How to convert cubic meters to tons - cube of rubble in tons

How many cubes of rubble are in a ton?

Any construction, be it large-scale or small construction of a private house, requires a preliminary calculation of materials. Large organizations have a whole staff of workers involved in the preparation of construction estimates.

If you plan to carry out an independent construction of a house or other structure, then you cannot do without buying a non-metallic material.

In order to correctly spend the planned funds, a preliminary calculation of the volume in cubic meters or in tons is required.

When hiring a freight transport with a certain carrying capacity, you have to adapt to the equipment. Therefore, you need to first calculate

how many cubes of rubble in a ton, so as not to create an overweight of transport.

How to convert cubes of rubble to tons? There is a solution

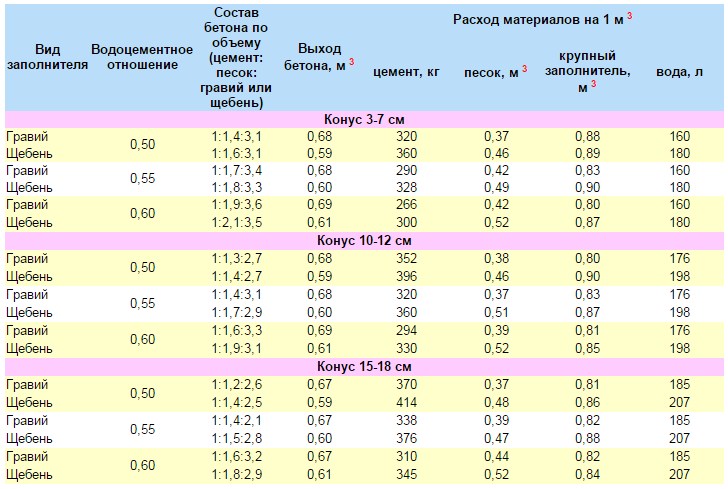

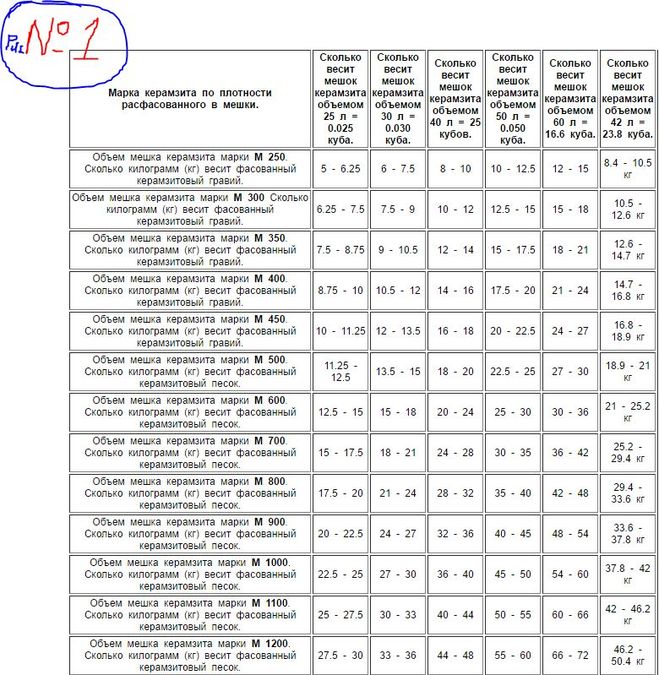

To calculate the weight, you need such an indicator of the characteristics of the material as the bulk density of crushed stone. This value is found in a laboratory way. To perform the test, a laboratory worker uses a one-liter metal cylinder. The empty container is weighed first. The control sample of crushed granite is poured into the cylinder from a height of 15 centimeters to the upper level of the container. The container filled with material is weighed again. The laboratory technician calculates using a special formula. Now that the bulk density has been found, you can calculate how much a ton of crushed stone weighs in cubes, or vice versa.

Converting a ton of rubble into cubes: an example

In order to find this value, the weight must be divided by the bulk density. Let's say the bulk density is 1600 kg / m³, which means 1000 kg, we divide by 1600 kg / cm³, we get 0.625 m³ in one ton of material. For example, there is a dump truck with a lifting capacity of 20 tons. How many cubic meters of crushed granite can be transported by transport?

Converting tons to cubic meters using formulas or practical actions

In order to convert tons into cubes of crushed stone, you need to divide 20,000 kg by the bulk density of 1600 kg / m³. As a result, a volume of 12.5 cubic meters is obtained, which can be taken away by a dump truck with a carrying capacity of 20 tons.

In this example, the value of the bulk density of 1600 kg / m is relative. In order to calculate as correctly as possible how many crushed stone cubes in a tonne, a more accurate indicator of the bulk material mass is required. To do this, you can call the manufacturing plant for the extraction and processing of crushed granite in advance, and then independently perform the calculation.

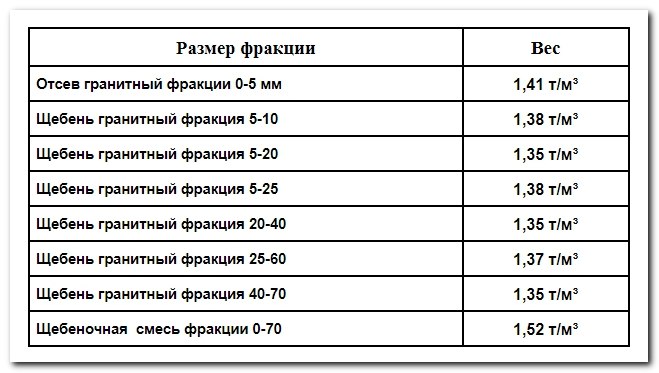

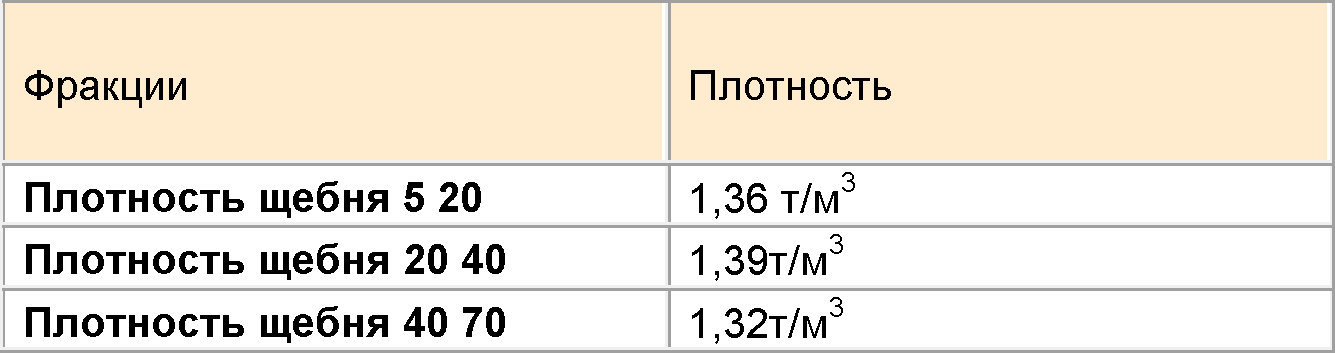

From the practice of specialists of the ProBeton company, a ton of crushed stone of granite fraction 5-20 takes about 0.6 cubic meters, and a ton of granite crushed stone of fraction 40-70 - about 0.75 cubic meters.

