Useful information - how much rubble is in KamAZ 10 tons and in concrete

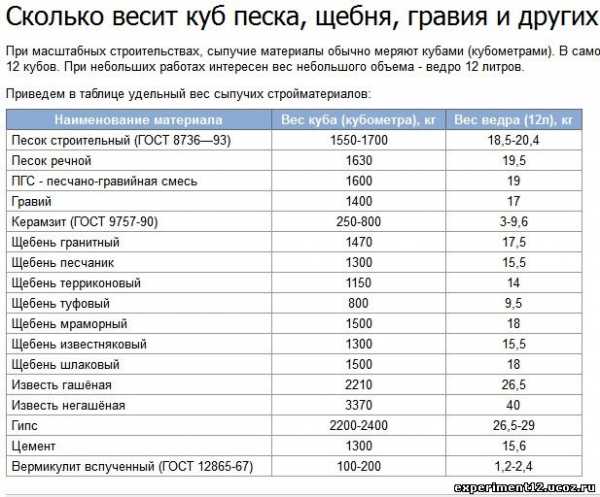

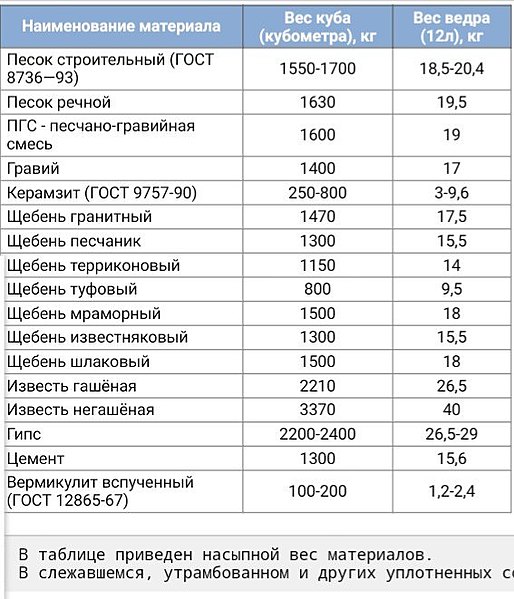

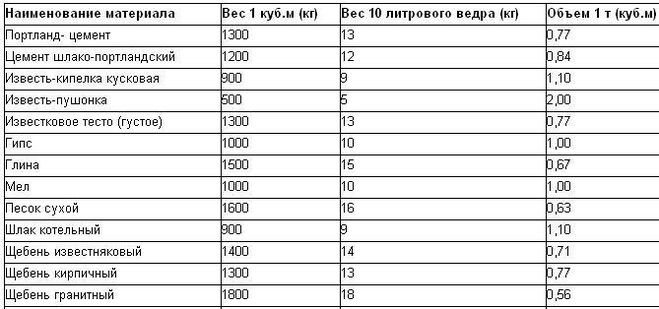

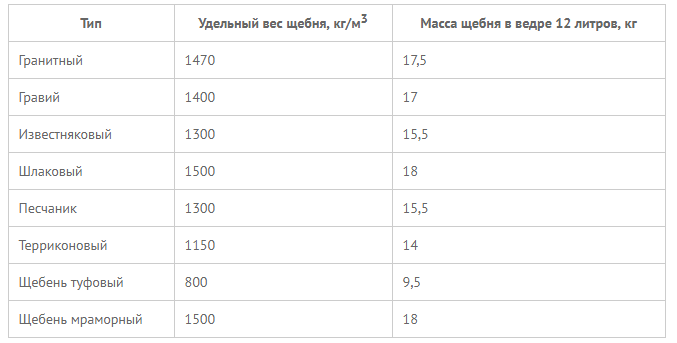

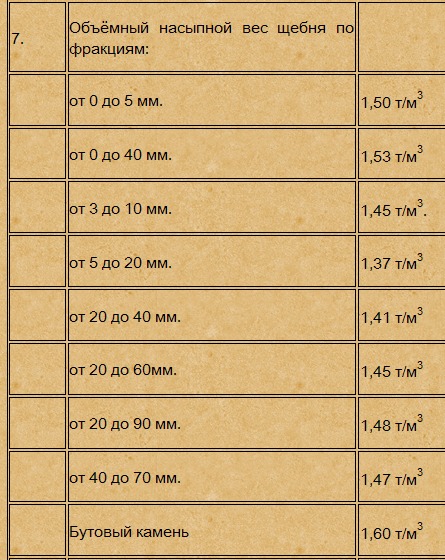

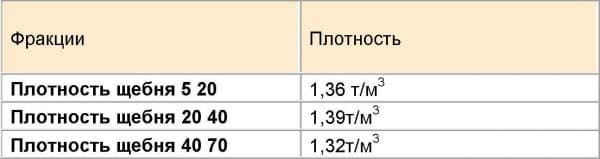

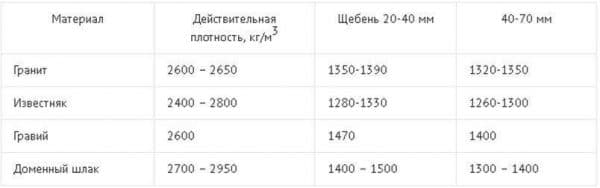

Departing from theory a little aside, you can consider real situations, for example, how many cubes of rubble in KAMAZ are 10 tons. After all, knowing that 8 m2 of crushed stone is needed, the question becomes which car will be able to deliver it. For the basis of the calculation, we take standard gravel crushed stone GOST 8267-93, fraction 40 70, which weighs 1600 kg.

To determine how much m2 of material KAMAZ will bring, the total transported weight of the truck is sufficient and divided by the weight of 1 cubic meter. That is 10,000 / 1,600, which is 6.25 m2. Based on the example, an insufficient amount of crushed stone is obtained.

Then you can do 2 ways: choose a less heavy material, sandstone will have a suitable volume, or order a more spacious car. In this case, 8 m2 * 1600 kg = 13 tons, this is the minimum carrying capacity of the car.

Let's take as an example the question, 10 cubic meters of rubble is how many tons. Without changing the type of material, you can calculate that 10 m2 * 1600 kg = 16 tons.So, in order to purchase 10 m2 of gravel, you will have to order several cars for 9 tons or one for 18 tons.

A similar question, 5 cubic meters of rubble is how many tons. Only this time we will consider the example of a limestone rock, the weight of which is 1330 kg / m3. Thus, 5 cubes have a mass of 6650 kg (1330 * 5), it can only be taken away by a car with a carrying capacity of 8 tons.

