Storing joint sealant

Sealing and vulcanizing pastes should be stored in tightly closed containers at temperatures ranging from minus -200C to plus + 40C in covered warehouses.

When transporting and storing the components of the sealant at a negative temperature, before use, they are kept at a temperature of plus + 15 ... 25 ° C for at least 24 hours.

Shelf life: 12 months in sealed (not damaged) original packaging. During the guaranteed storage period, the vulcanizing paste may delaminate. Stir thoroughly before use.

SECURITY MEASURES

Avoid contact with unprotected skin and mucous membranes (eyes, mouth, etc.). In case of contact with open skin areas, they should be cleaned with white spirit or acetone, and then washed with warm water and soap. Not explosive.

"U-30M" three-component thiokol sealant

General-purpose three-component thiokol sealant U-30M GOST 13489-79 is intended for sealing fixed metal (except for brass, copper, silver and their alloys) and other compounds that are efficient at temperatures from minus -60 ° C to plus +130 ° C in air and fuels (up to plus +150 ° С for a short time in air) and has the ability to cure at temperatures above plus +15 ° С

Description of thiokol sealant

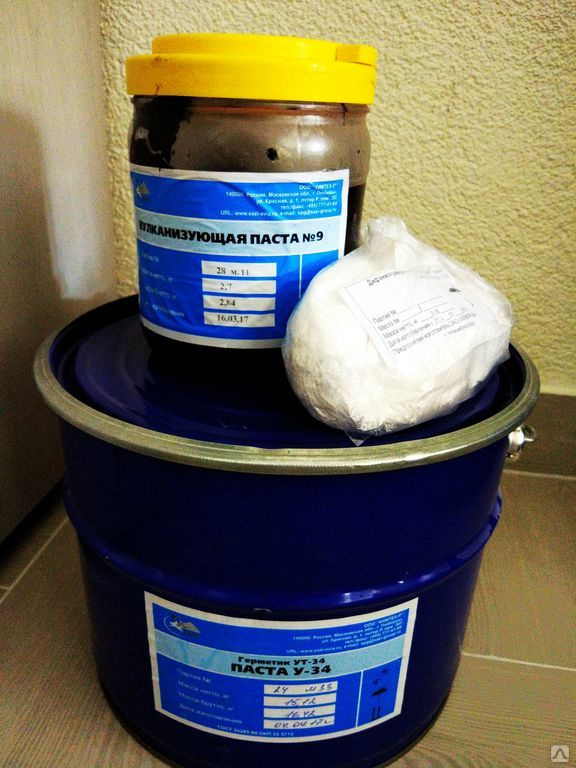

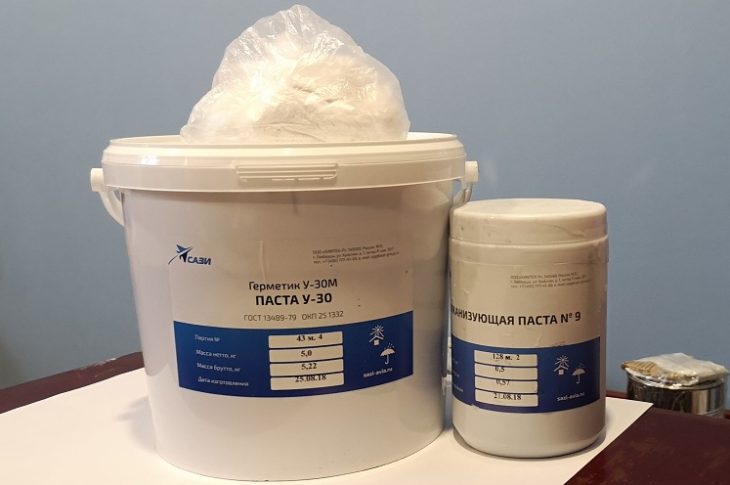

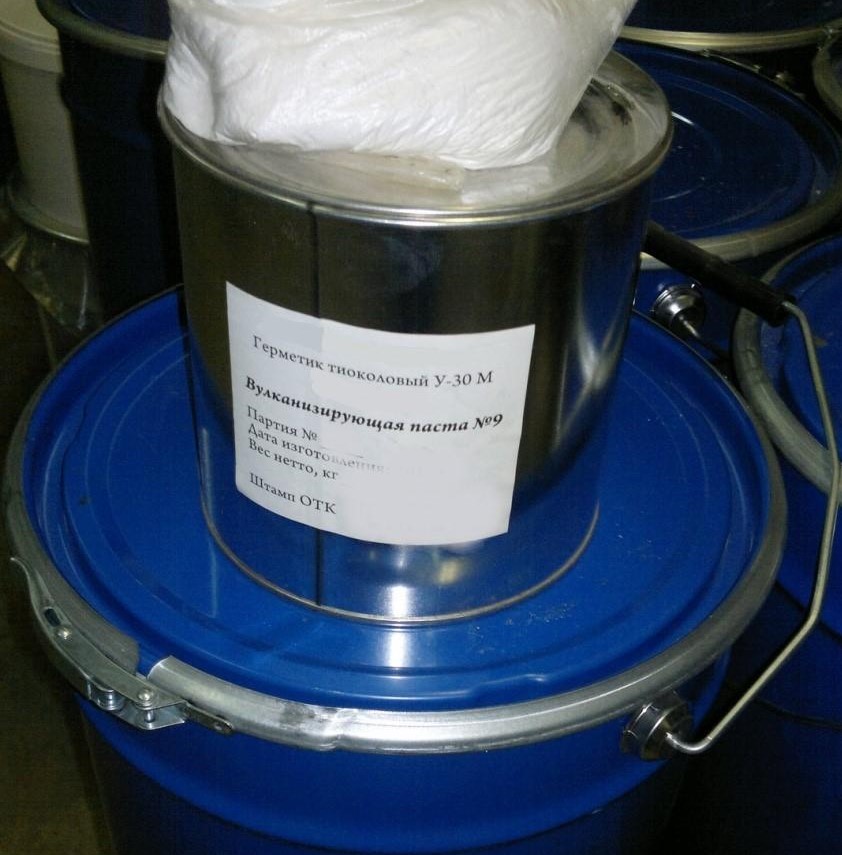

Thiokol sealant U-30M GOST 13489-79 is supplied in Kazan and Naberezhnye Chelny in the form of a set of three components: a sealing paste, a vulcanizing paste and a vulcanization accelerator, which are mixed directly at the facility.

After curing, an elastic rubber-like material with high deformation and strength properties, vibration and weather resistance is formed.