Experienced developers use an average figure that varies from 1400 kg / m³ to 1600 kg / m³, and depends on the fractional composition. The smaller the grain size, the higher the value of the bulk density, since the fine stone of crushed granite takes up a denser volume.

If it is difficult for you to independently convert tons of crushed stone into cubes or vice versa, then just call the managers of the plant supplying the material, who will quickly calculate the price cost depending on the available transport for delivery.

Pricing

The following factors influence the formation of the final cost of CBC:

- Density. The higher it is, the more and the cost. Conversion tables from tonnes to cubic meters depending on density can be found freely available on the Internet. Also, high density can be specified initially to facilitate transportation.

- The ratio of sand and. The second ingredient is noticeably more expensive. The highest cost is for the enriched ASG.

- The quality of the components.The sand should be washed to remove clay particles and dried, and the gravel should have a certain structure and size of stones.

- A delivery method that excludes contamination of the material and the ingress of water into it.

- Lot size.

The optimal supplier is a company that provides a full range of work and has its own extraction of components. This allows you to control the cost and quality of products.

Goebbels: "Everything ingenious is simple and everything simple is ingenious!" This statement is valid for technologies and designs that have been around for millennia. Building sand is a cheap, affordable, high-quality, environmentally friendly building material. No facility is built without crushed sedimentary rock.

If you decide to create a durable structure, you should adhere to the recommended proportions in the preparation of mortars and mixtures. For most people, this is not an easy process. How many cubic meters of sand are there in a ton? How to correctly determine the weight without heavy measuring equipment?

No less relevant question that those who want to build are asking themselves: "And the Moscow region with delivery?" The price of building materials determines the feasibility of investments. MSC Region offers to buy a wide range of building materials with good quality delivery and at a loyal price. The reason for the affordable cost lies in the successful alliance of production, distribution and service providers.

Actual weight

The bulk weight of 1m3 of crushed stone is taken based on tabular data, but they may differ from real ones. The mass of the volume can be increased or decreased due to the increase / decrease in humidity, the presence of non-screened impurities. Weight loss is not as dangerous as an increase, the danger lies in the wrong selection of transporting equipment (lifting capacity of cranes, dump trucks).

Determine the mass of crushed stone by weighing the embankment on the spot. For this, equipment is installed on the scales, its mass is fixed, and then loaded. After that, the KAMAZ is brought back to control the permissible load and, if it is fulfilled, the crushed stone is sent to the object.

When choosing a transport, it is also necessary to take into account the volume of the body: a KAMAZ of crushed stone with a carrying capacity of 15 tons will be able to transport no more than 15,000 kilograms of grains of the desired fraction, but no more than 10 cubic meters of embankment (volume limitation). Thus, for delivery there will be only 13,500 kg of crushed stone of fraction 5 ... 20 mm.

How many tons in a cube of sand, gravel, asphalt (and vice versa)

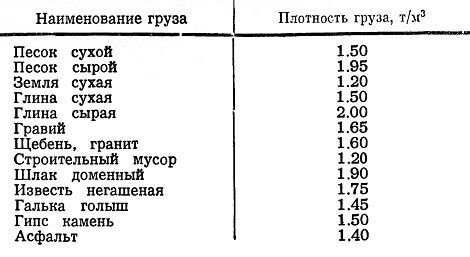

Converting weight units to volumetric ones is difficult for people who are not familiar with the density values of these materials. In reality, however, these operations are quite simple.

Most often, it is necessary to determine or transfer from one measure to another the volume and weight of sand, asphalt crushed stone. Accurate calculations help save money. The remaining material causes an acute feeling of annoyance because of wasted money, clutters up the territory, requires additional efforts to collect and store it.

Sand

It is the most commonly used building material. It is used for the preparation of reinforced concrete, all solutions, dry mixes, the manufacture of bases for foundations and roads, filling embankments, sandblasting, decorative finishing of paths, platforms, flower beds, in drainage and filter systems.

The weight and volume of the bulk material are related by the formula through the density (or specific gravity), expressed in kg / m³ or in t / m³:

m = V · ρ, where m is the mass of the material in t, V is the volume in m³, ρ is the density in t / m³.

Using this formula, knowing two quantities, it is easy to determine the third. For example, to calculate how many tons in a cube of sand, you need to carry out the following calculations:

Known values: volume - 1 cubic meter, sand density - 1.5 t / m³ (value from a reference book or a quality passport of the material sold).

We find the required mass of sand:

m = V · ρ = 1 m³ · 1.5 t / m³ = 1.5 t.

To determine how many cubes of sand are in 1 ton, we use the same formula, changing it to find the volume:

V = m: ρ = 1 t: 1.5 t / m³ = 0.67 m³.

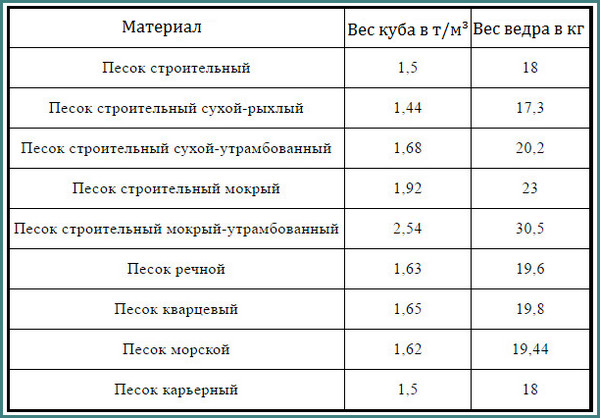

The actual density of sand is, depending on its size and relative humidity, from 1.4 to 1.9 t / m³. The exact value of the density of a particular product can be obtained empirically, having accurate scales and containers with an easily measurable volume, for example, cylinders.

Even more accurate results will be given by laboratory analysis, which, in addition to density, will determine other quality indicators - size distribution, moisture, content of clay and other impurities. If there is no opportunity for research, use the reference value established in the region as a reference. For example, in St. Petersburg the value of such a density for sand is 1.43 t / m³.

Crushed stone

This is also a widespread building material. It is the most important component of reinforced concrete. It is used for filling railway embankments, preparation of liquid concrete and asphalt concrete, in the manufacture of road pavement for highways.

