PROMOS - Calculate the cost

|

Scroll |

Up to 1000 m3 |

from 1000 to 10000 m3 |

from 10,000 m3 |

|

Demolition of administrative, residential premises |

from 500 rubles / m3 |

from 400 rubles / m3 |

from 350 rubles |

|

Demolition of warehouse, industrial, garage premises |

from 350 rubles / m3 |

from 300 rubles / m3 |

from 250 rubles / m3 |

|

Dismantling of reinforced concrete foundation |

from 2600 rubles / m3 |

from 2400 rubles / m3 |

from 2200 rubles / m3 |

|

Manual dismantling of brickwork |

from 6000 rubles / m3 |

from 5000 rub / m3 |

from 4000 rub / m3 |

|

Manual dismantling of reinforced concrete floors |

from 9500 rub / m3 |

from 8000 rub / m3 |

from 7000 rubles / m3 |

|

Loading, removal and disposal of construction waste |

from 650 rub / m3 |

from 600 rub / m3 |

from 550 rub / m3 |

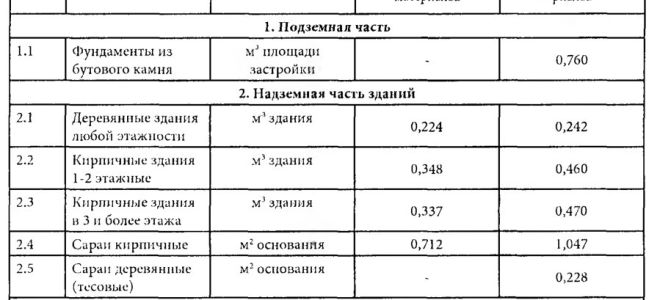

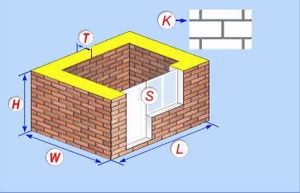

1. Cost of dismantling in the geometry of the building (in the "air"):

Building length x Building width x Building height (from the bottom of the foundation to the roof ridge).

2. Calculation of the real volume of construction waste, prepared for removal in a "solid":

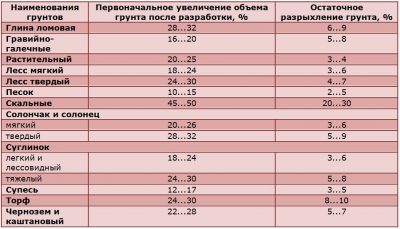

V debris in solid = V building in air: K loosening

Where:

K loosening = 2.3 - 3.0 is an empirical coefficient that takes into account all individual coefficients of loosening of the resulting construction waste.

3.Calculation of the Weight of the removed garbage:

P weight pin. Garbage = V garbage in solid x Mob.

where Mob. = 1600 kg / m3 is the volumetric mass of construction waste obtained during disassembly.

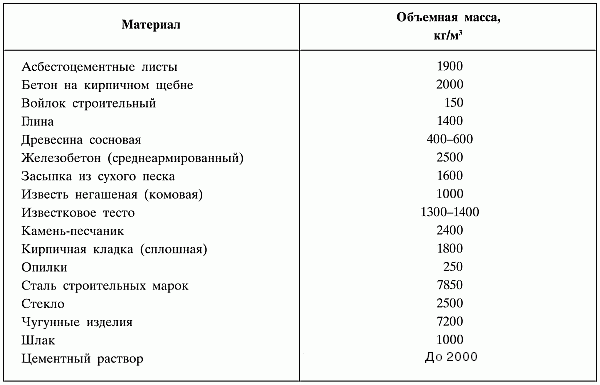

The volumetric mass of construction waste should be taken as averaged according to the following standards:

- when dismantling concrete structures - 2400 kg / m3;

- when dismantling reinforced concrete structures - 2500 kg / m3;

- when dismantling wooden and frame-filling structures - 600 kg / m3;

- when performing other dismantling works (except for dismantling metal structures and engineering and technological equipment) - 1200 kg / m3.

Call: +7 (495) 966-23-05

Dimensions (edit)

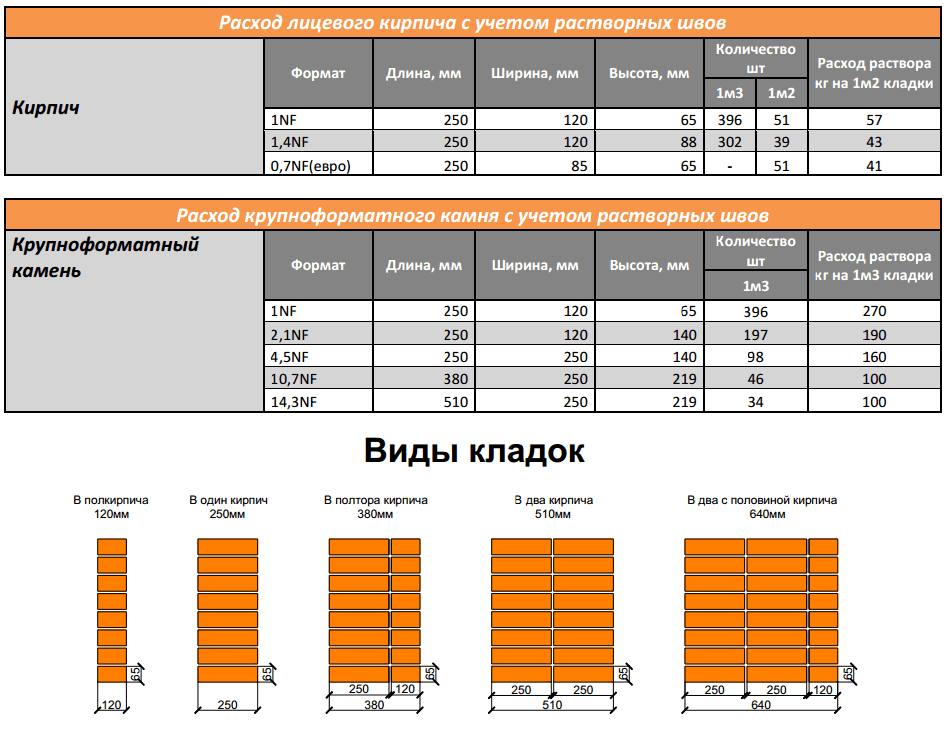

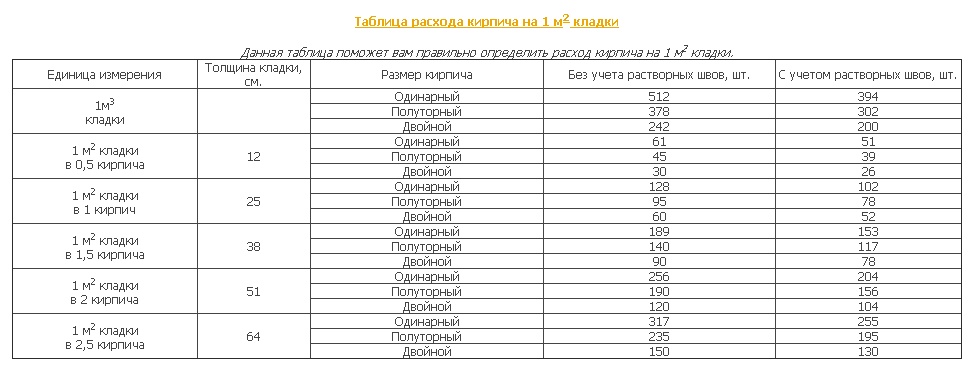

Before calculating how many bricks per cubic meter, you should decide on the dimensions of the bricks used.

Whether it will be a single, one and a half or double brick.

Each of them has its own, standard dimensions, differing only in the height of the product. At the same time, the length and width remain unchanged.

