Preparing paint

Dilution of paint

The paint in the can has a thick consistency. Undiluted composition is great for creating relief compositions, but too thick for normal painting. In this regard, the emulsion is first thoroughly stirred, and then water is added to it. The quantity is determined based on the recommendations of the manufacturer or empirically. Water is added until the paintwork material acquires the desired consistency. Correctly diluted paint resembles fat milk in density.

If you plan to use a spray gun, tap water will not work, because after the coating dries, a whitish coating forms on it. In this regard, distilled water or alcohol is used for dilution.

The paint must be thinned just before use. Already after 15-20 minutes, the composition thickens. If this time is missed, the paint should be thinned again.

Tinting

The water-based composition is available in white. If you want to give the paint a different color, add pigment to it. This can be done at home or right in the store, if there is specialized equipment there.

If you are tinting yourself, it is recommended to purchase a pigment with a margin of 10-15%. This will allow you to recreate the composition for updating the coverage in the future without problems.

Kohler is added gradually, after which the solution is thoroughly mixed. If the intensity of the shade obtained does not suit you, then you need to add more pigmenting agent.

First, you should dilute a little tinted paint, which will allow you to see how it will look on the painted surface. Moreover, the shade of the dried coating differs from the color of liquid paintwork. You also need to keep in mind that paint with a broken period of use or improperly stored can have a significantly changed color (in comparison with the original) and poorly adhere to the surface. Poor quality paint forms a bubble coating or simply drips off the surface completely.

Paint consumption

The approximate consumption per m2 is indicated by the manufacturing company on the bank. Based on these data, it becomes possible to plan the consumption of paintwork materials.

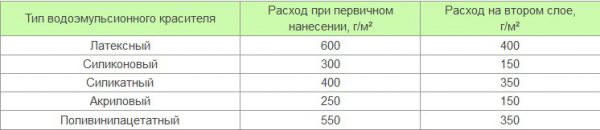

You can also calculate the amount of paint you need, based on the General consumption rates of water-based paints and varnishes:

However, it should be remembered that the consumption rates of 1m2 of the same paint can vary greatly depending on additional factors. In particular, we are talking about the type of material to be painted. A smooth surface absorbs 15-20% less paintwork materials in comparison with a rough one.

Note! The calculations take into account the number of layers. Most often, one layer is not enough to paint the surface - they will need at least 2-3

Also, the used tool affects the material consumption. For example, the use of a spray gun allows you to reduce the consumption of paintwork materials, but only if the painting is carried out in calm weather.

The flow rate also depends on the temperature and humidity of the air. In hot weather, the liquid quickly evaporates from the dye, and therefore the coating is formed unevenly - you have to reapply the layers. Additional losses of paintwork materials are a common occurrence when painting the ceiling, since the composition simply flows down.

Instruments

To apply paint, use brushes, rollers or spray guns. Brushes are best for small surfaces with many angles and raised details. A spray gun is a convenient tool, but not everyone has it available, and buying it for one painting is not always advisable.Therefore, a roller is most often the best for surface painting.

There are several types of rollers:

- Foam rubber. They are distinguished by their low cost. Too much dye is taken up, and therefore bubbles and irregularities form on the coating.

- Velor. It is more difficult to buy them due to their lower prevalence. Velor rollers are characterized by low absorbency. This property has a positive effect on the quality of the painting, but the roller will have to be dipped very often.

- Hairy. The best option for painting. On sale there are rollers with different pile lengths (affects the layer thickness). The most expensive fleecy rollers are made of felt and fur. Also a good choice is polyamide fiber rollers.

TOP-5 rating of popular water-based paints: which is better

| Country-

manufacturer |

pros | Minuses | |

| Tikkurila | Finland | · Optimal combination of price and quality.

· Modern production technologies. · Continuous expansion of the range with new products for different surfaces. · Unpretentiousness in everyday life (vapor permeability, dirt-repellent properties, etc.). · Hypoallergenic. |

· The need for professional tinting.