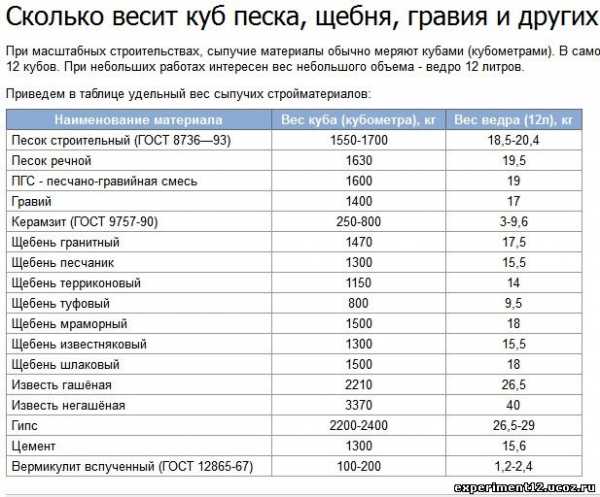

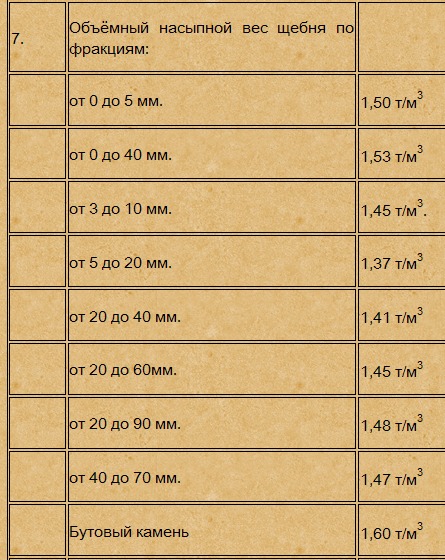

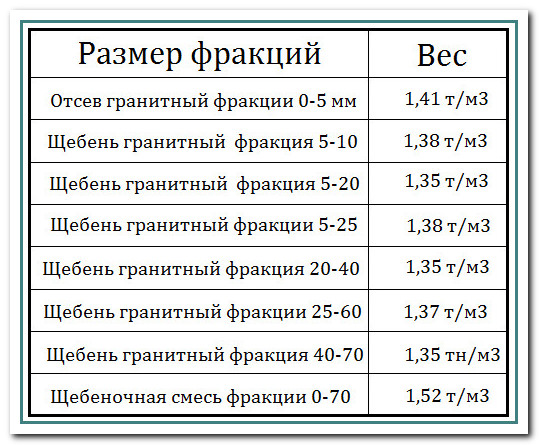

Crushed stone has several size fractions - from 5 mm to 100 mm. Depending on the size of the granules, the density of the material also changes slightly. Thus, the bulk density of crushed stone with a fraction of 5-10 mm is 1.41 t / m³, and a fraction of 40-70 mm is only 1.34 t / m³. This is explained by the fact that there are more air gaps in coarse gravel.

To find out how many tons are contained in one cube of crushed stone, it is necessary, as in the case of sand, to find out its density - this value in t / m³ will be the answer to the question.

To determine how many cubes of crushed stone in 1 ton, the already known formula will help: V = m: ρ = 1 t: 1.41 t / m³ = 0.71 m³.

Asphalt

It is extracted in its natural form, and also produced artificially on the basis of petroleum bitumen. Density varies from 1100 kg / m³ for natural fractions to 2450 kg / m³ for heavy asphalt concrete with the highest content of crushed granite.

To find out how many tons 1 cubic meter of asphalt weighs, you need to find out the density of the rolled asphalt, which the manufacturing plant indicates in the product passport.

The answer to the question: how many cubes in a ton of asphalt - for the heaviest asphalt concrete will be as follows: V = m: ρ = 1 t: 2.45 t / m³ = 0.41 m³.

In practice, the density of asphalt in the rolled state is determined by drilling a cylindrical sample from the finished roadway, measuring its weight and volume, calculating the density value using a known formula.

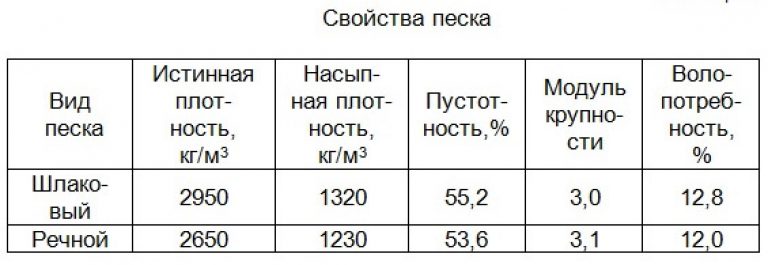

Properties and characteristics of sand

All the necessary requirements for the quality of the sand used in the preparation of concrete are documented. Certain characteristics of this substance can be studied only in the laboratory, but there are those that are checked by eye just before the construction is carried out.

Particle size

To know what kind of sand to take for the preparation of concrete, first of all, you need to decide on one of the most important parameters of the material - the size of the grains of sand. The following types of this substance are distinguished according to the size of its particles:

- consisting of large particles (grains of sand have a size exceeding 3.5 mm);

- increased coarseness (size of grains of sand from 3 to 3.5 mm);

- large (within 2.5-3 mm);

- medium size (2-2.5 mm);

- fine fraction (1.5-2 mm);

- very small (1-1.5 mm);

- thin (0.7-1 mm);

- very thin (up to 0.7 mm).

To find out the size of the grains of sand, experts pass the substance through a sieve with an appropriate hole diameter.

In fact, such a division is more conditional, only documented.

In real life, there are 3 types of sand for the particle size: fine, medium size and with coarse fractions.

What sand is used for mortar? To make the structure really strong, you need a large type, but so that there are many small grains of sand in it.

Otherwise, a huge amount of voids will be noted in the concrete, which can reduce the strength of the finished structure. In addition, the resulting voids can be filled with cement, which is equal to an increase in the cost of the finished product.It is an irrefutable fact that particles of the same size do not adhere tightly to each other, thus the number of voids is much greater. Based on this, a mixture of sand with different sizes of grains of sand is mainly used in order to achieve the maximum density between the concrete components at the output.

Based on the size of the grains of sand, the substance itself can be divided into 2 classes. In the first class, there are no particles below 1.5 mm in diameter. It is an optimal material for construction, because the presence of such a fine aggregate has a negative effect on the settling of coarse grains of sand. The second class is characterized by the presence of small particles.

Volume weight

This indicator characterizes the weight of 1 m³ of sand in its natural state. Typically, the weight of a cubic meter of this element is approximately 1.5 -1.8 tons. It is desirable that this figure is lower.

Composition

According to its constituent elements, sand is divided into:

- Granulometric (combines the combination of grains of sand of different sizes).

- Mineral: quartz, dolomite, feldspar and limestone.

- Chemical (in accordance with the components available in the composition, the intended scope of application is determined).

Humidity

Usually, this figure is 5%. If the substance is dried, then its moisture content will be 1%, with the addition of moisture in the form of precipitation - 10%. Moisture determines the amount of water that must be mixed into the concrete mix.

Immediately before use, you can independently check the moisture level of the sand. If you squeeze it with your palm and it crumbles, therefore, the humidity is optimal, if not, then its indicator is more than 5%. But it is better to check this characteristic in the laboratory.

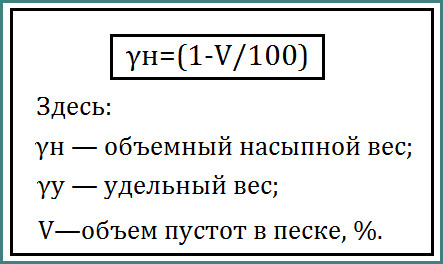

Porosity factor and bulk density

The coefficient characterizes how sand, and then concrete can resist moisture transmission. Verification of this coefficient is carried out only in the laboratory.