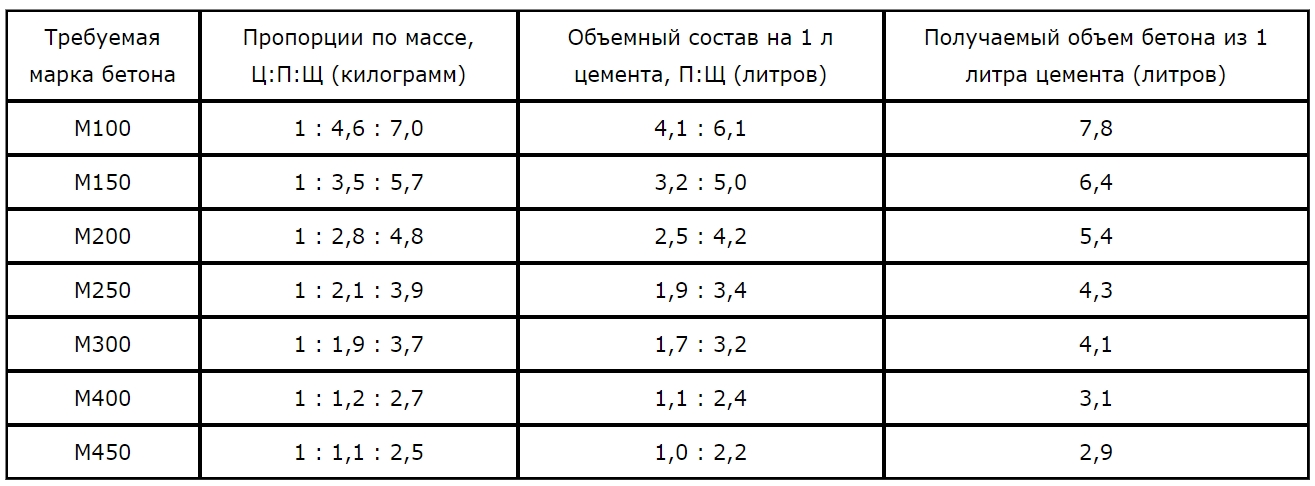

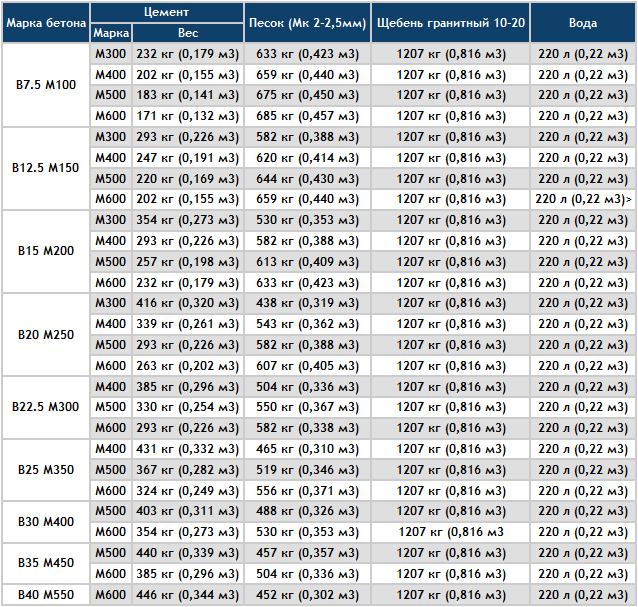

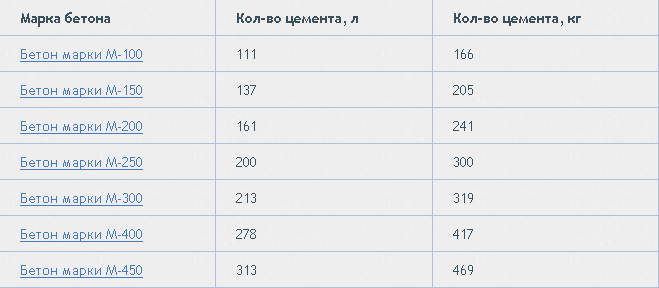

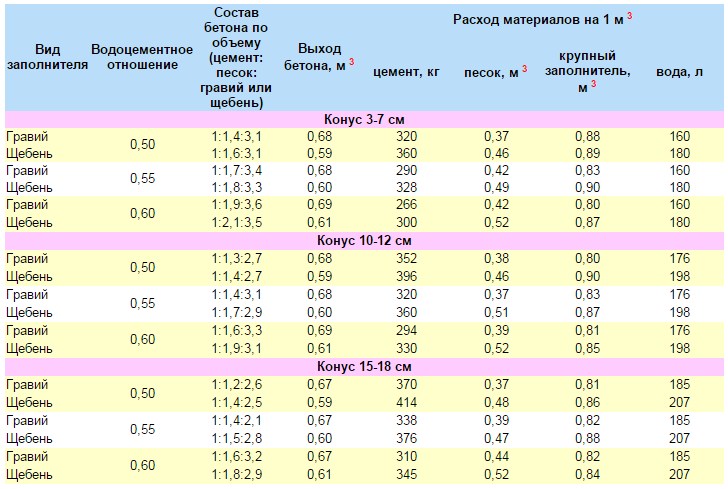

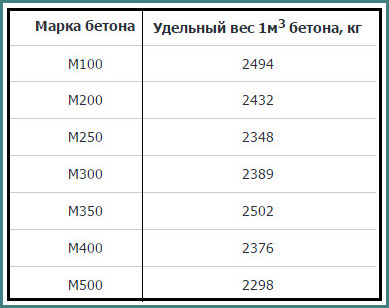

Another question is how many tons of crushed stone are in a cube of concrete. It is necessary to know it, since, in general, during construction, only the surface area is known, which will be filled with mortar.

