Types and sizes of oven bricks

When constructing a furnace, it is important to ensure such parameters as a long service life, high heat transfer rates, and optimal dimensions of the furnace. To achieve them, it is recommended to use a special oven brick.

When choosing it, it is important to take into account not only dimensions, but also physical properties. When the blocks have the correct shape, size, do not have any deviations in terms of appearance, and also provide good traction, then be sure that the built stove will serve you efficiently and for a long time.

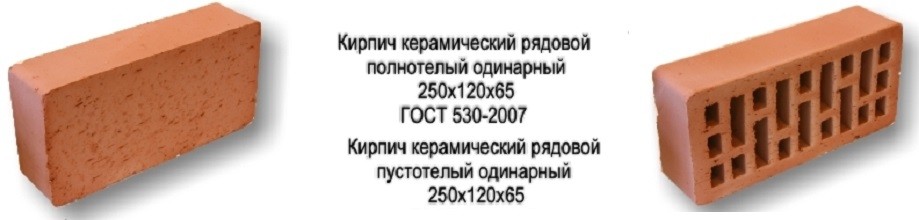

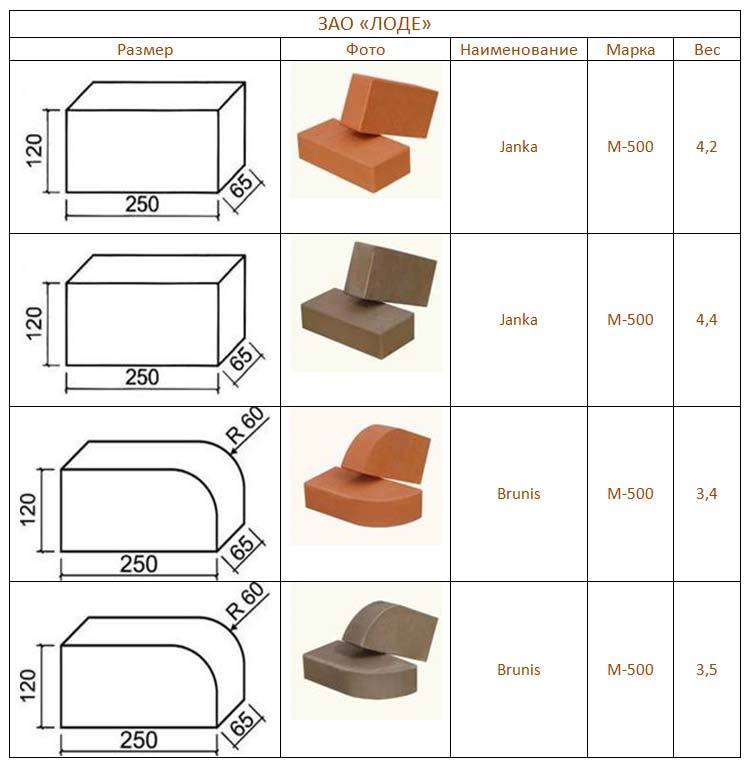

Which brick is best to use for the oven. For the construction of a furnace, a suitable material is ceramic (the pros and cons of ceramic bricks are described here), grade M-150. But it is much better when the masonry of the structure is made from materials from several manufacturers. Single refractory bricks can be of several varieties. Each species has its own size, weight and physical properties.

The video tells about the dimensions of the oven brick:

This product is based on alumina materials. They make up 70% of the total composition. When buying such a product, you must be guided by the following recommendations:

- Tap a little and determine its quality by the sound. If you hear a metallic sound, the test item is solid.

- You can determine the quality of a product by its color. If it is a faded shade, then it is not suitable.

- Hit the brick hard to make it fall apart. If during this process dust has formed, then the product is of high quality.

- If the surface of the material has a glassy coating, then this indicates that it has been severely burned out. During the construction of the furnace, such a brick will not provide adhesion.

- Using a hammer, break the product into 2 parts. If the color inside becomes darker, then this indicates that the sample is burnt.

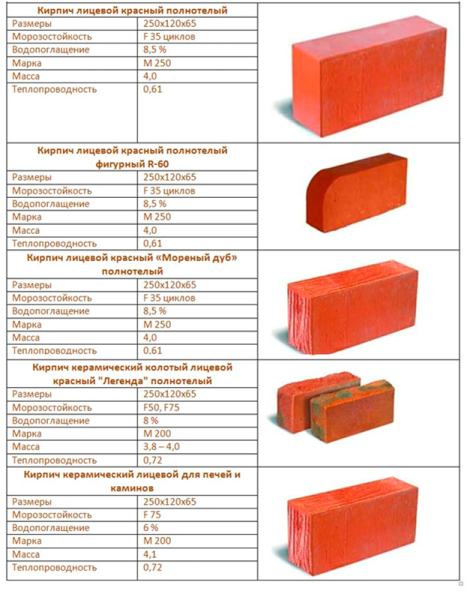

Facial red and double silicate

Observance of geometry is very important for the first type. Such material is always sold in a wide variety of shades and colors.

As for double sand-lime brick, when choosing it, it is important to take into account the degree of heating of the future structure.

See a photo of panels for the kitchen with a picture.

Clinker

This material is one of the most versatile. It is allowed to be used for laying the stove both inside and outside the house. It has the following advantages:

- shock resistance;

- high environmental friendliness;

- attractive appearance;

- wear resistance;

- not subject to temperature differences;

- waterproofness.

- long-term operation;

- the brick is able to "breathe".

The process of making refractory in Russia began to be introduced back in the 19th century. At that time, steel was actively melted. But the melting process must take place at high temperatures. To solve the problem, it was necessary to use a material that could withstand such a temperature regime. Refractory brick production is based on refractory types of refractory clay.

Also, it is distinguished for the masonry of the furnace by the components that make up its composition.

So, the following materials are distinguished:

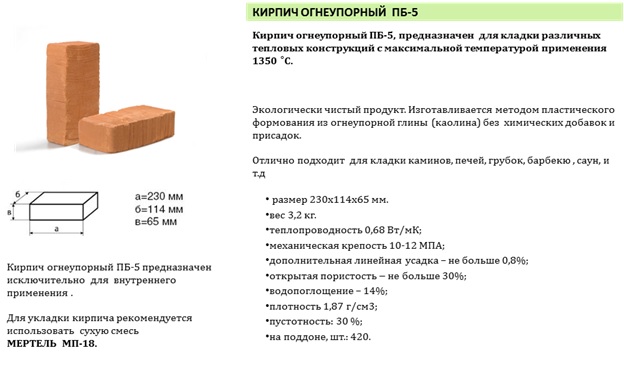

- Fireclay bricks contain a large amount of clay. The ease of obtaining the product made it possible to acquire the product in great demand in the construction market. It is actively used when laying stoves inside the house. To impart porosity to the brick, aluminum oxide is added to its composition. The lighter the brick, the more efficiently it conducts heat energy. With high-quality fired fireclay brick, it is possible to obtain a yellow tint.Here you can see the weight of fireclay bricks.

- Quartz is obtained by combining chamotte and quartz sand. It is used where there is a direct effect of fire. It has a granular structure. In the photo - quartz brick:

- The main brick is obtained by using fire-resistant lime-agnium masses.

- The carbonaceous material is pressed coke or graphite, which is widely used in the construction of blast furnaces.