On average, the optimum density should be kept at the level of 1.3 - 1.9 t / m3. If the indicator is lower, then this indicates that there are unnecessary additives in the substance, higher - about high humidity. All information must be submitted in the appropriate documentation.

What affects the weight characteristics?

There is a whole list of factors to consider when calculating the weight of sand. Among them are grain size, size of fractions, amount of moisture and even density. The weight will also differ when there are impurities in the composition of the building material. They strongly affect the indicator in question.

It is also worth taking into account that there is always free space between the grains. It, in turn, is filled with air

The more air, the lighter the material and vice versa. The heaviest is compacted sand. Speaking specifically about the mass of natural material, then it can be real, bulk and technical. Indicators are determined taking into account the ratio of mass to volume.

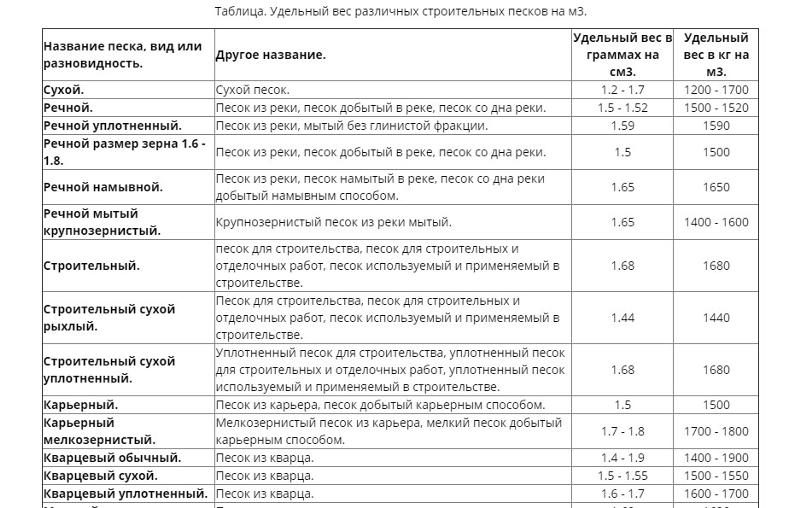

For the derivation of the final index, not everyone takes into account the porosity. You need to understand that the real mass is lower than the same true value. And all because in real terms, the indicator is only conditional. Now let's talk about the bulk density. If this is dry material, not mined from a quarry, but from a river, then its indicator is 1.4-1.65 tons per m3. If we take the same type of sand only in a wet state, the indicator will already be 1.7-1.8 tons. In a compacted state, the same sand shows a figure of 1.6 tons per m3.

But there are other types as well. For example, material that is mined in a quarry way. Sand with small grains, which is also called fine-grained, has a bulk density of 1.7-1.8 tons. If it is a material made of crystalline silica, then its bulk density is 1.5 tons per m3. If it is crushed sand, then the indicator will be 1.4. and if compacted, then 1.6-1.7 tons per m3. There is also material that is mined in a different way, in this case we are talking about the development of rock, which goes under the 500-1000 brand.Here the bulk density is 0.05-1.

Of great importance on the weight under consideration is the amount of foreign constituents, which are also called impurities, and the saturation with minerals. Sand can be made from an initially heavy mineral or from a light one. In the first case, the indicators will be more than 2.9, in the second less than this level.

Speaking specifically about volume, there are three types of sand. It is supplied for coarse, medium and even fine construction mixes. Why is faction size so important? Because this parameter affects the ability of the sand to absorb moisture. How much you have to spend to create a mixture will also differ. You can find on sale sand 1, 2 classes. If the grains are from 1.5 mm, then we are talking about the first class, in the second this indicator is not taken into account.

The specific gravity largely depends on the method of laying the building material. This can be either a classic bedding, or a compaction by workers, or just a loose surface. The more water is contained in the sand, the greater the mass of such building material. Also, if it was kept wet at a temperature with a minus sign, then its specific gravity increases.

Natural material

There are the following types of natural sand:

- riverine is the cleanest view. Due to grains of sand of a neat, water-cut form, it is widely used in the manufacture of various solutions;

- marine - undergoes a double filtration system to remove salts and silt. This allows it to be used in the formation of the landscape as drainage and the production of building mixtures. The method of extraction, additional processing determines the high quality and the corresponding price;

- quarry - has a significant amount of foreign impurities, including clay and dusty elements. Their influence on the weight of building sand in a volume of 1 m3 will be described in detail below. Often, manufacturers sift or wash it. Sifting gets rid of foreign stones, large fractions. Such sand is used in solutions for foundations, masonry and plaster. By washing, it is cleared of clay, dust deposits.

How much does 1 cubic meter weigh?

- Exactly 1,000,000,000 cubic millimeters.

- How much a cubic meter weighs is about the same as asking what is the length of one kilogram. Volume is measured in cubic meters, and weight is the force of attraction (towards the Earth). Therefore, the question is completely incompetent. Although such a question can be used to test whether students understand the difference between weight and volume.

- It is generally accepted that 1 cubic meter of volume takes place in a cube with sides of 1 meter

Each substance has its own density and therefore the weight of one cubic meter of different substances will not be the same.

Personally, I believe that almost everyone should know how much a cube of water weighs.

1 cubic meter of pure water weighs 1000 kg.

in practice, a container with a liquid of 1 cubic meter (1000 liters) will look like this

Many liquids are lighter than water, such as

1 cubic meter of kerosene weighs 820 kg, gasoline (on average) - 740 kg, olive oil - 920 kg.

but there are some that are heavier than water

1 cubic meter of sea water weighs 1020 kg, glycerin - 1260 kg.

As for dry substances, their volume is found in different ways, for example

1 cubic meter of brickwork might look like this

find it by multiplying the width of the masonry by its height and length (in our case, 0.4m * 0.5m * 5m = 1 meter cube)

1 cubic meter of brickwork weighs on average 2450 kg.

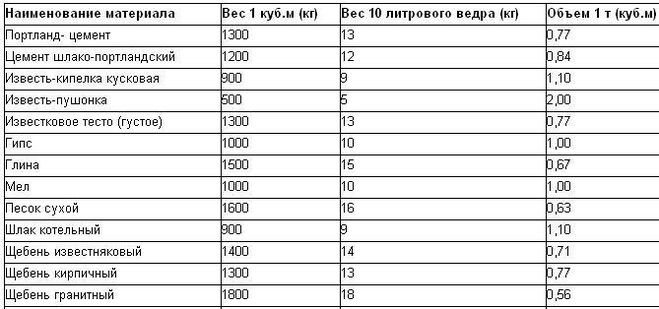

To find out the weight of other materials, you can use the density tables of the substances.

- cubic meter of what? clarify the question please. For example water, 1 liter is roughly 1 kilogram. means water in 1 cubic meter of 1000 liters ...

- A cubic meter is an ordinary cube, only the length of its edges is equal to one meter.

The weight of a cubic meter can be different.

We look and compare

1 cubic meter of water equals one thousand kilograms, but if the water temperature is about zero degrees, then the weight of a cubic meter will be less, only 999 kg 972 grams.

And the weight of 1 cubic meter of sand depends on the moisture content of the sand. The higher the moisture content of the sand, the lower its density and, accordingly, the greater its volume. River sand weighs more than sand from a quarry. On average, 1 cubic meter of sand by weight is from 1200 to 1700 kg, which is about 1500 kg on average.