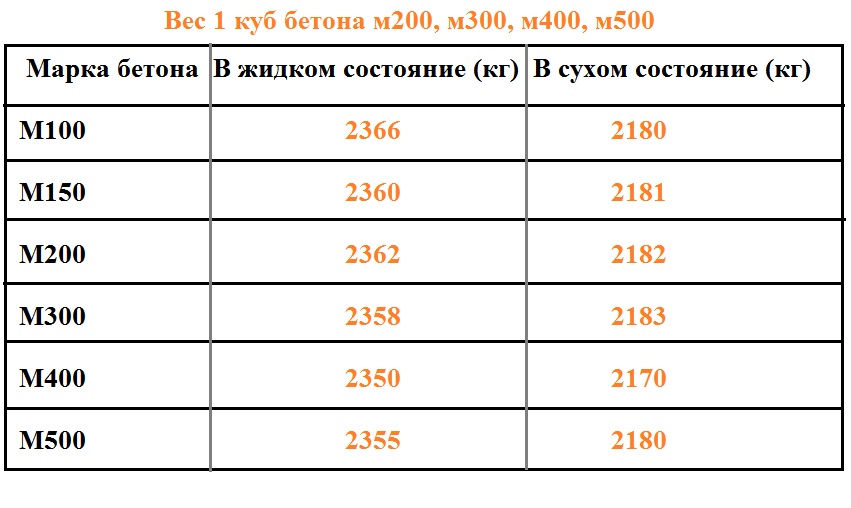

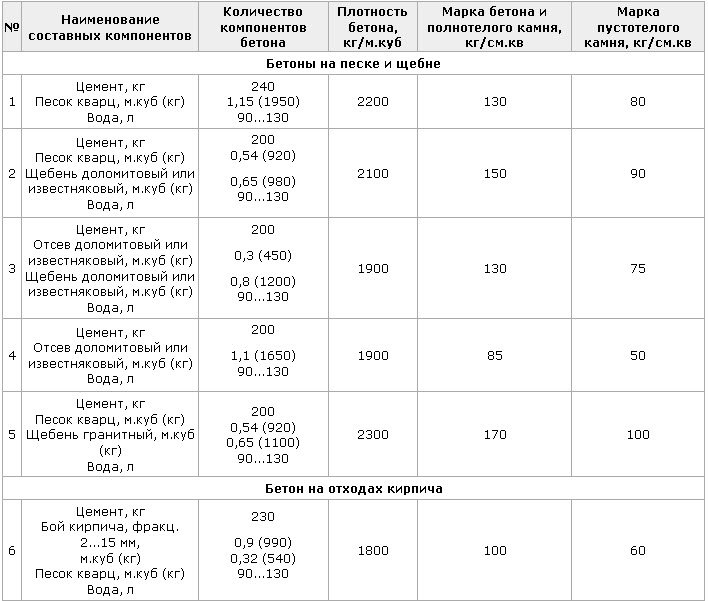

Now you need to determine the proportion of crushed stone, but it strongly depends on the ratio of ingredients when mixing concrete. According to the standards, for the preparation of the M300 solution, 1207 kg of crushed stone will have to be used, which is 0.816 m3.

Properties of standard silicate bricks

When choosing a white sand-lime brick, you need to pay attention not only to its size, but also to its characteristics. GOST regulates the following parameters of silicate white:

- Strength;

- Frost resistance;

- Fire safety;

- Heat conductivity;

- Moisture absorption.

The brand indicates its strength characteristics. So, silicate is produced in several brands M75, M100, M125, M150, M175, M200, M250, M300. The lower the grade, the lower the strength. The first grade material is recommended for the construction of one-story buildings. For the construction of 2 or more floors, it is better to use the brand starting from M100. Bricks М150-200, suitable for high-rise buildings.

Frost resistance is indicated by the letter F, indicates the number of freeze-thaw cycles that a brick can withstand. According to frost resistance, bricks are of 15, 25, 35, 50 brands. The degree of frost resistance is strongly influenced by the ability of the material to absorb water. The faster and the more moisture the material absorbs, the lower the frost resistance indicator. To increase this indicator, special water-repellent solutions are applied to the laid out masonry, thereby increasing the service life of the masonry. When choosing white bricks for construction in central Russia, it is better to use frost resistance grades from 25 to 50.

Fire safety of silicate lies in the absence of flammable components in its composition.

Heat conductivity is about 0.85 W / (mx C). This is a low figure, so the outer walls need additional insulation.

The main disadvantage of silicate bricks is the rate of water absorption. It reaches 10 percent, due to which the strength of the stone can drop by 25 percent. For this reason, it is not used in foundation construction or basement construction.

The relationship of quantity and weight

Once you've made the decision to build with bricks, it's only natural that the next step is to figure out the amount of building material you will need. This, in turn, will determine the cost of the entire project. Having designed the walls, you will have to calculate the ratio of length to height, in other words, area.

But that's not all, there must be an appropriate foundation under the new wall.

Of course, there is no such thing as an overly strong foundation, but it may turn out to be unreasonably expensive.

Summing up all the possible miscalculations, you can imagine how important it is to accurately calculate the weight and volume of the planned materials. Quite logically, the question arises, how much does one brick weigh? This is, so to speak, an elementary unit, knowing the weight of which, it is possible to determine the weight of 1 cubic meter

meters of products, convert indicators from pieces to tons.

Pallet location

How to calculate how much masonry is in a cube, taking into account the seams, and the volume of brick in m3, is understandable, but in order to avoid excessive overload, it is worth finding out how many products will fit in them and what is the maximum allowable weight

To determine this indicator, pay attention to:

- The material from which the bricks are made: silicate, ceramic.

- Stone sizes approved by state standards.

- The shape of each element: with or without voids inside. In the second option, the voids are contained in an amount of no more than 13%. They are used to lay out various types of walls. The weight of one such ceramic product is 3.3-4.7 kg, and silicate - 3.7-6 kg. Hollow voids represent 13-45% of the total structure. Air gaps are present in the composition of such bricks, due to which their heat transfer properties are reduced. Ceramic hollow stones weigh up to 5 kg, while silicate stones weigh a little more. Therefore, the shape and material of each product plays a role.

To determine how many kilograms a pallet filled with one-and-a-half bricks will weigh, take the weight of one stone and multiply it by the total.

To the general calculations, you need to add the weight of the wooden pallet itself, which is 30-40 kg. Pallets are used to bring materials to the right place. They are made of wood or metal. They can also combine several options. To determine the amount of stone in the pallets, you must first find out the standard dimensions of the products.

Usually, manufacturers in the accompanying documentation indicate information about how many products can be laid out on a pallet as much as possible. To calculate how many elements can be placed on it, you need to divide the maximum number allowed by the manufacturer and divide by the weight of the brick.

If the bricks are laid in an overlap or in the form of a herringbone, then the exact data will not work.

To make the material easier to calculate and transport, they prefer to lay it in the form of a cube. For stability, the structure is tied with a fixing tape. How many stones fit depends on their size.

What buyers and builders need to consider

According to the requirements of GOST 530-2007, single ceramic bricks are produced only with a size of 250x120x65 mm. A similar material is used if you need to lay out load-bearing walls and a number of other structures. Its severity differs depending on whether hollow or full-weight facing blocks will be laid. A red facing brick that has no voids will weigh 3.6 or 3.7 kg. And in the presence of internal grooves, the mass of 1 block will be at least 2.1 and maximum 2.7 kg.

When using a one-and-a-half facing brick that complies with the standard, the weight is 1 pc. taken equal to 2.7-3.2 kg. Both types of decorative blocks - single and one and a half - can be used to decorate arches and facades. Full weight products can contain a maximum of 13% voids. But in the standards for material including voids, it is indicated that cavities filled with air can occupy from 20 to 45% of the total volume. The lightening of the brick 250x120x65 mm allows to increase the thermal protection of the structure.

Additional Information

All of the above applies to ceramic facing bricks. But it also has a silicate variety. This material is stronger than an ordinary product, it is created by combining quartz sand with lime. The ratio between the two main components is selected by technologists.However, when ordering sand-lime bricks 250x120x65 mm, as well as when buying its traditional counterpart, you must carefully calculate the mass of the blocks.

On average, 1 piece of building material with such dimensions weighs up to 4 kg. The exact value is determined:

-

product size;

-

the presence of cavities;

-

additives used in the preparation of the silicate block;

-

geometry of the finished product.

A single brick (250x120x65 mm) will weigh from 3.5 to 3.7 kg. The so-called one-and-a-half corpulent (250x120x88 mm) has a mass of 4.9 or 5 kg. Certain types of silicate, due to special additives and other technological nuances, can weigh 4.5-5.8 kg. Therefore, it is already quite clear that a silicate brick is heavier than a ceramic block of the same size. This difference must be taken into account in projects, to strengthen the foundation of buildings under construction.

Hollow silicate brick measuring 250x120x65 mm has a mass of 3.2 kg. This makes it possible to significantly simplify both construction (repair) work and the transportation of ordered blocks. It will be possible to use vehicles of lower carrying capacity. In addition, there is no need to reinforce the walls. And therefore, the foundation of the building being built will be easier to make.