It is possible to buy the general construction three-component thiokol sealant U-30M GOST 13489-79 at manufacturer's prices in Kazan and Naberezhnye Chelny.

Thiokol sealant U-30M has excellent adhesion to almost all building materials, including recommended for use in contact with aluminum alloys, non-anodized, magnesium alloys, cadmium and unprotected steel (except for brass, copper, silver compounds).

Thiokol sealant U-30M has high adhesion to metals, rubber, wood, concrete, brick, plaster, plastic, laminate, glass, ceramics and other building materials without additional preliminary priming.

AREAS OF USE

Construction three-component thiokol sealant U-30M GOST 13489-79 is intended for:

1) surface and intraseam sealing of riveted, welded, bolted, flanged metal and other joints (except brass, copper, silver) in such areas as:

a) industrial construction, b) tank construction, c) shipbuilding, d) mechanical engineering, e) when repairing equipment.

2) as coatings for protection against atmospheric, corrosive and abrasive destruction of metal parts of transport, reinforced concrete (reinforced concrete) structures, roofs, foundations, tunnels, pipelines, sedimentation tanks, livestock complexes, electroplating areas, etc .;

PROPERTIES OF SEALANT U-30M

Three-component thiokol sealant U-30M GOST 13489-79 has good deformability, moisture and air tightness.

Thiokol mastic U-30M has good resistance to UV radiation from the sun and the effects of atmospheric precipitation.

Thiokol sealant U-30M

Based on polysulfide oligomers GOST 13489-79

Sealant U-30M is a general-purpose sealant used for riveted, welded, bolted, flanged joints. For surface and internal sealing of stationary metal (except copper, brass, silver alloys) compounds operating in air, dilute acids and alkalis, fuel. Can be used to make aquariums.