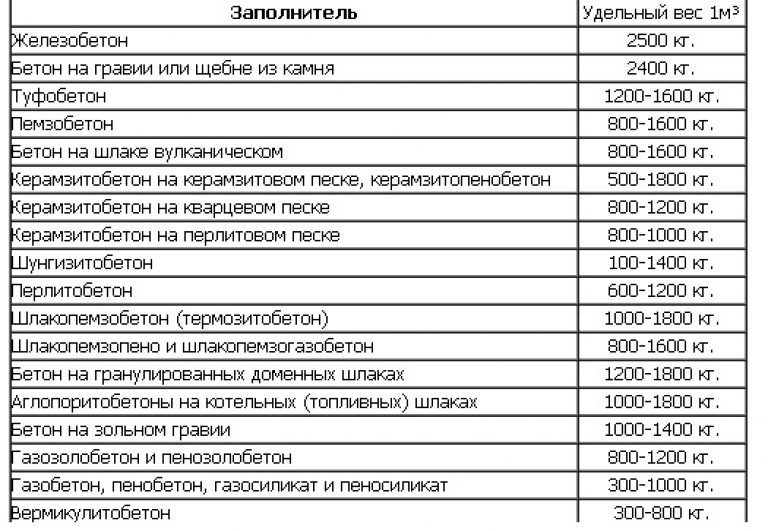

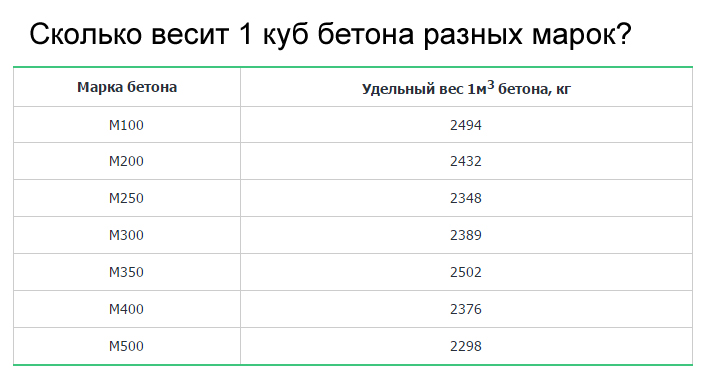

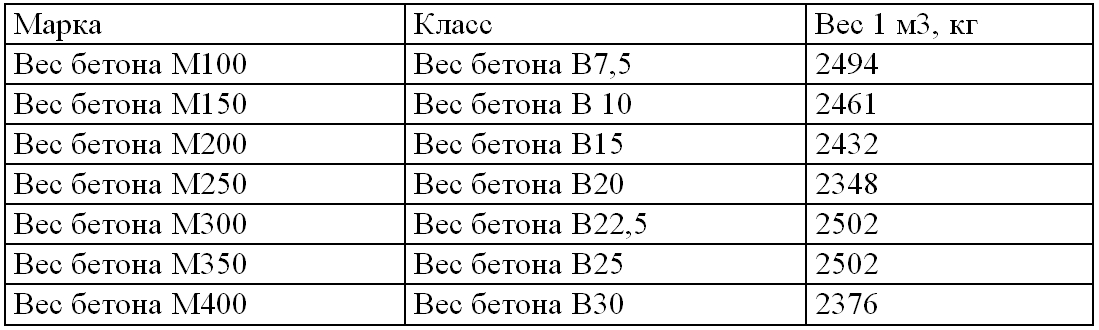

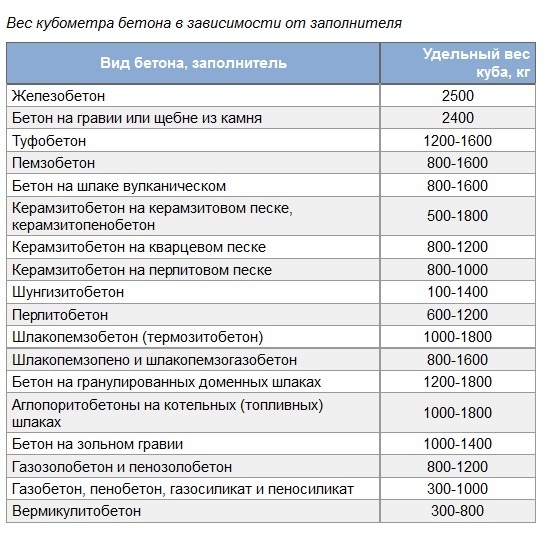

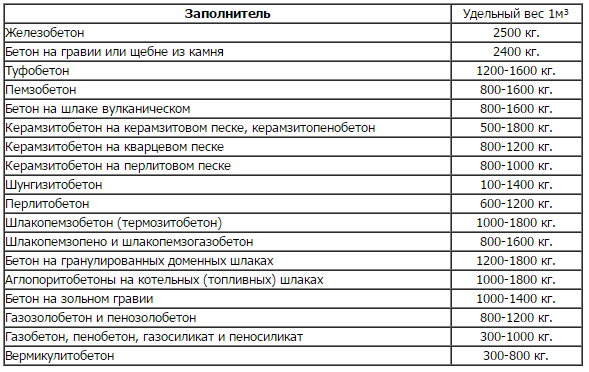

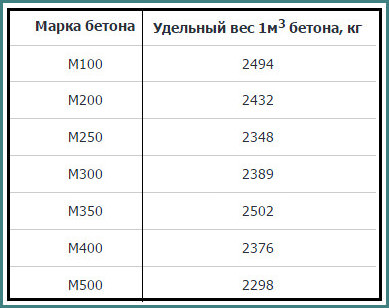

Also concrete, weight per cubes is different.

Lightweight concrete is from 500 to 1800 kg, and very light up to 500 kg. According to the marking, the weight and density, and the higher the brand, the stronger and denser the concrete

- A cubic meter of different substances has different weights. From school physics, we remember that weight depends on the specific gravity of this substance. A cubic meter of sand is different from a cubic meter such as iron.

The greater the specific gravity of a substance, the more will weigh a cubic meter of this substance.

- Indeed, often the volume also has quot; weightquot;. A simple example can be given: you can load a truck with foam, while the weight itself will not be very large, while the goods will take up the entire volume of the truck and you will have to pay the same as if you loaded the truck with a heavier load. Therefore, there is such a thing as volumetric weight. It is determined by multiplying the length of the three sides of a cubic meter, expressed in centimeters 100 * 100 * 100 = 1,000,000. Now the most important thing begins, you need to divide the resulting number by a certain number. Freight and courier companies use to calculate the volumetric weight to divide the resulting product by 5000. We get 200. This will be the weight of a cubic meter in kilograms. That is, a cubic meter quot; weighs quot; 200 kg.

.