The situation is slightly different with hollow products. Such a single sand-lime brick weighs 3.2 kg. Standard packaging includes 380 pieces. The total weight of the pack (excluding the substrate) will be 1110 kg. Weight 1 cub. m. will be equal to 1640 kg, and this volume itself includes 513 bricks - no more and no less.

Now you can consider one-and-a-half silicate brick. Its dimensions are 250x120x88, and the mass of 1 brick is still the same 3.7 kg. The package will include 280 copies. In total, they will weigh 1148 kg. And 1 m3 of silicate one-and-a-half brick contains 379 blocks, the total weight of which reaches 1400 kg.

There is also chipped silicate 250x120x65 with a weight of 2.5 kg. In an ordinary container, 280 copies are placed. Therefore, the packaging is very light - only 700 kg exactly. Regardless of the type of bricks, all calculations must be carried out very carefully. Only in this case will it be possible to ensure the long-term operation of the building.

If you need to determine the weight of the masonry, you can skip calculating its volume in cubic meters. You can simply calculate the mass of one row of bricks. And then a simple principle is applied. At a height of 1 m there are:

-

13 rows single;

-

10 bands of one and a half;

-

7 strips of double bricks.

This ratio is equally true for both silicate and ceramic varieties of the material. If you have to revet a large wall, it is more correct to choose a one-and-a-half or even double brick. It is recommended to start your selection with hollow blocks because they are lighter and more versatile. But if there is already a solid, solid foundation, you can immediately order full-weight facing products. In any case, the final decision is made only by the customers of the construction or repair.

See below for details.

How many bricks are in 1 m2 of masonry: necessary parameters, options for calculating the required amount

It is possible to determine how many bricks are in 1 m² of masonry under certain conditions, on which the desired figure depends.

Therefore, before tackling the calculations, you should decide on the design features of the barrier being erected. The calculation itself will not cause any particular difficulties.

The number of bricks in 1 m² of masonry walls and partitions is the basis for determining the need for ceramite for the entire volume of construction.

note

When it comes time to plan the procurement of materials for the construction of summer cottages, their characteristics are usually already known: if it is a ceramite fence or an internal partition of a room, the masonry will be half a brick, a household shed is made thick as a whole block, and for the outer wall of a residential building no less than in one and a half ceramite. Depending on the purpose, the following main types of the main element of the masonry are distinguished:

- Red brick is the most durable, it is used in the construction of load-bearing structures and in terms of volume it can be single, one and a half, double.

- White silicate block is used for non-critical structures: internal partitions and gazebos, to give the facade an attractive look. This kind in the form of a double volume is not released.

- Facing ceramite is used to decorate individual structures of architectural objects, and can be single in size with deviations in one direction or another.

To determine how many bricks are in 1 m² of masonry, one must take into account the factors that affect the desired result: the first is the thickness of the walls. It was mentioned above, measured by the length of standard ceramite: ½ part, in a whole block, one and a half, two or more bricks.

The thickness of the mortar joints between the individual elements in the masonry is the third condition for the successful solution of the problem. In the full volume of the wall, approximately one fourth of the gaps are accounted for.

Dimensions of bricks and gaps

There is a state standard - GOST 530–2012 Ceramic bricks and stones, where the nominal dimensions of products and their designations are given. Ceramites are in the greatest demand:

| Dimensions, mm | Normal or single - 1NF | One and a half - 1.4NF | Double - 2.1NF |

| Length | 250 | 250 | 250 |

| Width | 120 | 120 | 120 |

| Height | 65 | 88 | 138 |

The inter-brick space is filled with cement mortar, the average joint size is taken as 1 cm.Standards for the thickness of brickwork, taking into account the filling of the gaps:

| Type of | 0,5 | 1 | 1,5 | 2 | 2,5 |

| Size, mm | 120 | 250 | 380 | 510 | 640 |

Calculation of the number of ceramites

Obviously, in one square meter of masonry of 1.5 bricks, the number of elements will be greater than with a wall thickness of one length of ceramite.

Therefore, several calculations are performed if the structure will include partitions with different characteristics, including the shape of individual blocks.

For example, you can calculate how many one and a half bricks in 1 m² of masonry in one ceramite. Sequencing:

- The size of the one-and-a-half element is fixed - 250x120x88 and the wall thickness - 250 mm.

- Along the length of one meter, taking into account the filling of the seams, (1000/260) * 2 = 7.69 pieces are placed.

- The number of blocks in height is 1000/98 = 10.20. Here it is not multiplied by 2 - this was taken into account by the previous action.

- The desired result is 7.69 * 10.20 = 78 pcs.

Alternative way

It is based on determining the surface area of a single masonry element and further shifting towards establishing the quantity depending on the wall thickness. The initial data remains the same as in the previous calculation. The algorithm of actions is as follows:

- The area of the lateral surface of one element is determined as 0.26 * 0.098 = 0.02548 m².

- For a half-brick wall, the number of blocks will be 1 / 0.02548 = 39 pieces.

- The required value according to the condition of the problem - the number of ceramites in 1 m² of brickwork with a thickness of brick will be 39 * 2 = 78 pcs.

