Popular brands

There are a lot of manufacturers of vapor barrier and related materials. There are a lot of offers on the market from well-known firms or various companies from the countries of Southeast Asia. The quality of the products of these companies does not always correspond to the statements of the manufacturers. In addition, there are many outright fakes, when cheap and low-quality material is offered under the brand name of well-known brands. The risk group includes all products of the most famous companies. If during the purchase it seemed an unreasonably low price, or there were other doubts about the authenticity of the material, you should not hesitate to ask to show the certificates. If the products are real, there are no problems with this. If the seller finds it difficult to provide certificates, it is better to refuse the purchase and look elsewhere.

Delta films

Scotch tape with polyurethane foam backing. The adhesive layer consists of an acrylate compound with high adhesion to concrete, brick, plaster, wood, polymers and other materials. There are models with aluminum spraying, designed for bonding the metallized film of the same name. All types of tape are distinguished by their strength, durability, the ability to maintain their working qualities throughout the entire service life.

Vapor barrier Izospan

The company produces 4 types of insulation and related materials:

- hydro-windproof membranes;

- vapor barrier films;

- vapor barrier with reflective properties;

- connecting tapes.

Izospan films are made from polypropylene. They do not react to ultraviolet radiation, do not change their qualities under the influence of low temperatures. Provides complete cut-off from water vapor.

Izoltex films

A large number of insulation materials are produced under the Izoltex brand, including polypropylene vapor barrier. There are types with reflective properties, with anti-condensation coating, and ordinary film. All of them are distinguished by their durability, strength, and environmental friendliness. Installation of the material is not difficult and is carried out in the usual way.

Vapor barrier Yutafol N96 Silver

Reinforced polyethylene film intended for indoor installation on a heat insulator. The direction of laying does not matter, you can unfold the canvas with either side inward or outward. Fastening is done with a stapler or nails with flat heads. Sold in rolls of 75 m2, used for installation on flat, pitched roofs or walls.

Vapor barrier Izovek

Polyethylene film with an anti-condensation layer. The manufacturer offers several types of material, differing in different densities. The film has high performance and long service life. It differs from analogs in lower cost, which increases the demand among users.

Vapor barrier films Ondutis

This is an extensive group of insulation materials with different capabilities. Ondutis vapor barrier is represented by conventional and reflective materials intended for use in heated residential areas. The film shows high working qualities, is strong and durable.

Windscreen Installation Instructions

All windproof materials can be conditionally divided into two groups - sheet and roll. The sheet windshield is distinguished by the density of the material, it is suitable for upholstery of the facade. These are materials such as isoplat, drywall, fiberboard and fiberboard, as well as OSB boards.Roll materials include flexible and thin windscreen variations. Such as plastic film and polymer membrane. Installation methods differ depending on the type of product.

Installation of sheet windscreen

There is a specific order in which the layers of framing walls are placed. A vapor barrier and insulation layer is placed behind the interior decoration, if necessary, a ventilation gap, followed by one or more windproof layers. And then - facade decoration.

Modern windproof materials may not require additional wind protection, and sometimes also serve as a vapor barrier or insulation.

The procedure for installing sheet windscreen:

- All mounting surfaces and impregnations must be completely dry before installing the windscreen.

- The windscreen is only installed when the thermal insulation is fully installed.

- The material must be cut into several sheets with a vertical orientation.

- The sheath usually has one rough surface and a second smooth surface. For the convenience of subsequent finishing work, the sheets should be placed with the rough side inward.

- It is necessary to fix the sheet windscreen with dowels. Dowels with a large diameter head should be taken. For 1 sq. m. you must use at least 5 fasteners. 6. It is most convenient to fix the sheets vertically.

Installation of a roll-up windscreen

If you decide to use a roll-up windscreen, the order of placing the layers of the frame is modified. After the insulation material, several types of wind protection are used. A combination of OSB boards and polyethylene roll film is often found. Since the material is soft, it is necessary to install additional reinforcement of the structure - battens and counter battens. Only after that comes a layer of facade decoration.

The procedure for installing a roll-up windscreen:

- Wait for all layers of the frame construction to dry completely.

- It is required to buy roll materials with a small margin. To seal the joints, it is necessary to take into account the overlap of the material during fastening of about 10-15 cm.

- It is not necessary to cut the roll-up windscreen in advance.