Classification

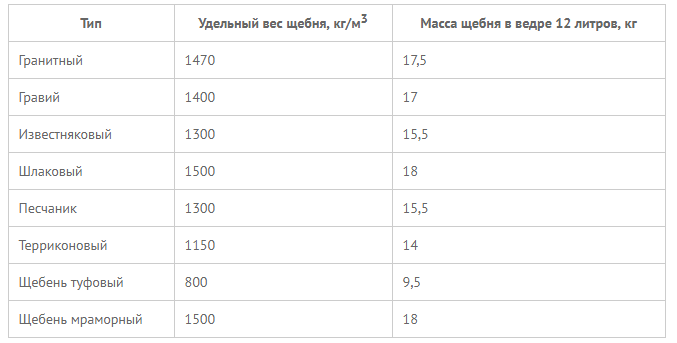

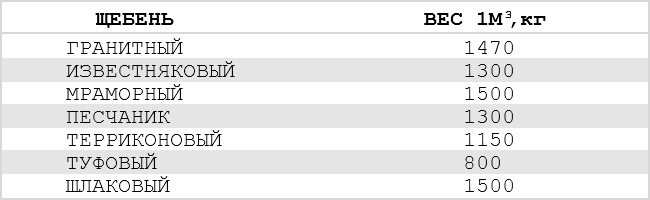

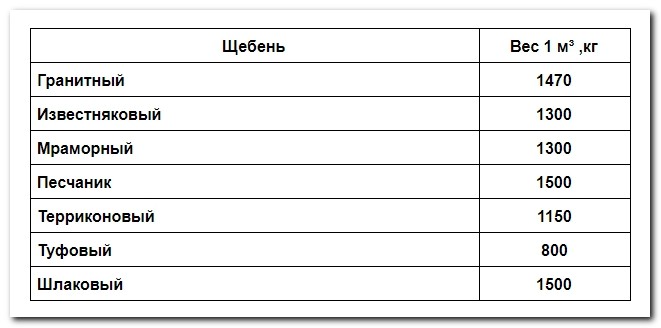

The weight of 1 m 3 of crushed stone depends on several factors:

- The rock from which the stones are obtained;

- Fraction and flakiness. For construction tasks, a grain size of 5 ... 20 mm is often chosen, for preparatory and other work, larger or smaller fractions.

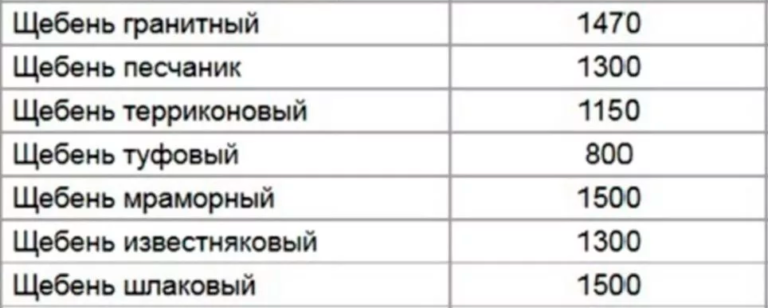

By origin, construction crushed stone is divided into several groups:

- Granite is the most durable and demanded, at the same time expensive and durable. The stones are dense, voidless, and flakiness according to GOST 8267-93 allows no more than 5% of flat grains. As a result, the density of the embankment is maximum.

- Natural limestone crushed stone is used as a filler for low-strength concrete and for the preparation of lime and its containing materials. Calcium compounds have a relatively small mass, so 1 cube weighs less than granite.

- Gravel is a product of crushing rocky rock, which is mined during the development of quarries in the mountains, riverbeds and reservoirs. It is a popular building material with optimal characteristics similar to granite, but much cheaper and more widespread.

- Slag is crushed stone obtained as a result of metal processing. Durable and cheap material with an impressive cube weight.

- Sandstone is crushed stone from hard rocks used in general construction works.

- Waste heaps are black crushed stone, a product of the dump of old coal mines. Grains are used in road construction due to pollution.

There are other types of coarse aggregate, but the listed types are mainly used in construction.

The presented types of rocks from which crushed stone is obtained have different characteristics: water absorption, weight, porosity, etc. This is the determining factor in the weight of a cubic meter of material.

Varieties

There are many varieties of sand and each has its own application.

River

Outwardly, it is a free-flowing material, not ore. You can find the material at the bottom of the river, it is from there that it is mined. What sets it apart from others is that it is the purest of all other types of sand. Its plus is that it does not contain clay, dust, salt, pebbles, and so on.

River

This type of sand is mined in two ways - by excavators, draglines and hydro-mechanized method.

It is used in everyday life and construction. If we talk about construction, then it is used for the production of reinforced concrete structures, in the production of paving slabs, slabs and so on.Characteristics: density - 1.5 kg / m3, humidity - 4%, specific gravity - 2.65 g / cm3;

Quartz

It is a special bulk material, which consists of small granules with a diameter of 0.05-3 mm. Quartz sand is formed as a result of the destruction of rocks that contain quartz. In its composition, it can have various kinds of impurities (clay materials, iron oxide, slags, and so on).

Quartz

It is the impurities that give the sand a certain shade, if we talk about pure quartz sand, then it is milky white.

Due to its good characteristics, such sand can be painted in any color, which helps to create decorative plaster. Characteristics: moisture less than 10%, clay content 1%;

Career

In essence, it is ore, free-flowing and granular type. It contains particles ranging in size from 0.7-5 mm. Quarry sand itself contains many additives: clay, all sorts of small stones, dust, and so on.

Career

Characteristic features of sand: size 0.7-5 mm, impurity content 10%;

Nautical

It is a non-metallic bulk material. It is easy to find it on the seabed. Its advantage is that there are almost no impurities in its composition, but there is salt during cleaning.

Nautical

But unfortunately, this type of sand is quite rare, since it is not always possible and convenient to extract it;

Artificial

Since the above types of sand are natural (except for quartz), artificial sand can also be noted, which can be created by grinding marble, limestone, granite. In fact, it has a homogeneous composition, without impurities, and this allows the correct calculation of its consumption.

Artificial

Before choosing the right sand, you need to know all of its characteristics, and correctly calculate the amount of sand using the rules and formulas.

The main characteristics of sand include:

- sizes, size index;

- radioactivity;

- a direct indicator of the bulk volume;

- the amount of impurities in the sand;

- filtration coefficient.

How to determine density - true and bulk

It is necessary to understand that the true density of building sand differs from the bulk one. The first value consists of the indicators of the material in dry form, based on the bulk density - the specific sand that is used during construction work.

These are extremely necessary indicators, for example, to dose building material before mixing concrete mortar.

At the heart of the density, as mentioned earlier, is the moisture content of the building material. So, if the sand has accumulated ten percent of moisture, lumps appear in it, which cause voids to appear.

Humidity

Despite the visual increase in the material (its volumes seem large), the density becomes lower, that is, in order to mix concrete, you need to take more material. With higher humidity, the water will begin to displace air bubbles between the grains, as a result, the sand will become denser.

To determine the moisture content, it is important to calculate the difference between the initial weight of the material and its weight as a result of complete drying in a hot vessel. By making accurate calculations, you can find out exactly how much material needs to be ordered for a particular construction

And this indicator does not depend on how the cost of the goods is determined: per cubic meter or per tonnage.

By making accurate calculations, you can find out exactly how much material needs to be ordered for a particular construction. And this indicator does not depend on how the cost of the goods is determined: per cubic meter or per tonnage.

For more information on determining density, see the video:

How much does 1 cubic meter of sand weigh?

