Colour

The most popular and affordable colors are black and silver thermal paint. The temperature stability of the dye and its cost change from the color. The black color exhibits the highest heat-resistant qualities, since the dark surface heats up faster. White, blue, green paint can withstand a short heating of 600 degrees. Red and yellow paint reduce the thermal stability of the coating by another 200 degrees.

According to the degree of color saturation, there are glossy and matte coloring compositions. If you need to paint over defects and irregularities on the heating element, then a matte effect will do. Such a surface transfers heat well, the room warms up faster. The shiny glossy surface of the fireplace will look advantageous and will become a bright central decor in the room. Glossy copper chrome will look spectacular in the interior.

Release form and which one to choose

In addition to characteristics and areas of application, paints are subdivided according to the packaging method. The main forms are aerosol (spray in cans) and liquid varnish in buckets (cans). Enamel in cans is packed from 1 kg, in buckets 10, 15, 20, in barrels - from 40 kg. Aerosol sprays for metals are produced in 400 - 500 ml cans. The shelf life of thermal paints is at least 7 months (depending on the brand). Colorless varnish is popular in the range of colors, then black and white. The lovers of silver and golden enamels should be noted separately. By the type of finishing surface, there are glossy and matte.

Before choosing a paint, ask yourself the following questions:

- What temperature range is needed? It makes no sense to pay a high price for heat-resistant enamel if you need, for example, up to 400 degrees

- What substances will it come into contact with? For a car engine, take oil-resistant and petrol-resistant, for a water tank - waterproof

- Where is the surface to be painted? In some cases it is preferable to work with a brush, while in others it is preferable to use an aerosol

- What color, texture is needed? Start from understanding the design and your desires

- How much enamel do you need? For a small area of the painted metal, take a small amount of thermal paint, and a large packaging will be more economical

In paint shops and ordinary people, a list of popular manufacturers and major brands has formed. The cheap ones include Russian paints, foreign ones are more expensive, while the quality is almost on par. Russian brands (on average from 350 rubles / kg): Elcon, Kudo, KO 8101, Certa (this company is recommended by our master), Thermoskol and Celsit. Foreign brands (on average from 510 rubles / kg): Tikkurila, Bosny, Hansa. The factories of the companies produce products in both forms - cans and cylinders.

Properties of heat-resistant paintwork

Due to its composition, heat-resistant paint has a number of properties that extend the life of equipment and products. These include:

- the ability to withstand high-temperature conditions and drops;

- thanks to composites and resins, the composition of the paint under the influence of temperatures turns into a polymer and becomes inert (does not emit substances harmful to human health);

- enamels lie well and easily on the surface during painting and adhere to it;

- the coating turns out to be quite durable, it is well washed, cleaned;

- paints protect metal products and equipment from corrosion;

- with temperature changes, the paints do not crack, that is, they are sufficiently plastic;

- polymer compounds provide additional electrical insulation.

Brick heater paintwork functions

Painting a stone heating device is carried out for the following purposes:

- protection of the furnace surface from absorbing dirt, and clothing - from brick dust in contact with brickwork;

- facilitating daily care, that is, maintaining the necessary sanitary and aesthetic condition;

- increasing the class of decorative design of the unit;

- adapting the design of the heating device to the existing interior.

Brick heaters covered with colorless heat-resistant varnish

Brick heaters covered with colorless heat-resistant varnish

If the brickwork is made without sorting the stone by color, then painting the case with heat-resistant paintwork materials (paintwork material) of one or more colors will correct the situation. But, even a stove finished with a facing brick is transformed after applying, for example, a colorless paint-and-lacquer coating, which gives a juiciness and matte shade to the masonry.

Views

In practice, the decorative properties of the paintwork are of no small importance. In most cases, consumers are offered gray and black silver varieties. Other paints are much less common, although you can use red, white and even green paint if necessary. The assortment of leading manufacturers includes matte and glossy coatings of each specific shade.

Dyes in cans are relatively inexpensive compared to aerosols. Aerosol, at a seemingly low cost, is actually consumed very intensively.

If you want to paint the brake drums of a car, then at best you will have to use one spray can for two of them. In addition, there is a great risk of other auto parts clogging up with paint, they must be thoroughly covered during operation. Drying time in most cases does not exceed two hours.

Classification

There are several types of heat resistant paints. They differ from each other in composition:

- One- and two-component polyurethane. They make the surface glossy, dry quickly and are suitable for a wide variety of ovens.

- Silicone. It is the best choice for rooms with sudden temperature changes. After staining, the surface takes on a silvery tint.

- Alkyd organosilicon enamels. Suitable for processing stone, brick, metal and other materials. Easily cope with aggressive environmental influences.

