Related Posts via Categories

- Bolt strength class - how well do the hardware resist shattering?

- Anchor bolt with nut - proven fastening option

- Dowel-nail - which fasteners are of the highest quality?

- Anchor bolts - a special type of fasteners for complex structures

- Bolt designation in accordance with GOST - we are guided in the world of hardware

- How to rivet a rivet - automatic and manual methods for different materials

- Bolt manufacturing - straightforward workflow

- Spring Cotter Pin - Eared Fastener for Mechanical Engineering

- High Strength Bolts - Complete Fastener Information

- Blind rivet sizes - what should you think about when calculating?

Peculiarities

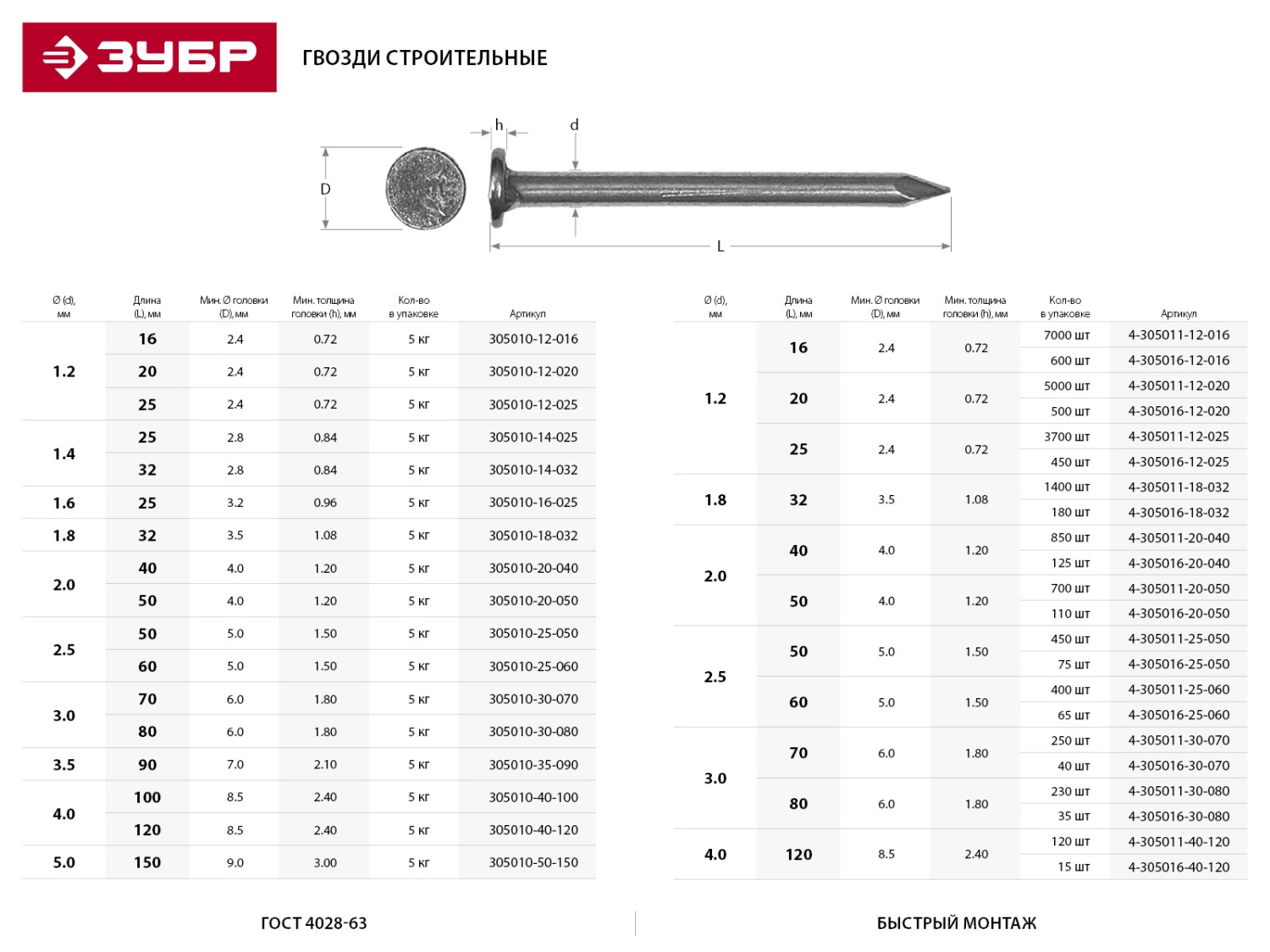

No matter how improved construction technologies, nails remain one of the most demanded elements for fastening. Construction nails are a rod with a pointed tip, at the end of which a head is located. The shape of the rod and the head can have a different shape and size, which determines the purpose of the hardware.