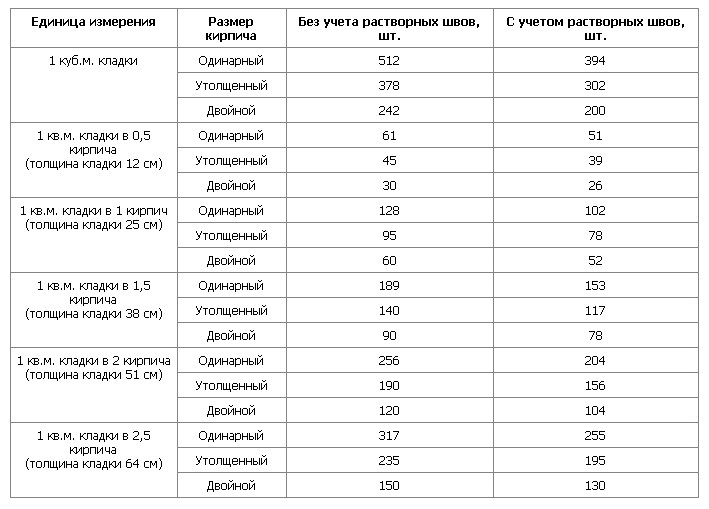

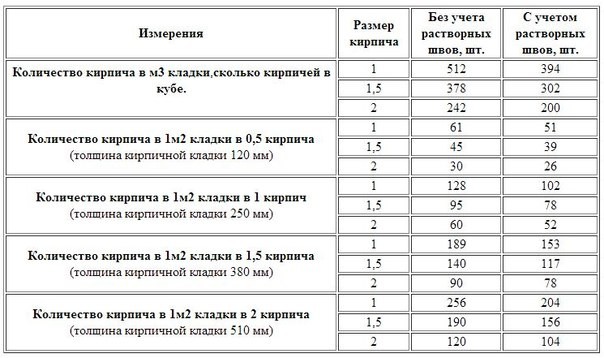

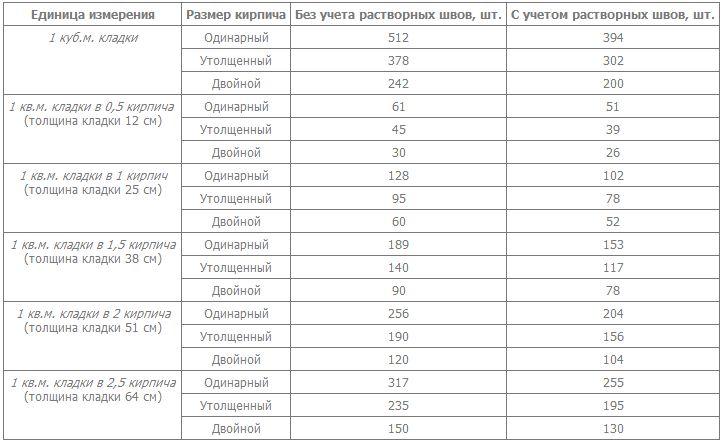

As you can see from the result, both methods gave the same answer. To simplify the use of data when determining the need for the purchase of materials, special tables are compiled, in which quantitative indicators are summarized for all options for ceramite masonry.

Table for determining the number of blocks in 1 m² of partitions

| Wall thickness in bricks | 1NF - single, pieces per 1 m² of masonry: close / with a seam | 1,4NF - one and a half, pieces per 1 m2: close / with a seam | 2.1NF - double, pieces in 1 m2: close / with a seam |

| 0,5 | 61/51 | 45/39 | 30/26 |

| 1 | 128/102 | 95/78 | 60/52 |

| 1,5 | 189/153 | 140/117 | 90/78 |

| 2 | 256/204 | 190/156 | 120/104 |

| 2,5 | 317/255 | 235/195 | 150/130 |

Using the table is simple: choose a value suitable for the conditions of the brickwork and multiply by the calculated area of the walls to be built with a given thickness. When determining the volume of the purchase, it is necessary to take into account that the amount of scrap in the purchased ceramite reaches 5% of the total number of bricks.

Required amount of equipment

Having determined the weight of the garbage, they proceed to the next stage - ordering equipment. If you correctly establish which car to order, you can seriously save money by avoiding unnecessary costs. It is the volume of waste (not weight) and the type of materials that must be taken into account: containers are quite suitable for light waste. It includes bars, wood of any kind, logs.

Having determined the weight of the garbage, they proceed to the next stage - ordering equipment. If you correctly establish which car to order, you can seriously save money by avoiding unnecessary costs. It is the volume of waste (not weight) and the type of materials that must be taken into account: containers are quite suitable for light waste. It includes bars, wood of any kind, logs.

When using a container, it is initially determined what capacity it must have in order for the disposal to take place as profitably as possible. They produce containers with a capacity of 8 m3, 20 m3, 27 m3, 30 m3, 32 m3. It remains to measure the amount of waste received and choose a more suitable option.

It would seem that such a frivolous moment as garbage requires a rather responsible approach. The main factor in solving problems with waste disposal is the ability to correctly determine their volume and weight.

Asphalt: historical facts

In Greek, "asphalt" means "mountain resin", and the ancient Egyptians and Babylonians were engaged in its extraction. The unique binding properties made asphalt a popular material for covering the surface of walls of buildings, roads, and giving strength to dishes. And how irreplaceable the asphalt was in shipbuilding! After all, ancient boats and ships, the hulls of which were impregnated with liquid asphalt, acquired exceptional moisture resistance.

Interesting: today there are natural deposits of asphalt on the territory of North America, the former USSR and Europe. The most ancient source of asphalt is the Dead (or Asphalt) Sea.

Specifications

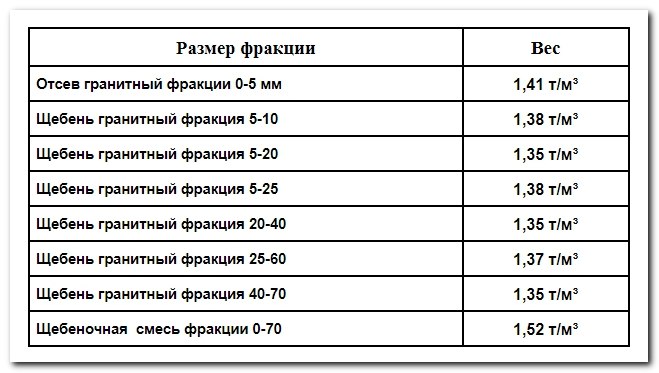

Flakiness

The flakiness index indicates the percentage of irregularly shaped particles to normal pieces of crushed stone. Impurities with needle-shaped and lamellar forms are generally considered undesirable.

Since the normal density of the material is impossible in the presence of such particles in the composition, voids are formed, due to which the weight of the crushed stone is reduced. Flakiness is defined as a percentage of the total mass of the material and the number of irregularly shaped particles.

The lower such impurities, the greater the weight, and, accordingly, the quality of the material. In the normal state, the crushed stone has the shape of a cube, therefore it fits well and is tightly fixed in the solution.

At the same time, the amount of the mixture is required less, and since the adhesive has a smaller area, the overall quality of the material increases, so high-strength concrete is achieved.

In fact, the norms allow flakiness, but if the manufacturer wants to ensure a higher quality of crushed stone, special techniques for removing particles will be used. Accordingly, such materials are somewhat more expensive.

Material purity

Of course, the type of rock is important, but the presence of impurities dramatically changes the quality characteristics of the material and changes its specific gravity. Here about the specific gravity of crushed stone 5 20 Ideally, the rock should be clean, but in real conditions it is unrealistic to achieve such an indicator

The permissible amount of impurities depends on the type of crushed stone and is regulated separately. The manufacturer of the accompanying documentation must fully disclose the quality characteristics of the supplied material and its composition.

Bulk density

In fact, the bulk density is used only when transporting and unloading material; during the construction process, crushed stone is compacted using a roller or manually.

Density

High-quality raw materials are less compacted, since the number of voids is already minimal. Ramming is ensured even when the material is laid down, during transportation, when forming a pillow, etc.

The best result can be achieved manually only with a vibratory plate, otherwise it is good to use the roller.

Density of various types

The better the material is purchased, the lower this indicator will be. Usually, with the correct shape of the crushed stone components, shrinkage is achieved only by 7-15%.

Dimensions and weight according to GOST

Standard sizes of single, one and a half and double products:

When designing buildings and structures, all characteristics are taken into account, including the overall dimensions and weight of the red brick.

Manufacturing products according to uniform dimensions allows the designer to easily select elements of a certain format for construction or cladding, and knowing their approximate weight - correctly calculate the loads of the structure being erected on the foundation.

It will be possible to purchase the material from any manufacturer and at any time after the preparation of the project.

Standard sizes of red brick in normal (regular) 1NF format:

- length - 250 mm;

- width - 120 mm;

- height - 65 mm.

It is the dimensions of single elements provided for by GOST that are a kind of reference point - i.e. a material with other parameters will have a different marking instead of 1NF, where the number indicates its proportions of the ratio with a single one.

So, the size of one and a half red brick will already be 250 × 120 × 88 mm, and will be designated as 1.4 NF. Products of these formats are produced as ordinary and facing.

