Installation Basics

Before installation, the lining for the bath must be adapted to the new conditions. To do this, it is released from packaging and left in the building where it will be mounted for a day, or even two.

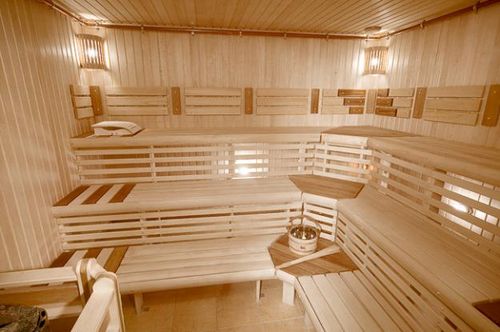

Decorating steam room shelves

Clapboard cladding consists of several stages.

- Installation of the first lathing and laying in the insulation cells. Only moisture and fire resistant materials like basalt wool are used as it. It's better to forget about styrofoam and the like. If the bath is used only in summer and is small in size, only the steam room needs to be insulated. In other cases, thermal insulation is laid along all walls.

- Installation of steam and waterproofing. Most often, glassine plays its role. The joints of the fragments must be glued with glue with water-repellent properties.

- The foil layer is needed to prevent temperature losses. The foil is fastened with a construction stapler or overlapping buttons, and the fragment should go onto the adjacent one by at least 10 cm.

- Equipment of the second lathing. The lining itself will be attached to it.

The elements are fixed either with studs with pre-drilled holes, or with clamps, or with staples at least 38 mm long (25 mm are not suitable).

Clapboard finishing usually starts from the ceiling. A ventilation gap of 2-4 mm must be left between the lamellas, otherwise constant swelling with drying will lead to deformation of the elements.

Be sure to watch the video:

The choice of lining and the calculation of the area

For high-quality work, it is necessary to choose the right material and calculate its amount.

Sheathing the inner surface of a room such as a bath is necessary only with those materials that can withstand:

- large temperature drops;

- high humidity;

- constant contact with water and various substances.

Board type and grade of material

To date, the building materials market is filled with a variety of clapboard from many manufacturers. Lamellas are produced both in Russia and abroad. Eurolining is produced with various profile section options. Also, wooden lining can differ in the quality of the surface of the back and front side of the board, the shape of the lock and its size, the type of material and other equally important parameters.

Most often they use lining of several popular profiles.

- Euro lining, which has clear sharp edges and forms seams visible to the naked eye when sheathing.

- Softline with more rounded corners.

- Calm. The seam with such a finish is almost invisible, because it does not have shelves-recesses. It can imitate a timber, have both fairly sharp and smoother rounded edges.

- Loundhouse, the front side of which is not smooth, but with different patterns. The pattern on the lamellas of the lamella is applied using curly milling on more expensive materials and using hot stamping on cheaper materials.

- Blockhouse (siding).

- Double-sided lining. Both the groove and the spike of such a board are exactly in the middle, so both sides are equally even - you can choose between them. However, this material has almost no ventilation (the ability to "breathe"), so it is not very well suited for interior decoration in wet rooms such as baths, swimming pools or saunas.

To determine the type of lining purchased, you can use the European DIN standard. The difficulty lies in the fact that many manufacturers use various GOSTs and even their own specifications, therefore, first of all, it is necessary to look at the surface quality of the material itself, and not at the marking. All lining is made using the same equipment and using the same technology, therefore, the grade of material is determined during inspection after the completion of the manufacturing process.

- Premium (or extra). Almost perfect lining quality. No twigs or cracks are allowed on the lamellas. A light blue tint, small chippings, roughness and unevenness are possible only from the inside.

- Class A. Twigs on such a board should not be more than 1 cm in diameter and occur no more often than once on a one meter long section. Cracks, if any, should be very small and, of course, blind. It is advisable that the manufacturer putty them on his own. All other defects are permissible only on the inside.

- Class B. Knots in diameter can be no more than a third of the lamella, but in any quantity. Through cracks and open pockets are also allowed.