- Water-based acrylic. The coating protects the metal from rust. This type of paint is not suitable for rooms with high humidity - such conditions greatly reduce its service life.

- Latex water-based emulsion. Such dyes are used to paint brick and concrete stoves. The finished coating has excellent water-repellent properties.

- Primer-enamel. Effectively and permanently protects any surfaces from corrosion, rust and high temperatures. Dries quickly. Primer-enamel is suitable for rooms with high humidity and aggressive environment.

Also, heat-resistant paints differ in their purpose:

- For industrial plants in which the temperature can rise to 700 ° C and above. Silicone resins must be present in the composition of such paint.

- For residential premises. Here, the temperature of the painted surfaces never rises above 100 ° C, so it is better to use resin-based materials such as acrylics.

- For surfaces with temperatures from 400 to 750 ° C. These products are most often available in cans.

- Dyes that contain epoxy resins are suitable for rooms with a temperature of 100-120 ° C.

Rating of the best high-temperature paints for metal

A large number of heat-resistant enamels for metal are presented on the construction market. It is difficult to choose among such a variety, but you can focus on those brands that have earned their popularity among buyers over the years.

A large number of heat-resistant enamels for metal are presented on the construction market.

A large number of heat-resistant enamels for metal are presented on the construction market.

Alpina Heizkoerper

It contains alkyd resin, as well as titanium dioxide. It is a high quality product that is easy to apply, getting an even layer without further scratching. The high cost is justified by the low consumption, ranging from 90 to 120 ml per square meter of surface.

The color is white enamel with a glossy effect, it can withstand up to 100 degrees. Most often used for water heaters. To obtain the desired shade, mix with pigments is used. Can be applied to cast iron, steel, aluminum and other types of metals.

White enamel with glossy effect, can withstand up to 100 degrees.

White enamel with glossy effect, can withstand up to 100 degrees.

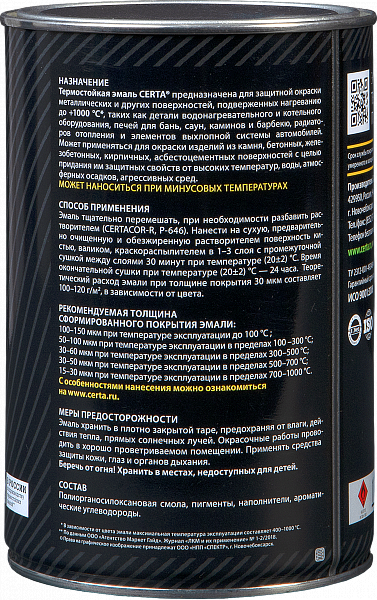

Elcon

You can also mix with different colors, there are about 250 shades in the coloration. However, the addition of colors leads to a decrease in temperature holding, if you leave the original black color, then the layer can provide protection from +1000 degrees. The coating can have a matte or glossy effect. Elcon refractory metal paint is sold as standard in cans, also in aerosols and buckets. In addition to metal products, it can be painted on brick, asbestos, concrete, but the surface should be hardened after painting.

In addition to metal products, it can be painted on brick, asbestos, concrete, but the surface should be hardened after painting.

In addition to metal products, it can be painted on brick, asbestos, concrete, but the surface should be hardened after painting.

Tikkurila Termal Silikonimaali

This paint is created from acrylic resin. Also black, sold only in cans, the coating is semi-gloss. You can use a spray gun to apply. This is a quality product that has a high price tag. You should also carry out a hardening process after painting, within 60 minutes the product should be exposed to 230-degree exposure. After that it can withstand up to four hundred degrees.

This paint is created from acrylic resin.

This paint is created from acrylic resin.

Bosny Hi-Temp

It is sold only in cans, while the price is quite high. The colors presented are silver and black. Temperature exposure reaches 650 degrees, the resulting painting effect is matte.

Alkyd resins are used in the base, it is not limited to use for metal, it is also suitable for wood, ceramics, plastic and other materials. Spraying is convenient, but small volumes of paint prevent large areas from being sprayed. It can be used without special surface preparation, it is permissible to apply directly to rusted areas.

Temperature exposure reaches 650 degrees, the resulting painting effect is matte.

Temperature exposure reaches 650 degrees, the resulting painting effect is matte.

Tikkurila Termal Silikonialumiinimaali

Also belongs to the high price category. The color of the coating is aluminum (gray), the effect is semi-matt, available in cans, withstands up to 600 degrees. It is based on silicone resin and has a low consumption.

To obtain a cured coating, heating is carried out to 230 degrees. After 30 days after painting, the surface can be washed with detergents.