The list of sizes of facing red bricks can be supplemented with euro format products (0.7NF, 250 × 85 × 65 mm), and ordinary ones - with double elements (2.1 NF, 250 × 120 × 138 mm).

Dimensions of red brick euro format

Thin face material (euros) will help reduce the financial costs of facing, and a large stone (double) will significantly speed up the process of building a house.

Many are often interested in the question of how thick the red brick is. For materials of basic formats (single, one and a half and double) it is standard - 120 mm.

The exception is euro size elements, the width of which is reduced to 85 mm.

Deviations from standard dimensions

According to GOST, the maximum permissible deviations from standard sizes on one element (regardless of the format) are:

- in length ± 4 mm;

- in width ± 3;

- in thickness ± 2 mm for front and ± 3 for ordinary material.

Standard red brick weight

The GOST does not reflect information on how much a single or red brick of other dimensions weighs - the standard indicates only material classes in terms of average specific gravity.

Depending on the class of average density, the products are divided into several groups according to thermal characteristics:

- 2.0 and 2.4 - ineffective (normal);

- 1.4 - conditionally effective;

- 1.2 - effective; 1.0 - increased efficiency;

- 0.7 and 0.8 - high efficiency.

Before proceeding directly to the question of how much 1 standard red brick weighs, you need to consider its types depending on the structure.

The material is available in several options:

Hollow (slotted)

With the amount of voids up to 45%. It is much lighter than corpulent, but less durable.

Corpulent - the number of voids is no more than 13% of the total volume of red brick. It differs in a larger mass, but the strength characteristics of the elements are an order of magnitude higher.

Table 1. Weight (weight) of red bricks of single (250 × 120 × 65 mm), one and a half (250 × 120 × 88 mm), double (250 × 120 × 138 mm) and euro (250 × 85 × 65 mm) formats:

The weight of a red facing brick does not differ from the weight of an ordinary hollow brick. The only thing worth noting is that cladding products are produced only 0.7NF, 1NF and 1.4NF, and there are no double formats for finishing work.

How much does an oven red brick weigh?

Kiln brick

Interested in the weight of red oven bricks, many consumers do not know its main purpose - this is a brick with increased characteristics, but not refractory.

Note! A material made of ordinary clay is intended for laying the body of the stove and chimney. If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products made from special types of clay are used.

If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products are used, made of special types of clay.

Standard kiln material also has a fairly high heat resistance and increased density compared to traditional building or cladding products.

In this regard, to the question of how much a red brick weighs for a stove, one can unequivocally answer that it is heavier than the usual corpulent one and its mass is in the range of 3.7-4.2 kg.

1 cubic meter: how many meters, liters, weight

1 cubic meter

To understand how many meters, liters or other units of measurement are in a cubic meter, you must first understand what a cubic meter is. A cubic meter is a unit of volume in a spatial figure. In other words, it is a container with a width, length and height equal to one meter.

How many meters per cubic meter?

This is an interesting question, even from the point of view of philosophy. "What philosophy?" - you ask, because this is mathematics.

- The fact is that a cubic meter is a unit of measure for volume, and a meter is a unit of measure for length.

- Therefore, these are two units that are not comparable with each other.

But we can say in another way, already delving into mathematical quantities:

- Along the ribs - 12 meters.

- 1 meter - length, width and height.

- 6 m² - the area of one face or the area of a cube.

- If you cut a cubic figure into strips, how many meters in a cubic meter will depend on the thickness of these strips. For example, if the cross-section of a meter is square and equal to 1x1 cm, then this is exactly 10,000 meters. If the section is 10x10 cm thick, then this is 100 meters. If you cut it into strips equal to the width of a human hair, you get a lot of meters.

If we formally relate a cubic meter (volume) and a linear dimension (meter), then one can indirectly correlate 1 cubic meter and 1 meter. But such a ratio will be more useful for practical application, and not for solving logical exercises.

The answer to this question is simple: there are 1000 liters in one cubic meter.

1 cubic meter

Cubic meter weight

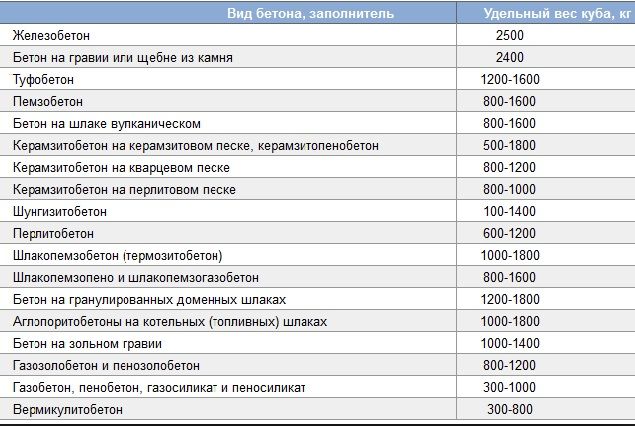

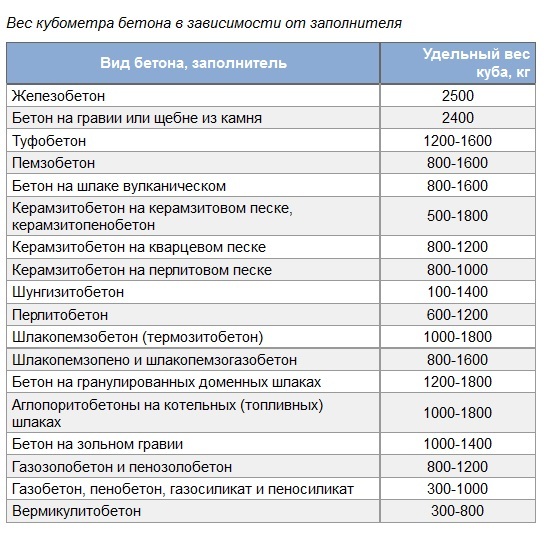

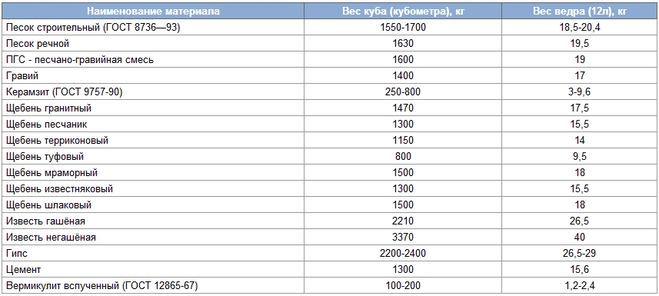

How much does a cube weigh? Any person can ask such a question. But few people know and think about how many kilograms in 1 cubic meter. meter. Answer: the weight value will depend on what is in the cubic meter. Often, cubes are measured as bulk materials (sand, gravel) and liquids (H2O, acid, alcohol) and even gaseous (gas). The turn came to figure it out in order:

- 1 cubic meter meter H2O - the weight value will depend on t ° C: water + 20 ° C weighs 998 kg, + 4 ° C - one thousand kg.