Features of the classification

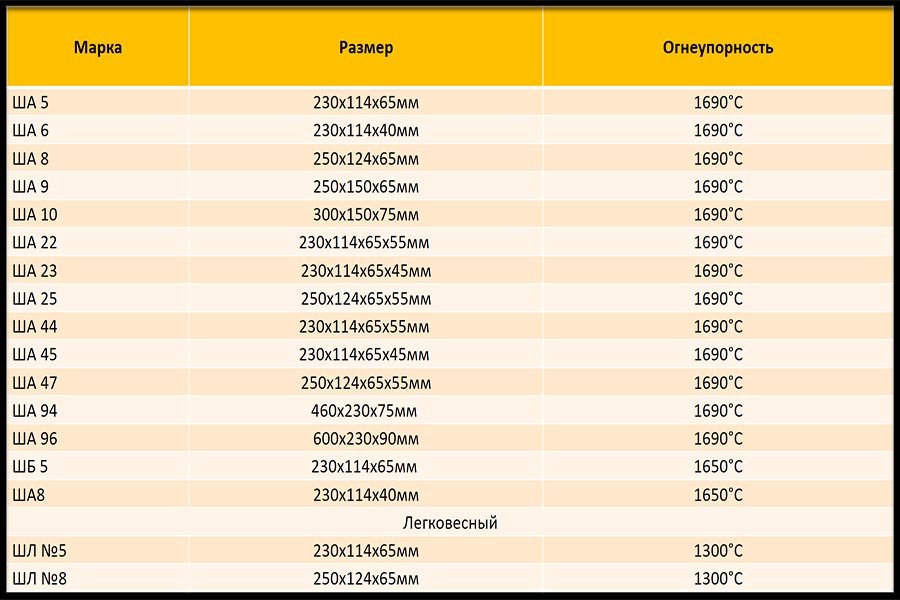

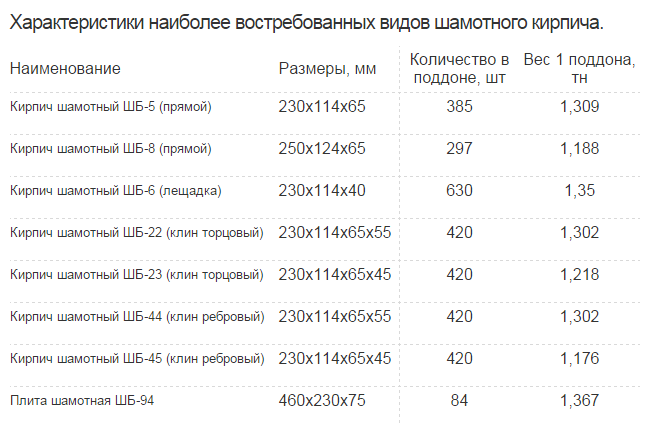

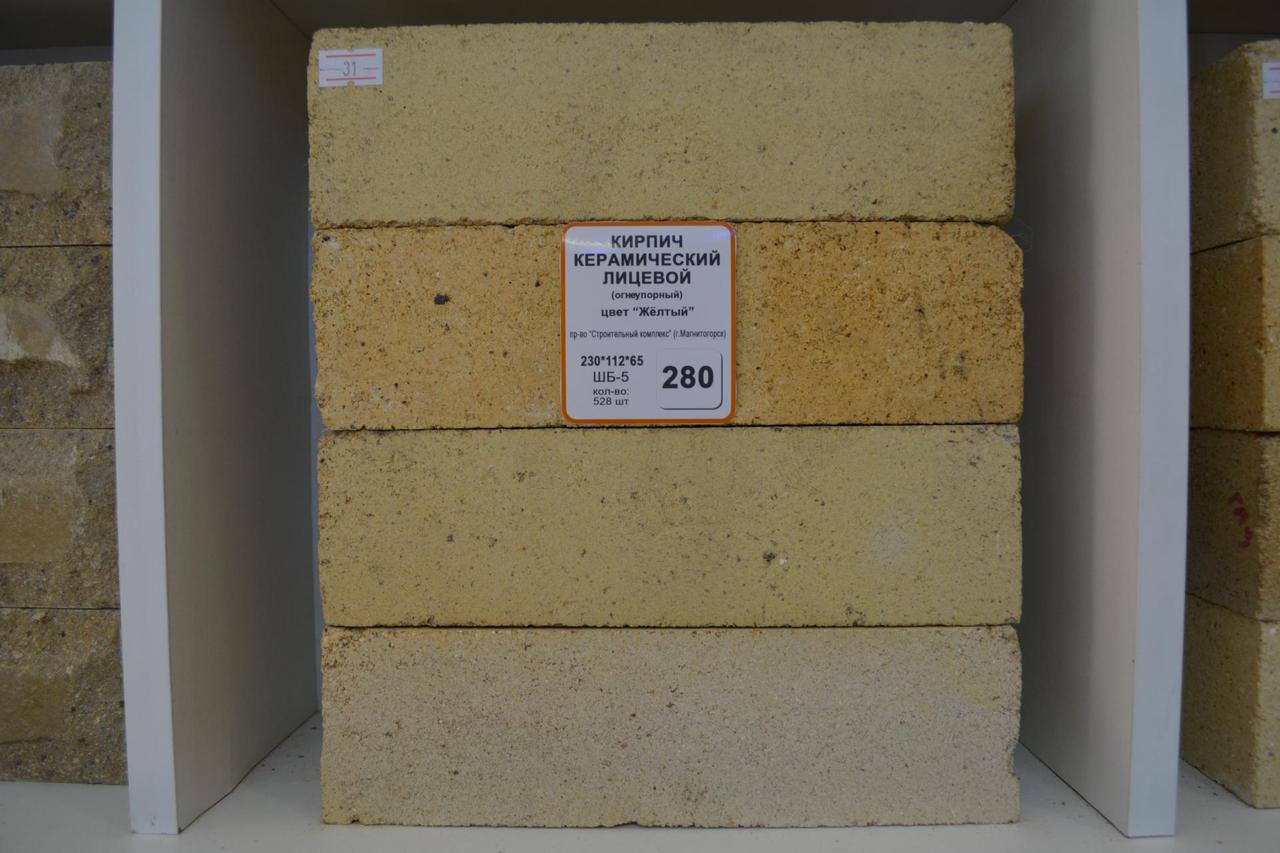

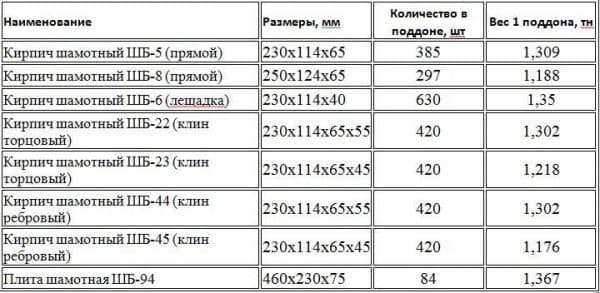

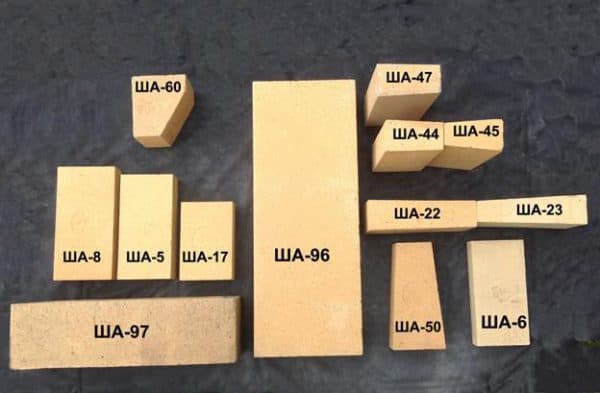

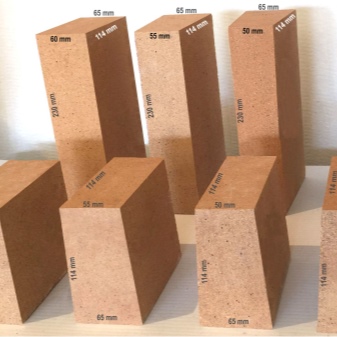

Designation and marking of ШБ-5, ШБ-6, ШБ-8, ШБ-9; SHA-5, SHA-6, SHA-8, SHA-9

Dimensions, mm 230x114x65, 230x114x40, 250x124x65, 300x150x65; 230x114x65, 230x114x40, 250x124x65, 300x150x65

Shape: straight

All materials made from refractory clay are marked with letters and numbers. The first should be the letter "Ш" - shows that the brick was made from aluminosilicate clay. The second letter exists in two variations "A" / "B". The letters indicate that the product is used for all types of masonry.

Marking

The presence of only one of these letters informs the buyer that the manufacturer is guided exclusively by GOST standards. The designation “SHA” means that the product contains a huge percentage of aluminum oxide.

That is, approximately 30%, which increases the fire resistance up to + 1690C. “ШБ” aluminum oxide has approximately 28%, which makes it possible to carry up to + 1650С. If after the letter "Ш" there is a number, for example "Ш5", this means that the manufacturer did not use the Gost indicators, but applied its own manufacturing technology.

The product with the “5” mark corresponds to the dimensions of 230x114x65 mm. The last two indicators indicate the manufacturer.

The standard shows similar abbreviations for a refractory product:

- SHA, SHB - general purpose;

- SHKU - bucket;

- SHAV - cupola;

- Broadband access - domain;

- ШЦУ - double-sided for lining.

Heating devices are equipped using a general purpose product. Let's analyze the standard dimensions of refractory bricks in detail. The alumina type is considered to be more in demand, including refractory clay and fireclay product.