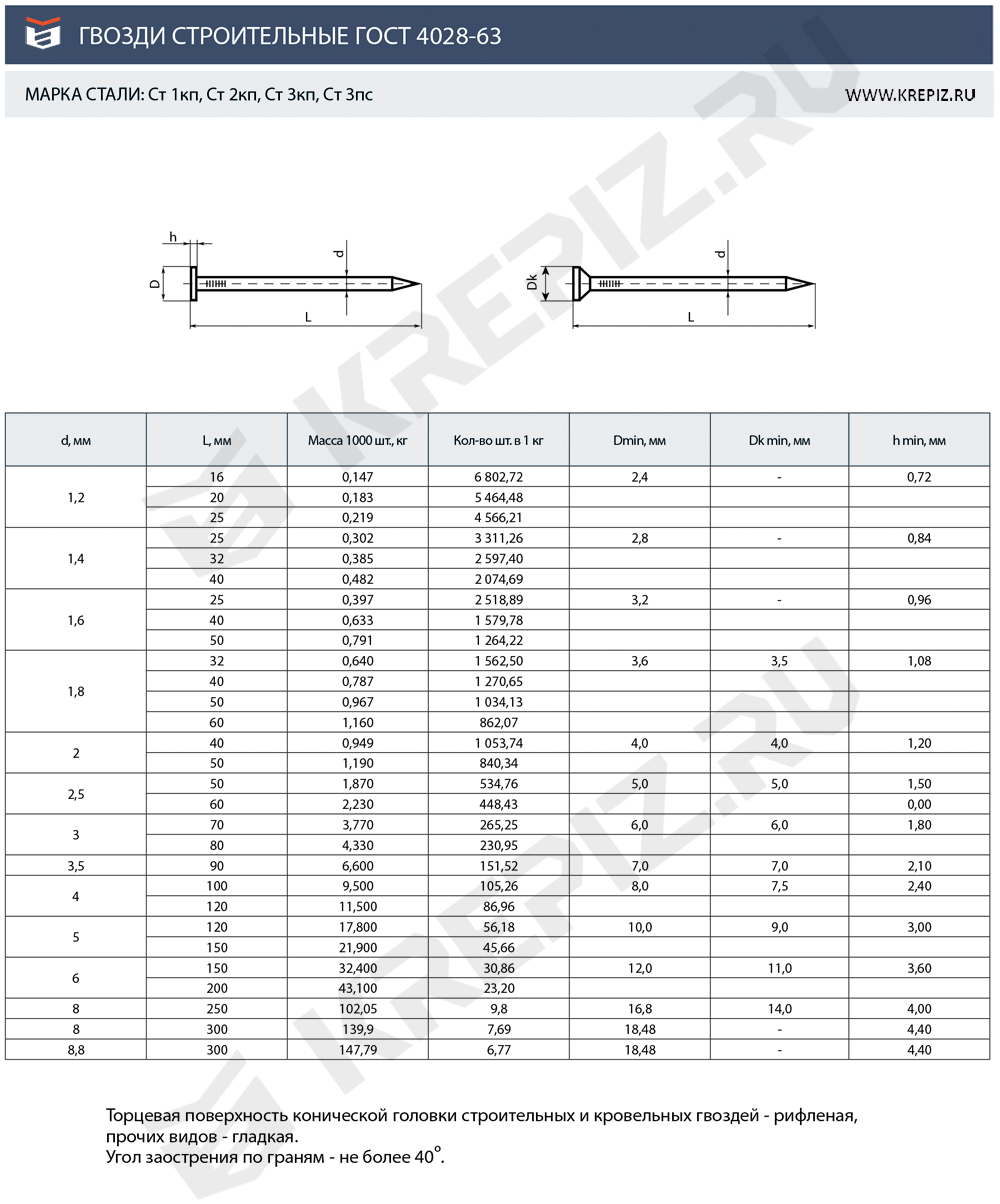

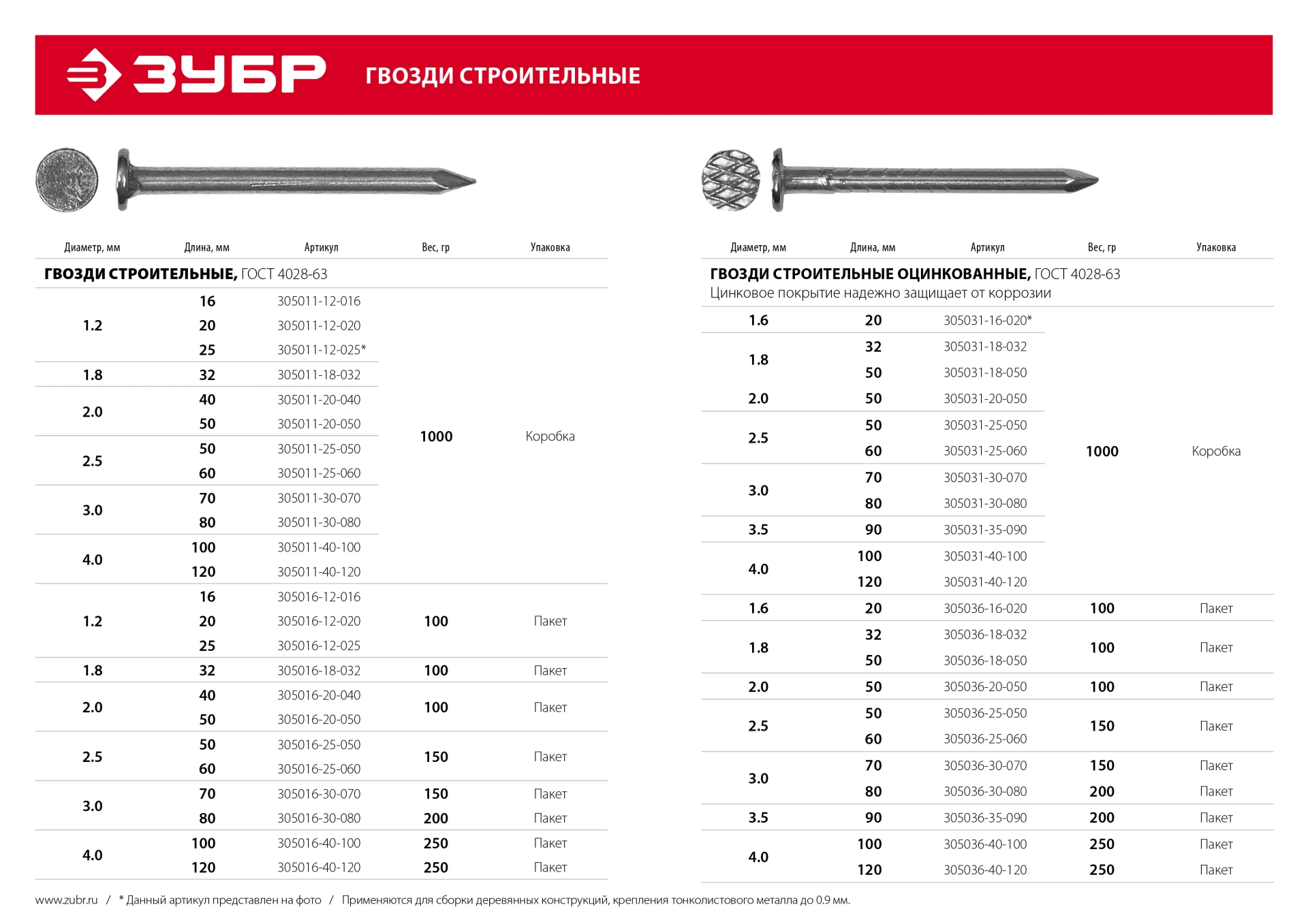

For construction nails, there is a valid GOST 4028, it regulates the manufacture of these devices. The material for the production of hardware is usually low-carbon steel wire with a round or square cross-section, without heat treatment.

Specifications:

- the core of the product can have a diameter of 1, 2 - 6 mm;

- the length of the nail is 20-200 mm;

- indicator of one-sided rod deflection 0, 1 - 0, 7 mm.