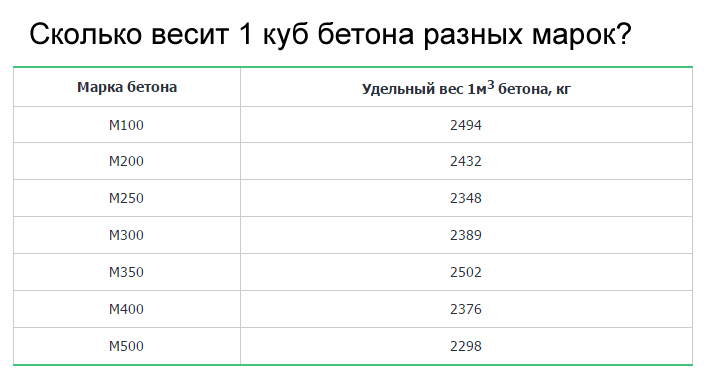

- 1 cubic meter meter of crushed stone - depends on the characteristics and structure of the stone. In addition, there is a common density and a bulk density. The usual density of crushed stone, gravel, granite or limestone is almost 2 times that of the bulk density. Therefore, the weight of a cubic meter of crushed stone will be from 1.2 tons to 2.6 tons, depending on how the material is compacted in a cubic meter.

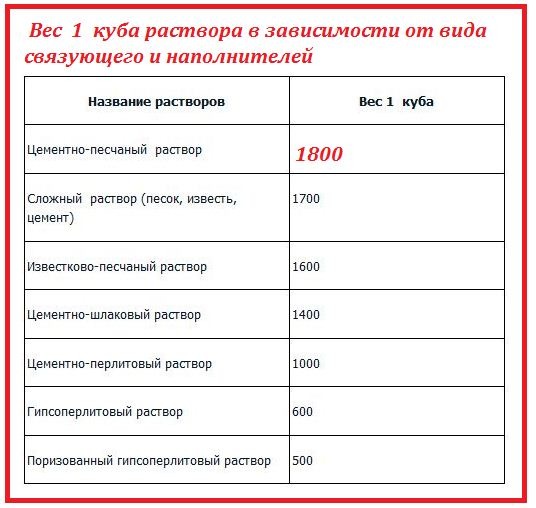

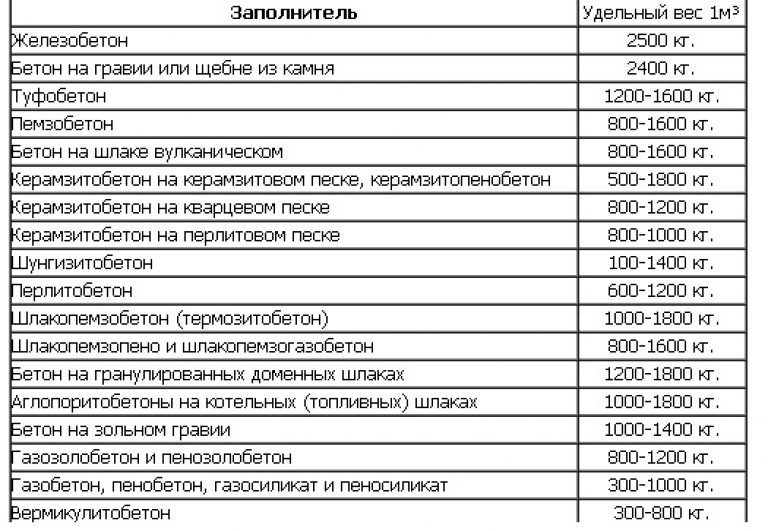

- 1 cubic meter meter of concrete material - depends on the properties of this material. Heavy concrete has a weight of 1.8-2.5 tons (depending on the composition). Lightweight concrete - 0.5 - 1.8 tons.

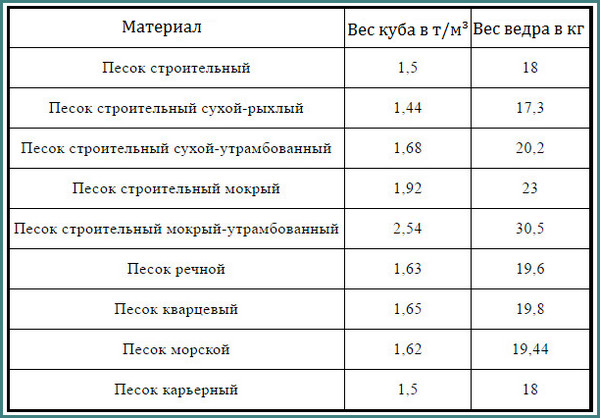

- 1 cubic meter meter of bulk materials - depends on the composite value and on the presence of moisture in the structure. The weight of sand mined in the mountains is 1.6 tons, sand-perlite is 0.05-0.25 tons, sand extracted from the bottom of the river is 1.4 - 1.86 tons.