- The layer must be fastened from the bottom up, gradually unwinding the roll. You need to fix the windproof material with a stapler.

- Watch the tension level of the material. It is optimal if you can collect a 1 cm fold.

- Cut the roll as you work immediately after fixing the material with a stapler. To do this, you can use a clerical knife.

- To make the wind protection more reliable, strengthen the joints of the layer with construction tape or adhesive tape for a vapor barrier.

Installation of wind protection elements

The windscreen is installed on top of the insulation, which is mounted with

outside of the house. It is recommended to retreat from the insulation material 2-3 centimeters. it

distance is required for ventilation. To organize the ventilation gap,

a crate is created from wooden bars. Use metal profiles

acceptable, but not recommended due to the high thermal conductivity of the metal,

leading to the appearance of bridges of cold and condensation.

To provide adequate protection from the wind, you need to lay

overlapping windproof film. The recommended overlap is 15 centimeters. The edges

the films are glued to each other with special adhesive waterproofing

ribbons. They must be vapor permeable, like a windshield film.

In order for the gluing to be reliable and of high quality, it is recommended to purchase

tape and film from the same manufacturer - materials must match well.

In addition to waterproofing adhesive tapes for the installation of windproof films

special brackets can also be used. The main thing is that they have

waterproof cap. This is a more modern option for creating a windscreen.

After installing the windbreak, it remains to secure the siding panels.

It is important to leave a small ventilation gap at the bottom and top of the cladding in order to

all moisture escaping from the walls of the house evaporated unhindered. Siding panels alone are not enough to renovate an old house

To protect the walls from cooling and freezing, you need to use an insulation material. And for the long-term preservation of the thermal insulation and decorative properties of the insulation and cladding, the use of a windproof film is strictly necessary

Siding panels alone are not enough to restore an old house. To protect the walls from cooling and freezing, you need to use an insulation material. And for the long-term preservation of the thermal insulation and decorative properties of the insulation and cladding, the use of a windproof film is strictly necessary.

Consequences of refusal to vaporize

Failure to understand the importance of vapor barrier for the roof often leads to attempts to save money or speed up the construction process. Many users believe that the material can be installed later if the need arises.

Other owners rely too much on ventilation. They are confident that increased air exchange in the attic will help remove humid air and solve all problems. However, in practice, the lack of vapor protection affects the same way. Condensation appears, the heat insulator gets wet, the rafters rot.

The biggest danger is that the process runs smoothly enough. The owner monitors the condition of the attic for a week, and draws conclusions about the normal state of the insulation cake. Sheathing is installed, the room is finished and put into operation. This makes it impossible for the user to control the condition of the materials hidden behind the skin. When destructive processes become apparent, the problem becomes critical. Usually, a major overhaul or complete replacement of rafters, roofing, and other supporting elements of the roof is required.

Pros and cons of windscreen

Material advantages:

• environmental friendliness (there are no harmful and toxic substances in the composition);

• fire resistance (achieved thanks to special additives);

• ease of use (laying technology does not require the use of special equipment);

• moisture resistance;

• does not lose properties under the influence of ultraviolet radiation;

• elasticity avoids deformation during installation;

• does not change the quality and characteristics at a sharp temperature drop;

• long operational period.

Of the disadvantages not of the membrane itself, but of its application, it can be noted that an incorrect installation leads to a deterioration in the thermal properties of the facade. The loose adhesion of the film to the insulation layer provokes the formation and accumulation of condensate from the side of the insulation.

Also, some builders forget about the need to leave a ventilation gap between the membrane and the cladding.

Why do you need a vapor barrier in the house

In order to clearly understand why a vapor barrier is needed, one should understand the features of the roofing structure and the whole house as a whole. In warm rooms, provided that the internal pressure exceeds the level of atmospheric pressure, the air is humidified and, rising up, tries to escape through the insulation layer. To avoid damage to thermal insulation, materials with vapor barrier properties should be selected for its installation. Fiberglass may be the best option.