The sale of hardware for construction is usually carried out in batches, each of which is in a corrugated cardboard box weighing from 10 to 25 kilograms. The package contains only one standard size of the nail, each unit of which must be marked.

The advantages of using fasteners for various jobs

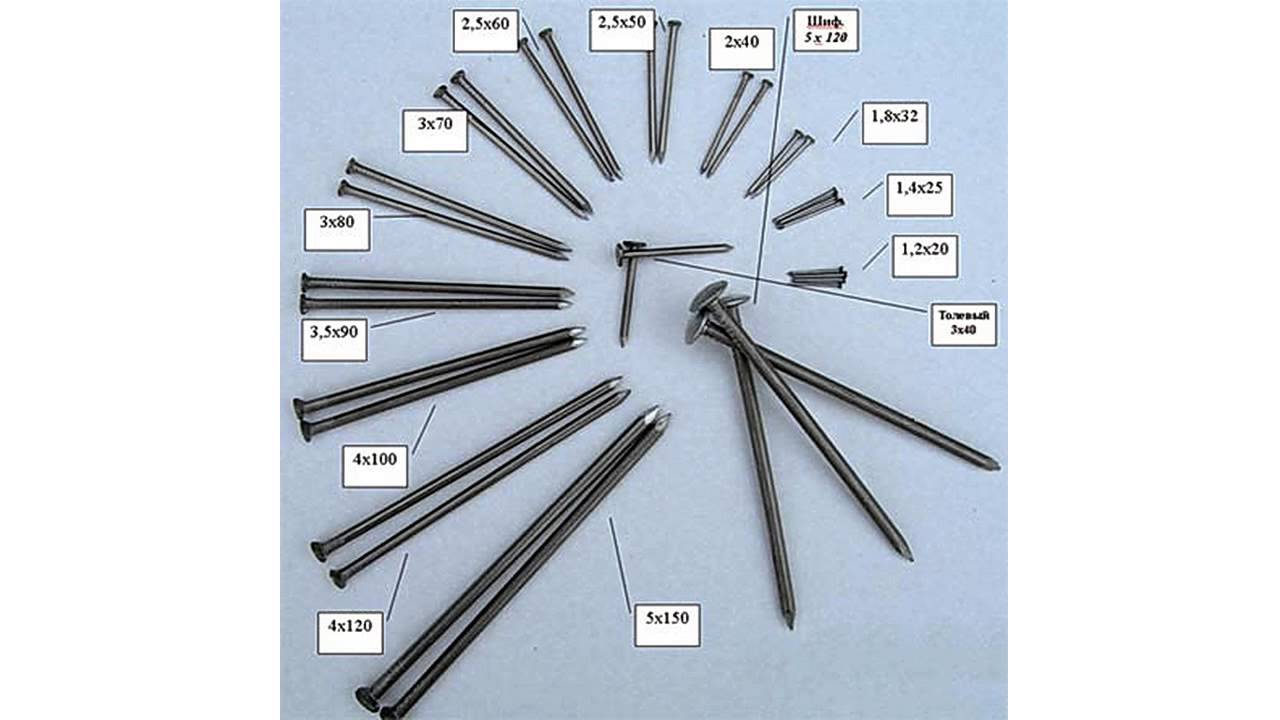

Considering the proposed photos of nails, you can visually assess their characteristics and choose the best fastener option for independent use.

In addition, when choosing the necessary accessories for connecting different elements and building structures, it is necessary to take into account the advantages of their use:

- universal bonding of homogeneous or different materials, in the process of carrying out all kinds of work;

- correctly selected nails for their intended purpose withstand different types of load during operation;

- a wide range of fasteners offered, suitable for performing all kinds of work processes and procedures;

- ease of use and ease of installation with the ability to use not only a hammer, but also other tools;

- long service life of the connected structures and the fasteners themselves, provided that they are correctly selected.