Specifications

|

Appearance |

Homogeneous mass of black color |

|

Viability, h |

2-9 |

|

Temperature limit of brittleness, ° С |

— 35 |

|

Operating temperature, ° С |

-60 ÷ +130 |

|

Conditional tensile strength, MPa, not less |

2,6 |

|

Elongation at break,%, not less |

160 |

Instructions for the use of U-30M sealant.

The U-30M sealant has a pasty consistency. It is applied to the surface of the product with a spatula, syringe, and when diluted with a solvent - with a brush. The U-30M sealant does not possess adhesion properties to metal, and therefore, sublayers are used to attach it to the sealed surfaces:

-

- VTUR sealant - in fuel tanks;

- glue 88H - for units operating in air.

Sealant preparation.

Prepare the spatula version of the U-30M sealant according to the following recipe (pbw)

| Equipment | For sealing | For renovation |

| Sealing paste U-30 | 100 | 100 |

| Vulcanizing paste No. 9 | 5-9 | 10 |

| DFG | 0,1-0,6 | — |

| Solution of DPG in acetone (1: 4) | — | 5 |

The pot life of the sealant is 2-9 hours and depends on the batch of the sealant, the dosage of vulcanizing agents and the environmental conditions. Prepare the sealant by mixing the two components before use. Vulcanizing paste No. 9 and DFG should be introduced sequentially or pre-mixed

Prepare the brush version in a clean, dry metal or plastic container by hand or using a stirrer. Into the U-30 sealing paste gradually, with stirring, add the required amount of solvent and mix until a homogeneous mass is obtained. Then add vulcanizing paste No. 9 and DPG and mix again for 3-5 minutes.

Sealing products.

Surface preparation and subcoating. The surface to be sealed must be cleaned of chips and dust with a hairbrush or clean napkins and then degreased. When degreasing, wipe the surface in small areas with clean cotton napkins moistened with BR-1 or BR-2 gasoline, and then, without letting the surface dry, wipe it dry with a clean dry cotton napkin. Repeat this until the wiping cloth remains clean. Degrease the surface covered with paint and varnish coatings only with BR-1 or BR-2 gasoline. The degreasing zone of the surface should be at least 30 mm higher than the boundaries of the sealant application on each side.

Sealant application.

All works on sealing should be carried out at a temperature of 15-35 ° C. For intraseam sealing, apply the sealant to one of the mating surfaces with a spatula or flat-tipped syringe. Apply the sealant in a continuous layer with a thickness of 0.5-0.8 mm with local thickenings in the places where the profiles are cut. Smooth out the sealant squeezed out during riveting with a spatula along the edge of the seam or remove. For surface sealing, the spatula version of the sealant is applied with a syringe or spatula to the surface of the structure joints along all edges and corners. The sealant layer along its entire length should be reduced to a "mustache", should not have burrs and thickenings. After 24 hours from the moment of applying the last layer of sealant, the product can be transferred for subsequent assembly and assembly work.

What are the sealants

The sealant is a pasty or viscous composition. The main components of its composition are polymers or oligomers. Currently, there are several types of sealants that differ from each other in the polymer contained in their composition.

The sealant is a pasty or viscous composition. The main components of its composition are polymers or oligomers. Currently, there are several types of sealants that differ from each other in the polymer contained in their composition.

Sealants are divided into:

- Acrylic.

- Silicone.

- Bituminous and rubber.

- Polyurethane.

- Polysulfide or thiokol.

- Butyl rubber.