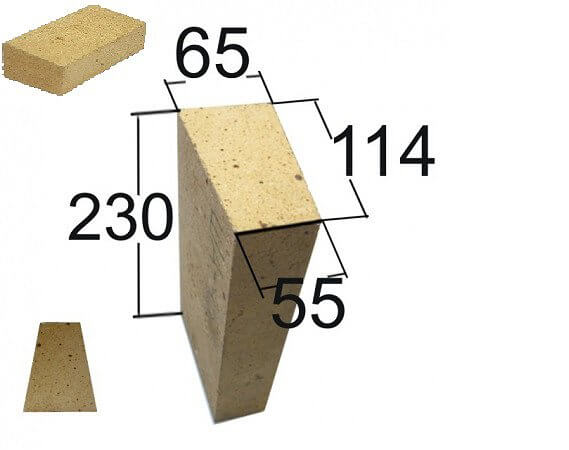

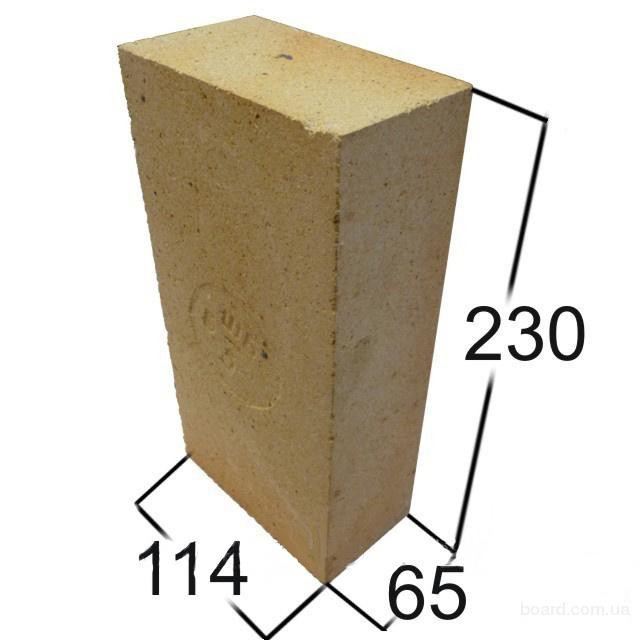

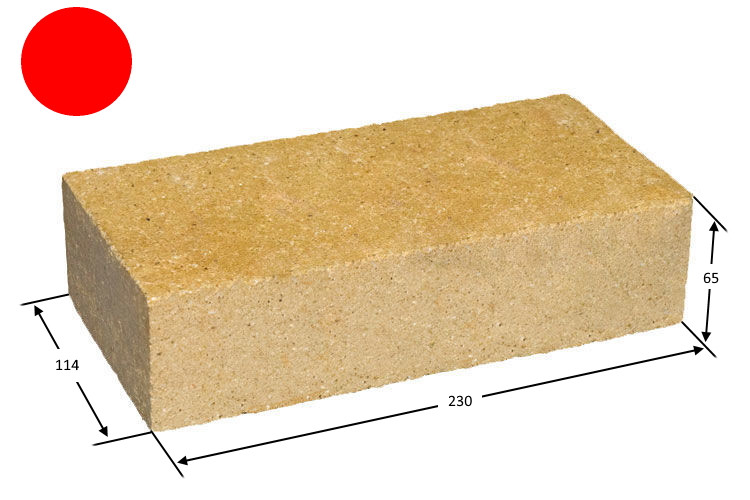

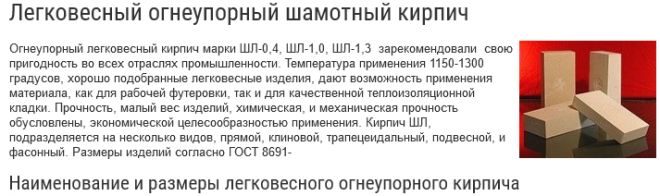

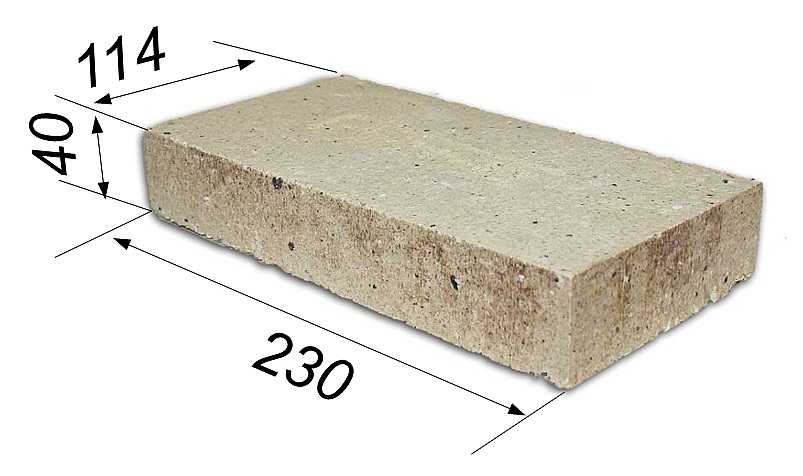

Accurate firing must be followed for this type. For furnaces, only products of the first type are used, which crack when heated. Refractory brick size “ШБ5” looks like a yellowish rectangle. Scales 230х114х65 mm.

Dimensions ШБ5

According to the standard, the material must meet similar characteristics:

- part of the binary compound of aluminum and oxygen - 28%;

- fire resistance - not less than 1,650oC;

- when softening, tºC is absent.

"ША8" product is used in industrial and private buildings. Possesses an increased index of aluminum oxide. Used for internal laying of chimneys.

Product rating:

- percentage of aluminum oxide - 30%;

- fire resistance - 1,690oC;

- softening tºC is not less than 1,300oC.

SHA-6 is used in the construction of heating units at t 1 690ºC. The main properties of the product do not differ from the “ША8” marking. The difference is solely in size. Product weight per piece - 3.4 kg. Scales - 230х114х40 mm. Cost from 30 rubles / piece.

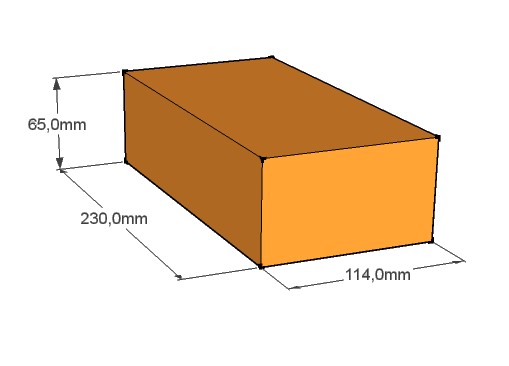

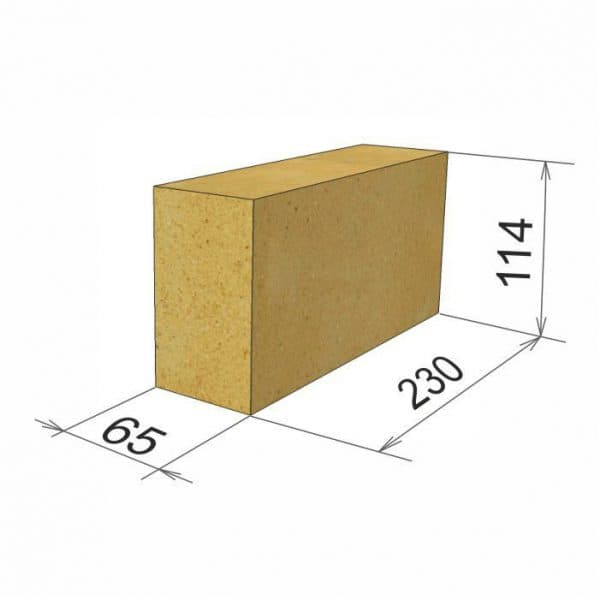

Types of Sha

Refractory bricks "ША5" are 230х114х65 mm in size. The mass is the same as that of the "SHA8". The price of a refractory grade is 30 rubles / piece. Dimensions are the main criterion in the selection of refractory bricks.

Areas with a very thin ball of mixture should be avoided. The calculation of the costs of refractory bricks is carried out using the construction scheme.

Marking ША5, ША6, ША8, ШБ5, ШБ8.

Size, mm 230x114x652, 30x114x602, 50x124x652, 30x114x652, 50x124x652, 30x114x652, 50x124x65, 230x114x652, 30x114x65.

Refractoriness, C 1 690, 1 690, 1 690, 1 690, 1 690, 1 300, 1 300, 1 150, 1 465.

Marking

When choosing a material for masonry, one should understand how much red bricks are needed for a particular area and a number of key properties that are responsible for the quality of the product. Only by using a high quality product can a smooth and reliable stove be created.

When selecting products, special attention should be paid to the following properties:

- uniformity and uniformity of the plane must be almost perfect. You do not need to purchase a brick, in the plane of which you can identify the remnants of inclusions, stones, inclusions, as well as cracks;

- the material must have a uniform, identical tone;

- the correct formation of the stone testifies to the quality. It is necessary that all the edges are the same in length, without flaws. The presence of protrusions will cause damage during installation;

- a different mass of bricks with the same dimensions indicates density. The larger the mass, the denser the product, and also the longer it accumulates heat. To build the base of the building, you should know the information about the weight of the brick.

