Applications

According to their purpose, self-tapping screws with a press washer are quite diverse. Products with a pointed tip are used to attach soft or fragile materials to a wooden base. They are suitable for polycarbonate, hardboard, plastic sheathing.

Painted roofing screws are used in combination with a polymer-coated profiled sheet, their classic galvanized counterparts are combined with all soft materials, sheet metal with a smooth surface. It is necessary to screw in self-tapping screws with a drill tip with a special tool.

The main areas of their application:

- installation of metal lathing;

- hanging structures on a sandwich panel;

- installation and assembly of ventilation systems;

- fastening the slopes of doors and windows;

- formation of barriers around the site.

Self-tapping screws with a pointed tip have an even wider range of uses. They are suitable for most types of interior work, do not spoil even fragile and soft coatings, decorative elements in interior decoration.

Photo of wood grouse screws on wood

We also recommend viewing:

- Crab system for shaped pipes

- What is a lifting shackle

- What is foundation bolt

- Why do you need a grover washer

- Dowel-clamp for cable fastening

- Lifting crane hook

- How to choose cable clamps

- Features of furniture fasteners

- Which toilet mount is better to choose

- Fasteners for timber structures

- Fasteners for plastic windows

- Advantages and Disadvantages of Screw Nails

- Best plastic dowels

- How to choose a threaded rod

- Self-tapping screw with drill

- How to choose self-tapping screws for metal

- How to choose a drywall dowel

- The most reliable pipe fittings

- The best screws for concrete

- How to choose pipe brackets

- High Strength Bolt Parameters

- Hex bolt

- Varieties of anchor bolts

- Construction nails

- How to use the drop-in anchor

- How to select and install a wedge anchor

- Features of dowel screws

- Hammer-in metal dowel

- What is a dowel-nail

- How to choose and apply a chemical anchor

- Sink bracket

- Types of brackets and fasteners for shelves

- How to choose a steel chain

- Choosing a bracket for the cornice

- Brackets for satellite dishes

- Choosing the best plastic clamps

- What is a construction bracket

- The best roofing screws

- Expansion dowel

- What are wood screws

- How to choose a wall mount for your TV

Self-tapping screw with a hex head ("hex self-tapping screw")

It looks like an ordinary bolt, but differs in the following features:

- infrequent screw thread;

- slightly pointed end.

The main application is fixing massive parts and large objects. "Hexagonal self-tapping screw" can be screwed into wood, and if you use a dowel, then into concrete.

Attention! The dowels for hexagonal screws must be two sizes larger than the self-tapping screw!

All work with such fasteners is carried out with keys of 17, 13 and 10 mm. It is clear that the head of the long and thickened screw will be 17.0 mm in size, and at the shortest 10.0 mm.

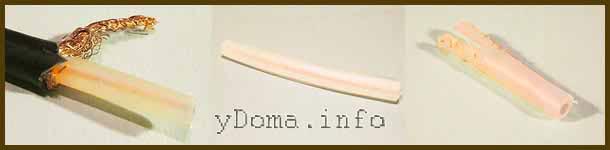

Making a dowel from scrap material

As a dowel, you can successfully use a furniture dowel. It is made from hardwood. Diameter 8 mm, length 40 mm, with longitudinal ribs. In the past, in the manufacture of furniture, fastening with dowels was widespread.

Sometimes there is a need to urgently fix an object on the wall, but there is no ready-made factory-made dowel at hand.In this case, you can independently cut it out of any dry piece of wood. A leg from a chair or stool will do. This has always been done before, for the reason that there were no plastic dowels on sale. For a homemade dowel, it is advisable to chamfer on one side to make it easier to hammer into the wall.

In order to screw the self-tapping screw into the wooden dowel, it is necessary, after driving it into the wall, to drill a hole in its center with a diameter slightly less than the diameter of the threaded part of the self-tapping screw.