A single brick has the following dimensions:

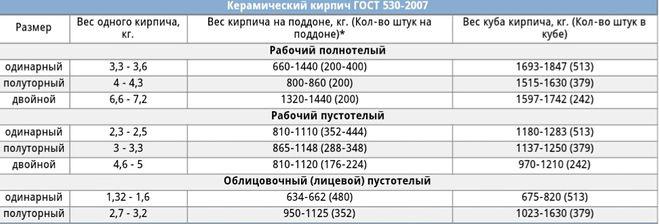

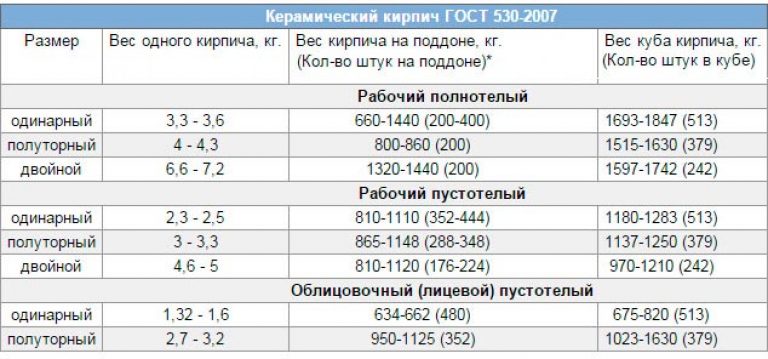

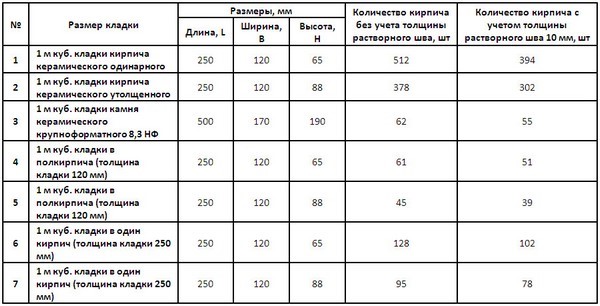

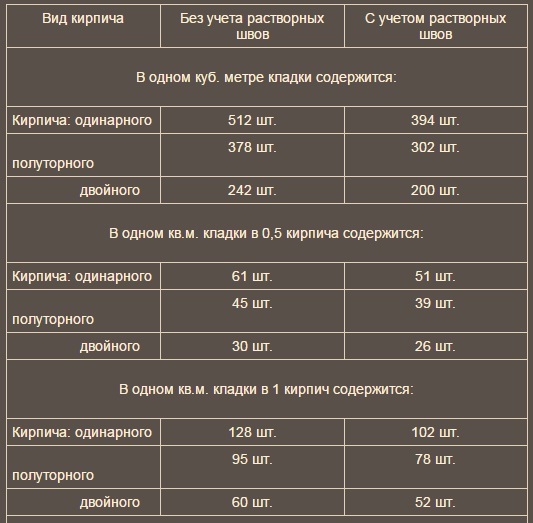

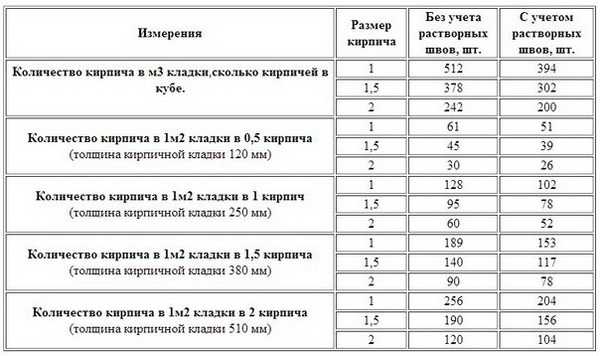

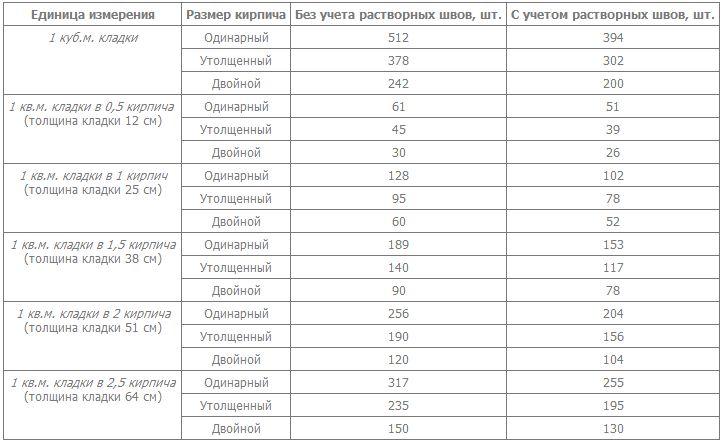

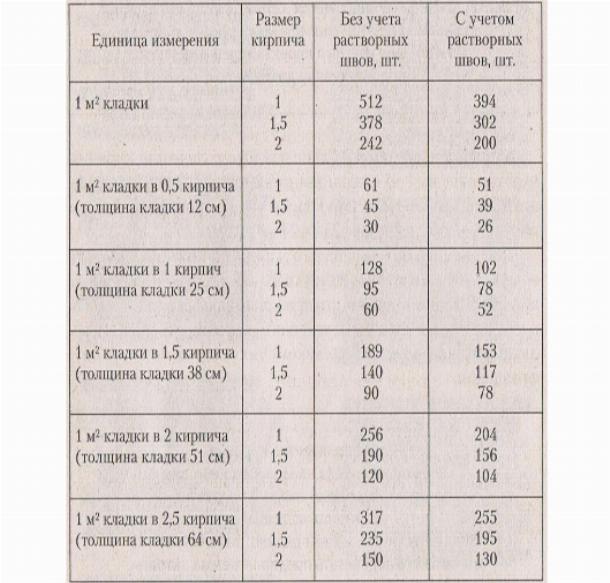

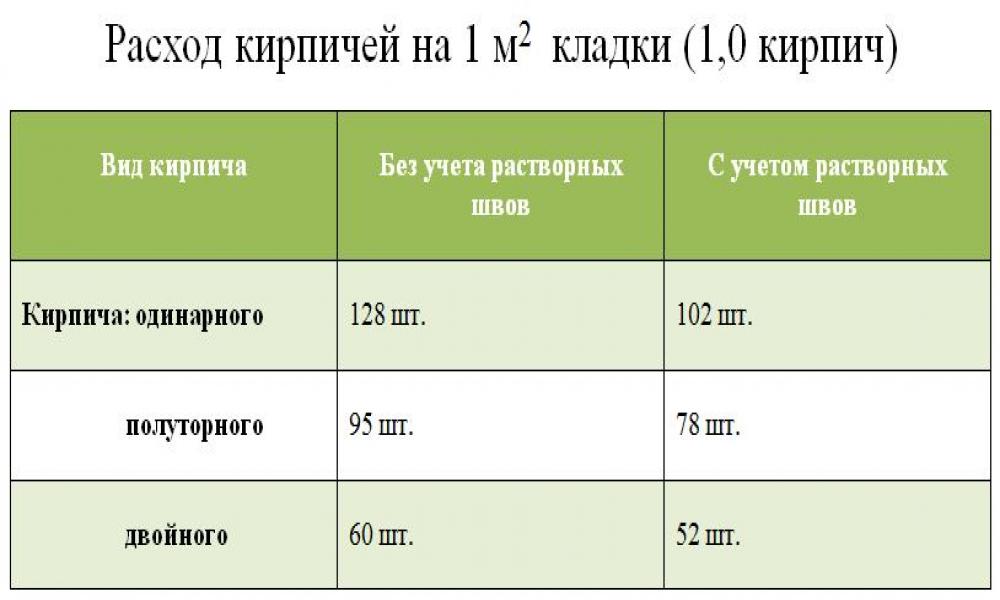

Based on these dimensions, as mentioned above, the number of bricks in one cube is 512-513 pieces.

And in order to calculate the number of bricks in a cube of masonry, you should add the size of the joints that the mortar occupies.

For example, if we take the size of the seam - 1 centimeter, then the number of building bricks in a cube of masonry will be about 394-395 pieces.

One and a half brick, differs in that it has a height of 88 millimeters. One-and-a-half bricks in a masonry cube are about 378-379 pieces.

And when calculating how many bricks are in a cube of brickwork, taking into account a seam of 1 centimeter, the number of bricks will be 302 pieces.

The double brick has a height of 138 millimeters. Most often it is hollow inside. Without taking into account the mortar, the number of double bricks in 1 cube is 242 pieces.

And the number of double bricks in a cube of masonry will be about two hundred pieces, with seams equal to one centimeter.