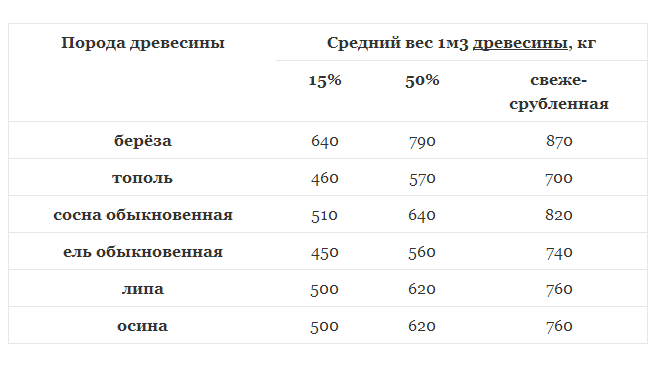

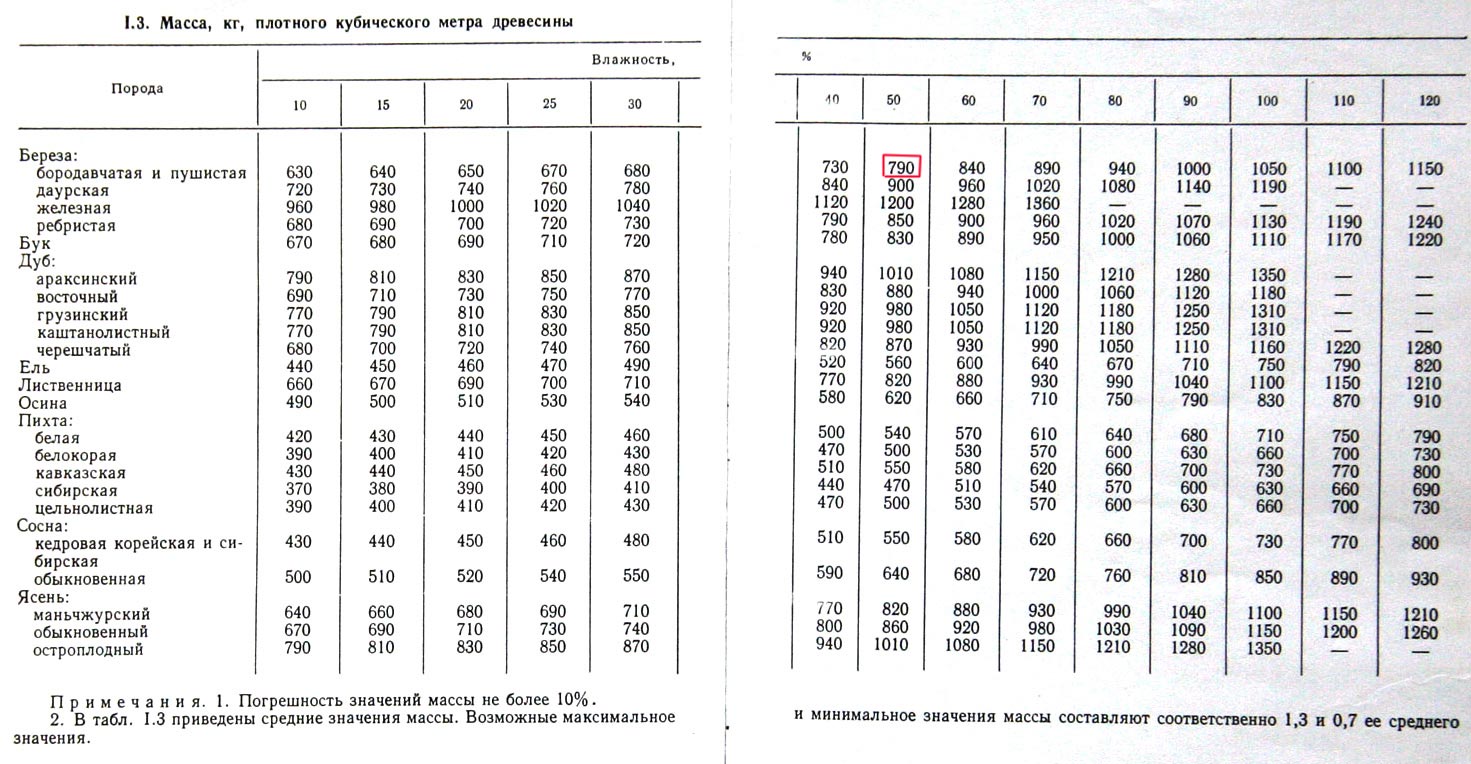

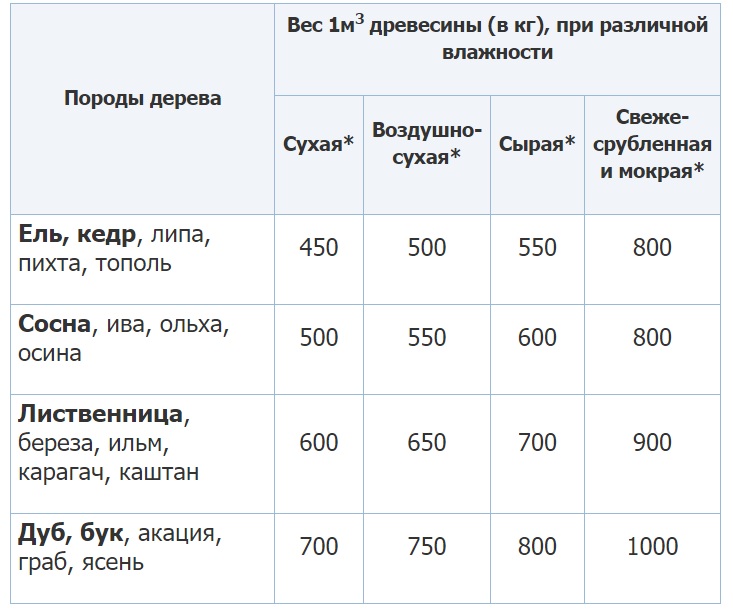

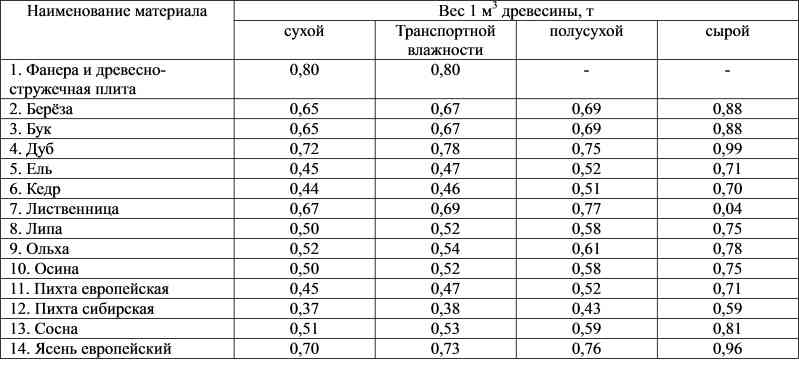

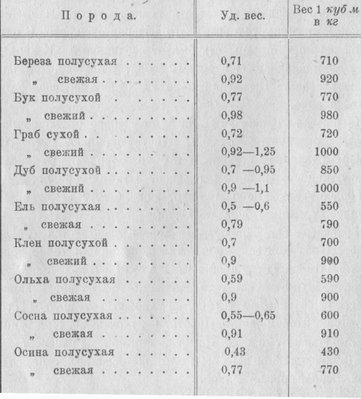

- 1 cubic meter meter of a tree trunk or finished product - depends on the species or the presence of moisture. More often, pine boards, beams and so on are used in construction, and it is the builders who may need to calculate how many pine products are in a cubic meter. Freshly cut pine trunk - 0.8 t, fully dried pine board - 0.47 t.

- 1 cubic meter meter of gas - the weight of this material cannot be found, since methane is lighter than air. But you can measure the mass of the gas. There are 4.46 moles of gas in 1 cubic meter of methane. Its molar mass is 16. Now calculations: 4.46 x 16 = 71 grams - the mass of the gas.

It should be noted that there is no answer to the question of how much one cubic meter weighs. It's like asking - how long is 1 kilogram, that is, everything is relative. If you are sure of what material is in the cube, then you can measure its weight, and it will depend on various physical and chemical indicators.

Density of construction waste

Construction waste consists of waste of different composition. These components have their own density. The coefficient is taken into account when:

- building routes;

- determining the carrying capacity of equipment for transporting scrap;

- designation of the quantity, type of containers being moved.

For bulk repair waste, bulk compactness is taken into account, calculated by dividing the mass of waste by volume. What matters is the free space between the elements of the raw material. Therefore, the indicator of the bulk density is less than usual.

The capacity of a cargo vehicle is limited, as are the dimensions of containers - the more accurate calculations of the volume and mass of waste, the higher the chances of saving time and money.

There are generally accepted density values for different types of material, indicated in the table below.

|

Raw materials |

Density of construction waste (t / m3) |

| Concrete |

2,4 |

| Remains of bricks, tiles, plaster strips |

1,8 |

| Wood |

0,6 |

Construction waste:

|

1,2 1,6 0,16 |

| Brick fight |

1,9 |

| Sand |

1,65 |

| Cast iron |

0,9 |

| Crushed stone |

2 |

| Linoleum scraps |

1,8 |

| Roofing material |

0,6 |

The calculation of the weight and compaction of engineering metal structures is calculated according to the information specified in the design papers.

Density factor is the main criterion when drawing up a plan for construction waste transportation services.