A good dowel can be made from a television cable, in which the central core is insulated from the braid with polypropylene, by cutting off a piece of the required length from it. To do this, you need to remove the outer insulation and screening braid, remove the central core. Next, cut the cut piece of insulation in half by a third of its length. In the uncut part, drill a hole equal to the diameter of the self-tapping screw. On the outside of the dowel, it is advisable to make notches with a soldering iron so that the dowel does not turn in the wall when the self-tapping screw is tightened.

You will get a dowel, no worse than an industrial design. True, there is a lot of fuss, but if you need only a few, then it makes sense to tinker yourself.

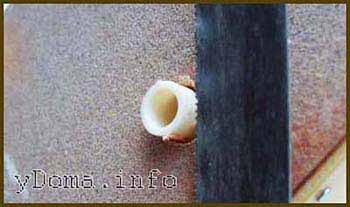

Sometimes, when drilling a hole in a wall, surprises happen. The drill, due to the heterogeneity of the wall material or in case of an unsuccessful hit on the joint of bricks, drills the hole not very accurately, and even much larger than the dowel. The dowel dangles, and in this case it will not be possible to hold the self-tapping screw in the wall. Sometimes the wall is very loose and a large piece of it breaks off. But there is a simple solution that I have been using since time immemorial.

An aluminum or copper wire with a diameter equal to the thread pitch of a self-tapping screw or screw is wound onto the self-tapping screw. It turns out a metal dowel with a thread. Since I came across a dowel with a double thread, I wound the wire in two passes. In such a wire dowel, the self-tapping screw is easily twisted and unscrewed. To exclude the twisting of the wire dowel in the wall, make a file on it on the sides of the face.

The dowel is mounted in the wall as follows. A solution of cement, alabaster, gypsum or other similar mortar is diluted, the drilled hole is filled and a wire dowel is inserted with a self-tapping screw screwed into it until drowning in this solution. If it is hard to insert, you can knock with a hammer. After the solution has solidified, the self-tapping screw can be unscrewed and the required item can be hung on the wall. It will hold on securely.

Sometimes it happens that the hole drilled in the wall with a drill of a given diameter does not ensure a tight fit of the dowel and when screwing the self-tapping screw into the dowel, it turns. In this case, you can use the composition "Liquid nails". From the tube, the drilled hole in the wall is completely filled with mortar and the dowel is immediately inserted into it. After half an hour, you can safely screw the screw into the dowel. Will keep tight.

With the help of liquid nails, according to the above technology, you can also securely fix a plastic standard dowel in a wall lined with a porous material, such as foam concrete.

There are times when the dowel cannot be completely driven into the hole, and it protrudes slightly, but cannot be removed. The protruding part must be removed. It can be cut with a cloth from a hacksaw for metal.

To exclude damage to the wall covering, it is enough to take a small sheet of sandpaper, make a hole in it with a diameter equal to the diameter of the dowel, put it on the dowel with the emery side to the wall and carefully cut it off. The wall covering will remain intact.

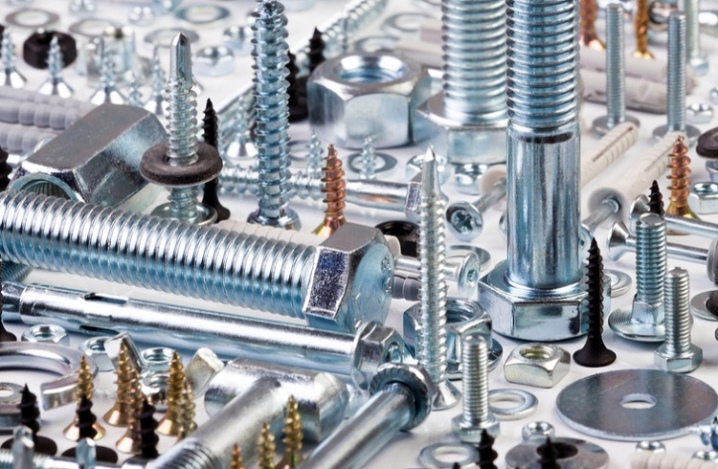

Definition of concepts

Hardware of various shapes and sizes are metal fasteners that are used to perform repairs, in construction, in the industrial and domestic spheres. In the construction industry, metal elements are used, which are conventionally combined into a group of fastening hardware. It includes the following products:

- nails;

- self-tapping screws;

- dowel-nails;

- anchor bolts;

- bolts;

- screws;

- screws;

- nuts;

- washers;

- hairpins.