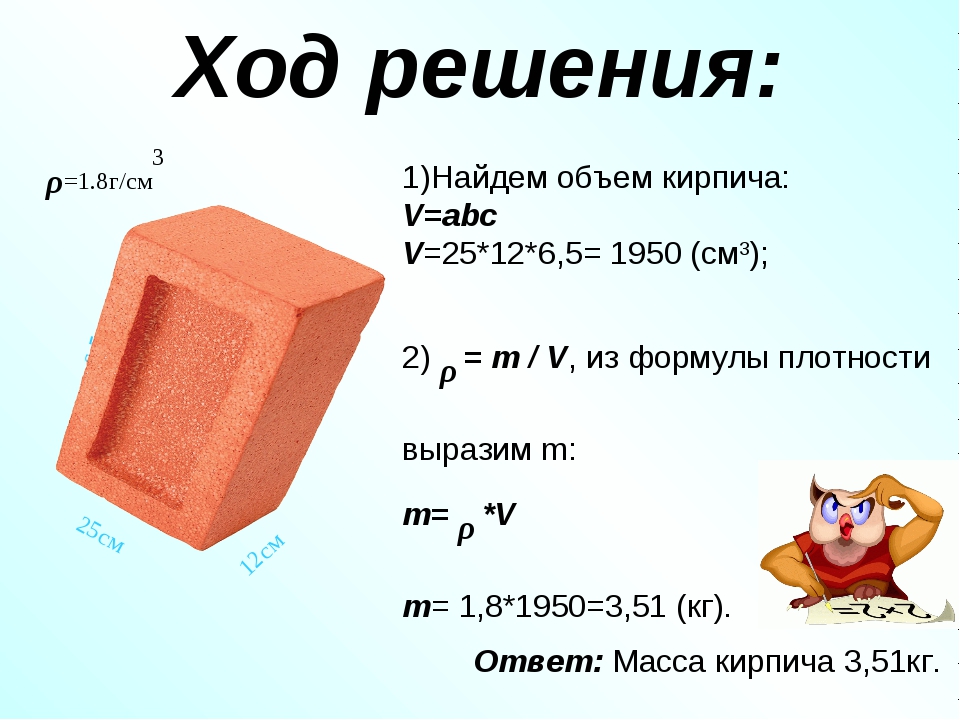

How to calculate how many bricks are in a cubic meter

In addition to standard sizes, there are custom bricks. In this regard, I would like to know by what principle how many pieces of bricks are calculated in a cube.

In order to determine how many bricks are in 1 cubic meter of clean brick, excluding seams, you must:

- Calculate the volume of one brick, in meters;

- Divide the Unit by the obtained value;

- Round the resulting number to an integer value.

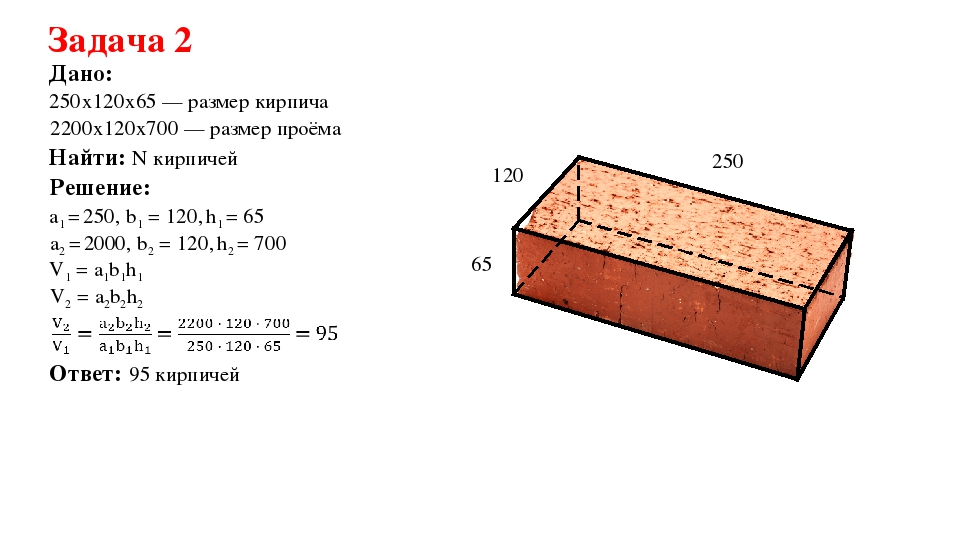

Let's calculate with a specific example.

As you know from school, to determine the volume, you need to multiply the length, height and width of the product.

Let's calculate the volume of a single, standard brick 250x120x65. Just so as not to get confused in the calculations, let's immediately convert millimeters to meters. So that everything is in the same units.

There are one thousand millimeters in one meter, which means that you need to divide the length, width and height indicators by one thousand.

The volume of one cube is equal to one. As you remember, the volume is calculated by multiplying the width, height and length, that is, 1 * 1 * 1 = 1 cubic meter.

Now we divide the unit by the volume of one brick and get - 1: 0.00195 = 512.82

The resulting value is rounded to the nearest whole number. This will be 512 full bricks, or slightly less than 513 bricks.

How many bricks are in one cube of masonry

Calculating how many pieces of single brick in a cube of masonry, you need to add the approximate height of the mortar to the height.

Let's take, as in the example above, the height of the seam for one centimeter, that is, 10 millimeters. Add to the brick height and get - 75 millimeters or 0.075 meters.

The same applies to the length of the brick. As you can imagine, there is also a mortar between the bricks in the masonry. 250 millimeters plus ten equals 260 millimeters or 0.26 meters.

In a similar way, you can calculate as many conventional bricks in a masonry cube.

Conditional brick means:

- How many silicate bricks are in one cube;

- How many basement bricks are in a cube;

- How many red bricks are in the cube, and so on.

The number of cubes in one thousand pieces of bricks

Sometimes it is required to calculate how many cubic meters are in a certain number of bricks. This is not difficult to do.

For this you need:

- Calculate the volume of one brick;

- Multiply the resulting value by the amount.

For example, we have one thousand standard, single bricks. As in the examples above, we will convert all values to meters and multiply the height, width and length.

That is, almost 2 cubic meters. Which, however, has already been seen from the example above. Where we got the result a little more than 512 bricks per cubic meter. Accordingly, in two cubic meters there will be one thousand and fifteen whole bricks.

When calculating bricks in masonry, do not forget to take into account the volume of the mortar. Which is added to the height and length of the brick.

And in the case when the masonry is not in one brick, for example, during the construction of columns, then the volume should be added to the width of the brick.

How to calculate the number of bricks in a cubic meter

Useful articles:

Brick fence reliability and protection;

How to make a new opening in a brick wall;

DIY brick fireplace;

Brick stove for a bath: reality or luxury;

Brick wall;

Brick cottage: briefly about everything;

Show off your hand-built brick barbecue to your friends;

Let's make a dream brazier out of bricks;

What you need to know about brick for the construction of a stove or fireplace.

How to determine how many brick units are in 1 m3?

First of all, you need to find out the typical dimensions of the building material. Single ceramic bricks are the most common. It is used in the construction of foundations, erection of walls of buildings inside and outside, outbuildings, etc.