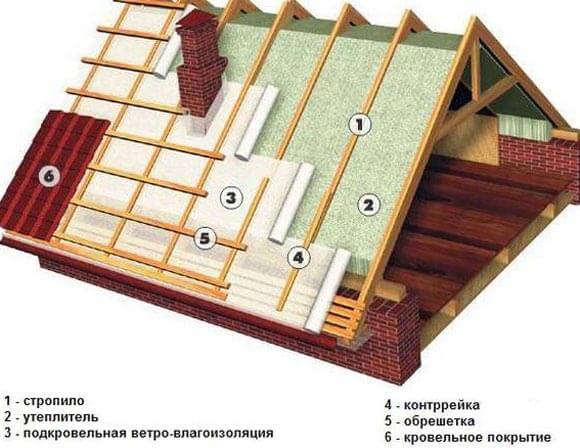

Country houses can have a single- and gable, multi-gable, hip roof, equipped for housing, or performing only the function of a roof. Depending on whether the under-roof space will be residential, the "pie" is being assembled.

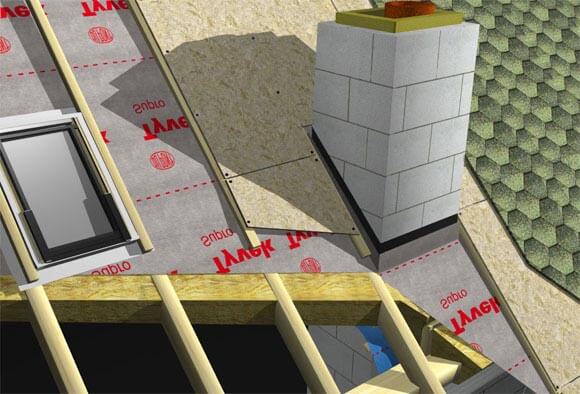

In the first option, vapor barrier materials for the roof must be purchased without fail, and in order to properly lay them, it is enough to read the short instructions:

- All work is carried out from the side of the room.

- The first layer is a vapor barrier membrane, on top of which insulation is placed.

- Next, a windproof membrane is attached.

- As soon as the required layer is ready, the lathing is created and the roofing material is laid.

If the roof is not going to be used as an attic, then it is simply covered with tiles and a windproof membrane.

Hydro and vapor barrier for a flat roof is attached, taking into account the ventilation gap - small holes through which air can easily pass from the ridge elements to the cornice. The presence of such a gap between the coatings provides not only ventilation of the under-roof space, but also allows you to lay hidden electrical wiring. Remember that it must be reliably protected from moisture by cables, otherwise a short circuit will occur.

Thanks to the arrangement of forced-exhaust ventilation, the issue of preventing the formation of moisture will be resolved.

How to properly install a vapor barrier?

A vapor barrier for a pitched roof is installed quite simply, so you can cope with the task yourself without the help of builders, armed only with a set of necessary materials:

- sheet plastic;

- glass;

- aluminum foil;

- metal sheets;

- extruded polystyrene foam;

- isospan, megaizole;

- do not forget about the vapor barrier tape, which is available in two versions - double-sided and single-sided.

The vapor barrier material is attached to the frame elements: beams, rafters and uprights so that the inner side of the canvas faces the insulation (for more details: "Which side to attach the vapor barrier"). Since the delivery of the vapor barrier is carried out in rolls, they are rolled from bottom to top, and each subsequent sheet is laid with an overlap on the previous one. To connect the sections, a special vapor barrier tape is used, it will also serve as a waterproofing of the seams (for more details: "Roof vapor barrier - instructions").

The need to use a windproof film in ventilated facades when installing is highly controversial.

The precedent for not using a windproof membrane was created by the manufacturer of a well-known brand of Chelyabinsk insulation. They received a new Technical Certificate for their own products, containing a clause allowing the use of insulation with a cached layer without the use of a wind-waterproof membrane. The development assisted in promoting the product to the market. By itself, this insulation is quite expensive, but when installing the "pie" of the facade system, the contractor saves due to the lack of a membrane. This idea was picked up by other manufacturers of insulation, and away we go.

This state of affairs fundamentally does not suit membrane manufacturers, which is logical. Manufacturers conduct extensive educational activities aimed at disseminating information about the consequences of abandoning the hydro-wind protection layer.

Arguments for the application of windscreen refer to:

The insulation collapses under the influence of high pressure and gusts of wind in the ventilated gap of the system.

The insulation gets water and moisture, and, in winter, without having time to dry, it turns into ice. By the way, there is a separate article about the installation of the facade in the winter. Thus, the properties of thermal protection are reduced.