- Class C is the entire remaining lining, on which both blue spots and a large number of large knots are visible. They can be uneasy even on the surface of the side that is visible after installation. However, it is believed that lining of this class is unacceptable to use for finishing walls.

Wood

The bath is not only a steam room, but also a washing room, a dressing room or even a pool. For each of the premises, it will be more appropriate to choose a certain type of wood.

Wood is divided into two categories:

- coniferous: pine, spruce, cedar;

- deciduous: linden, aspen and others.

One of the most popular material options for euro lining is lime board. Linden is quite strong, does not change the structure of fibers for a long time and is resistant to various negative factors. The atmosphere of the linden bath is saturated with freshness and purity.

It is easy to work with aspen clapboard, time makes this material only stronger. If the surface of such a lining darkens, it is easy for it to return to its original appearance by sanding the surface. Both linden and aspen are used to decorate the hottest and wettest room in saunas - the steam room.

It is also allowed to use cedar for its decoration, however, due to the fact that the cedar heats up very quickly, discomfort may arise when you touch the loungers and walls made of this material. Coniferous species of trees are used for sheathing mainly the washing or dressing room. Pine and spruce give off resin abundantly and, like cedar, have a high heating rate, but using this material will save money and choose from an extensive decorative range of lining. It should be noted that coniferous wood must be first degummed in order to avoid a large number of streaks on the walls.

Important nuances

You should start attaching the lining from the corner. You can use clamps, screws, nails. The heads of the nails should sink slightly into the wood surface: drive them in as carefully as possible. Otherwise, it is quite possible that people in the sauna will catch on these hats.

If possible, it is better to use clamps. Such devices are resistant to corrosion. There will be no holes in the tree from them. This fastening device is very convenient. It will be absolutely safe for people relaxing in the sauna.

When thinking about which fastening material to choose, be guided by your preferences and the specific situation. If the work needs to be done as quickly as possible, it is better to opt for ordinary nails.

Starting at the corner, attach the first plank. Then insert another element into the groove, and so on. Finish the entire sauna.

Peculiarities

Lining is a wood profile that can have different shapes and widths. It is characterized by a tongue-and-groove connection and can be made of different types of solid wood. The problem of choice may lie in the selection of the right breed, since not only aesthetic components (texture, shade) are important, but also functionality

The price, of course, can play a decisive role, but it is important to understand that all varieties are different.

Products from some species are distinguished by a healing effect, which manifests itself when the skin interacts with high temperature and steam. One of the features of the material is a high degree of drying. In addition, the lining does not need additional finishing costs, since during the production process it is impregnated with special compounds.

Today, all varieties are divided into 2 types: ordinary and euro lining. Each type is subject to regulations and application restrictions. At the same time, the lining is diverse in appearance: it can be flat, convex, with or without chamfers. Regardless of the thickness of the board, it lends itself well to cutting, so even a beginner can work with it.

The lining is also convenient in that it allows you to mask communications and unevenness of the base. In addition, it is a good sound insulation, since it is able to absorb sound waves. It is a finishing material that helps to retain heat. He can indicate the chosen idea of stylistics and hint at the status of the owners of the house.

Surfaces can be sheathed in different ways. Walls can be finished horizontally, vertically, and also by mixing the direction of the profile. For example, vertical stripes of the lining against the background of horizontal ones will allow you to zone the sauna space. However, when choosing, it is worth considering the footage of a particular room, so as not to visually break it up with an abundance of vertical or horizontal lines. Lining can visually reduce the height and width of the walls, so the choice of width is just as important as the breed.

Choosing the best material

In order to sheathe the inside of a bath or sauna, it is better to take lining from trees such as linden, alder, aspen or cedar. Linden lining does not deteriorate from water and does not rot. It has a pleasant honey smell and a beautiful creamy shade. It handles well as it has a small number of knots. Linden improves the condition of the liver, has an anti-cellulite effect. She is also able to give a person strength and energy. This is the best sauna paneling.