Using a Fastener Securing Gun

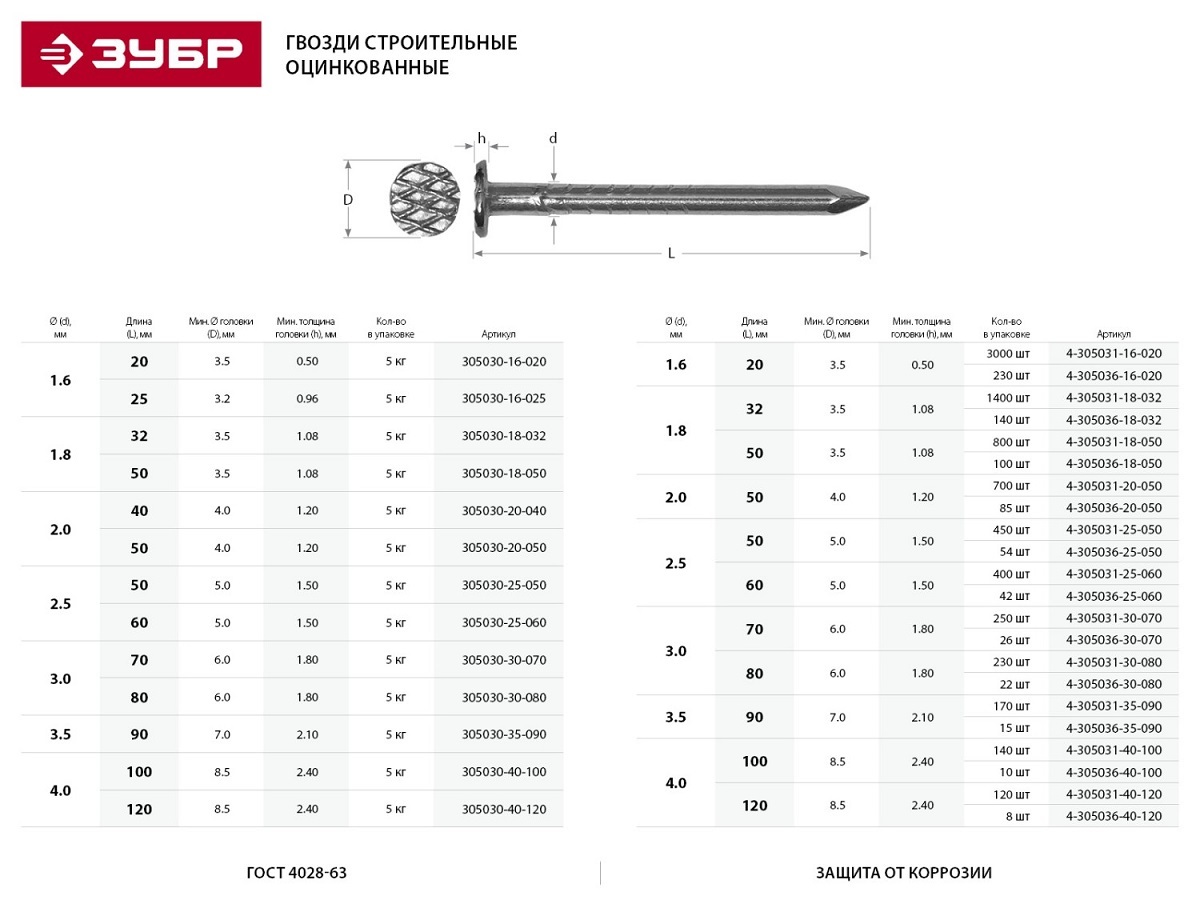

The most common type of fasteners are construction nails, which are of different types according to the degree of protection:

- black nails without a protective layer;

- galvanized, covered with a layer of zinc;

- copper-plated, protected from water and steam;

- brass plated, with absolute corrosion resistance;

- chrome plated, distinguished by the optimal cost.

To increase productivity and speed at nailing, construction guns are used to help automate the installation process. In this case, it is necessary to select the correct mode of operation of the device and ensure full compliance with security measures.

Photo of nails

We also recommend viewing:

- Threaded hairpin

- Wedge anchor

- Dowel nail

- Cable ties

- Fasteners for wires

- Shelf brackets

- Screw nails

- Driven anchor

- Metal dowel

- Roofing screws

- Drywall dowel

- Sink mount

- Furniture fasteners

- Hex bolt

- Antenna bracket

- Wood grouse

- Steel chain

- Grover

- Wood fasteners

- Expansion dowel

- TV mount

- Construction shackle

- Dowel screw

- Self-tapping screws for metal

- Eaves bracket

- Metal fasteners

- Fasteners for windows

- anchor bolt

- Foundation bolt

- Plastic dowel

- Dowel clamp

- Wood screws

- Rigging shackle

- Crab system for shaped pipes

- Pipe bracket

- Clamp for cable

- Fasteners for pipes

- Chemical anchor

- Load hooks

- Self-tapping drill

- Plastic clamps

- Toilet mount

- High strength bolt

- Concrete screw

4 How to work with nails correctly

Finally, we bring to your attention a few tricks that will help you easily and effortlessly drive a nail into any surface.

You don't need to hold the nail with your fingers the entire time you hit it with a hammer. It is enough, having put it to the place intended for hammering, lightly knock on the head so that the nail enters 2-3 mm. Then the fingers can be removed and thereby save them from injury. If the nail is bent during driving, you can take it by the bend with pliers and continue driving.

Pliers or a nailer are usually used to remove the fasteners. Moreover, using pliers, it is recommended to make rotational movements in the direction and counterclockwise. When using a nailer, it is recommended to place a thin piece of wood underneath it to keep the wall or floor surface from damage.

Working with fasteners

When fastening two parts, it must be borne in mind that for good adhesion, the nail must sink into the lower part at least 2/3 of its total length. The same rule applies to walls.

In order to qualitatively mount the hinged structure, the nail is driven in, slightly tilting its head away from you, so that the structure is held stronger under load. When laying boards on the floor, it will be best to nail the first row of boards, holding the nails straight, and for the second and subsequent rows observe a slight slope so that the nail point "looks" towards the previous row. Thus, it will be possible to minimize the gaps between the boards.

When driving a bent nail, it is important to take into account that, when plunging into the wood, it will not straighten, but will continue to move along a curve. Perhaps such a property will be useful for assembling any non-standard design.

But it will not be easy to get it out of the tree afterwards.

For hammering small nails it is better to use a “doboinik”, since it is very inconvenient to hold small nails in your fingers. In addition, this way you will not damage the surrounding material, even if you miss the nail. This is especially true in the presence of expensive plaster or wallpaper.

2 Classification of nails and their features

We propose to consider the main configurations and the purpose of construction nails:

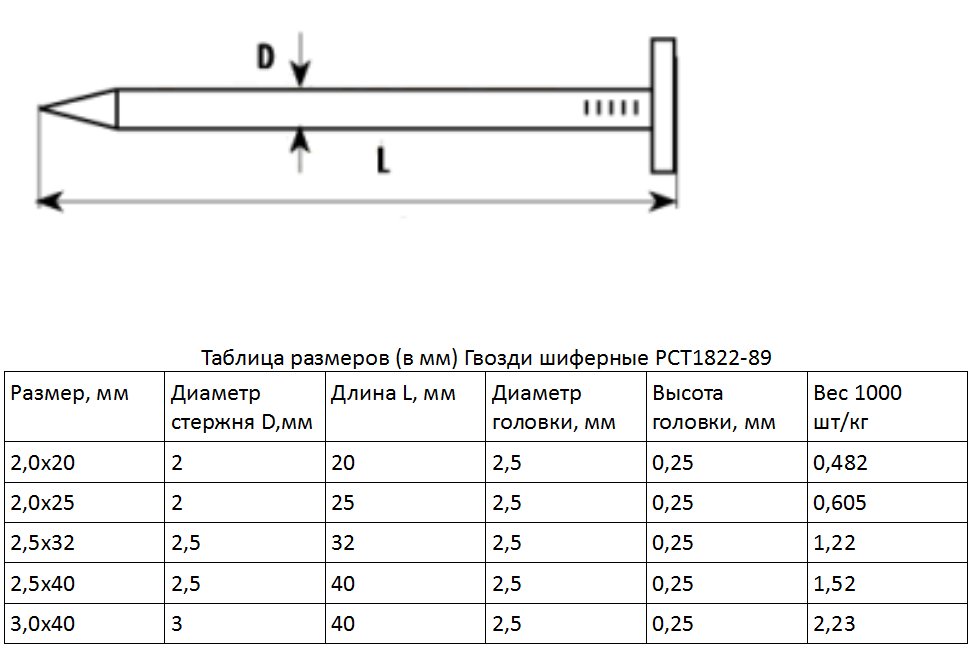

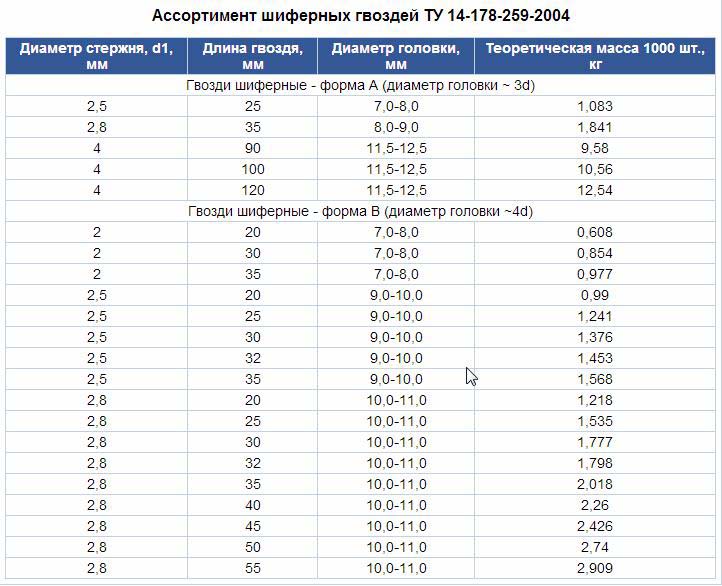

Slate nails. They are used for fastening slate sheets to the timber roof frame. Outwardly, these nails are round in cross-section, with a round flat head, the diameter of which is 18 mm. As for the rod, its diameter is about 5 mm, and its length is up to 100 mm. In this case, it is better to buy galvanized nails to avoid rusty streaks on the roof covering.

Roofing nails. With a diameter of 3.5 mm, the length of these nails is only 40 mm, and they are used when laying roofing iron, to attach it to the substrate.