It is based on silicone resin and has a low consumption.

It is based on silicone resin and has a low consumption.

Top 7 refractory paints for metal up to 1000 degrees

To protect the heating radiator, metal stove or other objects from corrosion and aggressive external influences, they are covered with heat-resistant paint and varnish enamels. The paintwork can withstand up to 1000 degrees C. The enamel not only protects, but also gives an aesthetic appearance.

It is difficult to make a choice in favor of this or that paint. A fresh coating will give the items a new look. We have compiled for you a rating of the most popular paints and varnishes. All submitted candidates have been verified by operational practice and experience.

Tikkurila termal silikonimaali

Country of origin Finland and Russia. Used for painting metal products. Based on silicone resin. Suitable for indoor and outdoor use. Resistant to high temperatures up to 400 degrees. This property provides protection for chimneys and dampers. Used for painting a car muffler. Black color.After drying, a semi-matt sheen is formed. Protects the structure of the metal.

Apply by brush or spray. The time of complete drying at a temperature of +230 C is exactly 1 hour. You can use the surface cleaners after one month. One liter of enamel is designed for 16-20 square meters. If the paint is applied in one layer. The price matches the quality. The only negative is heat treatment after application for complete drying.

Celsite-600

Black paint. Withstands exposure to temperatures up to +600 degrees. High degree of protection when using metal under the influence of high temperatures and moisture. Resistant to the influence of petroleum products, oil, gasoline. It is used for painting: electric motor, transformer, household heating appliances, bridge, tank, metal structure, railway tanks, calipers. Can be applied to reinforced concrete, asbestos-cement, brick, plastered surfaces. The enamel is applied in three layers. The color is black, the surface takes on a matte shade.

Certa KO-85

Certa is used for items that operate at temperatures from -50 to 900 degrees C. Heat-resistant enamel. It tolerates temperature changes well, including high temperatures. Protects against aggressive environments and high humidity levels. Prevents corrosion, moisture ingress. It is applied at minus 30 degrees Celsius. Transparent paintwork material. Used instead of varnish for covering bricks, concrete, ceramics. Apply in three coats to achieve a matte finish. In one layer, the brick acquires a wet effect.

Elcon

To obtain the desired color, it is mixed with a color scheme. At the same time, the pigment contained reduces the level of protection and durability of the painted coating.

The color palette is very rich. Gloss is matte and glossy. The product, painted in classic black color, can be heated up to 1000. And all other colors are not higher than 700 degrees. You can create beautiful patterns on the stenciled walls without involving specialists. In addition to metal surfaces, it protects concrete, brick, asbestos products from the influence of an aggressive environment.

Kudo

The composition does not include toxic components. When used, no harmful substances are released into the air. Can be used inside living space, stove or fireplace, chimney. No primer is required before application. Complete drying time 2 hours. It is considered to be slightly flammable, difficult to ignite. The room temperature is not lower than + 3C. The service life is not less than 20 years. Universal, used on products of different surfaces.

Dali

Matt paint for interior and exterior use. It is used for painting the exhaust systems of a car, chimney, chimney. Black color. Before opening the can, the manufacturer recommends mixing the contents well. Apply by brush or spray. Drying time from 1 to 3 hours. If you want to apply several layers to the product, then the time interval for each layer is 1 hour. Thermal hardening for 2 hours at a temperature of 200 degrees.

Serebryanka heat-resistant Novbytkhim

Heat-resistant universal. Used for glass, brick, concrete, plaster surfaces. The formed layer protects against oil, gasoline, water, and vapors, salt fog in the range from -50 to +600 degrees Celsius. Withstands sudden changes in temperature, but within the range indicated on the package. The enamel is waterproof, dries quickly. No more than three layers are applied. Stir not only before application, but also during application. Prepare the surface in advance. Remove dust and dirt. The composition includes organic substances.

Manufacturers overview

Since the actual performance of paint products is critical, there are a number of leaders who best protect load-bearing structures. The "Thermobarrier" coating guarantees steel protection for up to two hours, the minimum level is three quarters of an hour.

The cost and parameters of paints can vary greatly. "Nertex", for example, is created on a water basis and reliably covers the structure from high heat.

"Frizol" fully meets the standards of GOST, it can have the properties of the second-sixth groups. The time of use of the coating is a quarter of a century, fire resistance meets all the requirements.

Protection of the Joker brand works well, but it is advisable to use it only in rooms where the security level is equal to the second, third or fourth groups.

"Avangard" is a product of the recently appeared company of the same name, but it has already managed to gain solid authority and become famous for its excellent ratio of efficiency and price.