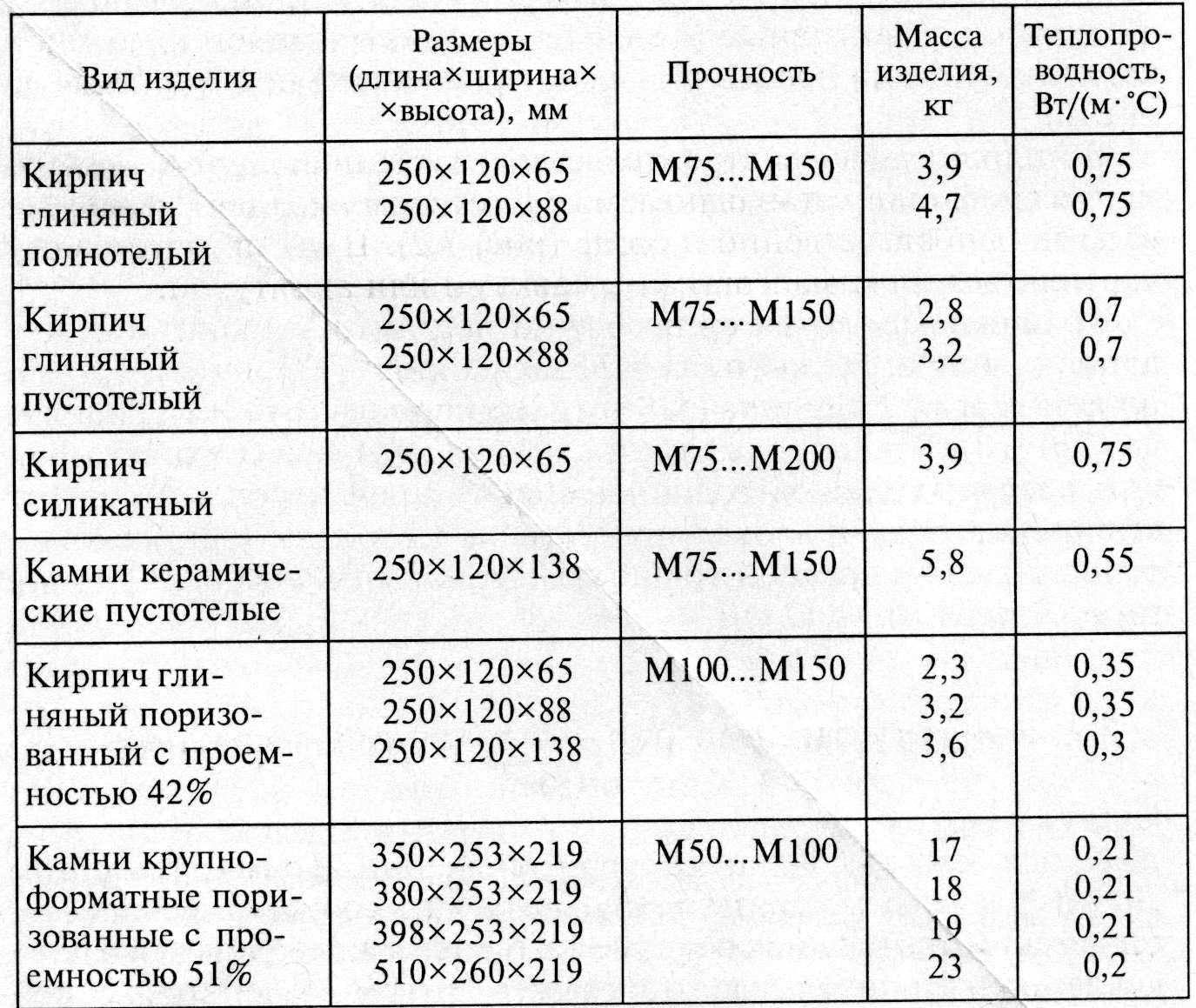

According to the requirements of GOST 8394-73, a working brick has clearly established dimensions: length - 25 cm, width - 12 cm. Height is 6.5 cm. The use of such dimensions is most convenient when laying rows along and across. If you need to reduce the construction time of a house, a one-and-a-half brick with dimensions of 250x120x138 mm is used. The double material has dimensions of 250x120x138 mm. But due to their low durability, double bricks are not advised to be used in laying foundations and floors in the lower part of buildings.

How to calculate the amount of garbage

In order not to pay extra money for garbage disposal, the price of which depends on many factors, it is necessary to correctly calculate the volume of waste. The experts of MosMusorovoz company competently calculate the amount of garbage, the cost of waste disposal and the time frame for the completion of work. However, you can make calculations yourself if you want to estimate in advance how much you can meet.

Formulas for calculating the volume and weight of garbage

Let's say you decide to dismantle an old building and order the removal of construction waste. First of all, you need to calculate the volume of the structure "in the air", in a real position:

1. We measure the length, width and height of the building. This should be done from the lowest foundation line to the highest point of the roof (ridge). We multiply three numbers by each other. This is the volume of the building in geometry.

2.Then we determine the actual volume of waste that will be disposed of. To do this, you need to divide the resulting volume of the building "in the air" by the coefficient of loosening. The latter is a generally recognized indicator: 2.0 - 3.0. It takes into account the spread of the resulting loosening after the destruction of the building. More reliable data are obtained using an indicator of 2.0 - 2.65. This also includes furniture, stoves and other "fillers" of the interior volume of buildings, if any.

Thus, we find out the real volume of garbage in the so-called solid, or dense body, that is, in an unassembled state.

3. The third stage is the calculation of the weight of waste requiring disposal. The real volume of waste removed must be multiplied by the Mob indicator. This is the average indicator of the volumetric mass of construction waste that is generated during dismantling. This indicator is separate for each type of material:

- when dismantling concrete structures: 2400 kg / m3; - when dismantling reinforced concrete structures: 2500 kg / m3; - when dismantling buildings made of brick, stone, plaster layers and facing tiles: 1800 kg / m3; - when dismantling structures made of wood and frame filling structures: 600 kg / m3; - when carrying out other dismantling works (excluding dismantling of metal structures and engineering and technological equipment, the indicators of such materials are calculated separately, based on the design data): 1200 kg / m3.

The resulting figure is the weight of waste in tons.

Garbage collection cost calculation

Now you know the volume and weight of future waste. To determine the budget, you need to calculate how much equipment will be needed for recycling and what kind of equipment will be needed.

Let's take as a basis the resulting volume of garbage (not weight) and the type of waste. Light trash with a large enough volume requires containers. This includes timber, wood, logs. For heavier waste, closable bins for larger loads will be needed. These types of waste include brick, concrete debris, soil masses.

Garbage collection by container

If your garbage type allows you to use a container, determine how much of the container will be most beneficial for you. Thus, the MosMusorovoz company provides the opportunity to use containers with a volume of 8 cubic meters, 20, 27, 30 and 32. Divide the volume of waste that you plan to dispose of by the volume of one container. If the resulting figure is more than 4, choose a container with a larger volume - this way you can save money.

Garbage removal by dump truck

The same calculations can be made for the volume of the bins. The resulting number of required containers or bunkers, multiply by the cost of one. So you will approximately calculate the amount of money that will be spent on the disposal of solid waste or other waste classifications.

Factors affecting the cost of garbage collection

Such calculations will be approximate. Why? The following factors affect the real value:

- the type of garbage movement (it can be horizontal and vertical); - distance of movement of garbage from the point of dismantling to the container (sometimes it is not technically possible to drive closer);

- packing waste into bags;

- the number of workers and the deadlines to meet.

The final cost should be discussed with the experts of the waste collection company. MosMusorovoz will be happy to help you with calculations and waste disposal.

Garbage disposal in a container of 8 m3 From 5500 rubles.

Garbage removal in a container of 20 m3 From 12,000 rubles.

Garbage removal by container 27m3 From 13500 rub.

Garbage removal in a 32 m3 container From 14,000 rubles.

Ready to order your garbage collection? Do you need a consultation or a quote? Leave your contacts and our specialist will contact you

garbage volume, calculate garbage volume, garbage collection,

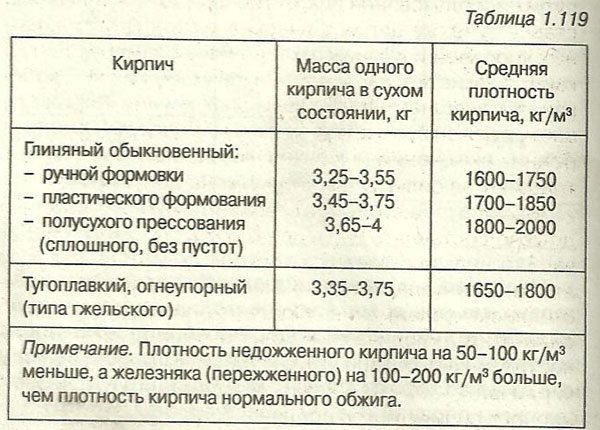

Weight characteristics of materials

For the manufacture of brick stone used in the construction industry, various materials are used, differing in performance and production characteristics of the process. All factors together set the parameters of the brick material, which is considered the most common of all the others.

Ordinary brick

Ceramic brick stone is obtained from fired clay. The material has a high strength index, perfectly retains thermal energy, and successfully withstands environmental influences. Moreover, its weight is quite large - from 3.5 to 3.8 kg. To reduce this figure, manufacturers began to manufacture the hollow material, keeping its original dimensions. The weight of such a brick is only 2.5 kg.

It follows from this that the solid dimensions of the material ready to work do not always mean that it weighs a lot, because this indicator depends on the structural structure of the stone.

The specific gravity of brickwork of 1 m3, lined with solid bricks, will be equal to a similar volume of hollow material, because it is determined without taking into account hollow sections, but the volumetric weight will differ significantly.

In addition to these types, a brick stone is made for wall decoration, which differs in other dimensions.

This material used in the construction industry has a long history of origin, because it used to be made of clay, dried and put into business. The degree of strength of such a material, as well as the service life, left much to be desired, because the stone quickly collapsed from the effects of moisture and the sun.

Today, ceramic material is fired in kiln installations that create the required temperature regime.