Euro lining

If you choose an alder material, then your steam room will have a pink tint. Alder is very water resistant. Therefore, it has always been used as a building material for wells and berths. The aspen lining is very durable. It is not prone to chips and is not afraid of mechanical stress. But you need to carefully choose the boards so that there are no knots on them. They can cause burns.

Aspen contributes to the recovery of people who suffer from bronchitis, joint diseases. The smell of this wood has a slight bitterness. It has anti-inflammatory and anthelmintic effects. It is not for nothing that aspen is considered a vampire tree. It takes negative energy from a person and thereby facilitates his condition.

The walls of the steam room can be sheathed with pine clapboard. But on condition that the air temperature in it does not exceed + 100 *. Otherwise, the wooden walls will “cry” with resin tears. In addition, pine is a species that does not tolerate moisture and large temperature drops. The lining may lose its shape and presentation.

But we must remember that lining made of pure cedar is quite rare. More often you can find cedar pine finishing boards on sale. And this is not the same quality at all. Thermal conductivity is higher and the presence of resin on the walls, which heats up quickly and can lead to burns. Also tar fumes make breathing difficult.Cedar cladding can be of different colors, ranging from the lightest to the darkest, as shown in the photo.

Some tips for planking a bath

First you need to fill the slats on the walls in the horizontal direction. The distance between the beams is up to 70 cm. This is the so-called crate. Treat it with a special paste against wood bugs and other pests. Then attach the lining itself to them. You will learn how to do it right by watching the video.

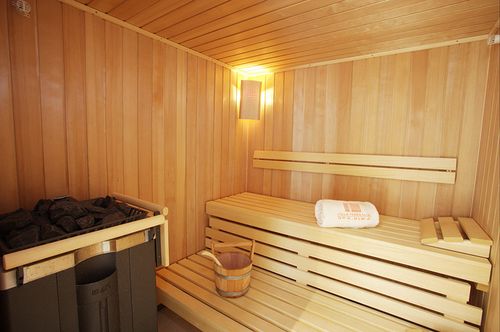

Usually, the lining is fastened with small nails or self-tapping screws. But this is not the best option. Nails can rust over time in constant humidity conditions. Cracks can form in the wood around hammered nails or screwed-in screws. It is better to choose for this special brackets - kleimers - pressing the boards to the base (see photo).

It is also important to mount the boards in an upright position. Water will flow freely along the wall without lingering in the grooves

And the wooden paneling will serve you long enough (see photo).

The void between the battens is filled with insulating material. It can be rock wool or something else. Then, using a stapler, a waterproofing film is attached. The cladding itself begins to be done from the corner, gradually moving along the perimeter of the room and processing each wall.

When everything is finished, you can cover the lining with some kind of protective compound, for example, varnish or wax. If you did everything according to the rules, then the appearance of your bath or sauna will be attractive for a long time.

Breed selection

Today, for finishing a sauna, they often buy lining of 6 different types of trees. At the same time, in addition to advantages, any profile also has disadvantages that you need to know when buying a sheathing material for specific operating conditions.

Linden

This is one of the best types of lining, used for cladding steam rooms for many centuries. This profile is characterized by low thermal conductivity. It heats up, however, it does not burn, even if the room temperature is high. Due to the essential resins, the sauna will be filled with a pleasant aroma.

This lining has a pleasant light shade and healing properties, it soothes the nervous system. However, at a low cost, the profile is prone to rotting. It is possible that the cladding will soon need to be replaced. In addition, linden lining attracts pests, so it will have to be constantly treated with special impregnations.

Aspen

No less popular profile for sauna cladding. Compared to linden, aspen lining is harder and more resistant to high temperatures inside the sauna. It is not susceptible to cracking and drying out. The material has a pleasant beige tint. This lining has essential oils, which are less than in lime counterparts.

However, the aroma of such a profile, released when heated, is quite specific, it tastes bitter, so not everyone likes it. Another disadvantage is the tendency of aspen to rot in conditions of constant dampness. In addition, this is the case when the choice must be especially careful, since the presence of knots or resin pockets will necessarily lead to burns when touching the surface of the sheathing. The cost of products is similar to fake options.