I do not know what kind of sand you are interested in, but if the sand is construction GOST 8736-77, then its specific gravity can fluctuate, depending on humidity and other factors, from 1.55 to 1.7 tons / m3, and on average they consider 1.6 tons. / m3.

I have often seen the figure of 1.3 tonnes - in terms of clean building sand. By and large, the clay content decides everything.Another point, dry sand is lighter than wet, respectively, as a rule, we mean dry sand.

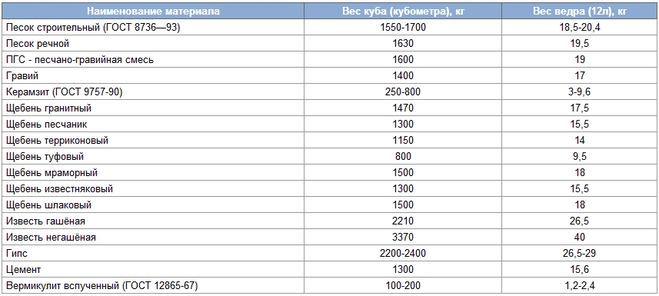

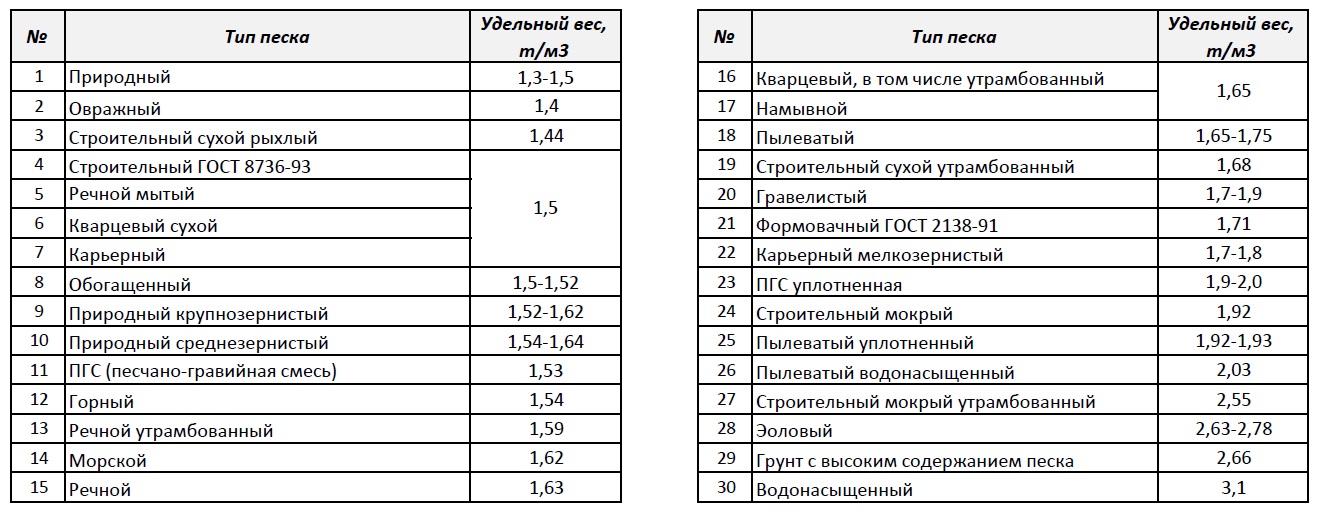

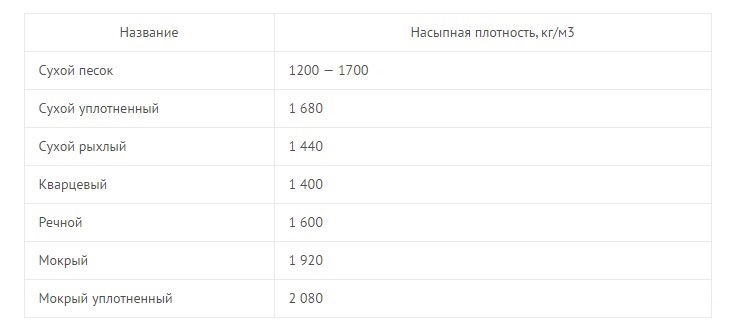

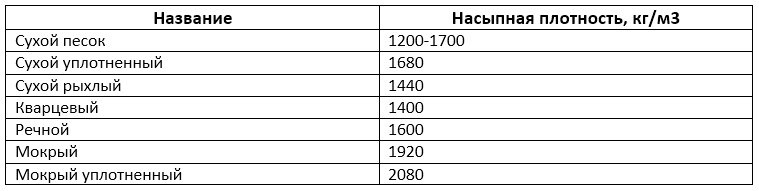

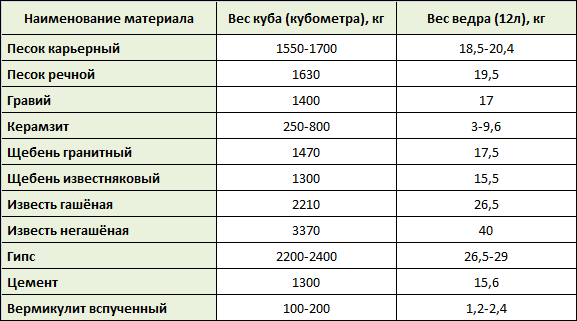

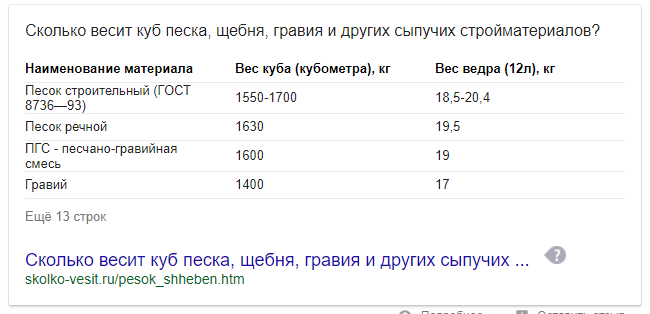

In accordance with the table of the density of various substances, you can see how much 1 m3 weighs for the following types of sand:

Dry loose sand - 1440

Dry compacted sand (compacted) - 1680

Dry sand - 1200-1700

Applying the formula Body mass = volume x density, we find that the given figures are the weight in kilograms of 1 m3 of sand of the desired type.

How much does a cube of sand weigh?

The sand is different, respectively, and the weight is different. So the weight of 1 cubic meter of mountain and river sand is 1500-1580 kilograms. But the weight of 1 cubic meter. slag sand is 800 kilograms.

The weight of the sand depends on the moisture content and the material of the sand itself, but be guided by a weight of 1500 kg. up to 2100 kg. To transport such an amount, you will have to use special equipment: a trailer or a truck.

The weight of the sand can vary depending on the moisture content and its composition. Typically, the weight of sand is between 1.5 and 1.8 tons per cubic meter.

Construction sand according to GOST 8736-77 should weigh 1.6 tons.

As a rule, one KAMAZ can carry 12 cubic meters of sand.

The weight of a cubic meter of sand, depending on various factors, can vary significantly and vary from 1200 kilograms (dried sand) to 2000 kilograms (wet, with a high clay content). For a simplified calculation, usually 1500 kg.

