, add a color scheme of the desired color and even glitter. If the design requires a transparent seam made of liquid glass or epoxy, then the addition of shiny elements will make it more effective.

A self-made fugue is inferior to industrial compositions, but the quality can be similar. Before mashing, it is worth making sure that the self-made fugue has the necessary qualities or is close to these parameters:

- elastic, easy to fit at the seams;

- after drying, it does not crack, does not crumble, and does not fall apart when left;

- the setting time of the composition should be equal to the processing of one square meter of the facing surface;

- for damp rooms, the composition of the fugue must be moisture resistant;

- the grout mixture must withstand washing with household chemicals;

- aesthetics of the composition: the grout should correspond to the idea, the general design of the facing surface.

Sealing joints in brickwork

Sealing the wall in the house will get rid of the cold, will help to avoid water entering the room. Perfectly sealed walls increase the strength of the structure.

It should be noted that in modern construction, a special pistol is used to seal the seams. Such a construction gun is intended strictly for trowelling mixtures.

It fills the seam tightly and thoroughly without excess. When choosing building materials, you need to pay attention to the brick itself.

The first thing you can do when choosing a quality brick is to take a certificate from the manager who implements it. But it also happens that the trade representative does not have documentation, and if there is, it is not a fact that it is genuine. This means that you need to determine the quality of the brick for the construction site with your own eyes and hands.

Experts recommend that you first inspect the appearance of the product. If it is cracked, then the purchase should be discarded. Cracks usually appear when the production technology has been violated. You also need to be wary if there are foreign inclusions in the bricks. When they are gray with a loose texture, it could be a suspicion of the presence of quicklime. Accordingly, when it comes into contact with water, the brick will collapse. In order to check the strength of the product, you need to choose a brick of less quality and try to break it. Good products won't break into many pieces. If there are a large number of them, then this indicates violations during mixing.

If the middle of the brick is dark, then there were irregularities during the heat treatment procedure. If a silicate brick is purchased, then its corners must be strictly even. It should be noted that silicate products are cheaper, but less durable.

How to care for your tiles

In order for the coating to last for a long time, you need to know how to properly care for the tiles.

For glossy structures, do not use strong acid-based detergents. This can damage gaps and seams between products.

It is best to purchase specialty products for tiles, stoneware tiles and porcelain stoneware.

Do not use metal brushes or abrasive powders, as they severely scratch the surface of the coating. This is especially noticeable on glossy ceramic tiles.

The best tile cleaners

In order for the tile to retain its attractive appearance for a long time and not fade, it is better to use specialized mild detergents:

- Mister Muscle. Eliminates plaque, rust, removes stains from the surface of the tile and gives it shine. It is necessary to apply the liquid to the dirt, wait 3-5 minutes and walk again with a damp sponge. It copes well with stubborn stains and does not run off vertical surfaces. In this case, you do not need to scrape and rub the plaque with a washcloth. The detergent perfectly removes even the formed mold from the grout.

- Frosch. Suitable for most types of tiles. Effectively removes dirt, grease, streaks and plaque from ceramic tiles. Frosch is harmless to the body. The product neutralizes unpleasant odors and kills germs. To clean the tiles from dirt, dilute 2 caps of detergent in 5 liters of water and clean the surface. Not intended for pure use.

- Cif Anti-plaque. Removes accumulated dirt thanks to a unique water and dirt repellent formula. In a matter of seconds, it removes limescale and soap stains from the surface of the tile. Sif should be applied evenly to dirt, wait 5 minutes and rinse with clean water.

- Domestos. Effectively removes fungus, whitens grout joints and disinfects. Directions for use: Dilute 2 caps of gel in a 5-liter bucket of water and remove dirt with a sponge or soft-bristled brush. Then rinse the surface with water and wipe dry.

- San wedge (Santik). Liquid for removing limescale, rust and other contaminants from tiles. It must be applied to the surface for 5-10 minutes and then remove the remnants of dirt.

Also, for cleaning tiles, you can use auxiliary products:

- Bleaching powder. Dilute the powder with clean water. Pour the solution into a spray bottle and spray it onto the desired surface. Then leave for five minutes and rinse with plenty of clean water. Allow the ceramic to dry or wipe the surface with a dry cloth.The chlorine solution kills germs and gets rid of mold.

- Melamine sponge. Easily wipes off small dirt, removes limescale and does not spoil the appearance of the cladding. You just need to wet the sponge and rub the dirt.

- Steam cleaner. A gentle alternative to aggressive cleaning fluids. Steam cleans the surface of the tile as well as chemistry. And at the same time it does not have any mechanical effect. The steam supplied under high pressure liquefies grease stains on the tiles and disinfects the surface to be cleaned, killing microbes. The steam cleaner is excellent at fighting mold and limescale in the bathroom. It removes even grease stains in the kitchen with ease.

To prevent the ceramics from fading and scratching them during operation, they need to be treated with a special varnish. A durable protective coating is created, the color does not change for many years, and the maintenance of the tile surface is greatly simplified, because almost no dirt accumulates on the varnish.

With proper cleaning and good timely maintenance, ceramic tiles will last for many years.

Conclusion

The final grout improves the look of the masonry, makes it expressive and beautiful. If you know about the methods of work, use the necessary tools and good quality mixtures, you can do the joining yourself. Correct renovation will delight you with attractiveness and durability.

If the owner of the house is not sure of his abilities, then it is better not to risk time and building materials - immediately seek help from specialists. Only an expert can guarantee the quality of the assigned tasks.

The video provides interesting and informative information: