Now let's calculate how many blocks are needed to build a house

For your home, you will need to substitute your numbers to get the result.

OPTION 1 (very detailed based on the house plan)

- define the perimeter of all (and also internal) walls of the house (even in the case of a complex configuration, this is easy to do): fold the lengths of all sides based on the plan;

- determine the area of all walls: the perimeter (item 1) x the height of the walls;

- determine the total area of all openings - doors and windows;

- from the area of the walls (item 2), subtract the area of the openings (item 3). As a result of calculations, you will receive wall masonry area;

- masonry area of the walls (item 4) x block thickness = volume in cubic meters meters of blocks (number of blocks in cubic meters) required for masonry walls;

- count blocks per cubic meter (item 5) / number of blocks in a cube = number of blocks in pieces ,necessary for masonry walls.

Now let's consider the calculation of the number of blocks using the example of a specific house, using the plan of our house:

we find the dimensions of the house on the plan and for the calculation we take the length and width of the house: 10,800 m (the width of the house) x 2 + 24,000 m (the length of the house) x 2 = 69.6 m. is the design length of the outer walls of the house. Why in our case only the length of the outer walls is taken into account - this will be discussed a little later;

we find on the plan the design height of the house. We have it equal to 2.70 m., And the height of the basement of 0.4 m is not taken into account in the total height of the house 2.7 m

Pay attention to this when calculating for your home !;

- When laying the outer walls, the blocks will be laid in such a way that the width of the wall is 300 mm (0.3 m), i.e. the height of the block in the masonry will be 200 mm (0.2 m). As a reminder, the dimensions of our gas silicate block are 200 x 300 x 600 mm.

- when laying the walls, we used the thickness of which during laying is about 1.5 cm or 0.015 m per one row of masonry;

- in other words, taking into account the solution, the height of the block in the masonry can be taken equal to 0, 215 m;

- we consider how many rows of blocks we will have to lay: 2.70 m (design height of walls made of blocks) / 0.215 m (block height) = 12.56 rows. Of course. no one will lay half a block, so you need to decide how many rows you want to lay? We have chosen for our house the option with 13 rows of blocks when laying walls;

- those. without taking into account the solution, the height of the wall would be 13 x 0.2 m = 2.6 m

- we consider the total area of the outer walls: 69.6 mx 2.6 m (house height) = 180.96 square meters;

- it is necessary to find out the area of the walls minus the window and door openings, therefore, we also calculate the area of all openings on the basis of the plan;

- the plan shows that our house has two entrance doors (this is understandable: the house is designed for two families), two doors to the veranda and one door to the utility room. For simplicity of calculations, we will take the dimensions of the doorways the same: 1.2m x 2.10m.Total we get: 1.2 x 2.1 x 5 = 12.6 sq.m .;

- windows in the house will be:

- 2 large (2 x 1.2) x 2 = 4.8 sq.

- 6 medium: (1.5 x 1.2) x 6 = 10.8 sq. M .;

- 3 small for utility rooms: (0.7 x 1m) x 3 = 2.1m

- the area of window and door openings will be: 4.8 + 10.8 +2.1 + 12.6 = 30.3 square meters;

- the area of walls made of blocks, excluding window and door openings, will be: 181 - 30 = 151 sq. m;

- we consider how many blocks are needed for 1 sq.m. masonry walls: 0.2 m (block height) x 0.6 m (block length) = 0.12 square meters; 1 sq.m / 0.12 = 8.33 blocks;

- we consider how many blocks are needed for laying the outer walls, taking into account the openings: 151 sq.m. (wall area) x 8.33 pcs. = 1258 pcs.

- We planned to lay the inner walls in the following way: the width of the block during laying is 0.2 m, the height is 0.3 m. Similarly, we calculate how many blocks are required for the inner walls: the area of the inner wall is 48 sq. m .;

- we consider how many blocks are needed for 1 sq.m. inner wall masonry: 0.3 m (block height) x 0.6 m (block length) = 0.18 sq. m; 1 sq.m / 0.18 = 5.56 blocks;

- 48 sqm * 5.56 = 267 pcs. blocks needed for the inner wall;

- final settlement: 1258 + 267 = 1525 pc ... blocks needed;

- 1525 / 27.7 = 55.05 or 55 cubic meters blocks are needed to build our house.

OPTION 2

Now gas blocks and other aerated concrete products can be considered one of the most promising wall materials, so many private developers turn their attention to them. If aerated concrete is chosen for the construction of a private house, then before the construction of the building it is necessary to create its project, which indicates the main dimensions of the walls, both external and internal, as well as the number and dimensions of windows and doors

At the design stage, the density of the blocks and their main dimensions are determined. It should be noted that the walls of the aerated block can be finished with ceramic bricks, which allows them to slightly increase their thickness and thermal insulation properties.

Weight calculation

How much does the block weigh?

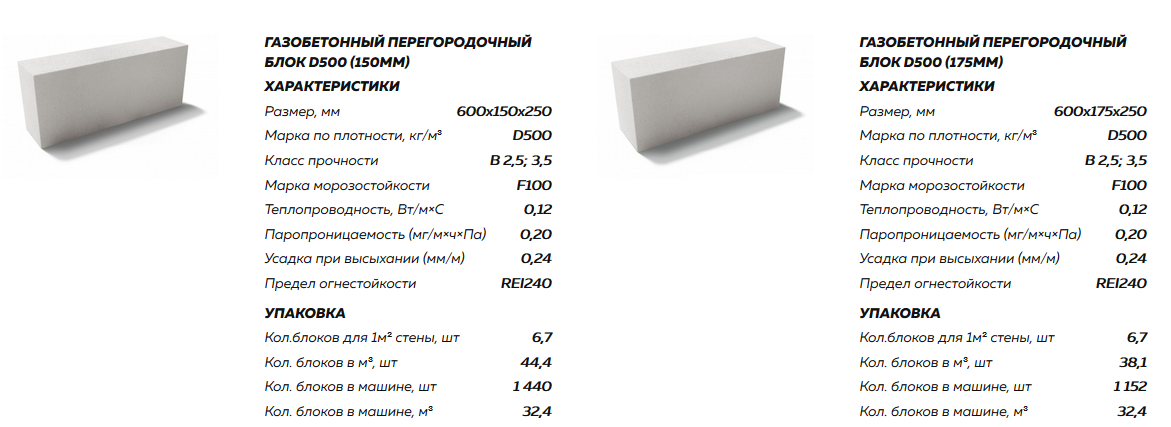

To carry out calculations, you must initially know the dimensions of the material and density.

Calculations are carried out according to the formula m = V * p. The designations are as follows: m - block weight (kg), V - volume (m3), p - density (kg / m3).

Help To find out the volume, you need to multiply all the values.

Calculation Given:

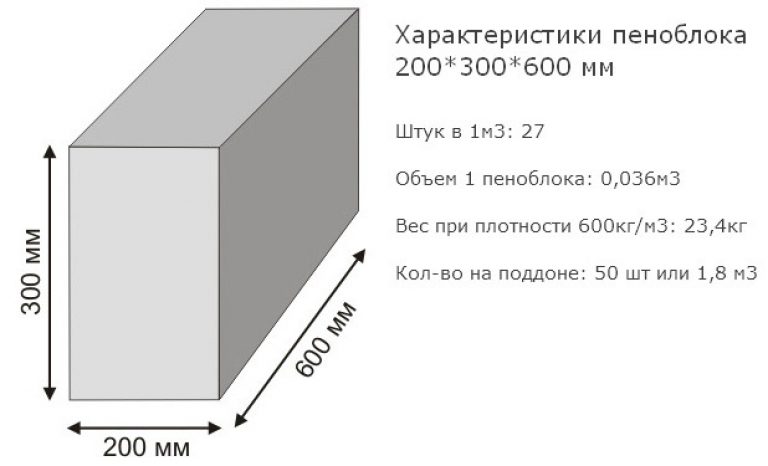

- Size: 200x300x600 mm

- Density: 500 kg / m3.

Solution:

- Knowing the dimensions, you can calculate the volume. For the specified product, it will be:

V = 200 mm * 300 mm * 600 mm = 36000000 mm3 = 0.036 m3 - Further, starting from the mark on which the density is indicated, the weight of the block is determined:

m = 0.036 m3 * 500 kg / m3 = 18 kg

Answer: The weight of the aerated concrete block 200x300x600, excluding humidity, is 18 kg.

Calculation Given:

- Size: 250x400x600 mm

- Density: 400 kg / m3.

Solution:

- V = 250 mm * 400 mm * 600 mm = 60,000,000 mm3 = 0.06 m3

- m = 0.06 m3 * 400 kg / m3 = 24 kg

Answer: Weight 250x400x600 excluding humidity is 24 kg.

If the calculation is made in order to determine the load of the walls of the house on the foundation, then humidity does not play a big role in determining the mass in this case. Since the humidity parameter in the walls in use does not rise above 5% in all weather conditions.

At the initial stage of construction, the foundation will be loaded with walls, the load from which is greater than the calculated one due to the release moisture. But by the time of installing windows, erecting a roof, interior and exterior decoration, installation of equipment and furniture, the wall material will release a significant part of the moisture into the environment and take the estimated mass. That is why moisture should not be taken into account when calculating loads.

Some self-builders build aerated concrete walls alone. And not by hearsay, they check on themselves the mass of the block only when laying the first row. In this case, they should understand that fresh factory blocks, due to the moisture content in them, will be heavier than the values calculated above by about 25%. If the wall thickness of the project is 500 mm, then one person will not be able to lift such heavy products. He will either have to take an assistant, or buy a lighter material with a thickness of 200 mm and 300 mm (and lay out a double wall out of it).

Note to the builder

In addition to standard blocks with straight edges, some modern factories produce blocks with hand grips on both sides.

It is convenient to lift and carry such material.

In this case, the consumption of glue does not increase, since according to the installation technology, the voids do not need to be filled.

So, in our first example, a fresh factory block, just off the assembly line, will be 30% heavier than the calculated values. Its weight for our first example will be:

m = 18 kg * 1.30 = 23.4 kg

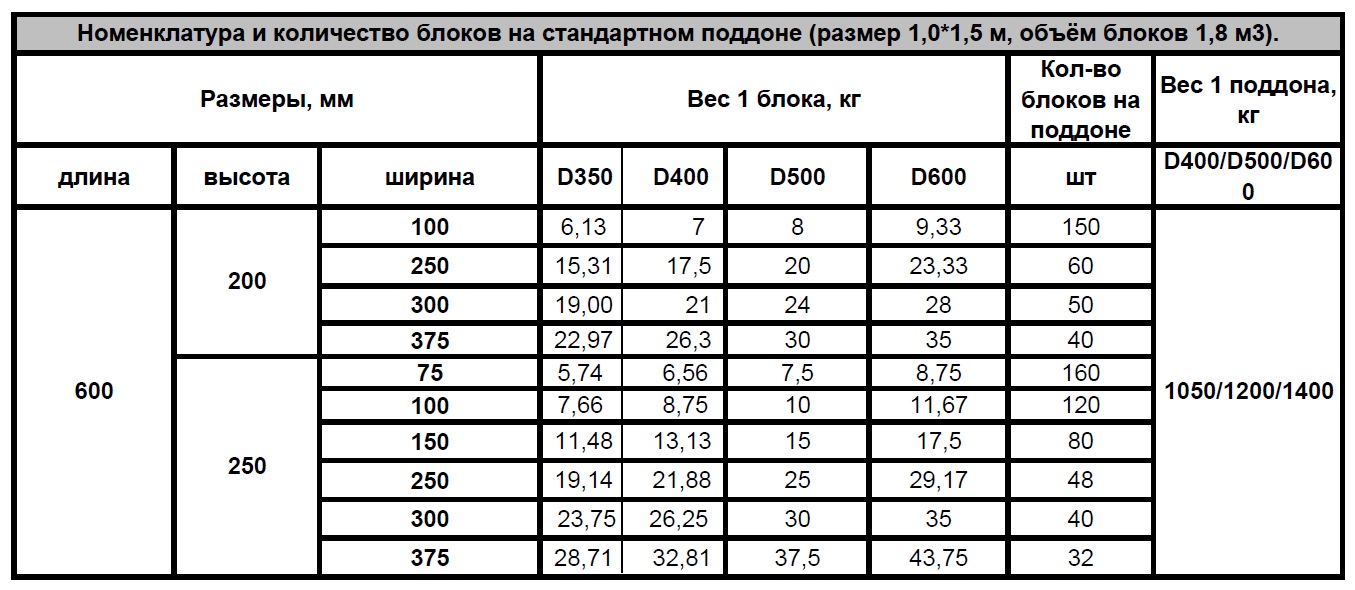

Pallet weight with blocks

This characteristic is useful when planning the delivery of material to the site. Each truck has limit values for carrying capacity and the volume of goods transported.

Let's say visually it seems to you that 10 pallets will enter the truck. But the driver, having learned the mass of the pallet, will say that he can take only 8 pallets. And he will be right, as the carrying capacity of the vehicle must not be exceeded.

It is easy to determine the mass of a pallet with aerated concrete. Knowing the number of units of material in the pallet and the weight of one gas block, multiply these values.

By the way, many sellers release the material from the warehouse in whole pallets.And in the price list indicate the density and volume of the pallet.

We already know that the density of blocks corresponds to the mass of one cubic meter. Accordingly, multiplying the density by the volume, we get the desired weight of the pallet.

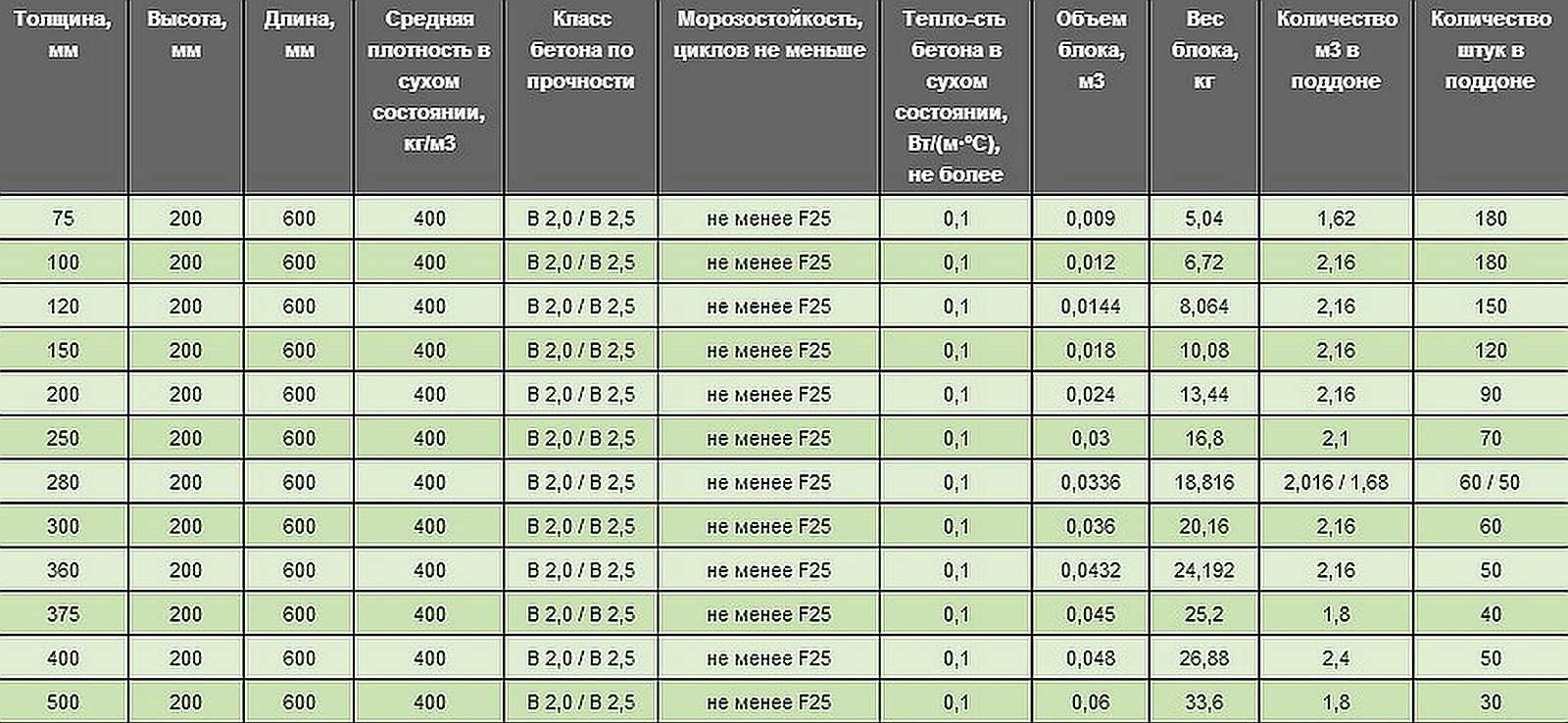

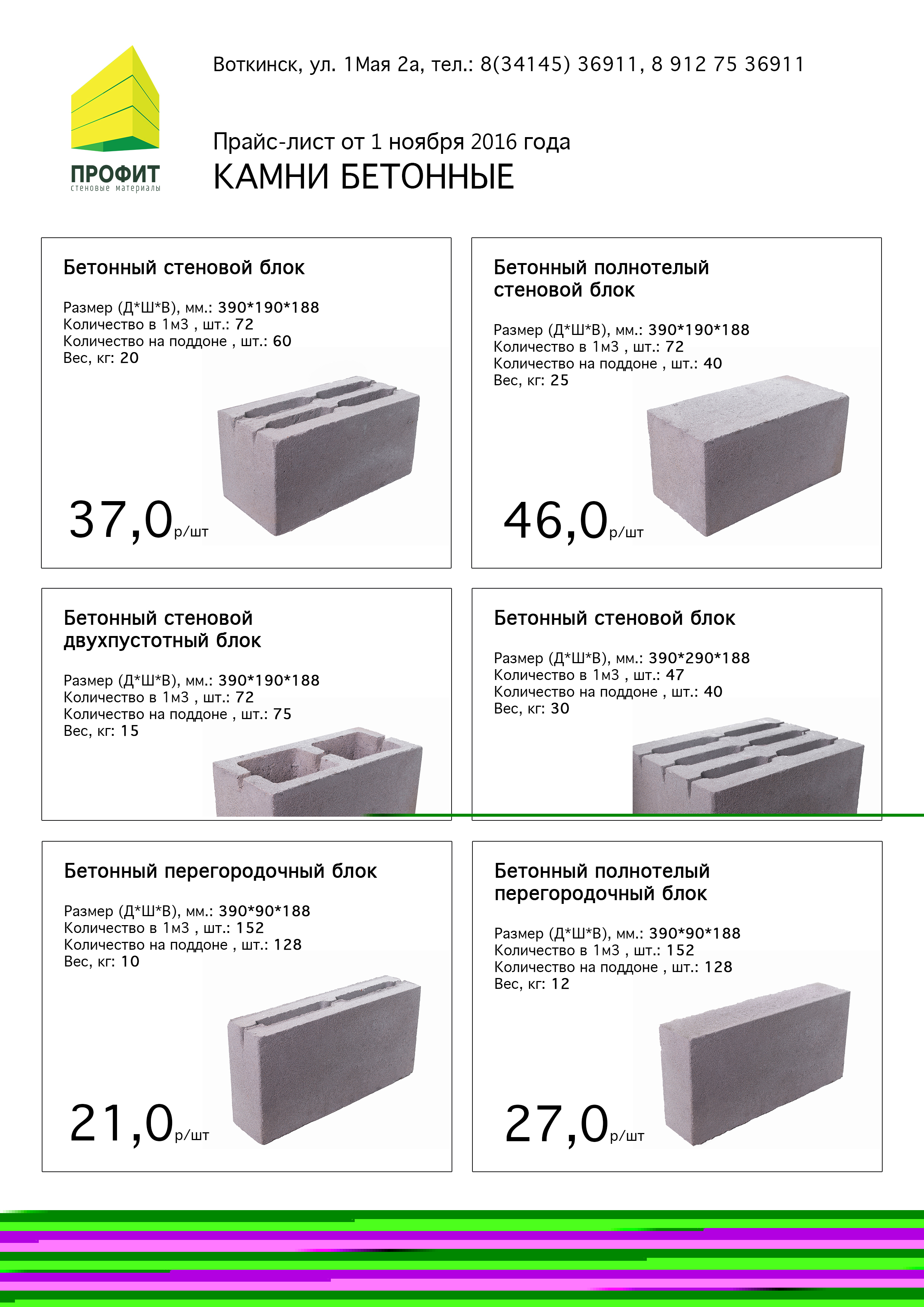

For example, as can be seen from the proposed price list, the volume of a pallet with blocks of 600x200x300 mm is 1.8 m3. Let's calculate the mass of the pallet for the density D400.

m = V * p = 1.8 m3 * 400 kg / m3 = 720 kg

How much does a cube of aerated concrete weigh and determine the real density

At the beginning of the article, the very first table shows these values without any calculation. The weight of a cubic meter of gas silicate material corresponds to the density indicated in the marking (D400, D500, etc.).

However, situations are different. You may want to check the compliance of the factory gas silicate with the declared characteristics. Or you don't have enough pallet of blocks, and your neighbor has surplus. At the same time, your neighbor does not remember the characteristics of his aerated concrete.

Attention! Having learned the real mass, we can calculate the real density.

In this case, we need to weigh 1 block and calculate using the inverse formula p = m / V. Where:

- m - weight (kg) - you need to find a scale and weigh 1 block;

- V - volume (m3) - we considered it above;

- p - density (kg / m3).

Don't forget to take moisture corrections.

How to calculate

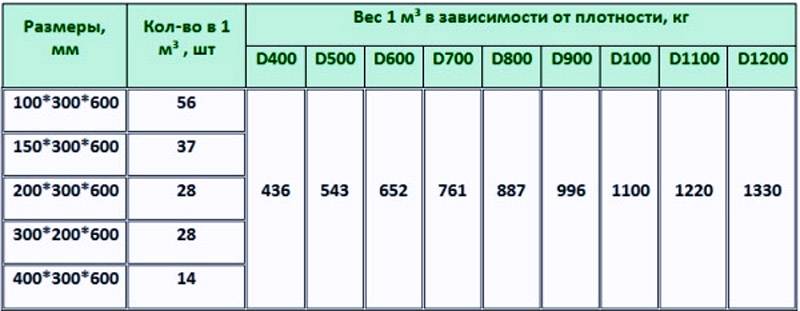

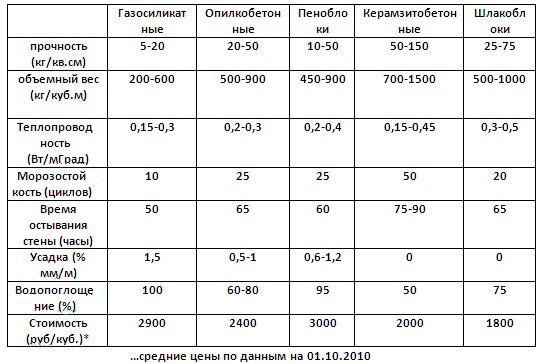

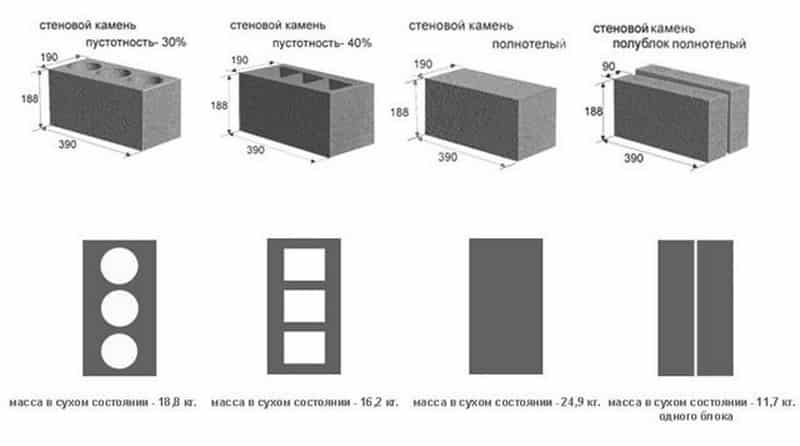

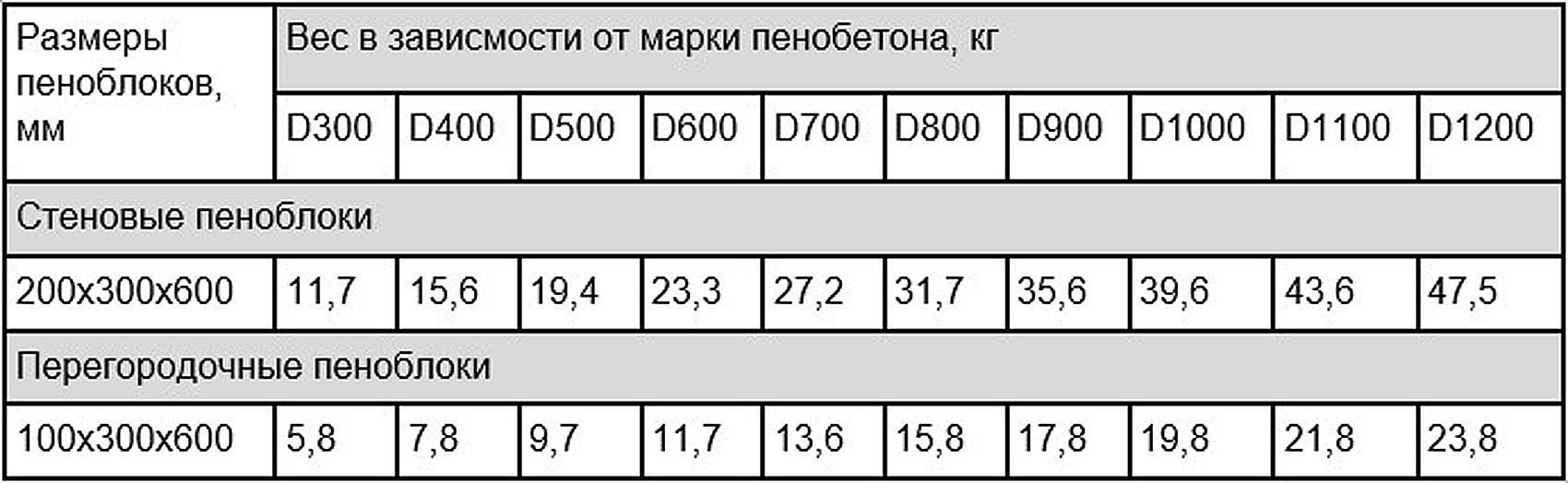

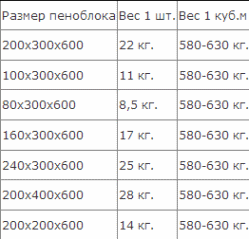

If it is necessary to calculate the weight of 1 m3 of a foam block, its dimensions and density must be taken into account. There are standard mass values adopted for blocks of a certain density and size.

The standard weight of foam blocks measuring 600x300x200 millimeters of popular brands:

- D500 - with a porosity of 0%, the weight is 23.4 kilograms, if the porosity is 20%, then 18.75 kilograms, 50% - 11.7 kilograms.

- D600 - at 0% porosity, the weight is 27.72 kilograms, at 20% 22.18, if the porosity is 50%, then the weight is 13.86 kilograms.

The specific gravity according to the standards is determined by the brand: a cubic meter of D400 material weighs about 436 kilograms, D600 - from 450 to 900 kilograms, D1000 on average per cubic meter should weigh about 1100 kilograms. These figures are relevant provided that all established standards are strictly adhered to. Weight is determined by its composition and proportions of sand, cement, water, foaming agent.

The volumetric weight of a cubic meter of foam concrete in kilograms can be calculated by density: multiply the volume by the density

But in this case, the moisture indicator is not taken into account, which is very important. Indeed, as a certain volume of water is absorbed, the block increases its weight, sometimes by a significant indicator

The volume of the block is calculated by multiplying the height and width by the length.

So, for example, if you need to find out the weight of a D600 density block of 600x200x300 millimeters, then the total volume of the structure is 0.036 cubic meters (the value in meters is multiplied 0.6x0.2x0.3). The marking says that a cubic meter of a foam block weighs 600 kilograms. Thus, the weight of one block will be: 0.036 x 600 = 21.6 kilograms.

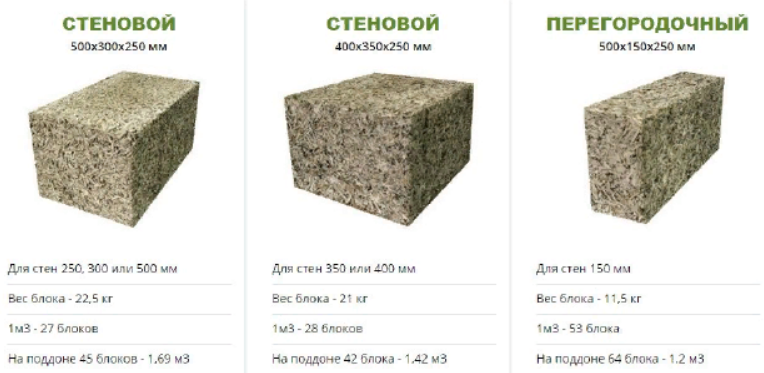

There are 27.8 pieces per cubic meter of volume. foam block measuring 600x200x300 millimeters. If we use blocks 100x300x600, the same volume will hold a little more than 55 pieces. Given the weight of 1 piece of product, you can calculate the total weight of one pallet / pallet.

But in all these calculations, the sorption moisture content of the material is not taken into account. So, according to GOST 25485-89, the level of sorption moisture content of foam concrete can be equal to 8-15% when it is produced on the basis of sand and, in addition, it can absorb up to 22% when using ash as a filler.

If we take it for a fact that the sorption humidity is at a minimum (8%), then another 1.728 kilograms must be added to the weight of the product with dimensions of 600x200x300. Thus, the total mass of the foam block will be at least 23.328 kilograms. If the sorption humidity is maximum, then the mass of the block will be 26.352 kilograms.

To avoid the need to independently perform all calculations, when buying a block, you need to clarify all the characteristics with the manufacturer, which must be confirmed by the appropriate certificates and other documents.

Due to the fact that foam blocks have a lower density and mass in comparison with traditional materials, as well as due to a decrease in the volume of mortar for masonry, the total weight of pressure on the base of the building is significantly reduced

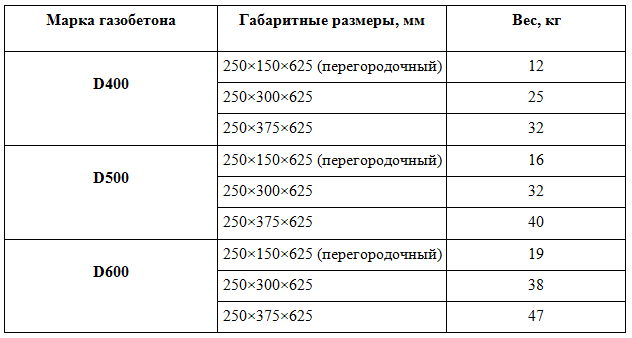

This is important for both the partition wall and the wall unit. Significantly affects the characteristics of the scope of application of foam blocks: structural grades D600-900 have a weight of 23-36 kilograms, insulating D300-500 - 12-19 kilograms

The densest and heaviest blocks measuring 600x300x200 millimeters can weigh 40-47 kilograms. The average weight of the partition block is 21 kilograms. GOST prohibits the production of blocks with a length of more than 600 centimeters. Wall blocks for thermal insulation weigh 11.6-19.5 kilograms, partition wall blocks with dimensions of 100x300x600 millimeters weigh the least (5.8-9.7 kilograms).

Once again, it is worth mentioning the need for water correction when calculating

It is especially important to consider the value for grades D1000-1200: the dry weight of the blocks is 47 kilograms, but when saturated with moisture, the elements can weigh up to 50 kilograms. For one block, this is not much, but taking into account a large number of elements in transportation and calculating the load on the foundation, the values are significant

It is very important to be able to calculate and know how much a foam block weighs, both at the stage of implementation of calculations in the project and during the construction of a building. Only taking into account all indicators and adherence to technology will allow you to get a reliable, strong and durable structure

Do not overpay for extra cubic meters

Time to work, time to rest

Time to work, time to rest

Building a house out of the city from aerated concrete blocks will require accurate calculations of building materials. No one will count them individually, it is necessary to decide how many blocks are in a cube of aerated concrete, how many cubes are needed for complete construction. The building can be one or two-storey, therefore the calculations will be individual for each specific case.

Two-storey house with openings for windows and doors

Two-storey house with openings for windows and doors

How many aerated concrete blocks in a cube with standard dimensions of 600x300x200 do you need to purchase to build a not very large structure? Mathematics is an exact science, but it allows for rounding.

Aerated concrete: the number of pieces in a cube will determine the dimensions of length, width, height

Aerated concrete: the number of pieces in a cube will determine the dimensions of length, width, height

For correct calculation, the following formula is applied: (L x H - Spr) x 1.05 x B = V, where

- L is the total length of all walls made of aerated concrete blocks, m;

- H is the average height of aerated concrete walls, m;

- Sпр - total area of door and window openings, m²;

- 1.05 - safety factor for trimming;

- В - block thickness, m;

- V is the calculated value of the volume, m³.

How many aerated concrete blocks are in a cube, if the products have such a configuration

How many aerated concrete blocks are in a cube, if the products have such a configuration

The above formula is of a recommendatory nature.

Containers, cubes, pieces, weight of aerated concrete

Different sizes of gas blocks are important when building a house

The video in this article will help you understand that when choosing aerated concrete blocks, the following criteria must be taken into account:

- What will be the load on the walls (5 floors and 25 - a big difference);

- Coefficient of thermal conductivity;

- Parameter deviation;

- It is correct to calculate how many squares are in a cube of aerated concrete, so that the proportionality of the masonry is observed during construction, and the whole process is simplified.

Different configuration of gas blocks ensures safe operation of facilities

Different configuration of gas blocks ensures safe operation of facilities

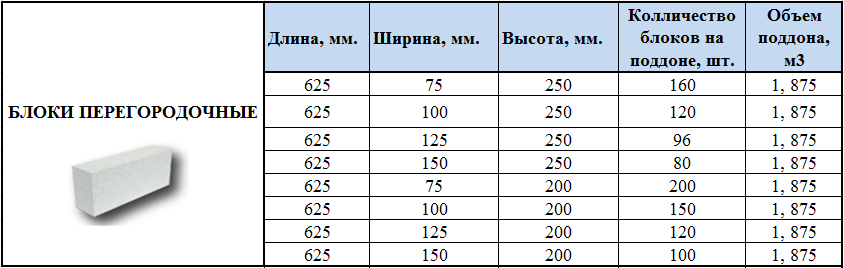

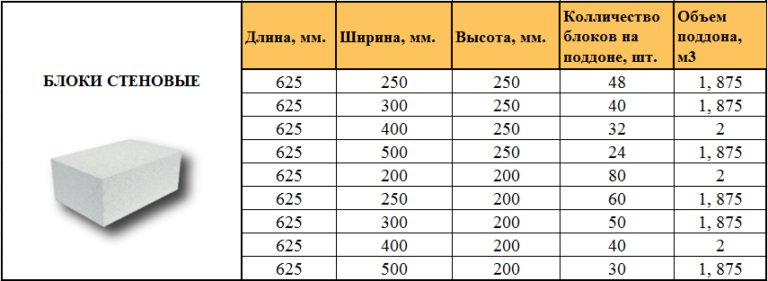

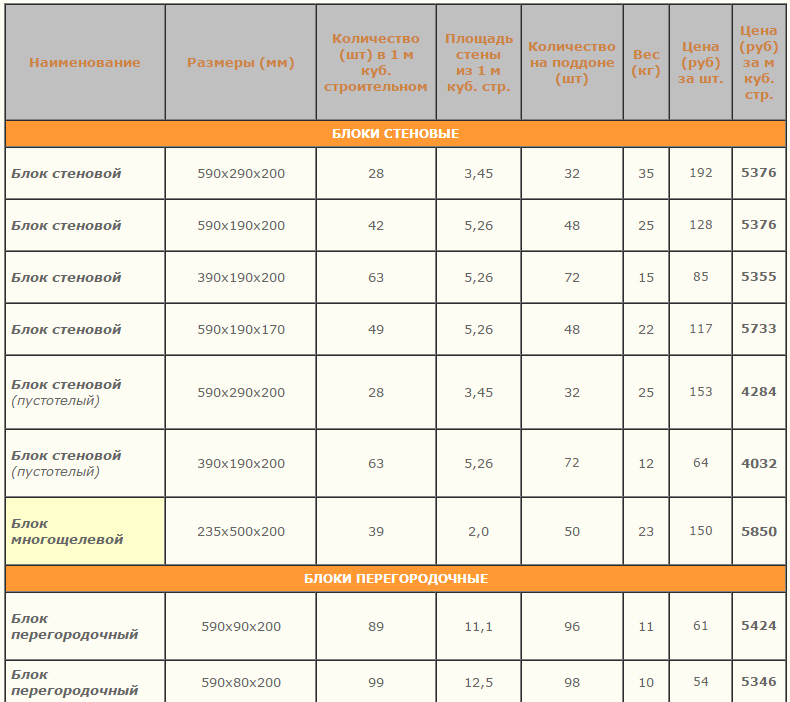

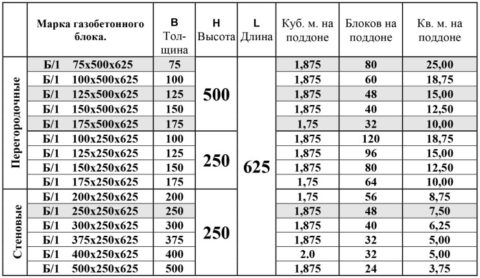

The dimensions and configuration of aerated concrete blocks affect their quantity when stacked on pallets. How many cubes of aerated concrete are in a pallet, and what pallets are there?

- For transportation, pallets of 3 types are used: 0.9 m³, 1.44 m³, 1.8 m³. Different numbers of aerated concrete blocks are stacked on different pallets.

- With a simple arithmetic operation, you can determine how many cubes in one pallet of aerated concrete blocks with standard dimensions of 600 x 300 x 200 mm (60x30x20 cm) can fit.

- The product of sides with dimensions of 100 cm is 1,000,000 cm³ or 1 m³, the volume of the block is 60 * 30 * 20 = 36000 cm³ or 0.036 m³.Dividing 1 m³ by 0.036 m³, we get 27.7 pieces of blocks in one cubic meter.

- Now let's return to pallets, which are conventionally divided into standard and non-standard ones. Aerated concrete: number of pieces in a cube with standard volumes of 0.9 m³: 0.036 m³ = 25 pieces; 1.44 m³: 0.036 m³ = 40 pieces; 1.8 m³: 0.036 m³ = 50 pcs.

Number of square meters, cubic meters and blocks on a pallet

Number of square meters, cubic meters and blocks on a pallet

- The principle of calculating non-standard modules on non-standard pallets is somewhat different from standard calculations. A construction foreman will quickly make simple calculations by measuring the volume of aerated concrete blocks laid on a non-standard pallet. In practice, it looks like this: the dimensions of the pack are 1 m in width, 0.8 m in length, 1.2 m in height, their product gives 0.96 m³. Linear indicators of the block under consideration are 0.6x0.3x0.2 = 0.036 m³. 0.96 m³: 0.036 m³ = 26.6 pcs.

- This is a clear example of the fact that when buying one pack of gas blocks, losses will amount to 0.6 volumetric index, because the manufacturer puts whole products on pallets. Large orders account for these shares, which can add up to impressive numbers.

- The photo shows different configurations of aerated concrete blocks with different densities, which means weight and price.

- The weight of one block is calculated by multiplying the volume of the module by its density indicated in the marking. For example, a module weight of 0.036 m³ with a density of 500 kg / m³ will be 18 kg.

The table will help you not to waste time on calculations.

The table will help you not to waste time on calculations.

When receiving an order, it is necessary to compare the calculated values with the numbers indicated in the accompanying documents with your own hands. Why is this done? There are many facts about the presence of industrial waste in the modules, which are used as fillers. A weight check will indicate their presence in the modules and poor product quality.

How many cubes of aerated concrete are in the pallet, what quality it is, can be determined without resorting to the services of specialized laboratories. Buildings made of aerated concrete blocks will stand for many years, as evidenced by their characteristics.

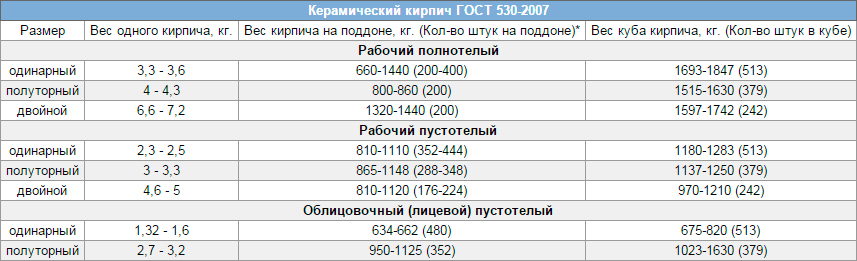

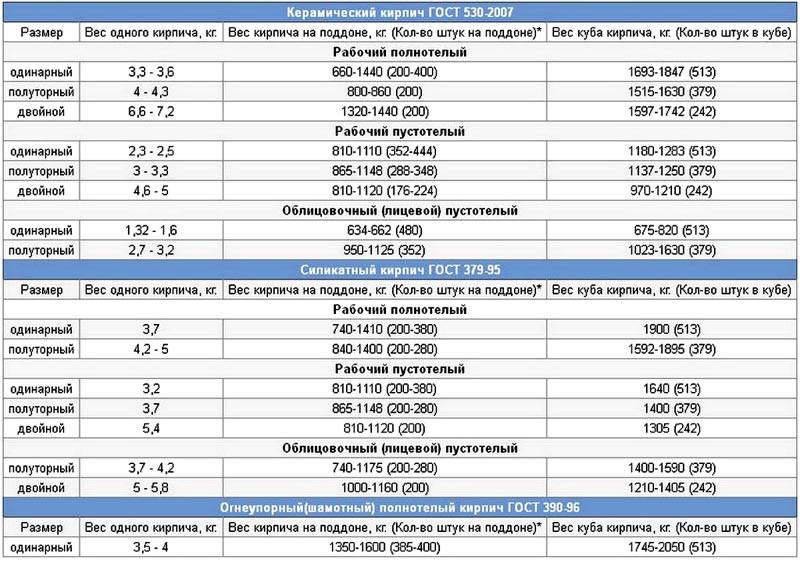

Volume and specific gravity of silicate brick

The first characteristic directly depends on the degree of voidness of the product and the density of the material.  It is defined as follows: the mass of a brick is divided by the product of its geometric dimensions. The lightest are facing hollow products: 1200 kg / m3 (double); 1400 kg / m3 (one and a half). In working blocks with voids, the volumetric weight ranges from 1300 to 1640 kg / m3. The heaviest are solid ordinary bricks: a single cube weighs 1900 kg, and a one-and-a-half cube weighs an average of 1700 kg. By multiplying the volumetric weight by the cubic capacity of the masonry, the load on the foundation of the structure is determined.

It is defined as follows: the mass of a brick is divided by the product of its geometric dimensions. The lightest are facing hollow products: 1200 kg / m3 (double); 1400 kg / m3 (one and a half). In working blocks with voids, the volumetric weight ranges from 1300 to 1640 kg / m3. The heaviest are solid ordinary bricks: a single cube weighs 1900 kg, and a one-and-a-half cube weighs an average of 1700 kg. By multiplying the volumetric weight by the cubic capacity of the masonry, the load on the foundation of the structure is determined.

The specific gravity depends on the porosity of the product, the quality of the raw material. To calculate the value, you first need to find the net volume - subtract the volume of voids from the total, and then divide the mass of the brick by the resulting number. The standard specific gravity for silicate blocks is 2000 - 2400 kg / m3. A decrease in the actual value, in comparison with the norm, leads to a deterioration in the strength characteristics.

Scope and features of solid silicate brick

Solid silicate blocks (ordinary brick, corpulent) differ in the minimum proportion of technological pores - no more than 13%. The corpulent is used for the following types of construction:

- external and internal load-bearing walls;

- partitions;

- columns;

- one-story and multi-story houses;

- country cottages;

- outbuildings.

The weight of a single sand-lime brick without voids is 3.7 kg (it is 10 - 30% denser than a hollow brick). To speed up the masonry, blocks are used whose thickness is increased by 1.5 times. The weight of one-and-a-half silicate bricks is from 4.2 to 5 kg.

Scope and features of hollow silicate brick

The volumetric weight of brick products is reduced by creating slot-like holes - they are through or deaf and have the shape of a circle, oval or square. The voids are small: due to this, the solution practically does not get into the holes, and they become a heat-insulating barrier.The advantages of hollow bricks:

- low thermal conductivity;

- reducing the load on the foundation;

- the ability to reduce the number of rows of masonry and wall thickness;

- solution saving - up to 10 - 15%.