In places of strong moisture penetration, the insulation can become overgrown with moss.

Arguments against wind protection:

Many people think that the windscreen burns. The propagation of the thrust in the gap from the bottom upwards promotes the spread of the flame. Therefore, a horizontal fire cutoff is used on each floor. Which is also wrong, becausethe principle of a ventilated facade is violated.

The rest of the arguments boil down to the refutation of the provisions of the defenders of the application of the system. They say that the insulation does not collapse from the wind, because it has a cached layer that is denser in relation to the base density of the mineral slab. And mineral wool wetting in the ventilation facades is not terrible, because the wind flow in the air gap is such that it dries up the water almost instantly.

The editors will leave their opinion on the need to use a windproof membrane with you, so as not to be torn apart by the opposing sides.

And the truth, as always, is somewhere in between.

Purpose

Facade systems with an air gap, under the influence of the wind flow, pass moisture between the joints, which gets on the insulation, moisturizing it, thereby deteriorating its properties. The windproof membrane performs a protective function in relation to the insulation of walls and internal elements of the roof, not allowing to reduce the heat-saving characteristics of the premises. In addition to its main purpose, the material has other important properties:

- UV resistant;

- Able to pass steam;

- Resistant to active chemicals and bacteria;

- Chemically inert and does not emit harmful substances;

- High tensile strength characteristics;

- Non-flammability.

For the roof, a layer of wind insulation is required. Without it, water penetrates into the attic and rapid destruction of structures. The membrane allows water vapor to pass through and keeps the structural elements dry. Properly installed roof windscreens will keep the attic dry and free of condensation, extending the life of the entire building.

What tasks are assigned to wind protection

There is a misconception that wall insulation compensates for wind insulation and resists moisture penetration. However, thermal insulation and wind protection in no way replace each other.

The direct purpose of the insulating layer is to exclude the penetration of wind into the room

Particular attention is paid to preventing blow-out at the joints and corners of the structural elements of the house. Wind protection increases the thermal efficiency of the frame house - there is no cold coming out of the cracks, and the cost of heat through the walls and roof is minimal

In addition to the main function, the wind barrier has additional tasks:

Insulation protection. The insulation ensures the removal of vapors from the room, preventing the accumulation of moisture inside the insulating layer

The absence of dampness is an important condition for maintaining the insulating qualities of the insulation.

Frame ventilation. Normal air circulation prevents decay of timber frame house elements.

The windscreen of the under-roof space additionally serves as a hydro-barrier, reducing the risk of leaks during rain and melting snow.

The main types of wind protection

There are many varieties of windproof materials that differ in their composition, basic properties and price:

- Drywall

- Fiber boards

- OSB boards

- Fiberboard slabs

- EPPS

- Izoplat

- Vapor barrier polyethylene film

- Spunbond

- Polymer membranes

Depending on the basic properties, it is possible to determine what good outdoor wind protection is best for a frame house.

Drywall

Facade drywall belongs to environmentally friendly materials. Thanks to a special impregnation, it does not allow moisture to pass through. This is a fairly reliable and durable way of wind insulation. Drywall does not burn, which reduces the risk of fire. It is resistant to temperature changes, so it is great for residential buildings. Also, the material is easy to process. The disadvantages of facade drywall include its fragility and high price.

Fiber boards

Another environmentally friendly material is paraffin-impregnated fiberboard.Due to the flexibility of the slabs, they adhere very tightly to the walls, which does not allow wind and moisture to seep through. Paraffin prevents the tree from retaining water, so this method of wind insulation is quite durable. It also helps to preserve heat because the porous structure of the fiberboard allows moisture to escape from the house, making the air in the room dry and warm.

OSB boards

This material consists of several layers of wood chips held together with resin. OSB boards not only protect from weather conditions, but also make the building frame itself much stronger. The disadvantages of this method of wind protection include low vapor barrier. OSB boards can be used only for a combined method of wind protection, so that another material can provide the necessary ventilation of the walls.

Fiberboard slabs

The best way to insulate the wind is with fibreboard. This is a completely environmentally friendly material. The boards are composed of a mixture of cement, glass and wood chips. Due to the fact that the composition includes cement, fiberboard plates do not deform under the influence of weather conditions, and also strengthen the facade of the building well. They prevent the building from losing heat, and also create sound insulation. Wood shavings allow the walls of the house to "breathe". The material is easy to process.