When choosing a ceramic stone, you should pay attention to its main parameters:

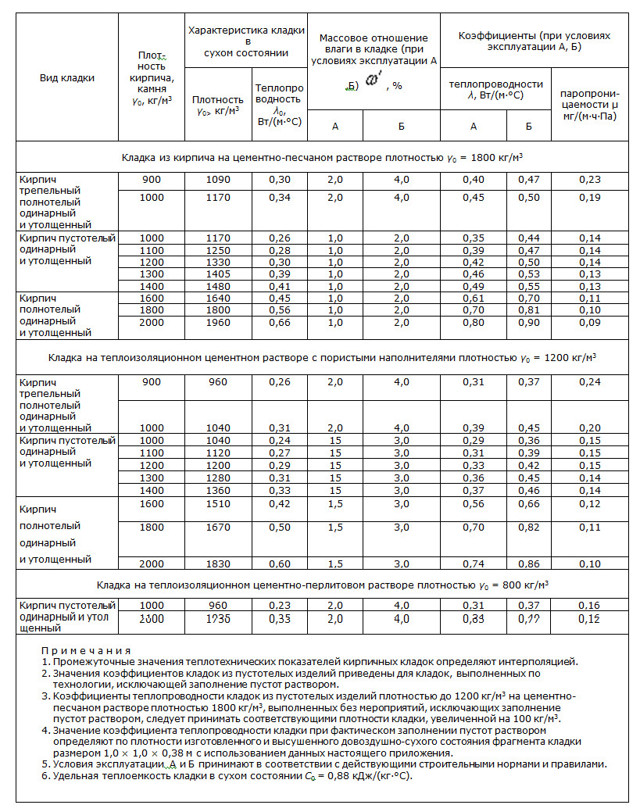

- the weight of 1 m3 of ceramic brickwork reaches 1.7 - 1.9 tons;

- the heat conductivity index is 0.65 - 0.7;

- the water absorption coefficient does not exceed eight percent, which is made possible only due to the porosity of the structure;

- the brand of brick stone depends on its strength and compressive resistance, denoted by numbers from 75 to 200;

- a special characteristic is frost resistance. It is determined in a cyclical way, and, if the material is of high quality, it can withstand up to fifteen freezing and thawing processes.

A large number of brick stone properties depend on the firing temperature.

Silicate brick

In construction, this material is also popular and is considered the heaviest.

The material is distinguished by good soundproofing qualities, a long operating period, exceeding the service life of the red analogue. It is divided into working and facing stone.

The mass of brickwork in 1 m3 is influenced by the structural structure of the material:

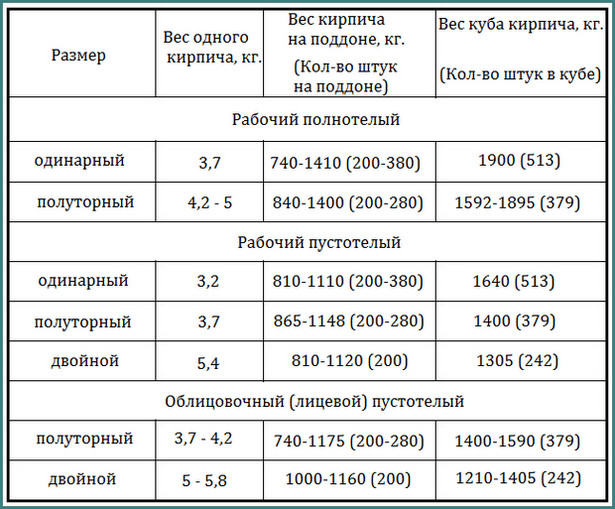

- an ordinary brick weighs 3.7 kg;

- having voids - 3.2 kg.

It is quite natural that the parameters of one cubic meter of masonry are also different.

The first production of silicate material began in the nineteenth century. Brick is made from:

- sand, cleaned of impurities and corresponding to certain characteristics;

- quicklime;

- specially prepared industrial water;

- additives and additives that increase the value of the strength of the material.

Especially popular today is a double silicate brick, which has improved characteristics. It is produced as follows:

- all ingredients are mixed in certain proportions established by the technological documentation;

- the composition is molded, sent to autoclaves for firing;

- the products are subjected to high pressure in order to achieve the desired compaction of the brick material.

Cement mortar

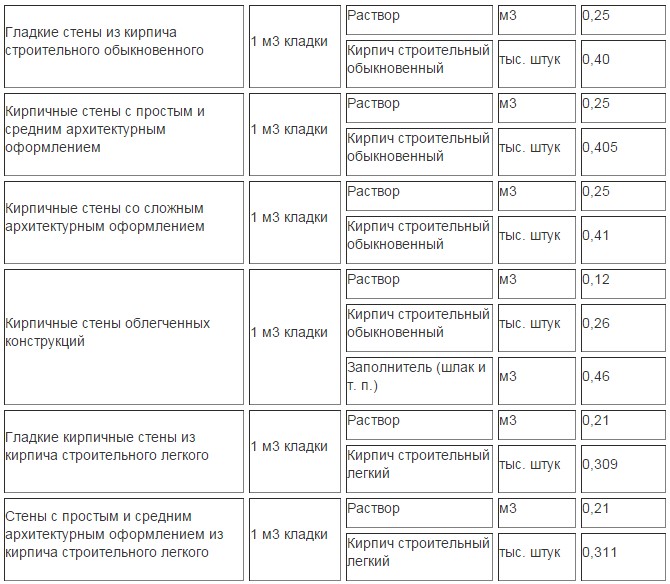

The consumption of mortar material depends on numerous parameters - the dimensions of the brick, the width of the seam row, etc.

Wide seam areas increase mortar consumption.In addition, the weight of the solution is influenced by the brand of cement material and its volume required to prepare the mixture. As a rule, up to 0.3 m3 of mortar is required for laying one cubic meter of masonry, which will be approximately five hundred kilograms.

Weight of 1 m3 of brickwork

The quality factor of brickwork depends on the type of building material and the correctness of its laying.

To determine the number of bricks per cube of masonry, it is necessary to take into account the volume indicators of the entire structure. In addition, the consumption of material is determined by the typical characteristics of the brick and the thickness of the joints.

The raw materials used in the manufacture and the processing conditions determine the dimensions (see Standard size of red brick) and the specific gravity of the brick (see Weight of sand-lime brick). With regard to brickwork, this parameter also depends on the number of seams, the mass of the mortar used and the type of masonry. Thus, the specific weight of brickwork is in the range of 1400-1990 kg / m3. The next value required for the calculation is the volumetric weight (unlike the previous one, the presence of voids and pores is taken into account).

The mass of the masonry wall must be calculated in order to determine the optimal and boundary loads on the base. This value predetermines not only the type of foundation to be built and its material, but also many other design and design parameters.

Today, brickwork remains the most common type of wall. It is characterized by stability and strength, along with this, it has a decent mass, which affects the foundation of the building.

The most demanded material in this case is red brick, the standard dimensions of which in millimeters are as follows: 250x120x65, weight - about 4 kilograms. Rough counting takes place because each brick has structural voids, which are allowed by the standards, but their number is not constant. That is why it is more expedient for calculations to take the weight of 1 m3 of brickwork, and not one brick.

When designing any structure, many nuances must be taken into account. In order to fully compose a picture of the upcoming loads on the building, plan the base and correct the dimensions of the building, you need to familiarize yourself with the technical characteristics of the material - brick.

Through these parameters, it is possible to give an objective assessment of the bearing capacity and strength of the future building, therefore, when designing, they must be taken into account.

Quite often, the decent weight of a brick wall prevents the use of this material. This is not possible if the ground under the base of the building is unstable, moist or mobile. In such cases, alternative materials are used that have an advantage over traditional red bricks in weight:

- expanded clay concrete blocks;

- foam concrete;

- gazosipikate;

- cinder blocks.

Indeed, all of the above materials allow you to build fairly practical and lightweight buildings in less time and with some savings. Nevertheless, they are significantly inferior in strength to classic bricks, and some of them shrink during operation.