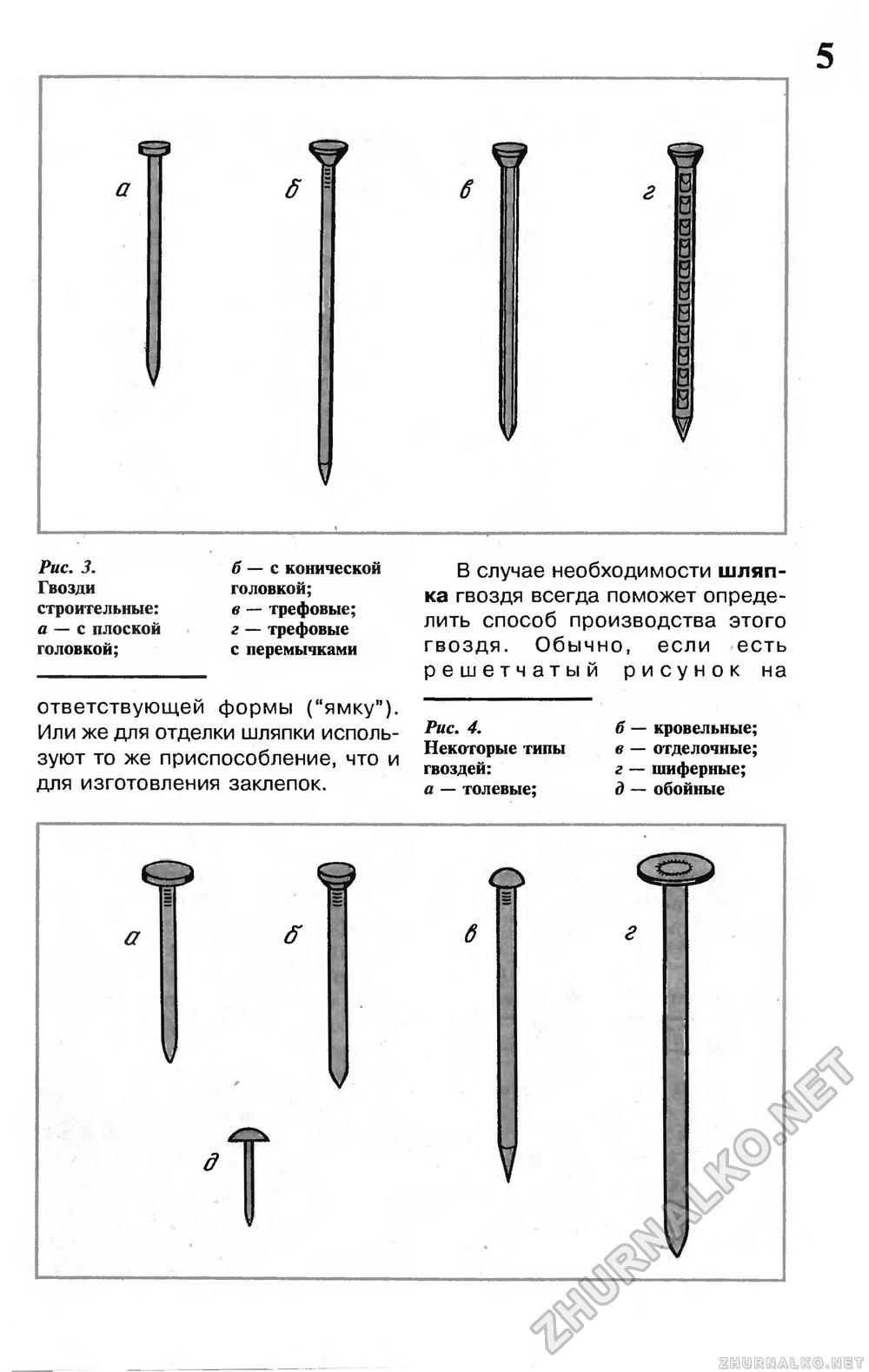

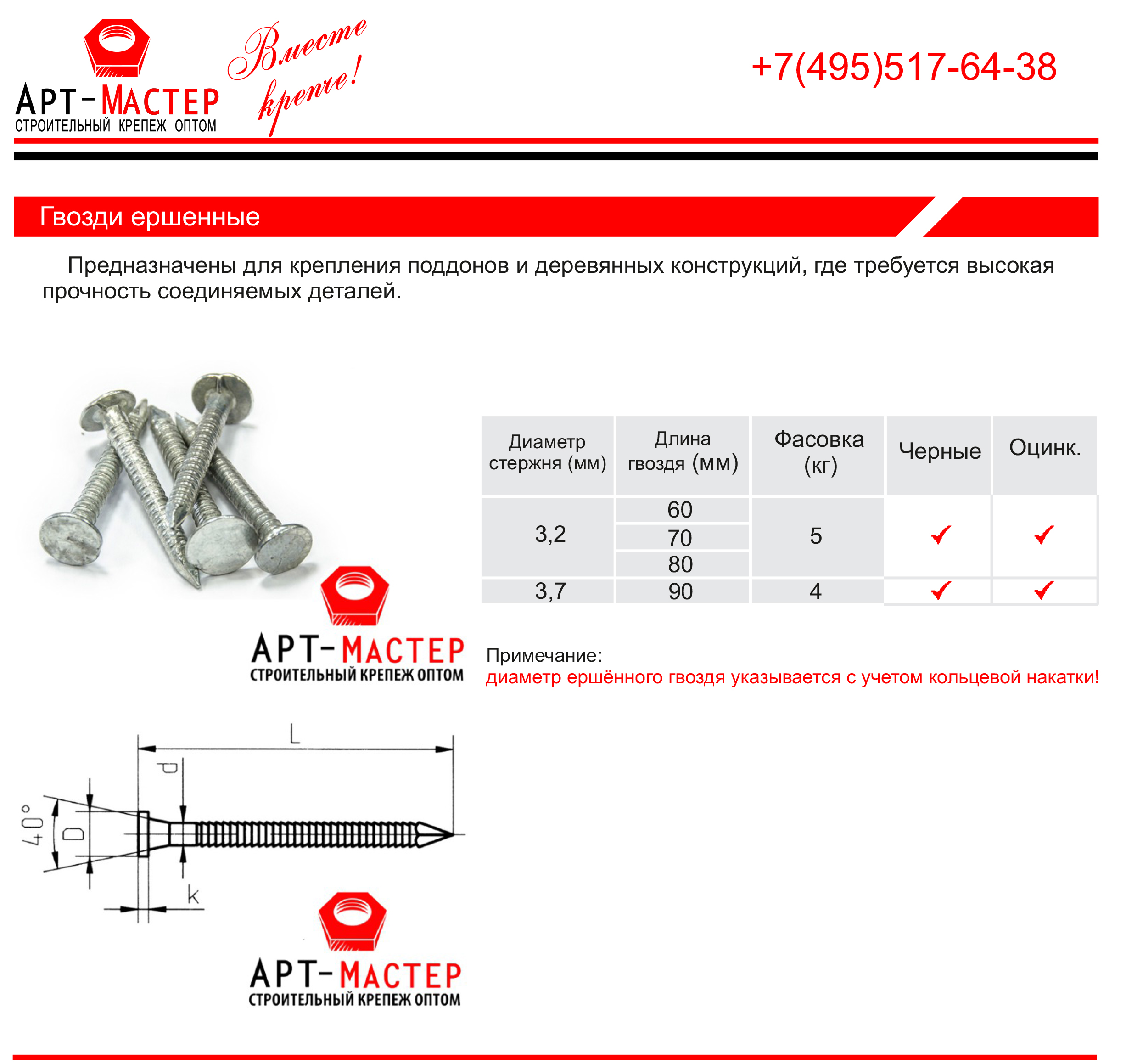

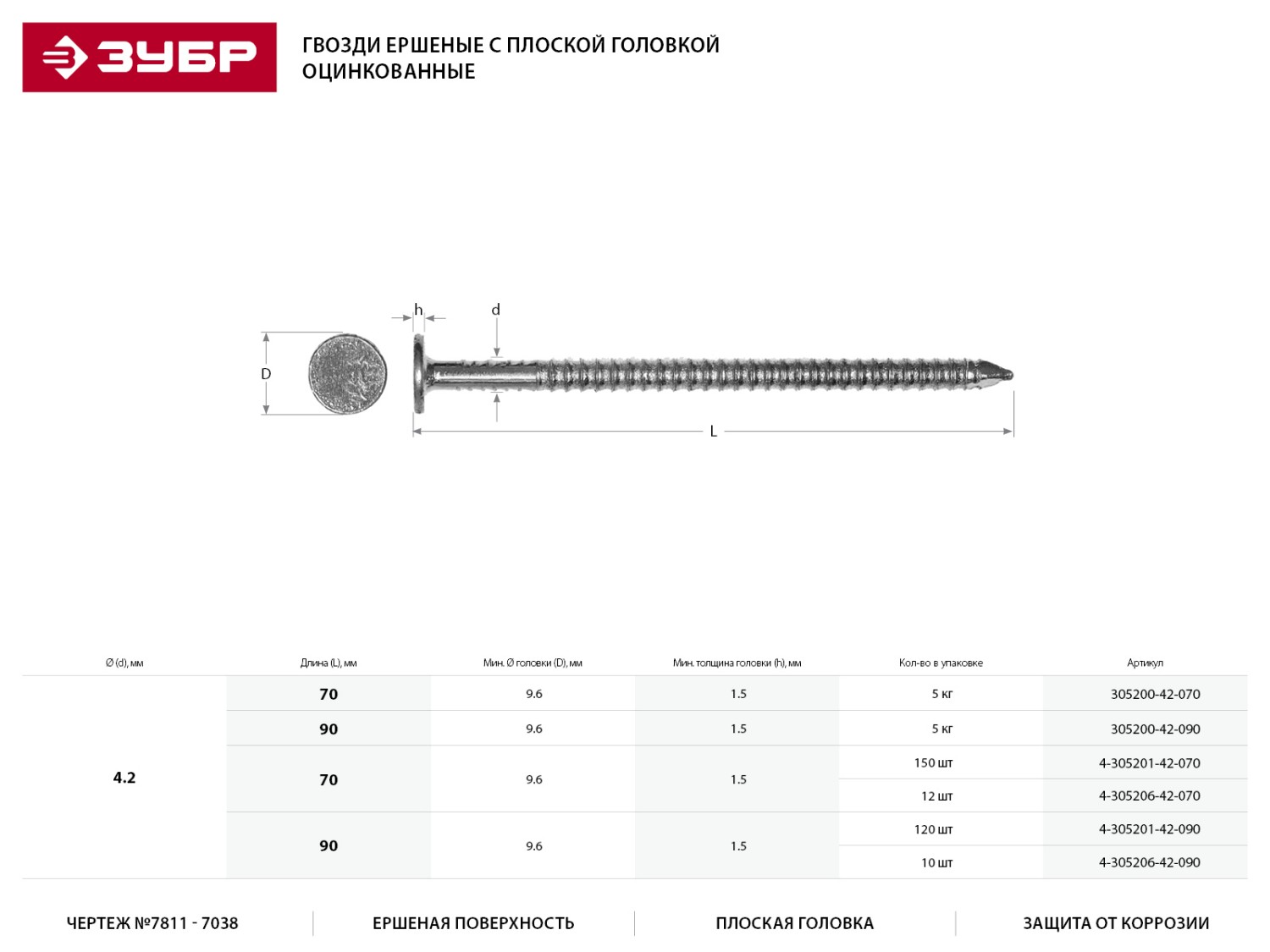

Clubs nails differ in that they have grooves along the rod, either solid (continuous) or with bridges. These nails are more securely held in the wood, and they are also used for fastening various types of roll coatings.