Table 1.Composition of a typical polysulfide material

| Basic paste (components) | The weight, % | Katali mash paste (components) | The weight, % |

| Polysulfide polymer | 80-85 | Lead dioxide | 60-68 |

| Titanium dioxide, zinc sulfate, copper carbonate or silica | 16-18 | Dibutyl (dioctyl) phthalate | 30-35 |

| Sulfur | 3 | ||

| Other substances (magnesium stearate, deodorants) | 2 |

Each type of sealant has its own specific properties and scope. The area of application of the sealant is directly related to their composition and properties. So, some sealants are used during the installation of windows, repair of bathrooms, others - for joining elements in shipbuilding, others - for application to automotive parts in order to prevent leakage of the working environment through the openings of the structure, etc. It is also worth saying that for quite a long time not a single production of modern double-glazed windows can do without polysulfide sealant. Taking into account its properties, it is safe to say that polysulfide sealant for insulating glass units is an irreplaceable paint and varnish material, due to which reliable sealing of the second circuit of glued insulating glass units is ensured. There are also universal sealants that are designed to connect elements made of various materials. However, despite the existing variety of sealants, they also have common properties. These properties lie in the fact that any sealant initially has a viscous-flowing consistency, which ensures its easy application, which subsequently hardens, thereby forming a strong structure. Thus, an absolutely tight layer is obtained in the places of joints and voids, where the sealant was applied.

Marking

When studying the technical characteristics of this material, several main brands of thiokol sealants can be distinguished.

U-30M. Density 1400 kg / m2. The quantity tensile strength is 2.6 MPa. It is widely used for products that have constant contact with air, since it is resistant to natural atmospheric aging. It is also used to create flexible waterproof coatings. This brand has proven itself well in contact with gasoline and other petroleum products. But it is not recommended to use this sealant on silver, brass, bronze, and also copper surfaces that have not been previously treated with anti-corrosion varnish - this brand has poor adhesion to them.

Like the previous brand, UT-32 is highly resistant to engine oils and gasoline. And she also cannot contact with brass, copper and silver.

- U-30MES5M. In addition to traditional use in various fields, the sealant can also be used as an adhesive for the installation of individual assemblies and parts. It can function as a protective layer against corrosion and weathering. It can be used for interior work, as well as for joining elements of various equipment.

- UT-34. It is used in engineering, aviation, electrical, technical industries, in the construction of tanks, shipbuilding, in the construction of civilian facilities. The density of this sealant is 1600 kg / m2. It can be operated at temperatures from -60 C to +150 C.

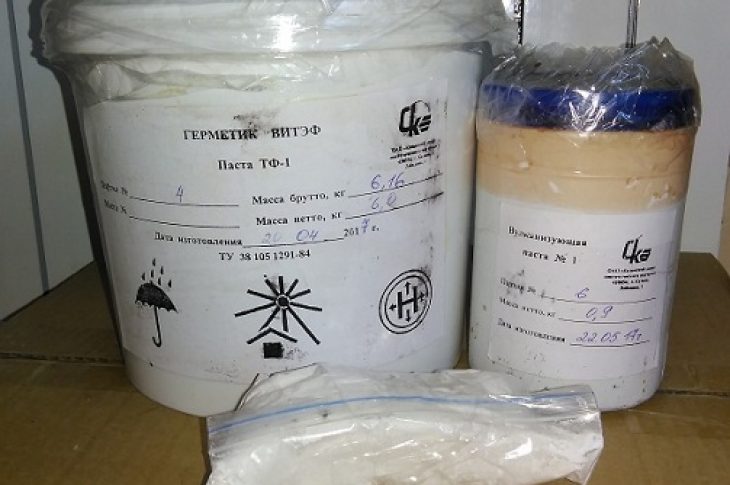

- VITEF-1NT is recommended in cases where contact with aluminum and magnesium alloys, as well as cadmium steel, is expected.

For information on how to choose the right sealant, see the next video.

Polysulfide sealant manufacturers

When choosing a sealant for any work, there is a question not only about its characteristics, but also about the manufacturer. Today, a huge number of paint and varnish companies have sealants in their product portfolio. Among them are both domestic and foreign manufacturers. Each company has its own characteristics of production. And which manufacturer to give preference to is just a matter of taste.However, it is worth noting that often domestic manufacturers' sealants are in no way inferior in quality to European ones. The most famous manufacturers of sealants on the paint and varnish market are: Kvadro (Czech Republic), Dufa and Jobi (Germany), DL Chemicals, Kim Tek (Belgium), Perma-Chink, Weatherall, Sashco (USA), Henkel, and many others. Among the domestic companies involved in the production of sealants can be noted: "Vostokstroyizolyatsiya", Architect Group, LLC "Azimut YUG". It is worth mentioning that there are foreign companies that have their own facilities in Russia, where they produce their paints and varnishes. For example, one of the well-known companies is Henkel. Their companies are Henkel.