House sheathed with fiberboard slabs

House sheathed with fiberboard slabs

EPPS

EPPS, or Extruded Polystyrene foam, is a flexible and soft material for wind insulation. It provides good protection against adverse weather conditions, but does not provide adequate ventilation to the building. It is also worth abandoning the use of EPSP boards with thin walls of a frame house.

Izoplat

Isoplat is classified as environmentally friendly materials. It is produced by pressing hot pine needles fibers. Since isoplate is made of natural fibers, it creates good ventilation in the house. The material reliably protects against weather conditions. Also, it does not require the installation of additional boards, since one side of the board is ready for finishing.

Wind protection with isoplat plates

Wind protection with isoplat plates

Vapor barrier polyethylene film

The film is often used as an additional element for wind protection. It belongs to one of the cheapest ways to decorate a home. The vapor barrier film provides protection from wind, condensation, and also protects the walls from leaks. Polyethylene does not create the necessary ventilation, so it is worth installing the film with a small gap between it and the insulation. If this condition is neglected, the insulation will begin to collapse under the influence of moisture from the building.

Spunbond

Spunbond is a nonwoven fabric. This material creates good ventilation, as its structure allows excess moisture and steam to pass through. Install the spunbond by following a few basic instructions. It should be used only for walls and placed strictly vertically. There must be a small gap between the spunbond and the insulation. Thus, excess moisture will not destroy the structure of the walls. Spunbond was originally used only as an agricultural material, so it is inferior in its properties to other wind protection methods.

Polymer membranes

The membrane is an improved version of plastic sheeting. It consists of several layers of a polymer film. Small holes allow steam to freely penetrate through the material, but moisture does not leak through the polymer membrane. Some types of polymer membranes are fireproof, they also produce material with additional thermal insulation. The membrane is a durable and reliable material for wind protection.

Windproof membrane

Windproof membrane

How to properly lay sheet windscreen

If we are talking about the most popular frame construction today, then we should adhere to the correct sequence of wall layers. For example, after the finishing material inside the house, there should be a vapor barrier and insulation.After them there is a crate for the ventilation gap, and only then layers of wind protection and facade decoration.

Healthy! It is worth clarifying that some materials for wind insulation also have vapor permeability and can even be used as additional insulation. In this case, some layers of the wall can be discarded.

The general algorithm for installing a sheet windscreen is as follows:

First you need to make sure that all surfaces are dry. The same goes for impregnations.

Then a complete installation of thermal insulation is carried out

If mineral wool sheets are used, it is important to ensure that they fit snugly together.

At the next stage, the sheets of windscreen are cut so that they are installed vertically (in height). You can also mount it horizontally, but this is not very convenient.

Lay the sheets with the rough side down (if any)

This will greatly simplify subsequent finishing work.

Sheets are fastened with dowels (it is recommended to choose those with larger caps). As a rule, 1 "square" requires at least 5 fasteners.

Of course, each specific material has its own nuances. However, regardless of whether rolled material or sheet material is chosen, novice builders often make a number of mistakes.

Peculiarities

Wall windscreening plays an important role in any construction. The need for its arrangement is explained by the fact that heat tends to leave the building, there are several reasons for this.

- Infiltration - leakage of streams of heated air through cracks, as well as cracks and pores in the walls and floor.

- Breathability - even the most durable thermal insulation materials have micropores, so air masses spread throughout the entire internal volume of the insulation. This reduces its functionality, this figure can reach 90%.

That is why it is extremely important to use a windscreen, thanks to which you can adjust the temperature in the room. In addition, the wind and moisture protection film prevents the appearance of fungi and mold, dangerous to life and health, which invariably appear when condensation occurs.

There is an opinion that wind protection and vapor barrier are one and the same, but this is not so. The materials have a similar effect, however, the differences between them are very significant.

Vapor barrier is needed to protect the insulation layer from wet condensation coming from the room. It is used in construction as an addition to thermal insulation coatings. Wind protection is indispensable in situations where you need to protect the structure from the adverse effects of wind, precipitation and other weather phenomena. Ventilated facades have the property of allowing steam to pass through, so liquid in the form of condensate does not accumulate inside the insulation and retains its functional characteristics.