Alder

This upholstery material is called "the king's tree", it is distinguished by a pinkish tint and an interesting small pattern. Due to the antibacterial properties, mold or mildew will never appear on such a lining. It does not rot, which makes it more durable than its linden and aspen counterparts. Thanks to its healing qualities, it has a beneficial effect on the body.

When heated, this profile releases the pleasant aroma of cognac into the air. In addition, it is characterized by low thermal conductivity, therefore, when using such rails, burns from touching them are impossible. Solid wood does not absorb water, which contributes to a longer service life. The disadvantages of the profile are softness and high price.

Cedar

This type of finish is made from Canadian, Siberian and Altai mountain cedar. The price of boards depends on the variety of raw materials, while its range is very wide. Cedar lining is resistant to constant dampness. It is durable, has a pleasant pine scent.

The use of such material in a sauna will contribute to a beneficial effect on the body, since this lining is effective in relation to the cardiovascular system. It is bactericidal, has a minimum percentage of resin in the structure compared to spruce or pine, so it will not burn users with resin.

Abash

This profile is a product of exotic wood and is distinguished by its porous structure. It is due to the porosity that this lining is characterized by low thermal conductivity, it does not heat up. The material has a pleasant shade, which in different varieties of tropical wood can be light (lemon, milky or even warm white) or dark (chocolate). The color change is achieved through heat treatment.

Due to the high strength, it is possible not only to sheathe the walls and ceiling with such a profile. Abash is good for finishing furniture and sauna benches, it is resistant to deformation and does not shrink. However, unlike other analogues, apache has no smell, which is fundamental for many sheathing materials for finishing saunas. In addition, exotic lining is much more expensive than other analogues.

Hemlock

This profile is made from an exotic evergreen massif that grows along the Pacific coast, as well as in the mountains of Canada. This lining has a light beige shade, it is durable, because it is highly resistant to moisture. Its service life can be calculated in decades and reaches 100 years.

This board has antibacterial properties. It is durable, so it is difficult to damage it mechanically. Unlike other tree species, it does not emit resin, which excludes burning with resin. Additional benefits are healing qualities and pleasant aroma: Hemlock esters and oils are used in medicine and perfumery. The disadvantage is the high price of the profile.

How to choose

The lining, made according to domestic or European standards, has convenient dimensions - both length and width.

The standard thickness of Euro lining is 12.5 mm, width is 88 mm plus a tenon of 8 mm. Thinner planks can lead, especially in the sauna. All types of planks have grooves for joining into a single surface.

Euro lining is additionally characterized by the presence of channels on the reverse side for condensing moisture to drain, differs from domestic products in surface treatment methods and prices.

The material must be dry, the standard moisture content must not exceed 12%, which is possible only with proper production and storage.

During the packing of the planks, the company carries out sorting by appearance, the number of flaws on the surface. The lining without defects in the form of knots, microcracks, scratches belongs to the premium or extra class, has the highest cost. For a regular sauna, you can choose grade A and even B (second). Planks with noticeable defects make up the cheapest class C product (sometimes called the third).

> All types of lining on sale must be wrapped in a protective film, which allows the buyer to gain confidence in the conformity of the product to the declared quality.

Advantages and disadvantages

Lining is an excellent option because it has a good appearance and has all the qualities that are necessary for the finishing material of a steam room. There are many options for how to process it without harm to health.

Due to the fact that there are many types of lining, you can decorate the steam room in the style that you like best. When choosing a particular tree, you should think carefully about what kind of bath you would like to see in the end.In addition, you need to calculate the price, since the cost is different for each type of wood. There are, of course, other types of finishing materials, but they are more expensive and require much more attention during installation. In addition, the lining is easier to dismantle in case of damage.

Usually a bathhouse consists of a steam room, a shower and a dressing room. Each of these rooms has specific requirements. That is why the material that will serve as interior decoration must have specific technical characteristics and be of high quality.