Scope and technology of application

Due to its characteristics, thiokol sealant is used wherever it is necessary to prevent contact with various chemicals. These are, as a rule, gas stations, garages, fuel stations, fuel and lubricants depots. This material is used in the repair of metal roofs.

The sealant has found wide application in the manufacture of double-glazed windows. It is used to seal joints, cracks, cracks in concrete, reinforced concrete structures, where the deformation does not exceed 25%.

If you are going to use such a composition, you need to familiarize yourself with the technology of use, which is the same for all types.

Before applying, you need to be sure that:

- the surface is well cleaned of old building material;

- countersinking of the mounting holes has been made;

- those areas where the material is not applied are pasted over with adhesive tape;

- the material is ready for use.

If everything is ready, you can begin the sealing process. To achieve good work results, you need to take into account all the important recommendations.

How to choose the right type of sealant is described in the video.

Scope of application

Thiokol sealant has a wide range of applications.

- In aviation - sealing of fuel tanks, technical compartments, windows, sealing of an electric cable, when laying the runway at airfields.

- In shipbuilding - sealing the cable box, eliminating cracks and holes in wooden surfaces (decks, wooden frames, etc.), sealing pipe connections, protecting steel parts from erosion.

- In the automotive industry, they provide the strength of fastening of auto glass, protect metal parts from corrosion and abrasion, and seal welded seams.

- In the electrical, technical and food industries - sealing tanks for storing food liquids, filling cable soldering points, fastening parts that cannot be soldered, since they cannot withstand high temperatures or the surface can be damaged. The sealant is used in the assembly of household appliances - refrigerators, washing machines and others.

- In the space industry, they are used as protection against ultraviolet radiation, exposure to oxygen, and provide a vacuum.

- In medicine, imprints for dentures are made from thiokol mastic.

- In construction, polysulfate-based sealants are widely used to eliminate cracks and impermeability of building wall joints in order to protect them from moisture ingress and to avoid heat losses.

Among the disadvantages of thiokol materials, several factors can be noted.

Not suitable for plastic surfaces. The solvent contained in the sealant has a negative effect on it.

When mixed with a hardener, thiokol paste must be used within a few hours, after which the material is unusable.

The sealant is toxic and can cause allergies and even pulmonary edema.

Therefore, when working with it, it is necessary to observe safety measures and use protective equipment - gloves and a respirator.

Higher cost compared to other types of sealants.

Difficult to work with.Unlike other types of building pastes, which can be packaged in convenient tubes, thiokol mastic is sold in a wide container, which creates some difficulties when applying an even layer.

Peculiarities

Thiokol sealant is a vulcanizing paste made of two or sometimes more components. Such materials are considered the most reliable due to their special adhesion strength. This sealant is based on liquid thiokol, similar in properties to polysulfide rubber.

Therefore, thiokol sealants are also known as polysulfide sealants. In addition to rubber, various fillers can be added to the thiokol paste: plasticizers and structuring materials, polymers and coloring pigments. The paste is usually gray or black in color.

Positive qualities of thiokol sealant:

- non-flammable, oil-resistant;

- not subject to oxidation and alkalinity;

- does not change its properties with prolonged exposure to direct sunlight;

- does not collapse at high and low temperatures, is able to withstand temperature drops from -55C to + 130C;

- provides good adhesion to wood, metal, glass and other hard surfaces;

- not afraid of moisture, therefore it is ideal for sealing external and internal cracks in buildings for domestic and industrial purposes.

Two-component polysulfide sealant

Let's dwell on polysulfide (thiokol) sealants. Consider its composition, properties, advantages and disadvantages, as well as the area in which it is most advisable to use this type of sealant.

Let's dwell on polysulfide (thiokol) sealants. Consider its composition, properties, advantages and disadvantages, as well as the area in which it is most advisable to use this type of sealant.