· Price. · The need to combine with other finishing materials of the same brand. |

| Ceresit | Russia | · High adhesion (adhesion to the surface).

· Resistance to direct sunlight. · Uniformity of painting and tinting. |

· High cost with double application required on any surface. |

| Dulux | United Kingdom | · Eco-friendly, making the paint ideal for bedrooms and children's rooms.

· Continuous modernization of technologies, confirmed by international exhibitions and competitions. · Durability of the coating. |

· High price.

· Many nuances of application, which requires the involvement of a professional in painting. |

| Caparol | Germany | · A network of factories around the world.

· Affordable price. · High resistance to washing, abrasion. · High hiding power (one layer is enough). |

· Complete drying takes several days. |

| Dufa | Germany | · An extensive range of shades and textures.

· High quality formulations. |

· Poor hiding power and strength of the coating.

· Absence in the palette of a snow-white shade (often chosen for the ceiling). |

Types of paint depending on the chemical composition

There are several types of paints, differing in the type of polymer used in the composition. To understand which water-based paint is best suited for the implementation of the project, you need to know the features and differences of materials.

Acrylic

The most popular type of work is painting with acrylic-based water-based paint.

The most common representative is the water-based paint weak 1180

Latex is often added to acrylic water-based paint: in combination with acrylic, it provides excellent adhesive properties. The double-layer coating allows you to close even cracks up to one millimeter thick at the base of the painted surface. The composition can be used for work with any materials (concrete, brick, glass, wood, stone), including as a paint for metal, taking into account the preliminary priming.

Mineral water-based paint

An indispensable component in the composition of this material is cement or hydrated lime. Before painting with this type of water-based paint, it must be taken into account that it fits optimally on concrete / brick, but has a short operational life.

Silicone water-based paint

As well as with the previous type of paint, it is easy to understand why this paint has such a name. That's right - thanks to the presence of silicone-based resins in the composition. It is a more expensive material that is characterized by increased resistance to evaporation. This enamel can be used to paint walls and ceilings in rooms with high humidity - bathrooms, kitchens.After painting with water-based silicone paint, you can forget about things like mildew and mildew for a long time.

Silicate water-based enamel

The silicate enamel contains water dispersion, liquid glass and color pigments.

Silicate compounds let steam through without trapping air, but they do not keep the walls from moisture. In this regard, it is recommended to apply this type of water-based paint in rooms with low air humidity - in this case, it forms a durable coating that can retain its visual properties for twenty years.

Specifications

To describe the water-based composition, the following factors are important:

- Paint components. An aqueous solution can contain a variety of fillers, thickeners, antiseptic agents. Depending on the composition, the paint is intended for facade or interior work, wet or dry rooms, etc.

- Scope of use. The composition can be universal or for painting only one type of surface (for example, wood).

- Consumption of paint and varnish composition. Calculate the amount of paint in milliliters based on how much it will take to cover 1 square meter in one layer. In doing so, many factors are taken into account, including the type of material and the condition of the surface.

- Specific gravity. High-quality water-based paint has a density of approximately 1.5 kg per 1 liter.

- Viscosity. This parameter indicates the degree of dilution with liquid.

- Humidity of the environment during application and use.

- Drying time.

- Storage conditions.

- Shelf life.

- The service life of the coating.

There are other technical details to be aware of, including the proportions of paint components and common markings.

Note! Water-based paint is always white, and color is obtained by adding a special pigment

Component proportions

An important component of water-based paints is an emulsifier responsible for film formation.

The following components are used as film-forming agents:

- styrene butadiene;

- acrylic resin;

- polyvinyl acetate;

- styrene acrylate.

Also, mica, barite, talc, chalk are added to the composition. The proportions in which these or those components are contained in the paint are determined by its purpose.

The thickener function is performed by a complex compound - carboxymethyl cellulose. In everyday life, this component is called the adhesive composition of the CMC.