Features of fireclay brick masonry

The main feature is that the usual cement mortar for laying this type of brick is not used, since it does not have sufficient heat resistance.

Refractory brick masonry mortar

In hardware stores, you can purchase a ready-made composition that has all the necessary properties, namely:

- glue for laying fireclay blocks has sufficient heat resistance;

- after drying, the properties of the material are similar to the parameters of the brick itself;

- the material has good adhesion to fireclay blocks.

If for some reason it was not possible to buy a ready-made composition, you can make it yourself, for this you will need:

- finely ground fire-resistant clay;

- fireclay sand;

- purified water.

The solution is prepared in the following sequence:

- Fire-resistant clay is filled with water for 24 - 72 hours and mixed periodically.

- The settled clay is wiped with a mesh with a cell of no more than 3x3 mm.

- The sand is sieved and added to the clay in the ratio of 2 parts of sand to one part of clay. The resulting composition is thoroughly mixed.

- Water is added to the resulting mixture and mixed again. The ready-to-use solution should have the consistency of sour cream.

- You can improve the quality of the mixture by adding 3% water glass or salt.

Features of masonry heat-resistant blocks

There are a number of rules, the observance of which will ensure high-quality and durable masonry:

- the starting row is laid "dry", without the use of an adhesive. When laying subsequent rows, an adhesive mixture is applied to the lower and end surfaces, so that the thickness of the finished seam after laying does not exceed 5 mm;

- as soon as the adjustment of the brick is completed, the excess mortar should be removed immediately;

- the strength of the structure is ensured by stacking blocks with overlapping (staggered);

- seams must be sealed flush with the side of the blocks. Depressions and unfilled seams will inevitably lead to cracks;

- when laying corners and decorative elements, the blocks are stacked with the front side out;

- cutting fireclay bricks should be carried out with a grinder equipped with a diamond saw blade; using a trowel or pickaxe to correct the size is highly undesirable;

- the finished structure does not need any additional processing with special compounds, primers, etc.

Strict adherence to these simple rules will ensure a long service life and reliability of the structure.

Since structures operating in conditions of high and extreme temperatures are classified as especially critical, the correct choice of material is of particular importance. The use of fireclay bricks provides high heat resistance, resistance to mechanical stress and sufficient fire safety of the structure. In addition, one should not forget that the use of ordinary ceramic or silicate bricks when laying heat-resistant elements will not only not give the desired results, but also significantly increase the risk of fire.

Dimensions (edit)

The dimensions of fireclay bricks must correspond to the standard of each brand.Large discrepancies are highly undesirable, as this can complicate the use of the product and provoke curvature of the masonry. Small imperfections in the surface of bricks can be smoothed out with a putty, however, for products that are planned to be heated very much, the thickness of the seams should be as small as possible. The ideal option is 1–2 mm.

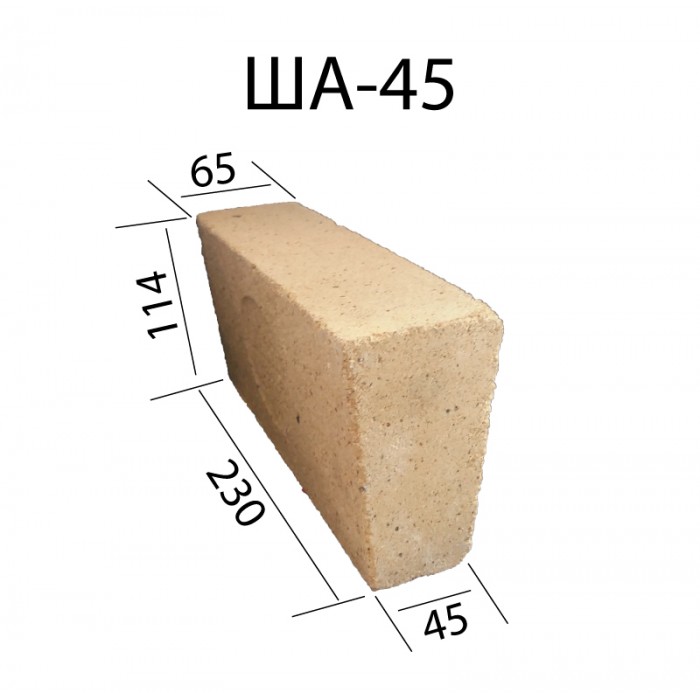

The main grades of chamotte have the following dimensions of length, width and height (thickness), respectively:

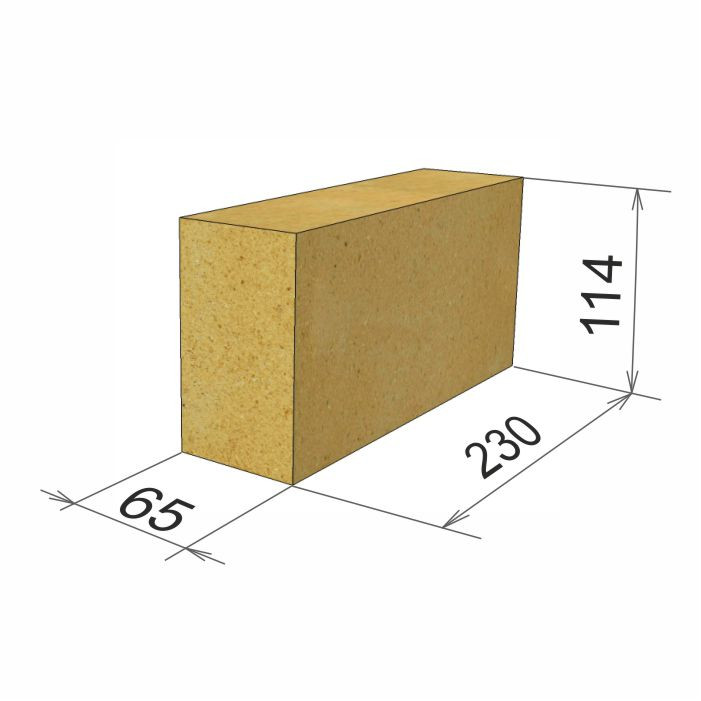

- SHA-5: 230х114х65 mm,

- SHA-6: 230х114х40 mm,

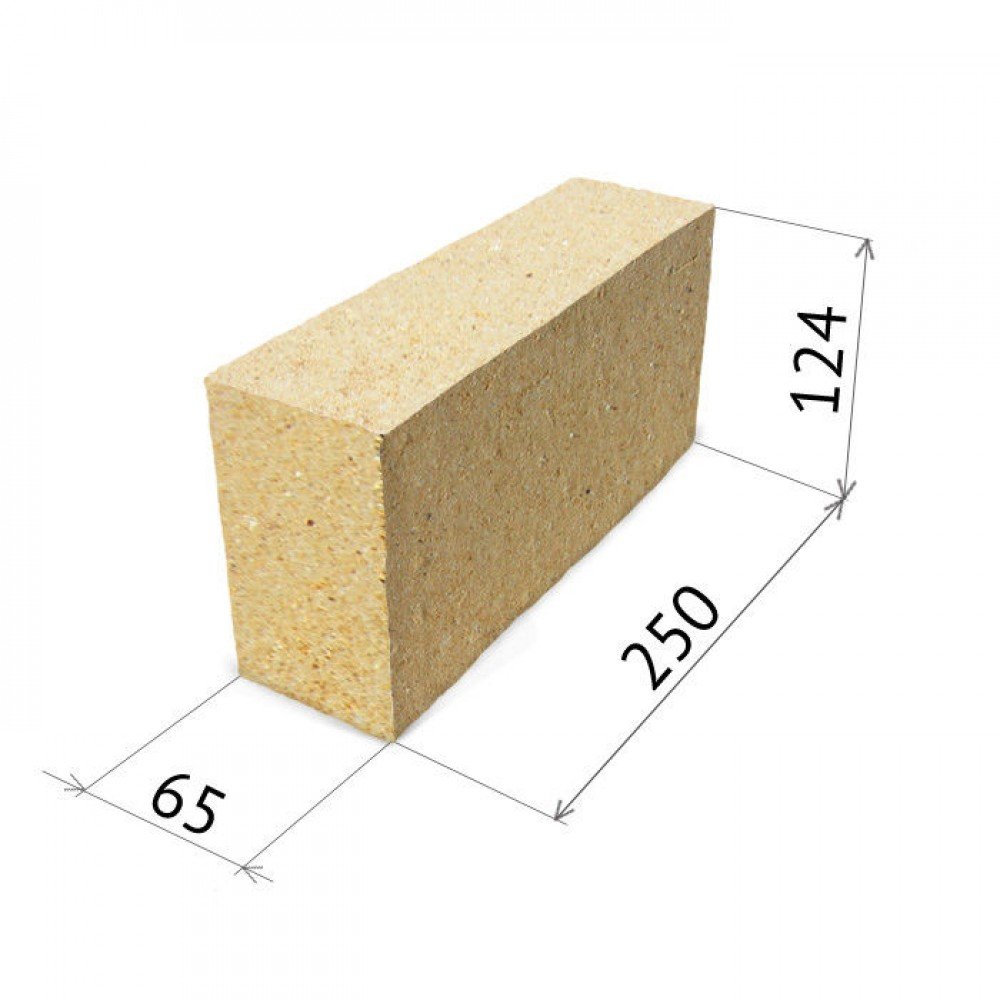

- SHA-8: 250х124х65 mm,

- ШБ-5: 230х114х65 mm,

- ШБ-8: 250х124х65 mm,

- ШЛ-8: 230х114х65 mm.