Carved nails have a screw shank and, compared to wire nails, are considered to be more durable, less prone to bending.

However, it should be borne in mind that such hardware can split the board, so they should be used with caution and only on sufficiently strong materials.

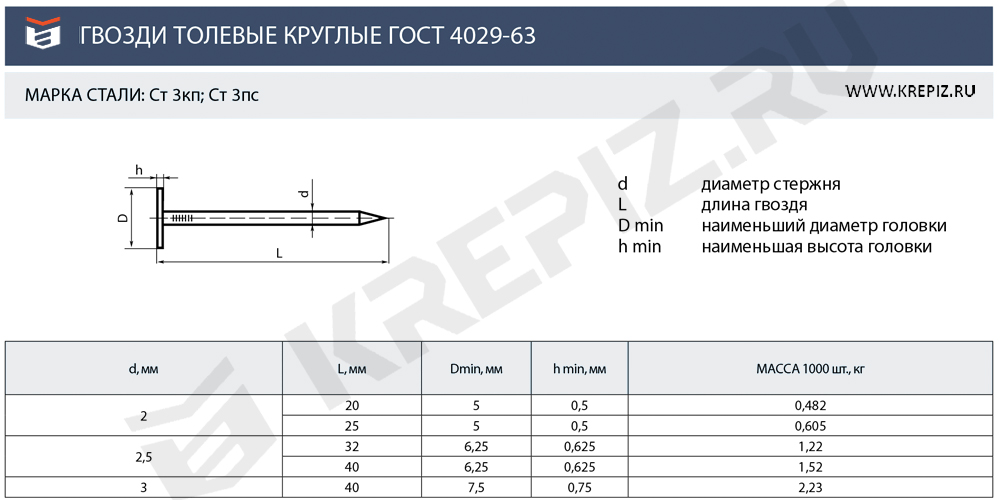

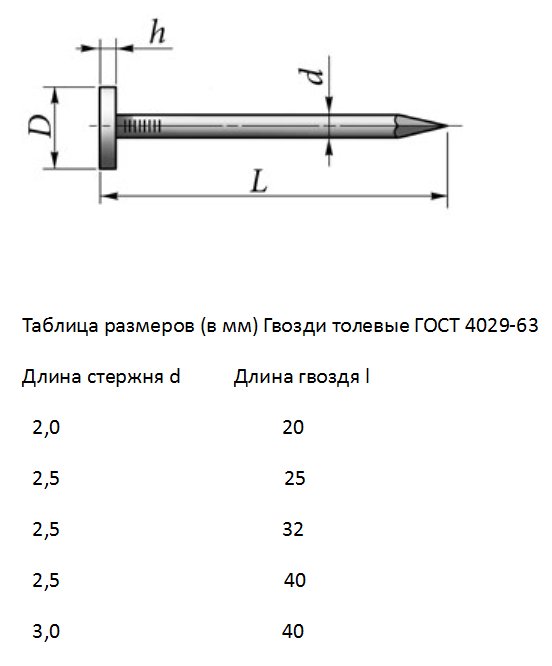

Roofing nails (round). These nails are characterized by a flat head with a larger diameter than usual.

A rod with a cross section of 2 and 2.5 mm in diameter, up to 40 mm long is intended for fastening and holding roofing materials supplied in rolls, for example, such as roofing felt or roofing felt.

Finishing nails are small in size with a semicircular head and are used for surface cladding with finishing materials.

Wallpaper round nails also serve for decorative purposes, with a rod diameter of 1.6 or 2 mm, they can be from 12 to 20 mm in length. Unlike finishing ones, the heads of these nails are not just semicircular, but are represented by the widest assortment of various reliefs, shapes and textures.

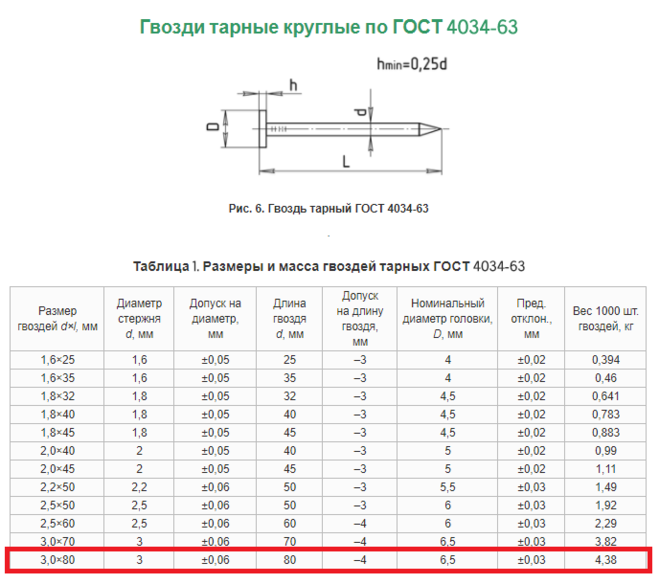

Tare nails, as their name implies, are used for the production of boxes and pallets. Their diameter ranges from 1.4 to 3 mm, but in length they reach from 25 to 80 mm. Their cap can be flat or conical.

Ship nails are used in the construction of ships or barges. These nails are characterized by a square or round cross-section, and for them, as well as for roofing, a zinc coating is required.

Different types of nails

Different types of nails

Description and application possibilities of fasteners

The price of nails set by manufacturers and sellers depends on their economic purpose and the scope of their intended use. Such fasteners belong to metal products, as one of the most common hardware used at different stages of the household to connect different elements to each other.