Note! It is recommended to use a spray gun for working with emulsion paint. Spraying allows for the best quality and most uniform coverage

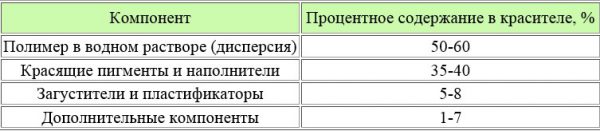

The table shows the ratio of the various constituents in water-based paint:

Water-based paint and varnish material is made by adding a white pigment, for example, zinc oxide or titanium dioxide.

According to the main component, all water-based dyes are divided into several types:

- silicate;

- acrylic;

- silicone;

- mineral.

Marking

On the paint can or in the accompanying documents, abbreviated letters and numbers are used. At the beginning there are letters suggesting the type of composition:

- VE - water-based paint;

- VD - water-dispersive.

The following letters indicate the type of polymer used:

- CS (styrene-butadiene);

- VA (polyvinyl acetate);

- AK (acrylate or styrene acrylate);

- VS (polyvinyl alcohol).

In addition to letters, numbers are used:

- 1 - compositions especially resistant to atmospheric phenomena;

- 2 - paints for interior work.

Note! Requirements for water-based paintwork materials are set out in GOST 281960-89. Unlike GOST, the TU rules are much less stringent, and therefore the quality of products manufactured according to TU cannot be guaranteed

Advantages and disadvantages

Water-based paints have many positive qualities:

- Good adhesion to various types of materials.

- Easy to dilute in water.

- Environmental Safety.

- Fast drying.

- Lack of unpleasant odor in the room after painting the surface.

- Strength. The coating does not flake off.

- Resistant to chemicals, including alkalis.

- Easy to remove dirt from the coating.

- Fire safety.

- High water resistance of certain modifications, which makes it possible to paint surfaces with such compositions in bathrooms and kitchens.

- Antibacterial properties.

- Long service life of the coating, reaching 18-20 years.

- The ability to mask surface defects (with the proper level of viscosity of the composition).

- Compatibility with all types of interiors. Thanks to tinting, the paint has the widest palette of colors.

- Low cost.

Water-dispersed paints also have disadvantages:

- Sensitivity to temperature when staining. The minimum threshold is 5 degrees above zero.

- Certain types of paints form surfaces that are not very durable.

- Not all water based compounds are suitable for metal substrates or glossy surfaces.

The best manufacturers of paints for walls and ceilings

If you do not know which paint brand to choose, then it is recommended to trust the professionals. They advise buying materials from only the best manufacturers who have been present on the Russian market for decades and produce the highest quality compositions.

Top manufacturers:

- Marshall. This Turkish company specializes in the production of various paints and varnishes. In their wide assortment there are also several types of paints for ceilings and walls. These materials are distinguished by good performance characteristics, are economical in consumption and withstand repeated cleaning.

- Finncolor. Any product of this Finnish company is universal. It is suitable not only for interior decoration, but also for exterior. Finncolor paints are appreciated for their relatively low cost and can be used in damp conditions (for example, in the bathroom).

- Emplis. The best Russian manufacturer of paints and varnishes produces inexpensive but high-quality products. It is resistant to external influences, and also retains its brightness and attractive appearance over a long period.

- Alpina. High-quality German paint pleases the owners of the apartment with the ability to repel dust and dirt. Thanks to this, she always remains clean and beautiful. Alpina products are often used during kitchen or bathroom renovations.

- Dufa. The paints and varnishes of this company are distinguished by traditionally high German quality and wear resistance. They can be used for interior decoration of any room, even damp ones.

- Tikkurila. This popular Finnish manufacturer is one of the top sellers in Russia. Its products are characterized by increased wear resistance and good decorative properties.