Each type of fastening hardware has a metric standard established by GOST, which is used by manufacturers of these products in their manufacture. Metric hardware has its own description.

The nail looks like a metal rod with a flat head at one end and a pointed end at the other end. Nails are used to join parts made of wood or other soft material. Hardware can be of different diameters and lengths, the surface of the working rod at the nail can be smooth or have a screw thread. And also there are nails with stepped notches. Such configurations of hardware allow you to make reliable connections used in the assembly of furniture, the construction of wooden structures, for the installation of finishing materials.

What are they?

There are several classifications of screw-screws. The most common division is by the type of cap, which can be:

- with a semicircular head;

- hidden;

- round;

- square or hex.

Another way of dividing is to sort the screws according to the tip shape. They are:

- blunt - such products do not look very reliable, they are used to tie various elements;

- sharp crutch screws are considered the most popular.

The third classification implies the division according to the hook thread. In this case, the screws are grouped into the following types:

- single-pass;

- double-sided.

Additionally, it is worth noting the presence of L-shaped elements.

Often, the distribution of fasteners along the slots is performed. In this case, the screws are divided into the following types: cruciform, straight or hexagonal, track.

Furniture screws

Such an element is also called komfirm or euroscrew. As a rule, such self-tapping screws are supplied with furniture. If you are doing the assembly yourself, then you will have options for both long and short fasteners of different diameters. Their common feature is a rare and high thread, a blunt end, and a flat head with a recess for a hex wrench or drill. The top is most often closed with a decorative plug, which makes the fasteners almost invisible.

Since the end of the Euroscrew is blunt, pre-drilling is always performed first.

Hexagon screws are also used for furniture, which are very similar to the usual bolts (they are called "wood grouses"). However, in this case, the threads will be thinner and the end of the fastener will be sharper. Such products are necessary for the installation of massive furniture or rather large elements. If desired, such a bolt can also be screwed into concrete. Only in this case will you need a dowel (twice the size of the screw).

Wood grouses are also used for pitched and other heavy structures.

Healthy! The hex screw can be easily removed with a wrench.

By wood

Wood screws are used to join wood products as well as plywood. It is best to use such fasteners in tandem with expansion dowels. It is necessary to have self-tapping screws for wood both in city apartments and in private houses.

The design features of wood screws can be found in the video.

The video shows the varieties of such hardware, as well as the fastening technology.

Wood screws are of various types and sizes. Their distinctive features:

- Cross-shaped connector.

- Countersunk or semicircular head.

- Sparse thread pitch.

- Sharp tip.

The adhesion of the materials to be joined will be more reliable if there is a large thread pitch.

The coating of the hardware is selected depending on the conditions of use. Self-tapping screws with a press washer (sharp) are also used, which tightly connect thin parts.

The coating is used:

- Black.

- Yellow or white.

- Silver.

For fastenings of 2 wooden elements, black ones are often used. For this, the holes need not be drilled.To attach other elements to the tree, yellow or white are used (in this case, you must first drill a hole in the parts to be joined). Silver are intended for a more durable connection of sheet material, particle boards or wood.

For the convenience of selection, table 1 of the sizes of wood screws is presented. It indicates the nominal diameter (diameter of the leg together with the thread), the length of the self-tapping screw with the head, the inner diameter (the diameter of the leg without the thread), and the width of the head.