As you can see, the differences between the sizes are very small, so it is better to check with them when choosing bricks for your furnace or other structure. At the same time, between SHA-6 and SHA-8, for example, the difference lies only in size, the rest of their qualities are absolutely the same. But such differences help to choose the optimal thickness of the brickwork.

The largest grades ShA-8 and ShB-8 are most often used in construction, when the work must be done as quickly as possible. And also the size of these bricks allows you to use the putty more economically compared to other options. And in total, there will be fewer openings between the bricks in the walls, which will increase the heat resistance of the final structure.

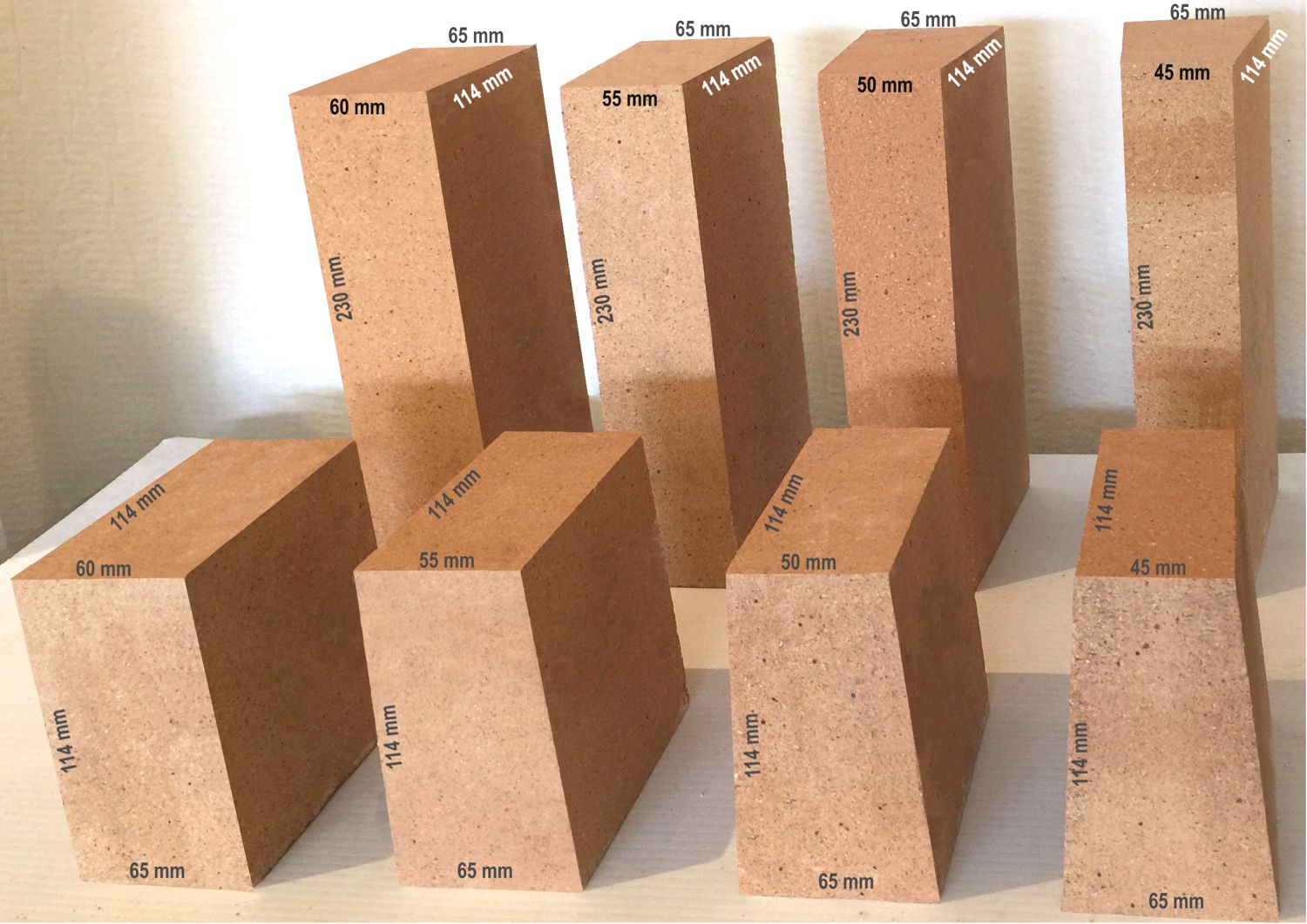

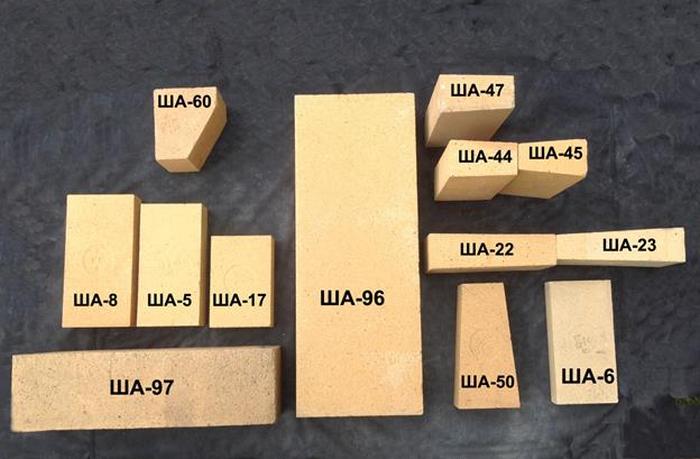

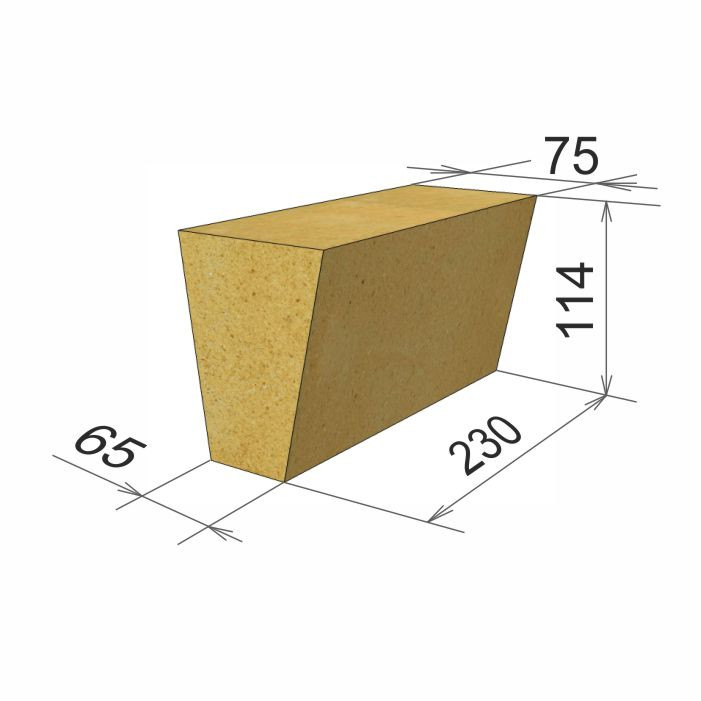

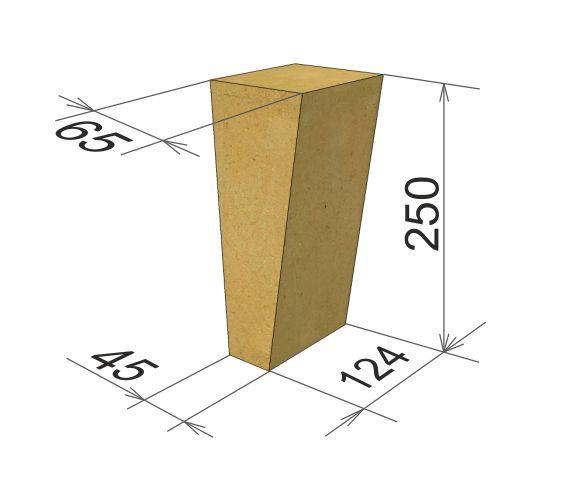

A separate category is fireclay wedge bricks. They differ from the standard ones in that some of their sides are not made perpendicular to each other, but with a bevel. Such bricks are used where you need to make a semicircular structure. For example, they are often used in the construction of fireplace arches.