Do not forget that the weight of the masonry cube can be affected by the reinforcement of the walls or individual components of the supporting structures. Sometimes the mass of mortar and reinforcing mesh is not inferior to the weight of the entire wall (see.Cement consumption for brickwork)

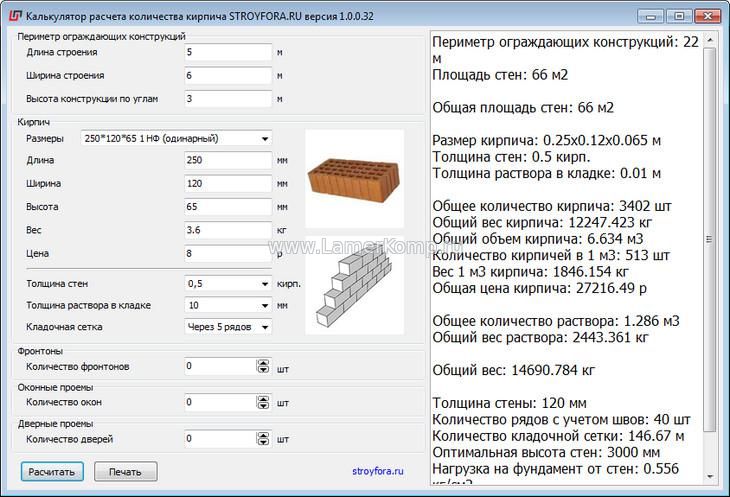

Calculator Purpose Information

Online brick calculator is designed to calculate the number of building and facing bricks for a house and a basement, as well as related parameters and materials, such as the amount of masonry mortar, masonry mesh and flexible ties. Also, in the calculations, the dimensions of the gables, window and door openings of the required number and size can be taken into account.

When filling in the data, pay attention to the additional information with the Additional information sign

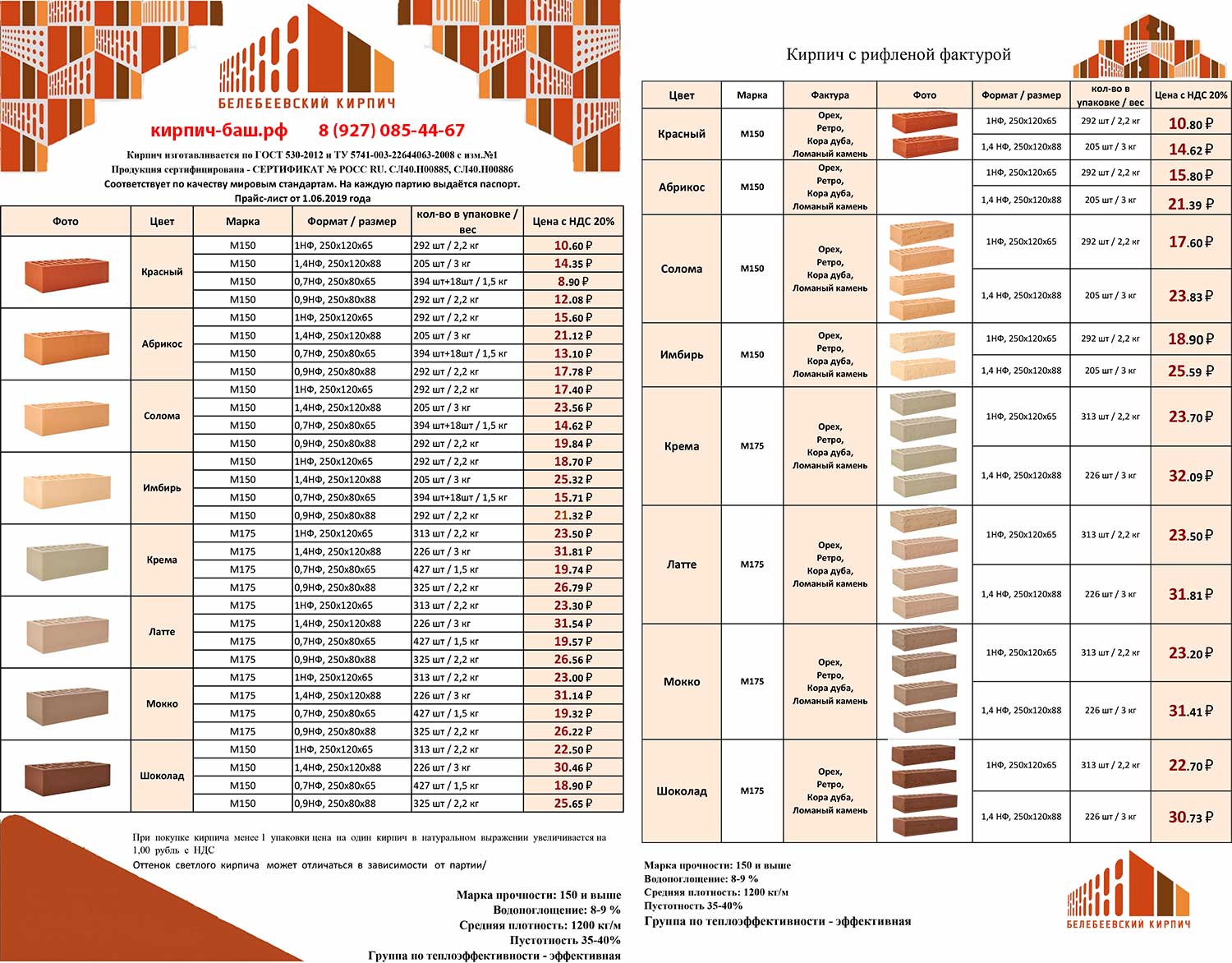

For a long time, brick has been the most demanded, widespread and common building material for the construction of durable and reliable structures. This situation persists for a number of reasons, despite the emergence of new, modern and cheaper building materials. There are several of the most common types of bricks for any building needs:

- from clay and various fillers

- (most common) of burnt clay

- from sand and lime

- from lime and cement

- made of special baked clay

- (fireclay) from refractory clay

Ceramic brick (clay), according to their purpose, are subdivided into facade, ordinary and clinker. Ordinary bricks (backing bricks) may not have ideal geometry and in most cases are used for laying rough walls of houses, basements, garages, which are subsequently plastered, painted and protected with facing materials and coatings. Its color has various shades of red.

Facing (front) is used for the construction of walls without any additional finishing in the future. There are also various special types of facade bricks that can withstand high mechanical loads and adverse weather conditions, and are usually used for paving paths, building all kinds of retaining fences, stairs, walls.

Clinker has an ideal smooth surface, various shades of red and black colors and has a high density.

Silicate is a light-colored calcareous-silicon artificial stone. Silicate brick differs from ceramic brick in that it is not fired during the manufacturing process. It is quite hygroscopic, and, accordingly, is not used for the construction of objects that will be operated in humid environments, such as basements and basements.

Also, silicate brick is not used in the construction of furnaces, pipes, chimneys and foundations, since it can withstand external destructive loads rather weakly.

Refractory It is divided into several types and is used for the construction of structures exposed to high temperatures, such as stoves, fireplaces, chimneys and smelters. The most common is fireclay brick, has a yellowish tint, made of special refractory clay (fireclay) and, unlike ordinary clay brick, can easily withstand high temperatures (up to 1400 grams), as well as numerous heating and cooling cycles without loss of strength.

Bricks are solid (the volume of voids is not more than 25%), hollow and porous-hollow. It is believed that indentations and voids in the material not only reduce weight, but also significantly increase the overall strength of the masonry by increasing the contact area between the brick and the masonry mortar.

The most common standard brick size: 250 - 120 - 65 mm (length - width - height), the so-called first "normal form" (1NF).

When calculating the number of bricks required for work, a rule called "format" is usually used, in which the dimensions of the brick itself are increased by 10 mm (this is the standard seam thickness), that is, it turns out: 260x130x75 mm.

Below is a complete list of calculations performed with a brief description of each item. If you did not find the answer to your question, you can contact us by feedback.

What affects weight?

The mass of the masonry is primarily influenced by the material for making the brick. The lightest are ceramic products, for the manufacture of which clay and plasticizers are used. Products are molded using a special press, and then sent to the kiln for firing. Slightly heavier are silicate and hyper-pressed products. For the manufacture of the former, lime and quartz sand are used, and the basis of the latter is cement.Clinker models are also quite heavy, made from refractory clay grades, followed by firing at very high temperatures.

In addition to the material of manufacture, the type of brick execution has a huge impact on the weight of a square meter of masonry. On this basis, two large groups of products are distinguished: solid and hollow models. The first are monolithic products of regular shapes that do not contain shaped holes and internal cavities. Solid stones weigh on average 30% heavier than their hollow counterpart. However, such a material has a high thermal conductivity and is rarely used for the construction of load-bearing walls. This is due to the absence of an air gap in the brick body and its inability to prevent heat loss in the premises during the cold period.