A working brick with voids is used for the construction of houses of various storeys, for laying internal partitions, and facing bricks for decorating facades. The weight of 1 silicate brick depends on the degree of voidness and dimensions - this is shown in the table.

table

Hollow brick weight

| Appointment | Standard size | Weight, kg |

|---|---|---|

| Worker | Single | 3,2 |

| One and a half | 3,7 | |

| Double | 5,4 — 6 | |

| Facial | One and a half | 3,7 – 4,2 |

| Double | 5 – 5,8 |

As you can see from the table, the weight of sand-lime brick 250 x 120 x 88 deviates from the average within half a kilogram. This is due to the fact that according to GOST 379-95, 3 types of one-and-a-half blocks are produced according to the degree of voidness:

- 28 - 31% - have 14 holes with a diameter of 30 - 32 mm;

- 22 - 25% - 11 voids with a diameter of 27 - 32 mm;

- 15% - 3 cells, the diameter of which is 52 mm.

What you need to know when buying sand-lime bricks

- Typically, brick blocks are dispensed on pallets, which hold from 200 to 380 bricks. By multiplying the weight of one product by their number in the package, it is easy to find the total weight;

- To select a delivery vehicle, you need to know the weight of the pallets. Depending on the material, the container weighs from 18 to 40 kg - this is a significant addition if the machine has a small carrying capacity;

- The above information on weight applies only to GOST products. But not all brick factories adhere to technological regulations. When purchasing products from a small manufacturer that does not have a certificate, it is worth weighing the brick and making sure that it does not differ too much from the standard and calculate the total weight;

When determining the load on the foundation, it is taken into account that the mortar is also included in the masonry. Depending on the thickness of the seam, its share can be significant

When calculating the weight of the wall, this should be remembered;

For special accuracy of calculations, attention is also paid to the method of masonry - in the process, different types of bricks are sometimes used.

Specific gravity of the sand-cement mixture

How much one cubic meter of sand-cement mortar will weigh directly depends on the bulk density and mass of the components of the mixture. Light fillers (perlite, expanded clay, etc.) reduce the mass of the finished solution, heavy ones increase it accordingly. In addition, much may depend on the proportion of the components taken, the characteristics of the solution preparation.

The classic composition involves the use of cement as a binder, sand (fine filler), crushed stone (coarse filler), water. In this case, when there are no additives and light fillers that change the density of the solution, the weight of a cubic meter of the mixture is standard.

How many different brands:

- М100 - up to 2494 kg / m3.

- М200 - up to 2432 kg / m3.

- М250 - up to 2348 kg / m3.

- М300 - up to 2389 kg / m3.

- М350 - up to 2502 kg / m3.

- М400 - up to 2376 kg / m3.

- М500 - up to 2980 kg / m3.

Types of concrete by density and weight:

- Especially light - lightweight fillers are used, special additives to increase the porosity of the mixture. Usually concrete is used for the purpose of thermal insulation, its density is 500 kg / m3.

- Lightweight - with lightweight fillers, porous structure. Typically, concrete is used to create lightweight building blocks, the specific gravity is 500-1800 kg / m3, depending on the brand.

- Heavy concrete is a classic mixture of large and heavy aggregates (crushed stone, gravel), which can weigh 1800-2500 kg / m3. Such concrete is considered the most popular and demanded in carrying out repair and construction works.

- Particularly heavy - it contains various types of metal scrap, magnetite, hematite, barite, which determine the main weight. Such mixtures are used in special facilities, for protection from radioactive radiation, etc. They can weigh 2500-3000 kg / m3.

M 200

A popular brand for making foundations, floors, pouring floor screeds, implementing the installation of building structures. The M200 index means that the solidified monolith from this solution is capable of withstanding loads up to 200 kg / m2 (that is, the grade determines the strength of the stone).

The main characteristics of concrete grade M200:

- High level of strength and reliability due to low density (class B25).

- Fast drying.

- Low thermal conductivity.

- Mobility at the P3 level.

- The ability to work with a mixture at temperatures up to +5 without changing its properties.

- Water resistance -

- Frost resistance - F

- No cracks and shrinkage deformations.

The proportions for the preparation of the M200 mixture from the M400 / M500 cement are indicated above. The specific gravity of the mixture is about 2430 kilograms.

M 300

The standard M300 is 1800-2500 kg / m3. The indicator depends on the density - and, therefore, the type of crushed stone that is included in the composition. The specific gravity of the mixture is also influenced by the method of using the solution, the presence of air cavities in it.

It is a concrete of heavy type, high strength, with the best characteristics of waterproofing and frost resistance. Frost resistance is at the level of F150, it can be increased due to the introduction of special additives into the composition.

Water resistance corresponds to the W5-W6 indicator, which means that concrete at a pressure of 0.5-0.6 MPa (5-6 atmospheres) will not let water through. The value can be increased by using hydrophobic cement and special additives.

The mobility of the composition is at the level of P4-P5 and depends on the volume of water in the mixture, the presence / absence of additives in the solution.

M 400

Concrete grade M400 is used where it is necessary to achieve high characteristics of strength, resistance to various influences, reliability and durability. So, the M400 index indicates that the frozen monolith is able to withstand a load of 400 kg / cm2, which is quite a lot.

It is a heavy concrete with a density of 2380 kg / m3, water resistance - within W6-W12, frost resistance - from F100 to F300. Specific indicators depend on the recipe for the mixture, the selected cement, other components, as well as the additives added to the composition.

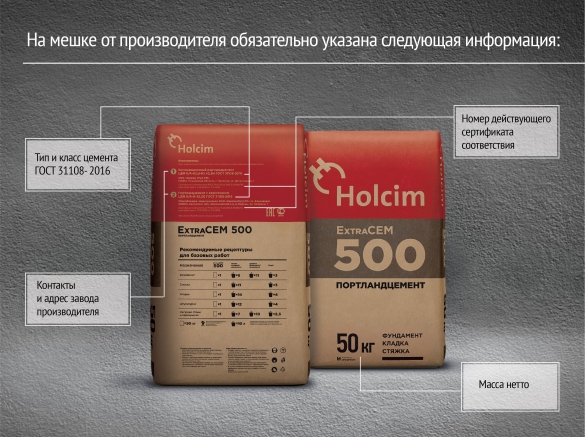

All types of 25, 40, 50 kilograms. On an individual basis, large volumes can be ordered at the factory, but usually, to perform work on a non-industrial scale, they consider how many kilograms of cement are needed for a certain volume of concrete solution and buy the corresponding number of bags of a certain volume.