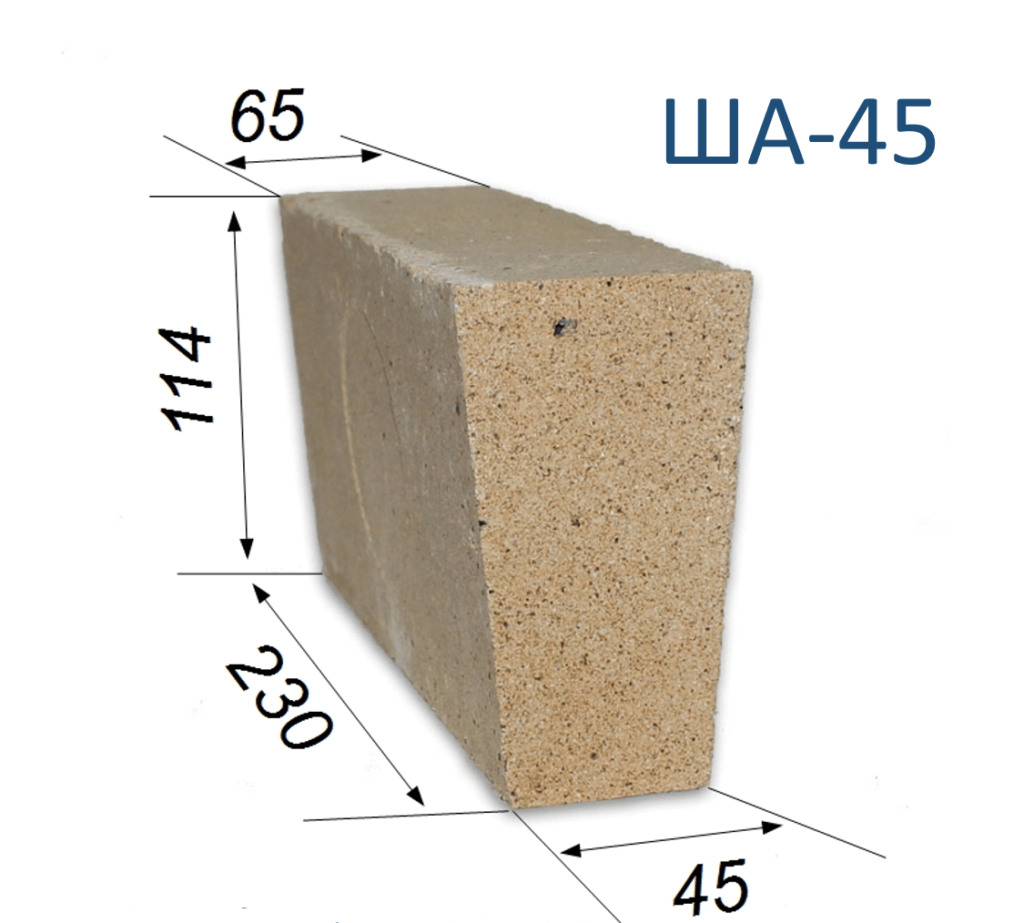

Wedge bricks include end and edge bricks. The most popular are ShA-22, ShA-23, ShA-24, ShA-44, ShA-45 and ShA-46. They are based on standard bricks, so the dimensions along the main planes correspond to the primary brands, but additional dimensions are added due to bevels. Most brands have a bevel in the range of 1–2 cm.

For information on the sizes of chamont bricks, see the next video.

Application of fireclay bricks

Fireclay bricks withstand contact with alkalis, such as lime, better than other refractory products. Therefore, it can be used in various industrial installations where combustion products contain active chemical substances (masonry and lining of boilers, fuel chambers, blast furnaces, etc.).

The solution used is of particular importance for imparting resistance to high temperatures to thermal aggregates. Usually, the same components are used for its preparation as in the production of the brick itself. When working with brands ШБ-5 or ШБ-8, refractory clay is used, to which crushed brick is added. Such a composition is usually called "chamotte clay" or mortar.

This is how dry mortar looks like.

At particularly high temperatures, a thickness of less than 1 mm may be required. Such work requires a special quality of the preparation of the mixture and high qualifications of the performers. In addition, the consumption and cost of the material significantly increases (only special grades with increased fire resistance must be used, the ShB-8 or ShB-5 brick will not withstand the load), and the total weight of the finished product also increases.

With all its advantages, fireclay brick also has a number of disadvantages that limit its use:

- Hygroscopicity. It absorbs moisture well, while the weight increases and the strength decreases when heated;

- Instability to freezing. Usually, fireclay bricks of the brands ШБ-5, ШБ-45, ШБ-94, ШБ-8 are used for laying household stoves, which often crumbles with irregular use and periodic cooling of the stove;

- High density. The material is difficult to cut if necessary to ensure the required dimensions;

- Relatively high price, long warm-up time, the need to prepare a special solution.

Summing up, we note that the use of fireclay bricks is optimal for facing areas exposed to strong thermal effects.At the same time, its use as the main building material for household stoves is constrained by the presence of a number of disadvantages caused by the technological features of production.

Fireclay brick: types, sizes and weight

If you're thinking of laying out a barbecue. brazier, stove or fireplace, then only refractory bricks can become the material. There are several varieties of it, including diatomite, magnesite, carbonaceous and quartz. However, according to its properties, fireclay bricks stand out, used in places with temperatures of the order of 1300 C.

This material has versatile characteristics. It tolerates sharp temperature changes when heated, demonstrates excellent thermal conductivity, does not react to alkalis and a number of other aggressive chemical compounds. Fireclay bricks also have an aesthetic function - products made of such material always attract the eye due to their variety of shapes (rectangular, arched, wedge-shaped and trapezoidal) and shades (from almost white to light brown).

Note: The darker the color of the fireclay brick, the better it is suitable for the construction of the firebox of the stove.

The disadvantages of fireclay bricks include the following:

- its porous material quickly absorbs moisture, which leads to an increase in weight, as well as a decrease in strength during the heating period;

- does not tolerate freezing well, so if the oven is used irregularly, it can begin to crumble;

- difficult to process, in particular, poorly cut due to high density and requires the use of a special solution during masonry.

Another serious disadvantage from the point of view of the consumer is the high price of fireclay bricks.

Refractory brick - technical characteristics: dimensions, weight, according to GOST, how much it weighs, do-it-yourself installation instructions, photo and price

Refractory brick - technical characteristics, application

Those who have already purchased building bricks in order to build a structure out of it (house, garage, fence) with their own hands have an idea of the classification of this building material (silicate, ceramic). They know what, for example, is a double sand-lime brick M 150 according to the standards.

Photo: the most popular refractory material - fireclay

It can be said that since it is double, then its geometric dimensions are 250 mm x 120 mm x 138 mm. And the brand - "M 150" is its strength indicator and indicates that this silicate building material will withstand a load of 150 kg per 1 cm2.

Properties, characteristics and standard sizes

Standards, regulations

Anyone who is interested in more complete information on the topic, standards on refractory materials used by humans in construction (laying stoves, fireplaces) today, can familiarize themselves with the following regulatory documents:

- GOST 8691 - 73 "General purpose refractory products".

- GOST 24704 - 81 "Corundum and high-alumina refractory products".

- GOST 390 - 96 "Fireclay and semi-acid refractory products for general use and mass production".

- GOST 24704 - 94 "Corundum and high-alumina refractory products".

- GOST 4157 - 79 "Refractory dinas products".

- GOST 5040 - 96 "Refractory and highly refractory lightweight heat-insulating products".

- GOST 21436 - 75 "Refractory and highly refractory products for lining of rotary kilns".

- GOST 6137 - 97 "Refractory aluminosilicate mortars".

- GOST 969 - 91 "Alumina and high-alumina cements".

Types of clay and fireclay bricks

Fireclay or alumina is the most common type of building material. It consists of refractory clay and chamotte. Correct firing is very important for this type. For ovens, only products of the first grade are used. They crack when heated and hold heat well.

You can find out what the yellow facing brick is and what its price is from the article.

Outwardly, it looks like a golden rectangle.