- Beckers. The Swedes are not far behind the Finns in the quality of their paint. The main feature of their materials is the availability of certificates of compliance with European environmental standards. Beckers products are very high quality, but quite expensive.

- Dulux. An English manufacturer of paints and varnishes produces paint that is ideal for a particular room. All of their formulations give off color saturation and good wear resistance.

- Sherwin-Williams. Everything that you can make money on is not bypassed by the Americans. Sherwin-Williams has been successfully operating in the USA for many years. It supplies its products to various countries of the world, including Russia. American paints are of high quality and environmental standards.

- Parkerpaint. Another US manufacturer produces paint that is suitable for almost any surface. The advantage of this company is the high quality of products and a huge selection of color shades.

What water-based paint to choose for the ceiling

On the market you can find a large assortment of paints and varnishes from different manufacturers. Their main difference lies in the main constituent component.

Water-based acrylic paint

The composition of the water-dispersion mixture contains polyacrylates. This is one of the most sought after finishing options. It is appreciated for its versatility of use, it is suitable for painting wood, concrete, plaster, brick, glass.

Can also be applied to metal surfaces, but with preliminary priming.

The advantages of acrylic water-based products include the following:

- sufficient elasticity;

- waterproofness;

- resistance to mechanical abrasion;

- strength;

- resistance to ultraviolet rays;

- good dirt-repellent qualities;

- allows you to mask cracks up to 1 mm deep;

- high degree of density when applied;

- low consumption when painting the surface;

- can be used in any room.

Silicone water-based ceiling paint

The components of the paint are silicone resins, which are excellent for painting ceilings. Due to the high degree of density, it is possible to hide defects on the surface up to 2 mm deep.

Due to the antiseptic properties of the composition, the appearance of pathogenic microorganisms, fungus, mold on the treated surface is blocked. It is this parameter that explains the possibility of using silicone water-based paint in rooms with a high level of humidity, including the bathroom, kitchen. After such a finish, it is quite easy to clean the surface.

It is not recommended to use silicone paint on reinforced concrete, there is a high likelihood of rust stains coming through

Important! If there is a need for such staining, then the surface should either be primed in advance, or use paint with anti-corrosion additives.

Latex water-based ceiling paint

The basis of this finishing material is made up of acrylates, latex is present, which provides increased water resistance. Thanks to this component, painted surfaces can be easily cleaned with detergents, up to 5,000 washing cycles without losing color or saturation. It is good to use latex paint on wood, metal, concrete surfaces, as well as plastered, covered with structured wallpaper, finished with sheets of drywall.

Latex water-based composition for painting the ceiling should be used in heated rooms

Among the positive characteristics of latex water emulsion are also noted:

- lack of a specific smell;

- environmental friendliness;

- high degree of elasticity;

- versatility of application.

Disadvantages:

- condensation appears on the painted surface;

- does not tolerate low temperatures;

- low level of resistance to ultraviolet light, fungus, and other pathogens.

Silicate water emulsion for ceilings

This water-dispersion composition contains such components as water glass, coloring additives. Of the indisputable advantages, it is worth highlighting:

- fire safety;

- high level of breathability;

- harmlessness to human health;

- good wear resistance;

- sufficient moisture resistance;

- durability of the finish.

Many manufacturers of paints and varnishes add antifungal components to this type of paint.

Polyvinyl acetate water emulsion for ceilings

This version of the paint is made by rubbing pigments on a polyvinyl acetate type emulsion. Among its advantages are:

- lack of a specific smell;

- material budget;

- resistance to moisture, mineral oils.

Of the minuses of this type of finishing finishing material, a low level of moisture resistance and mechanical stress is noted

Manufacturers

The production of water-based paint has been established for a long time and is very widely represented on the market.