Table 1. Dimensions of wood screws.

| Nominal diameter, mm | Length, mm | Outer thread diameter, mm | Internal thread diameter, mm | Head width, mm |

|---|---|---|---|---|

| 2,5 | 12-25 | 2,25 – 2,55 | 1,1 – 1,5 | 5,1 |

| 3,0 | 12-45 | 2,75 – 3,05 | 1,5 – 1,8 | 6,0 |

| 3,5 | 12-50 | 3,2 – 3,55 | 1,75 – 2,15 | 7,0 |

| 4,0 | 16-70 | 3,7 – 4,05 | 2,0 – 2,5 | 8,0 |

| 4,5 | 25-80 | 4,2 – 4,55 | 2,22 – 2,7 | 8,8 |

| 5,0 | 30-120 | 4,7 – 5,05 | 2,52 – 3,0 | 9,7 |

| 6,0 | 40-240 | 5,7 – 6,05 | 3,22 – 4,05 | 11,6 |

For metal. In order to select a self-tapping screw of the required length, measurements of the thickness of the parts to be connected are first made. When connecting two elements, the self-tapping screw must enter the wood by at least 1/4 of the thickness of the wood.

Self-tapping screws for metal are available with a drill end and frequent threads. Their diameter is proportional to the length of the product. Several types are used:

- Black coated.

- Bug.

- With a press washer (drill).

- White zinc coated.

For mounting drywall to metal, black coated hardware is used, which will be described below. For mounting wood, thin sheet material to metal, self-tapping screws with a white zinc coating are needed, which protect against corrosion. Such hardware is strong enough due to cementation of the product surface.

A self-tapping screw with a press washer (drill) is needed to fasten steel sheets to metal. This will be discussed in the sections below. Self-tapping screws called bug are used to connect thin metal materials. They have a phosphate coating and a semi-cylindrical head.

To work with metal, self-tapping screws with a nominal diameter of 3.5 to 5 mm are used. Their technical characteristics are presented in table 2.

Table 2. Selection of self-tapping screws for metal.

| Nominal diameter, mm | Length, mm | Outer thread diameter, mm | Internal thread diameter, mm | Thread pitch, mm |

|---|---|---|---|---|

| 3,5 | 10 – 50 | 3,2 – 3,55 | 1,75 – 2,15 | 5,0 |

| 4,0 | 60 – 100 | 3,7 – 4,05 | 2,0 – 2,5 | 10,0 |

| 4,5 | 110 – 120 | 4,2 – 4,55 | 2,22 – 2,7 | 15,0 |

| 5,0 | 125 – 220 | 4,7 – 5,05 | 2,52 – 3,0 | 20,0 |

For metal with a drill. When working with metal, only special hardware should be used. The right choice will ensure a high-quality connection of materials for a long period of time.

The end of a self-tapping screw for metal is often made not sharp, but with a drill. Due to this, the hardware is easily screwed into solid material. The main advantages of this design of products for metal:

- No additional perforation required.

- Installation work is carried out faster.

- The connection of parts is done better.

In order to choose the right self-tapping screw from Table 2, it is necessary to measure the thickness of the parts to be joined. For a firm attachment to the metal, the self-tapping screw must enter the base to a depth of 10 mm.

Calculation example: the thickness of the attached part is 30 mm + 10 mm (the minimum depth to which the hardware must enter the base) = 40 mm. In total, a self-tapping screw with a length of 40 mm is obtained.

What are they?

As with any fastener, the dimensions of a self-tapping screw are their diameter and length. In order to prevent the buyer from purchasing different products for the same marking when buying in different stores, all self-tapping screws must comply with certain dimensional standards. For European manufacturers, these are:

- DIN - German standard;

- ISO is an international standard;

- GOST is a domestic standard.

In many ways, these three standards coincide, although they have their own nuances. The manufacturer in the description of the goods is obliged to indicate the characteristics in accordance with one of them. And in order to make it easier to standardize self-tapping screws by standard size, they are divided into several types.