Has dimensions 230x114x65 mm.The volume of this brick grade is 1704 m 3. According to GOST, the product must comply with the following parameters:

- the proportion of aluminum oxide - 28%;

- fire resistance - not less than 1,650 ° C;

- the temperature at which softening begins is absent.

The weight of one piece of such a product is 3.5 kg. Price - from 35 rubles.

The product is used in industrial and private construction. Has a high content of aluminum oxide and is fire resistant. They are used for internal masonry (lining) of the arches of furnaces and chimneys. Product characteristics:

- the proportion of aluminum oxide - 30%;

- fire resistance - up to 1,690 ° C;

- the temperature at which softening begins is at least 1,300 ° C.

Weight 4.0 kg. Dimensions - 250x124x65mm. Price - from 32 rubles per piece. The cost may differ from the indicated one, it depends on the manufacturer and the volume of the purchase.

You can find out more about red solid brick and its price per unit from this article.

SHA-6 (narrow)

Suitable for the construction of heating units with temperatures up to 1,690 ° C. The main characteristics of the product do not differ from the SHA-8 brand. The difference is in size. The weight of one product is 3.4 kg. Dimensions - 230x114x40 mm. Price - from 30 rubles apiece.

The dimensions of a unit of goods are 230x114x65 mm. There are 385 bricks on a pallet. Unit weight - 3.4 kg. The cost of this refractory brand is from 30 rubles apiece. The laying of this and other types of bricks is carried out on a special refractory mixture.

Size is an important criterion for choosing a building material. The quality of the masonry, durability, practicality and safety of the finished structure depend on the accuracy of the fit. A loose fit of bricks should not be allowed, and areas with a too thin layer of mortar should also be avoided. The calculation of the consumption of refractory bricks is carried out according to the masonry scheme using construction drawings. It is also useful to read about what other refractory materials are.

vote

Article Rating

Refractory bricks

Ordinary building bricks, depending on the raw materials used in its production, are divided into:

- Ceramic - which is made from clay.

- Silicate - it uses a mixture of sand and lime, other additives.

But, these products of brick production can not be used everywhere. For example, with high-temperature technologies (up to 1800 degrees C) in the metallurgical industry, in the glassmaking (glassmaking) industries, the same ordinary clay brick (in common people, "red") will not withstand high temperatures for a long time.

With extreme heat and prolonged exposure to high temperatures, it will begin to melt, and then, cooling down, it will crumble. Although, as a masonry and finishing material, it is widely used in indoor fireplaces and stoves of baths, saunas, living quarters, where the temperature is not higher than 800 degrees C.

Variety of refractory structures and elements

Types of fire resistant building materials

In furnaces where glass is blown, porcelain is fired, in blast furnaces where steel is melted, a more resistant, fire-resistant material is used in the furnace core. Refractory bricks in accordance with GOST 8691 - 73 can withstand heat with a temperature of more than 1000 degrees C.

Refractories are produced with different properties and characteristics for different applications.

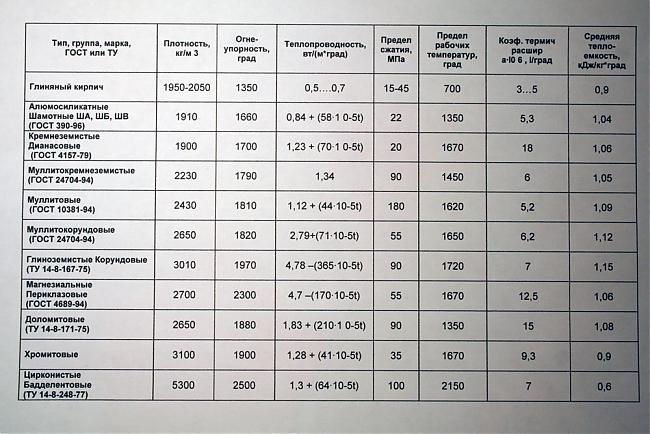

Fire-resistant material according to its physics - chemical composition, production methods and methods, temperature range is divided into four classes:

Composition and fields of application of refractories

- Quartz brick - consists of quartz (sandstone), with small additions of clay. As a result of firing, it acquires a cavity-free, full-bodied structure. In fireboxes, it is used in places where it has contact only with an open flame (for example, reflective arches in fireboxes, fireplaces, stoves). Stores accumulated heat well.

Important to remember! Quartz refractories should not have contact with alkalis, lime, iron oxides, which destroy it

- Carbonaceous - in a simplified form, it is compressed graphite or coke. It has the highest strength and fire resistance characteristics.It is used in highly specialized areas of construction (for example, in the construction of blast furnace structures).

- The main one - includes a lime-magnesian mass in its composition, which makes it possible to use this refractory for the production of Bessemer steel from phosphorous ores.

- Alumina - from its very name it is clear that in its basis clay makes up most of the structural component (about 70%). Therefore, it better (in contrast to quartz refractories) resists the destructive action of alkalis (lime). Easily tolerates rapid temperature changes.

It is easy to manufacture, and its price is lower than other flame retardant materials. It is widely used in the cores of furnaces, where the temperature is not higher than 1300 degrees C. Bricks of this type are also called "fireclay". It is marked with the letter "Ш", and the numbers following it carry information about its dimensions.

Designation, shapes and sizes of fireclay products (GOST 390-96, GOST 8691-73)

The size and shape of the refractory brick may vary. According to GOST alone, there can be more than a hundred such standard sizes.

Therefore, we will present only the most used products in private furnace construction. The rest can be found in the standards themselves.

The brand of building material depends on the maximum temperature of its application during operation.

Table: Limiting temperatures for the use of fireclay products

Refractory grade

Tables: Wedge chamotte

Thus, chamotte products for standardization are divided into:

- wedge or straight (normal sizes),

- large or small formats;

- shaped large-block, especially complex, complex, simple;

- special fireclay products for industrial and laboratory use.