One cubic meter of dry sand is 1500-1700 kg. Also depends on the type of sand. The sand can be compacted or, on the contrary, loosened. It is impossible to report the exact weight, in each case, it is measured individually, these are only approximate figures.

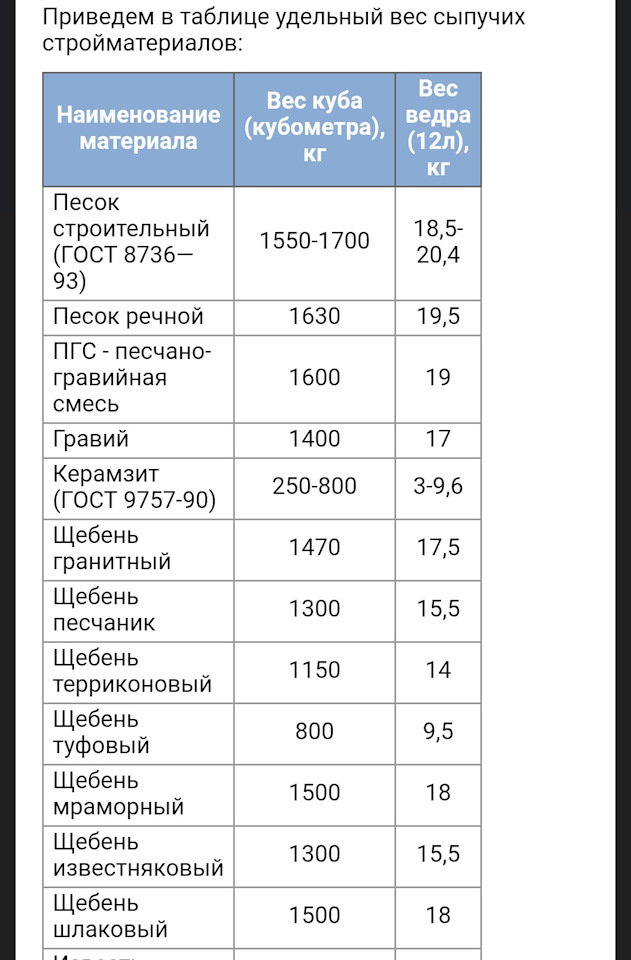

Weight of 1 m3 for various types of sand:

Weight of 1 cubic meter of ASG (sand and gravel mixture) - 1600 kg.

P = V * p * g

P is the weight of the sand

V - volume of sand

p - sand density

g - acceleration of gravity, g = 9.81 m / s2

How much does a cube of sand weigh?

One cubic meter of abstract sand weighs about one and a half tons. And if you are interested in the weight of a particular sand, take a liter of this sand, weigh it, multiply the resulting weight by 1000, and thus you will find out how much 1 cubic meter of your sand weighs.

Sand - sand strife. there are a lot of different sands in the world, which differ in composition, for example, sand from the desert and sand from gold mines, there is even salt sand. Therefore, its weight will be different. You also need to know what percentage of moisture in a particular sample, since the more water there is in the sand, the heavier it is. For example one building sand cube with GOST 873693 will weigh approximately 1550-1700 kilograms ...

.

How to determine how much a cube of sand weighs: material characteristics

Many country house owners are trying to figure out how much is the weight of sand in one cube

... This indicator is especially relevant for suburban construction, affecting such serious arrays of work as the construction of a building or the arrangement of the courtyard and the local area. How much does 1 cube of sand cost with delivery is one of the burning questions of any person who undertakes independent construction or is concerned about the purchase of material for hired workers.

Depending on how many kilograms in cube of sand

, the basic proportions of the concrete mix will be calculated. This point is very important, since an incorrect calculation will lead to a violation of technology and serious consequences.

Sand is used for a wide range of construction works

Why is it so important to determine how many cubes of sand are in 1 ton

An indicator reflecting how many kilograms are in 1 cube of sand

, with erroneous calculations, it can cause many difficulties:

- violation of the formulation of a mixture of concrete;

- incorrect consistency of the finished solution;

- loss of adhesive properties;

- poor concrete quality;

- disturbances in the solidification process;

- decrease in the strength of concrete;

- premature destruction of a structure made of cement mortar.

For this reason, it is very important to determine not only how much sand is in 1 cube

, but also what is the weight of the material contained in this volume

When calculating the required number of cubes of sand, take into account its specific gravity

The indicator reflecting 1 cube how many kg of sand is contained in a specified volume is called specific gravity or specific gravity. This measure, applicable to bulk materials, is in the range of 1500-2800 kg / m³. Accordingly, you can now estimate how many kg are in a cube of sand.

The specific gravity of a material can be influenced by various factors, including:

- composition of minerals;

- grain composition;

- size of fractions;

- humidity level;

- the percentage of compaction;

- impurities.

Tamping paving slabs using wet sand

Sand density

Today, many are concerned about the question of how much it costs sand cube

, but few people know that the final price is influenced by the characteristics of the material, one of which is density. Sand, like crushed stone, belongs to the category of bulk materials. Its density depends on the air spaces that form between the solid particles.

The density of sand is:

- technological;

- real;

- bulk - represents the ratio of the specific sand weights

to the volume occupied by this material. In this case, the volume includes not only solid sand particles, but also all pores, as well as voids in the composition of the embankment (taken as a basis for determining how much cubes of sand

in a bag or bucket); - true or conditional - the value is considered as the limit of the ratio of the specific gravity of the material to the volume it occupies, minus all pores and voids present in the embankment.

The density of sand varies in the range of 1.3-1.8 t / m³, and is equal to 1.3 t / m³ for river sand, and 1.4 t / m³ for open-pit sand.

Density of building sand is from 1.3 to 1.8 tons per 1 cubic meter

Sand fraction size

How many cubes of material are in a bag of sand can be determined taking into account its grain composition. To do this, it is enough to sift the grains of sand using special sieves. As a result, you will be able to determine the level of content in the material of gravel particles with certain dimensional data. Usually, the size module of the material is used in calculations.

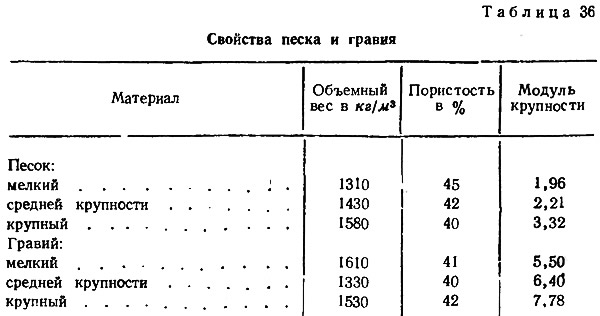

Table 1. Sand size modulus:

If you have fractions in front of you that exceed 2.5 mm, most likely you are dealing with quarry or river sand, how much a cube of material weighs in this case will depend on water demand.

According to the particle size, the material is divided into 2 classes:

- I - more than 1.5 mm;

- II - with any dimensional data.

It depends on the class of the material and the size of its fractions, how much it costs 1 sand cube

for construction work.

There are three sizes of sand grains - fine, medium and coarse