By wood

The main difference between such self-tapping screws is a rather large thread pitch. This is explained by the low density and hardness of wood, which makes it possible to produce thinner and longer hardware (from the words "metal products"). Their length ranges from 11 to 200 mm, and their diameter ranges from 2.5 to 6 mm.The harder the wood, the larger the size of the fastener has to be selected. Most often, self-tapping screws for woodwork are called universal. For home renovations, the cheapest self-tapping screws with plastic dowels are enough to fix baseboards, socket boxes or hang a shelf on the wall.

In cases where the material is too dense, holes are drilled before fastening to the self-tapping screw. In order not to spoil the structure, you should carefully select the drill diameter. This can be done using a small table.

|

Self-tapping screw diameter |

Drill diameter |

|

4.0 mm |

2.5-3.0mm |

|

4.5 mm |

3.0-3.5mm |

|

5.0 mm |

3.5-4.0mm |

|

6.0 mm |

4.5 mm |

For metal

Self-tapping screws for working with metal are somewhat different from those intended for wooden structures. Their length ranges from only 9.5 to 75 mm, and the diameter starts from 3.5 mm and ends already at 4.2 mm.

With press washer

Such elements can be called universal, because they are used to fasten wood, metal, plastic, siding and many other materials. Their distinctive feature is a large cap, which is called a press washer. With its help, it turns out to press the fastened structure more tightly, without using additional washers. Their length is from 13 to 64 mm, and their diameter is always 4.2 mm.

Roofing

The self-tapping screws, which fasten the profiled sheet strips, metal tiles and other types of roofing, have a length of 19 to 100 mm, and the diameter of the rod - from 4.8 to 6.3 mm

Instead of a regular cap, they have a large washer with a rubber gasket, which does not allow water to pass through, which is very important when installing a roof. However, they are often used for fastening other structures, for example, a fence made of a corrugated sheet or a metal garage door frame.

Furniture

Such self-tapping screws are called "confirmations", they are used when assembling various furniture. Their length is from 40 to 70 mm, and their diameter is from 4.72 to 6.05 mm. Such self-tapping screws always require preliminary drilling of the marked holes with a special confirmation drill; screw them with a special hexagon, and not with an ordinary screwdriver.

"Capercaillie"

Such fasteners are used for the installation of heavy structures, where high strength and reliability are especially needed, for example, in the construction of interfloor floors. Their length is usually 40 mm, and the diameter starts at 6 and ends at 10 mm. The hexagonal head is tightened with an ordinary wrench or a special attachment for a screwdriver.

How to choose?

Before purchasing a screw, it is recommended to take into account several parameters:

- the estimated load that will be exerted on the product during operation;

- type of mounting block;

- the dimensions of the future screw, which you can calculate yourself;

- gaps between threads, determined by additional calculations.

On average, screws with sizes from 12 to 220 mm and a diameter of up to 6 mm are considered in demand. The rest of the fasteners should be classified in the specialized class. Medium pitch herringbone screws deserve special attention. If you buy them, you will need to additionally purchase special dowels.

When it comes to purchasing dowels on a concrete base, it is better to give preference to models with a cylindrical or countersunk head. If necessary, you can consider in advance the design of such elements and study their features.

The difference between a screw and a self-tapping screw is described in the next video.

Major differences

Inexperienced craftsmen or people who are far from working with tools can get confused in the definitions of "screw" and "self-tapping", which can cause the wrong selection of fastening materials and complicate the main task

To easily cope with screwing fasteners into any base, it is important to understand the difference between these products. Differences are difficult to understand with the naked eye, but in work they are of great importance.