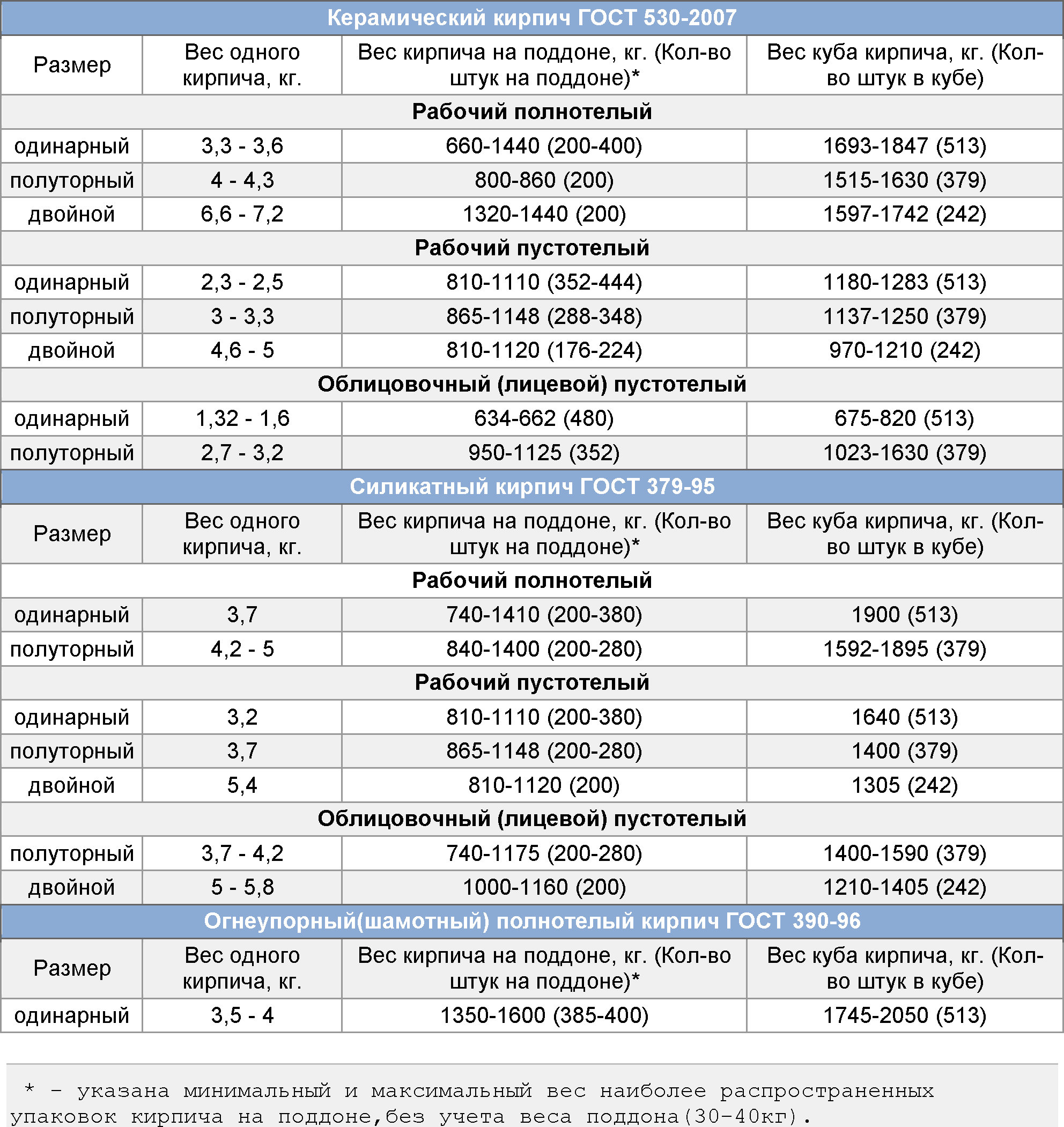

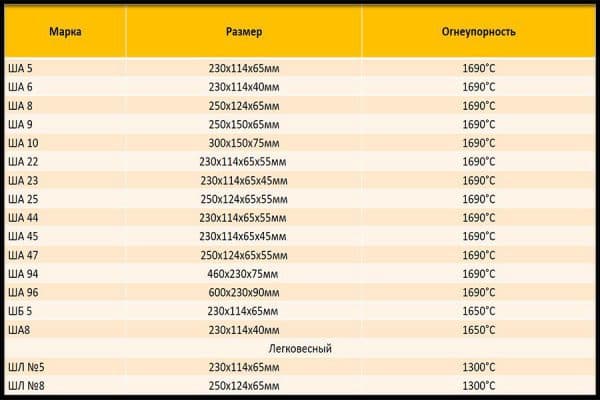

Weight characteristics of refractory (fireclay) brick GOST 390 - 96

The weight of refractory bricks depends on the raw materials from which it is made, on its shape and size. How much does the fireclay brick of the most popular brand (ША, ШБ) weigh, and its packaging (cages) without taking into account the mass of the pallet 30 - 40 (kg), see the table below

Types and marking of fireclay refractory bricks

Fire resistant blocks can be classified according to several criteria:

By molding method

The design of the forms and features of the technological process provide for the following types of molding:

- casting from slips or melts;

- semi-dry forming;

- melting;

- hot pressing;

- thermoplastic pressing.

By block configuration

For the laying of various structures, the industry produces the following types of fireclay bricks:

- wedge-shaped;

- trapezoidal;

- rectangular (straight);

- arched profile.

By chemical composition

Depending on the additives used that affect the thermal stability and mechanical properties, and the characteristics of the production technology, the following modifications of fireclay refractory blocks are distinguished:

- basic. In the manufacture of such bricks, fire-resistant chamotte clay is used, the mass fraction of which in the working mixture is 70%. Coke or graphite powder can be used as a filler. The material is used for facing furnaces designed for melting Bessemer steel;

- carbonaceous. This modification is characterized by a high percentage of carbon. The main purpose of carbon refractory blocks is blast furnace lining;

- quartz. Due to the use of silicon oxide, the heat resistance of bricks is significantly increased, however, contact with an alkaline medium leads to intensive destruction of the material;

- alumina. Aluminum oxide is used as a special additive. Alumina fireclay brick can work for a long time at temperatures from 1100 to 1300C and is not susceptible to frequent temperature changes. This type of heat-resistant blocks is widely used when laying household stoves, fireplaces and chimneys.

The marking of fireclay bricks includes letters and numbers that reflect the chemical and physical characteristics and overall dimensions of the material.Below are the markings for the most common modifications.

SHA, SHB, SHAK. The materials have high strength and heat resistance (1600 - 1700C), which allows them to be used in all areas of industrial and civil construction. They contain aluminum silicate, which ensures a long service life and resistance to mechanical damage. Another advantage is the optimal price / quality ratio.

ШВ, ШУС. Brick is widely used in industry. High heat capacity indices allow the use of ШВ and ШУС blocks for the construction of gas channels of steam generators; from such blocks, enclosing structures are erected to protect convection shafts.

ShK. This variety is used for the construction of industrial facilities that produce coke.

SHL. SL brick is characterized by high porosity and low specific gravity. The maximum allowable temperature maintained by the blocks is 1300C. The main area of application is furnace lining.

SHTSU. Double-sided end brick. Most often, rotating elements of the furnaces are laid out from the ShTSU blocks.

PB. This modification is characterized by a high clay content, which significantly reduces the heat resistance of the blocks, but the price of the products is quite affordable for a wide range of consumers.

PV. Products are used for interior masonry of stoves and fireplaces. PV blocks provide a long period of operation of the masonry and are capable of operating at temperatures up to 1300C. The scope of the material is limited by its high cost.

Features of the classification

Designation and marking of ШБ-5, ШБ-6, ШБ-8, ШБ-9; SHA-5, SHA-6, SHA-8, SHA-9

Dimensions, mm 230x114x65, 230x114x40, 250x124x65, 300x150x65; 230x114x65, 230x114x40, 250x124x65, 300x150x65

Shape: straight

All materials made from refractory clay are marked with letters and numbers. The first should be the letter "Ш" - shows that the brick was made from aluminosilicate clay. The second letter exists in two variations "A" / "B". The letters indicate that the product is used for all types of masonry.

Marking

The presence of only one of these letters informs the buyer that the manufacturer is guided exclusively by GOST standards. The designation “SHA” means that the product contains a huge percentage of aluminum oxide.

That is, approximately 30%, which increases the fire resistance up to + 1690C. “ШБ” aluminum oxide has approximately 28%, which makes it possible to carry up to + 1650С. If after the letter "Ш" there is a number, for example "Ш5", this means that the manufacturer did not use the Gost indicators, but applied its own manufacturing technology.

The product with the “5” mark corresponds to the dimensions of 230x114x65 mm. The last two indicators indicate the manufacturer.

The standard shows similar abbreviations for a refractory product:

- SHA, SHB - general purpose;

- SHKU - bucket;

- SHAV - cupola;

- Broadband access - domain;

- ШЦУ - double-sided for lining.

Heating devices are equipped using a general purpose product. Let's analyze the standard dimensions of refractory bricks in detail. The alumina type is considered to be more in demand, including refractory clay and fireclay product.

Accurate firing must be followed for this type. For furnaces, only products of the first type are used, which crack when heated. Refractory brick size “ШБ5” looks like a yellowish rectangle. Scales 230х114х65 mm.

Dimensions ШБ5

According to the standard, the material must meet similar characteristics:

- part of the binary compound of aluminum and oxygen - 28%;

- fire resistance - not less than 1,650oC;

- when softening, tºC is absent.

"ША8" product is used in industrial and private buildings. Possesses an increased index of aluminum oxide. Used for internal laying of chimneys.

Product rating:

- percentage of aluminum oxide - 30%;

- fire resistance - 1,690oC;

- softening tºC is not less than 1,300oC.

SHA-6 is used in the construction of heating units at t 1 690ºC.The main properties of the product do not differ from the “ША8” marking. The difference is solely in size. Product weight per piece - 3.4 kg. Scales - 230х114х40 mm. Cost from 30 rubles / piece.

Types of Sha

Refractory bricks "ША5" are 230х114х65 mm in size. The mass is the same as that of the "SHA8". The price of a refractory grade is 30 rubles / piece. Dimensions are the main criterion in the selection of refractory bricks.

Avoid areas with a very thin ball of the mixture. The calculation of the costs of refractory bricks is carried out using the construction scheme.

Marking ША5, ША6, ША8, ШБ5, ШБ8.

Size, mm 230x114x652, 30x114x602, 50x124x652, 30x114x652, 50x124x652, 30x114x652, 50x124x65, 230x114x652, 30x114x65.

Refractoriness, C 1 690, 1 690, 1 690, 1 690, 1 690, 1 300, 1 300, 1 150, 1 465.

Marking

When choosing a material for masonry, one should understand how much red bricks are needed for a particular area and a number of key properties that are responsible for the quality of the product. Only by using a high quality product can a smooth and reliable stove be created.

When selecting products, special attention should be paid to the following properties:

- uniformity and uniformity of the plane must be almost perfect. You do not need to purchase a brick, in the plane of which you can identify the remnants of inclusions, stones, inclusions, as well as cracks;

- the material must have a uniform, identical tone;

- the correct formation of the stone testifies to the quality. It is necessary that all the edges are the same in length, without flaws. The presence of protrusions will cause damage during installation;

- a different mass of bricks with the same dimensions indicates density. The greater the mass, the denser the product, and also the longer it accumulates heat. To build the base of the building, you should know the information about the weight of the brick.