Hollow models are distinguished by higher performance characteristics and lighter weight, which allows them to be most actively used in the construction of external walls. Another factor affecting the mass of brickwork is the porosity of the brick. The more internal cavities a product has, the higher its thermal insulation qualities and lower weight. To increase the porosity of ceramic models, sawdust or straw is added to the raw materials at the production stage, which burn out during the firing process and leave a large number of small air voids in their place. This allows for the same volume of material to significantly reduce its weight.

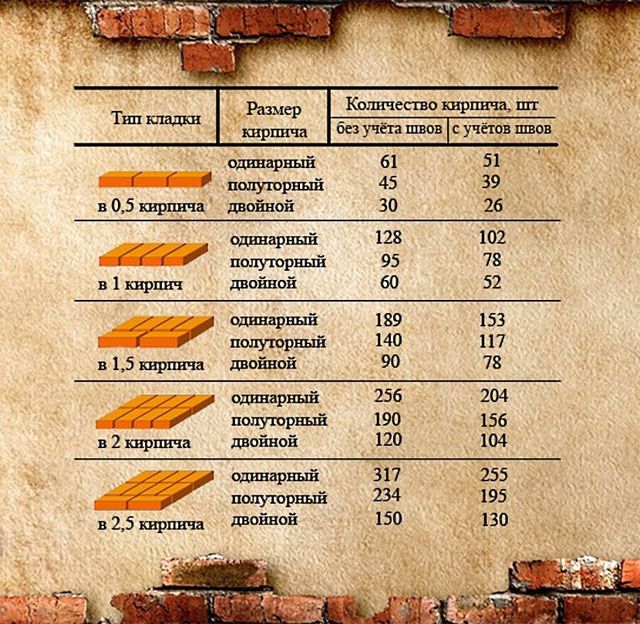

Calculations taking into account the thickness of the seams

When calculating the need for bricks for construction, it is necessary to take into account the thickness of the mortar joints.

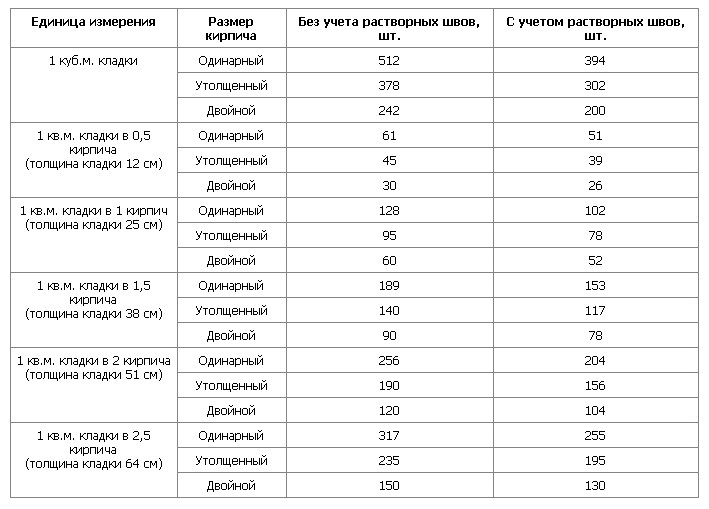

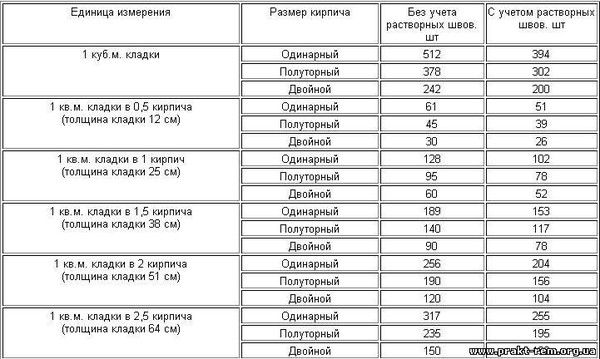

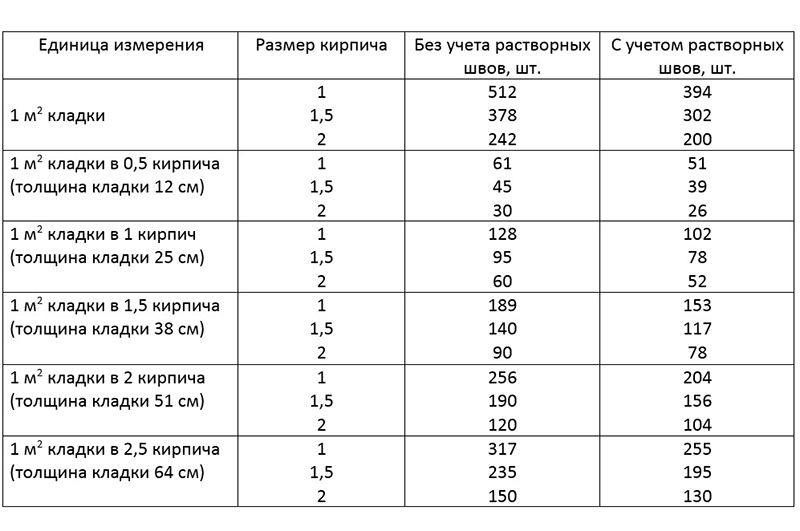

The task of determining the number of bricks. which will be contained in one cube of erected masonry, you cannot call it simple. We will have to take into account the thickness of the mortar joints, and the fact that when using single, one-and-a-half and double bricks, we get a different number of joints. In order not to over-complicate the task, it is better not to be guided by calculations, but to turn to practice. Repeated calculations show that the approximate number of bricks in one cube of masonry, taking into account the average thickness of mortar joints, is as follows:

- single - 394;

- one and a half - 302;

- double - 200 pieces.

In addition, the result also depends on the thickness of the masonry, and this dependence is quite complex. With a small amount of work, the error in the calculations will also be small and can be ignored. If the volume of work is large, the error may become unacceptably large. Then you can’t neglect it.

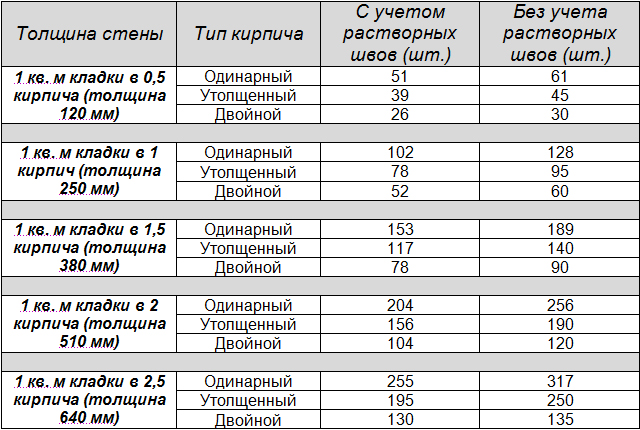

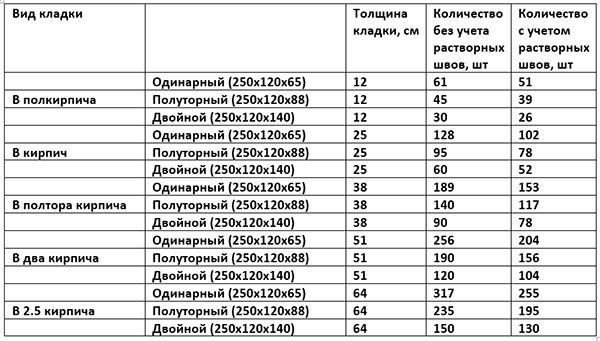

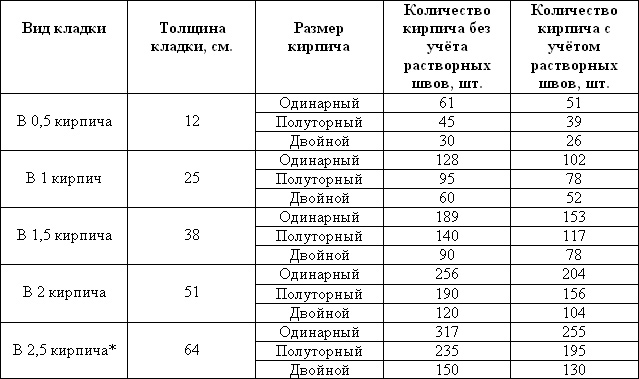

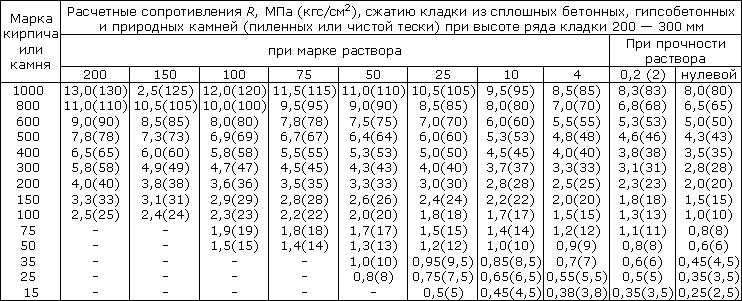

In this case, you can use the data on how many bricks of single, one-and-a-half or double size are required to build one square meter of masonry area with a given thickness. These data can be summarized in the following table:

Masonry thickness in bkirpichi

Further calculations are already relatively easy to carry out. You only need to know the total area of the side surface of the wall in square meters. Multiplying the number taken from the desired cell in the table by the masonry area, we get the desired result.