To understand the difference between a screw and a self-tapping screw, it is more convenient to present a comparative table of these two products.

|

Differences |

Screw |

Self-tapping screw |

|

material |

Crafted from mild steel |

They are made from solid types of steel. |

|

treatment |

No heat treatment or corrosion protection |

In the production process, they are heat treated, due to which they acquire greater strength, and corrosion treatment allows them to resist external factors. |

|

base shape |

Blunt edge of the product |

Sharp tip |

|

thread |

Fine thread with small pitch |

Coarse thread with a sufficiently large pitch |

The data in the table is sufficient to distinguish self-tapping screw, but there are a number of other features.

- When working with self-tapping screws, there is no need to drill the material, since the fasteners have a tip similar to a drill, well-cut threads and high strength, which allows the product to be used for working with wood, plastic, metal and concrete. For a strong and easy screw tightening, drilling the surface is indispensable.

- Self-tapping screws have high strength due to the passage of the hardening stage, which allows you to work even with strong materials, but despite all the positive qualities, they are fragile, so the head can be torn off or bite off with pliers. The screws are made of a softer material, so they do not break, but bend, which is more convenient for a number of cases.

- On self-tapping screws, the thread is applied to the entire rod, which allows you to screw the product to the very head and fix it as much as possible. The screws have an incomplete thread, they have a smooth space under the head, which helps with tightening work, since the material does not crack during dynamic work.

The following video describes how a screw differs from a self-tapping screw.

Dimensions and weight

The main parameters for small fasteners are size and weight. It is worth considering the first in more detail first. There are two main sizes of fasteners:

- diameter;

- length.

For the main diameter, take the one that allows you to determine the size of the circumference of the protrusions on the thread. Currently, more than 10 standard sizes of various screws are available with a diameter indicator from 1.6 to 12 mm.

A certain type of self-tapping screw does not always have all available diameters. The most popular in this regard are universal screws, the range of which is wider than the rest. For specialized self-tapping screws, the number of diameters is slightly less.

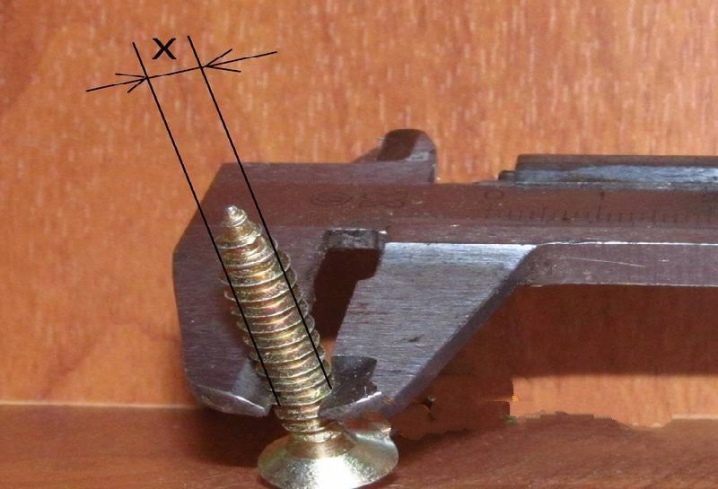

As for the length, this parameter is measured in two ways.

- For hidden head. The length is taken into account in full - from the bottom of the head to the end of the point of the product.

- For a convex head. The parameter is defined as the distance from the top of the head to the bottom of the self-tapping screw.

Regardless of the type of screw, the size range does not change in this case. It lies in the range from 4.5 to 300 mm. It is noteworthy that some specialized fasteners may have additional lengths based on individual customer requirements. It should be noted that a certain model of screws has a limited range of lengths.

Several parameters affect the choice of the diameter and length of the fastener:

- the load of the connection formed by the fasteners;

- dimensions of parts;

- the material into which you plan to screw the screw.

And this is not a complete list of factors that affect the final dimensions of the product. So, when determining the required diameter that you want to screw into a plastic expansion dowel, you should take into account the manufacturer's advice and recommendations. They are indicated on the package or in the passport.