Polysulfide sealants got their name from the main substance - thiokol, which is contained in their composition. In its structure, a thiokol is somewhat similar to a coach. Therefore, its second name is polysulfide rubber. In fact, these sealants are synthetic rubber with the best adhesive properties. Such sealants are most widely used in shipbuilding.

The structure and properties of polysulfide sealants.

The structure of such sealants is usually two or three component. That is, to prepare two-component polysulfide sealants, it is necessary to combine two components in the correct proportions - A (polymer, plasticizer and filler) with B (structuring agent, plasticizer and pigment).

Table 2 Typical 2K Polysulfide Sealant Formulation

| Raw materials | Weight, kg) |

| Component A | |

| Polysulfide | 200,0 |

| Plasticizer | 140,0 |

| Ground Calcium Carbonate Surface Treated (GCC) | 554,0 |

| Uly Thin Precipitated Calcium Carbonate (UFPCC) | 100,0 |

| Adhesion promoter | 6,0 |

| Total | 1000,0 |

| Component B | |

| Hardener (manganese dioxide, plasticizer, carbon black, accelerator, raw milled calcium carbonate (GCC)) | 90,0 |

These sealants have gained a good reputation and popularity for their following properties:

- Unlike other sealants, they offer maximum strength, flexibility and durability.

- They are resistant to moisture, as well as to all sorts of acids and alkalis.

- They are not exposed to ultraviolet radiation and most of the aggressive environmental influences.

- Resistant to substances containing oils and gasoline.

- Available for use in a wide temperature range - from -55 to +30 degrees Celsius.

- They have excellent adhesion.

- They have a long service life.

Table 3. Physical properties of carbonate fillers for 2K polysulfide sealants

| Marble 1 | Chalk 1 | Marble 2 | Chalk 2 | Limestone | |

| Surface area (BET), m2 / g | 4,2 | 4,1 | 3,1 | 2,4 | 1,3 |

| Brightness (Ry) | 94,7 | 85,3 | 93,8 | 85,3 | 89,3 |

| Oil absorption, g / 100 g | 17 | 17 | 12 | 16 | 13 |

| Particle size (d 50), μm | 2,4 | 1,5 | 3,8 | 2,3 | 6,5 |

| Limiting particle size (d 98), μm | 10 | 9 | 18 | 15 | 25 |

| Abrasiveness (according to Einlehner), mg | 6 | 9 | 11 | 11 | 14 |

Table 4. Rheological properties of 2K polysulfide sealant (component A)

| Extrusion speed, g / min (nozzle diameter 3 mm, pressure 2 bar) |

Marble 1139 |

Chalk 1130 |

Marble 2135 |

Chalk 2118 |

Limestone300 |

| Viscosity at different speeds of rotation 24 h after production, Pa s | |||||

| ŋ at 0.1 s̄¹ | 7326 | 6901 | 7631 | 6212 | 3512 |

| ŋ at 1 s̄¹ | 1016 | 1043 | 960 | 923 | 512 |

| ŋ at 5 s̄¹ | 246 | 251 | 194 | 225 | 133 |

| ŋ at 10 s̄¹ | 135 | 143 | 102 | 133 | 82 |

| ŋ at 50 s̄¹ | 36 | 18 | 24 | 27 | 27 |

Despite so many benefits, they are still not perfect. Like any substance, polysulfide sealants have their drawbacks.

Firstly, due to the content of a solvent in its composition, it is unacceptable to install plastic elements on polysulfide sealants, since, interacting with a solvent, acrylic, polycarbonate, ABS and PVC plastics become brittle and tiny.

Secondly, after preparation, this type of sealant has a very short life span, during which it must be developed.

And thirdly, when working with polysulfide sealants, you should follow safety rules and be sure to use personal protective equipment, since interaction with the skin can have negative consequences for a person.

By choosing a sealant taking into account all its features, as well as using it correctly, you can be 100% sure that in this case the sealant will last a very long time.

Sealant technology

It doesn't matter what type of sealant is used, the technology is the same. So, before applying the sealant to the surface, make sure that:

- All parts are cleaned of old sealant, as well as any rubbing.

- The mounting holes were countersinked.

- Areas where the sealant should not be applied are covered with adhesive tape.

- The sealant is squeezed out properly - well and abundantly.