Let's look at a specific example.

Suppose you need to build an internal partition 38 cm thick, 7 m long and 3 m high from a single brick. We start the calculation:

- We find the area of the side surface of the wall - 7 m * 3 m = 21 sq. m.

- In the table we find the number of bricks per 1 sq. m - 153.

- Their total number in the partition is 153 * 21 = 3213.

Knowing the exact number of bricks required for construction will allow you to use them to the maximum, without unnecessary leftovers. You should not just forget about the percentage of the fight - at least 5% of the total. When bonding the inner walls with the front ones, the flow rate can increase by 12%. If various kinds of excesses are planned: arches, ledges, framing, overlaps - you should focus on 15% losses.

How to calculate the volume of the masonry?

There are 2 ways to count:

- Online calculator. The easiest option.

- Measuring device, tape measure.Next, a special formula is used to determine the volume, as well as to calculate the material for masonry. This option will significantly reduce the speed of work.

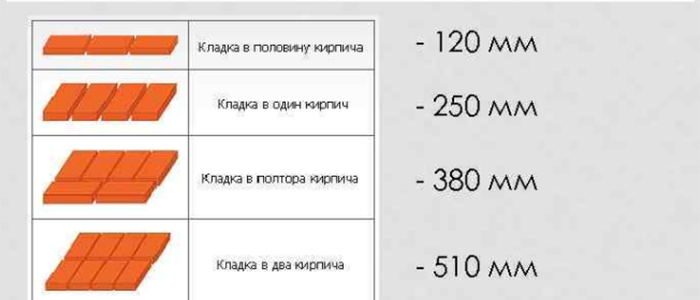

In order for the determination to be made accurately, you need to know the thickness of the masonry. According to it, in the end result, one of the most important characteristics of a structure is assessed: reliability and safety. Masonry can be of the following types, details about them in the table:

| Brick masonry type | Thickness, mm |

| In half a brick | 120 |

| IN 1 | 250 |

| 1,5 | 380 |

| 2 | 510 |

| 2,5 | 640 |

Calculation of the amount of material

When calculating the volume of masonry, you should also take into account the size and volume of the brick. Details on this in the table:

| View | Size, mm |

| Single | 250×120×65 |

| One and a half | 250×120×88 |

| Double | 250×120×138 |

Formulas used to determine

After determining the rows of masonry, you must subtract the area for each surface separately. For this, a mathematical formula is applied: S = l x h, where l is the length in meters, h is the floor height in m, S is the wall area. This method is suitable for calculating both external and internal surface areas, partitions, window and door openings. To calculate the volume of masonry per floor, the results obtained must be multiplied by the thickness of the masonry. To calculate the volume of walls and partitions, there is the following formula for the example of the main load-bearing wall: V = (F-F1) * b, where:

- V is the volume in m3;

- F is the surface area, in m2;

- F1 - area of window and door openings;

- b - surface thickness, m.

Volume when building lintels

When building any structure, there are rules that must be followed. The scope of work should include architectural details: cornices, parapets, loggias, which are built from the material that is provided for by the norms. Small details up to 25 cm are not included in the total. And also you don't need to include the following elements:

- columns made of reinforced concrete;

- inter-wall connections;

- thermal panels;

- foundation bars;

- niches for built-in tools.

The following elements are counted:

- hollows for finishing stripping of the bars;

- panel partitions;

- openings for heating and ventilation;

- holes for steps;

- niches for chimney channels.

Scope of work on laying ovens

It is necessary to count the cubic capacity of heating fireplaces, chimney pipes without subtracting voids. But at the same time, cold quarters, as well as vertical and horizontal cuts, are not taken into account in the volume. The area should be calculated at the level of the section near the firebox, but the height is taken from the base to the end of the structure. If the stove has a lining, then the masonry cube is considered without taking into account the facing material. But at the same time, the area is considered along the outer edges of the sheathing.

What buyers and builders need to consider

According to the requirements of GOST 530-2007, single ceramic bricks are produced only with a size of 250x120x65 mm. A similar material is used if you need to lay out load-bearing walls and a number of other structures. Its severity differs depending on whether hollow or full-weight facing blocks will be laid. A red facing brick that has no voids will weigh 3.6 or 3.7 kg. And in the presence of internal grooves, the mass of 1 block will be at least 2.1 and maximum 2.7 kg.

When using a one-and-a-half facing brick that complies with the standard, the weight is 1 pc. taken equal to 2.7-3.2 kg. Both types of decorative blocks - single and one and a half - can be used to decorate arches and facades. Full weight products can contain a maximum of 13% voids. But in the standards for material including voids, it is indicated that cavities filled with air can occupy from 20 to 45% of the total volume. The lightening of the brick 250x120x65 mm allows to increase the thermal protection of the structure.

Additional Information

All of the above applies to ceramic facing bricks. But it also has a silicate variety. This material is stronger than an ordinary product, it is created by combining quartz sand with lime. The ratio between the two main components is selected by technologists.However, when ordering sand-lime bricks 250x120x65 mm, as well as when buying its traditional counterpart, you must carefully calculate the mass of the blocks.

On average, 1 piece of building material with such dimensions weighs up to 4 kg. The exact value is determined:

-

product size;

-

the presence of cavities;

-

additives used in the preparation of the silicate block;

-

geometry of the finished product.

A single brick (250x120x65 mm) will weigh from 3.5 to 3.7 kg. The so-called one-and-a-half corpulent (250x120x88 mm) has a mass of 4.9 or 5 kg. Certain types of silicate, due to special additives and other technological nuances, can weigh 4.5-5.8 kg. Therefore, it is already quite clear that a silicate brick is heavier than a ceramic block of the same size. This difference must be taken into account in projects, to strengthen the foundation of buildings under construction.

Hollow silicate brick measuring 250x120x65 mm has a mass of 3.2 kg. This makes it possible to significantly simplify both construction (repair) work and the transportation of ordered blocks. It will be possible to use vehicles of lower carrying capacity. In addition, there is no need to reinforce the walls. And therefore, the foundation of the building being built will be easier to make.

The situation is slightly different with hollow products. Such a single sand-lime brick weighs 3.2 kg. Standard packaging includes 380 pieces. The total weight of the pack (excluding the substrate) will be 1110 kg. Weight 1 cub. m. will be equal to 1640 kg, and this volume itself includes 513 bricks - no more and no less.

Now you can consider one-and-a-half silicate brick. Its dimensions are 250x120x88, and the mass of 1 brick is still the same 3.7 kg. The package will include 280 copies. In total, they will weigh 1148 kg. And 1 m3 of silicate one-and-a-half brick contains 379 blocks, the total weight of which reaches 1400 kg.

There is also chipped silicate 250x120x65 with a weight of 2.5 kg. In an ordinary container, 280 copies are placed. Therefore, the packaging is very light - only 700 kg exactly. Regardless of the type of bricks, all calculations must be carried out very carefully. Only in this case will it be possible to ensure the long-term operation of the building.

If you need to determine the weight of the masonry, you can skip calculating its volume in cubic meters. You can simply calculate the mass of one row of bricks. And then a simple principle is applied. At a height of 1 m there are:

-

13 rows single;

-

10 bands of one and a half;

-

7 strips of double bricks.

This ratio is equally true for both silicate and ceramic varieties of the material. If you have to revet a large wall, it is more correct to choose a one-and-a-half or even double brick. It is recommended to start your selection with hollow blocks because they are lighter and more versatile. But if there is already a solid, solid foundation, you can immediately order full-weight facing products. In any case, the final decision is made only by the customers of the construction or repair.

See below for details.