The following statement is considered completely logical: the larger the diameter of the screw, the more durable the connection will be. However, at the same time, the amount of torque increases, and therefore there is a problem of head breakage or breakage of a tool that cannot cope with drilling material.The suitable screw length should be determined by summing the nominal length of the fastener dowel, the thickness of the element to be connected, and the diameter of the selected fastener. The last parameter will take into account the exit of the end of the self-tapping screw from the dowel.

Often companies involved in the production and sale of screws sell fasteners, calculating the price by weight. Therefore, this indicator is also considered important.

The choice of the length of the screws

There are several rules for choosing the length of a self-tapping screw that apply in different situations. When joining / joining two not very massive parts, the following selection rules work:

-

So that you do not connect, the sharp end of the self-tapping screw should not stick out from the other side of the parts to be connected. That is, in any case, it should be shorter than the parts to be joined. Moreover, it is believed that the maximum strength will be if at least 5-6 mm remains to the edge of the lower part. So count it.

The length of the self-tapping screw is selected depending on the parts to be fastened

- On the other hand, the minimum self-tapping screw should fit into the bottom part by at least 1/3 of the thickness of the part to be attached. That is, if you fasten, say, a beam of 100 * 100 mm, then the minimum length of the self-tapping screw should be 1/3 longer. For this timber, the minimum screw length is 100 + 100/3 = 133 mm. Take the nearest larger. If you fasten a board 28 mm thick, then the minimum screw length is 28 + 28/3 = 37 mm (usually 42 mm is chosen).

If a thin piece is attached to a massive base, another rule works. Then the length of the fastener should be 2-2.5 times longer than the attached part. So it is necessary to select the length of the self-tapping screw if you attach something to a wall, say, or to a concrete floor. In this case, in order to fix the same 28 mm board to the wall, the length of the fastener is 56-70 mm. This is the difference.

Self-tapping screw sizes: the most applicable options

How to choose the length of the self-tapping screws, it seems, should be clear. Now about what they are in general. The situation here is confusing. Neither screws nor self-tapping screws have a common standard. There are several standards of "worn out" years of release, in which the sizes of some types of self-tapping screws are prescribed.

- GOST 1145-80. Countersunk self-tapping screws.

- GOST 1144-80. Pan head screws.

- GOST 1146-80. Half-countersunk head screws.

The situation today is that each manufacturer produces its own "line". They are oriented, of course, on demand. Well, the parameters of the heads are usually made in accordance with one or another GOST. This will somehow stabilize the situation. Sometimes the assortment - diameters and lengths are also made according to the standard. In this case, in the description of self-tapping screws, the diameters in which they are generally produced are indicated, and then there is a postscript: it corresponds to such and such a GOST. This means that the heads comply with the specified standard, as well as that the assortment corresponds.

How, then, are self-tapping screws chosen in terms of length and diameter? Calculate / determine the length that is needed, determined with the type of head. Then they look at the diameters and make the final choice. Let's say right away that the principle “thicker is better” does not work for wood. This can be applied to metal. For wood, thinner ones are better, but with good carvings and made of good metal. This is ideal.

If the manufacturer has his own parameters of self-tapping screws, they are indicated in the description

But this is not enough. The store usually offers up to a dozen options of the same size, but from different manufacturers. And if it is more or less easy to decide on the metal and the type of processing, then it is difficult to choose which brand to take. There are, of course, proven ones, but they are expensive. Although, if we take the cheap ones, 30-50% can go to marriage. What kind of marriage? Now they bend, then the hats fly off. It is not always, but often. If you are "lucky" to run into such fasteners, it turns out that buying "expensive" ones would not be more expensive. Well, or not much more.

Now compare the two tables. They are compiled according to different GOSTs. As you can see, the diameters and lengths are the same. This makes life easier.If in the production of fasteners they adhered to the standard in terms of the diameter / length ratio, then everything is simple. If not, then the manufacturer in the description of the screws attaches a table with dimensions (as in the picture above).