We recommend rubber paint as a wear-resistant and easy-to-apply alternative to water-based compositions. As an interior material for walls and ceilings, such a coating primarily attracts by the ease of cleaning from grease and other contaminants. This is especially useful for families with small children - you can easily remove marks from markers or watercolor paint. The coating is environmentally friendly, safe for health and odorless. However, one should beware of inexpensive rubber paints, where price reduction is achieved by the presence of styrene-acrylic latex in the composition. With regular exposure to the sun (namely, UV rays) or water, the coating begins to crack and collapse. In a living room on the sunny side, even one month of operation is enough for such consequences.

Styrene-acrylic latex is absent, for example, in durable rubber paint "Mitsar" Rezolux Universal. The service life declared by the manufacturer is up to 10 years. In addition, due to its increased water resistance, the material can be used to cover walls even in bathrooms and toilets. The advantage of "Mitsar" Rezolux Universal in comparison with analogs is in increased hiding power, paint consumption per square centimeter of surface is about 150 grams. This is about four times lower in comparison with the popular Super Decor Rubber paintwork materials. Thus, with the same area, the cost of purchasing Mitsar products will be four times lower.

Note that Mitsar is a St. Petersburg manufacturer that has been producing paintwork materials for 12 years, special attention is paid to achieving the best key parameters along with the lowest price among all foreign and domestic analogues. For these reasons, the company constantly wins tenders for the supply of materials for enterprises of the State Defense Order

The company is known for its products adapted to extreme operating conditions, with increased mechanical stress, low / high temperatures and exposure to aggressive chemical environments. In the past few years, defense enterprises-customers in tenders, instead of parameters-requirements for paintwork materials, immediately indicated specific Mitsar products. This is a clear sign that the experience gained confirmed the correct choice in favor of the materials of this particular company from St. Petersburg.

You can choose any unknown manufacturer, possibly with a lower price policy, or you can spend money on higher quality paints from such well-known manufacturers as Dulux, Dufa or Tex. In their palette there are paints of all types and purposes, both matte and glossy, as well as semi-gloss and semi-gloss. These manufacturers have confirmed their reputation by the time spent on the sales market and the quality of their products.

For information on how to paint the walls with water-based paint, see the next video.

Surface preparation

In order for the paint to adhere well to the base coat, it must be carefully prepared. It is about removing irregularities, filling cracks and cleaning the surface from dirt and dust.

During the preparatory work, a considerable amount of debris can arise, and when painting it is easy to stain the surrounding interior items. To avoid damage to property, use plastic wrap, which is attached to the baseboards with masking tape.

Surface cleaning

First, you need to clean the walls of old paint or any other decorative coating. One of three methods is used to remove paint:

- Mechanical.

- Chemical.

- Thermal.

Note! An oil-based coating is incompatible with water-based paints, so it will have to be removed in any case. If the old paint is enamel, you can leave it, but prime the surface with drying oil with high quality

Typical Surface Cleaning Steps:

- Remove the old coating with a hard sponge or brush.

- If the wall is whitewashed, moisten it with water and remove the remnants of the whitewash with a brush or a regular sponge.

- If we are talking about oil paint, we use a building hair dryer to warm up the coating - this is the only way to soften it and remove it with a scraper or spatula.

There are products on sale for chemical cleaning of surfaces from old paint. Such chemicals destroy the previous coating, so that after some time after their application, all that remains is to mechanically remove the paint residues.

Sealing gaps

When the walls are cleaned, we start looking for and repairing cracks in the base coat. If you ignore this work, you will not be able to get a stable new coating and new cracks will inevitably appear on the painted surface.

We slightly expand the found cracks to fill them with a repair compound using a spatula or grinder. Next, we clean the cracks of dust and apply a primer for deep penetration painting. Let the material dry (most often we are talking about 4-6 hours of waiting).

The next stage is to seal the cracks with a putty compound or some kind of polymer (for example, silicone sealant). To prepare the putty, we use an electric drill with a mixer attachment. The composition must be brought to complete homogeneity, only then it is considered ready.

Once dried after filling, we treat the walls with a primer. We are again waiting for the surface to dry before continuing to work.