The main advantages of lining over other materials are:

- value for money;

- high moisture resistance;

- resistance to high temperatures;

- variety of species in stores.

The lining can be called an environmentally friendly and safe material for human health. Since the temperature in the steam room is quite high, the material with which the room will be decorated should in no case be heated. In addition, in order to know how to choose the material correctly, you need to inquire about the features of the wood species from which the lining can be made. Certain types of wood can release resins when heated, which sometimes cause allergic reactions. There are no obvious flaws in the lining, so you can safely purchase this material for decoration.

How to properly trim inside the bath

And now we will talk about how to properly sheathe a bath with clapboard from the inside. So, finishing work can be done in several ways:

- The horizontal arrangement of the cladding material.

- The vertical arrangement of the material.

Many builders claim that if the planking is done vertically, in this case, water will flow down freely, and if horizontally, it will begin to accumulate at the joints of the panels. Due to the fact that the water flows down unhindered, the lining will not collapse under the influence of water and will last much longer. This opinion takes place, although the statement is somewhat controversial. After all, if the material is laid horizontally, while the ridge is located at the top, in this case, water will also not accumulate.

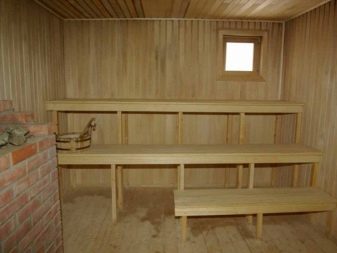

Therefore, the clapboarding of the bath can be performed both horizontally and vertically. Sheathing work should be carried out starting from the corner of the room and then slowly moving around the perimeter of the room. If it is necessary to finish the entire room, then first you need to sheathe the ceiling and then move on to the walls. Those places where the ceiling is adjacent to the wall must be covered with a plinth.

First, the first board is laid, it will be the starting board. Remember that even a very slight deviation from the level will be very noticeable when the sheathing is ready. This will greatly ruin her appearance. The laid planks need to be leveled all the time; for this, a building level is used. A plumb line is used to align the vertical panels.

The lining is fixed with screws or nails, but it is best to use clamps for this purpose. The fact is that while hammering in nails or screwing in screws, there is a risk that the board may burst, while the cleats are placed in the grooves and then screwed to the installed crate.

After the first board is delivered, the second is installed, and this continues until the entire wall or other surfaces are sheathed. The fastening of the slats to each other is easy and quick thanks to a special locking system.

How to lay it: horizontally or vertically?

Unfortunately, we cannot be guided only by aesthetics in choosing the method of lining the bath with clapboard inside. More precisely, not so: aesthetics can be used as the basis of choice only in a dry room, for example, in a rest room or dressing room.

If a decision is made to decorate wet rooms (steam rooms and washing rooms) with it, then it is better to focus on a method that minimizes future losses. By "losses" we mean the possible damage to the planks from moisture, which will require their replacement.

So, what happens when the installation of the lining in the bath is carried out vertically? In a humid room, humidity is distributed unevenly - after all, gravity drives it to the floor. As a result, each (!) Plank also gets wet non-uniformly.

When dry, this can lead to its cracking, but much more often over a long period of time, problems accumulate at the bottom - somewhere there is not very good ventilation, for example, and in this place the water stagnates. Therefore, the planks begin to rot. And since they are located vertically, the rotting area affects all the planks.

This is inconvenient - in order to dismantle and replace damaged areas, you will have to saw (do not change the whole thing!), And then replace each piece. The cost in terms of time and effort is especially clearly visible if we compare the situation with the horizontal upholstery of the bath with clapboard - in this case, several strips are replaced entirely, which does not cause any special problems in dismantling and installation.

The only disadvantage of the horizontal cladding of the bath from the inside with clapboard can be considered a visual reduction in the height of the so-covered room, and in the bath, as you know, the ceilings are already low. Therefore, as an option, you can combine both methods using the horizontal one at the bottom.