In appearance, nails are a simple structure, consisting of a head and a leg, which are necessary for joining materials.

The main features of the practical use of the fastening element are strong fixation and ease of installation during use.

With the help of a hammer, the nail is simply driven into the body of the materials and holds them in a fixed position due to the action of the physical force of natural friction.

Download document

GOST 4028-63

INTERSTATE STANDARD

CONSTRUCTION NAILS

Design and dimensions

|

Moscow Standardinform 2009 |

INTERSTATE STANDARD

|

CONSTRUCTION NAILS Design and dimensions Building nails. |

GOST |

Date of introduction 08/01/1964

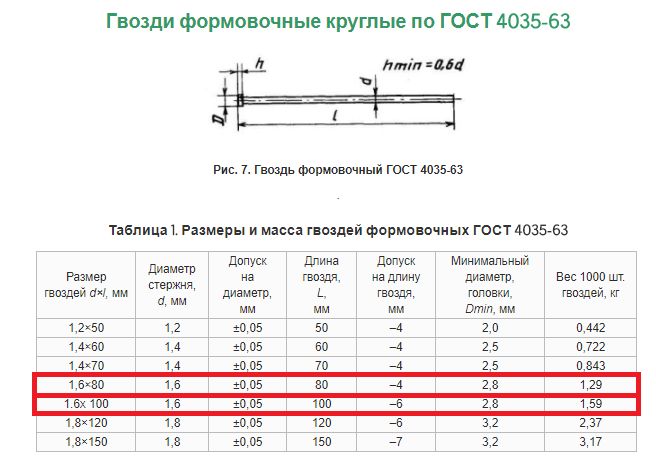

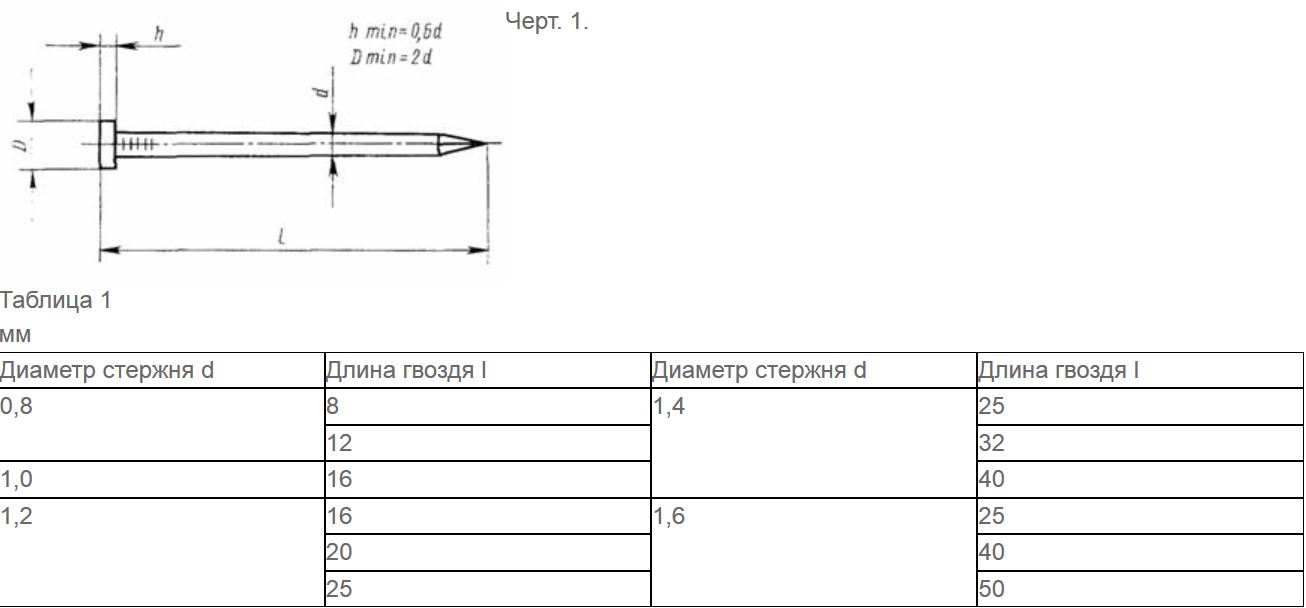

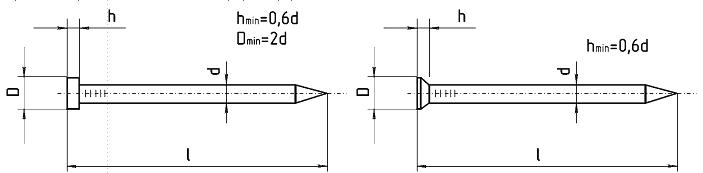

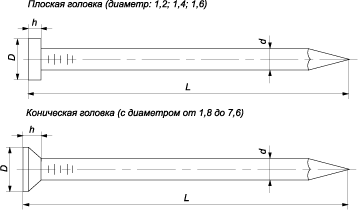

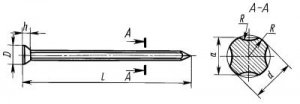

1. Design and dimensions of flat head construction nails

must correspond to those indicated in dash. 1 and in table. 1.

h min = 0.6d; D min =

2d

Heck. 1.

Table 1

mm

|

Diameter |

Nail length l |

Bar diameter d |

Nail length l |

|

0,8 |

8 |

1,4 |

25 |

|

12 |

32 |

||

|

1,0 |

16 |

40 |

|

|

1,2 |

16 |

1,6 |

25 |

|

20 |

40 |

||

|

25 |

50 |

Conventional designation of flat head construction nails,

with a rod diameter of 1.2 mm and a length of 25 mm:

Nails P 1,2? 25 GOST 4028-63

(Modified edition, Amendment No. 2).

2. The design and dimensions of construction tapered nails

head must correspond to those indicated in Fig. 2, 3, 4 and c

tab. 2.

Round nails

h min = 0.6 d

Heck. 2

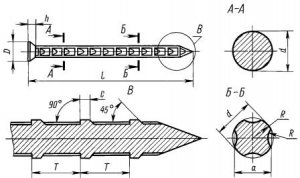

Nails of clubs

h min = 0.6 d

Heck. 3.

Nails of clubs with jumpers

h min = 0.6 d;c = 0.3 d;

T = (1.25 - 1.5) d

Heck. 4.

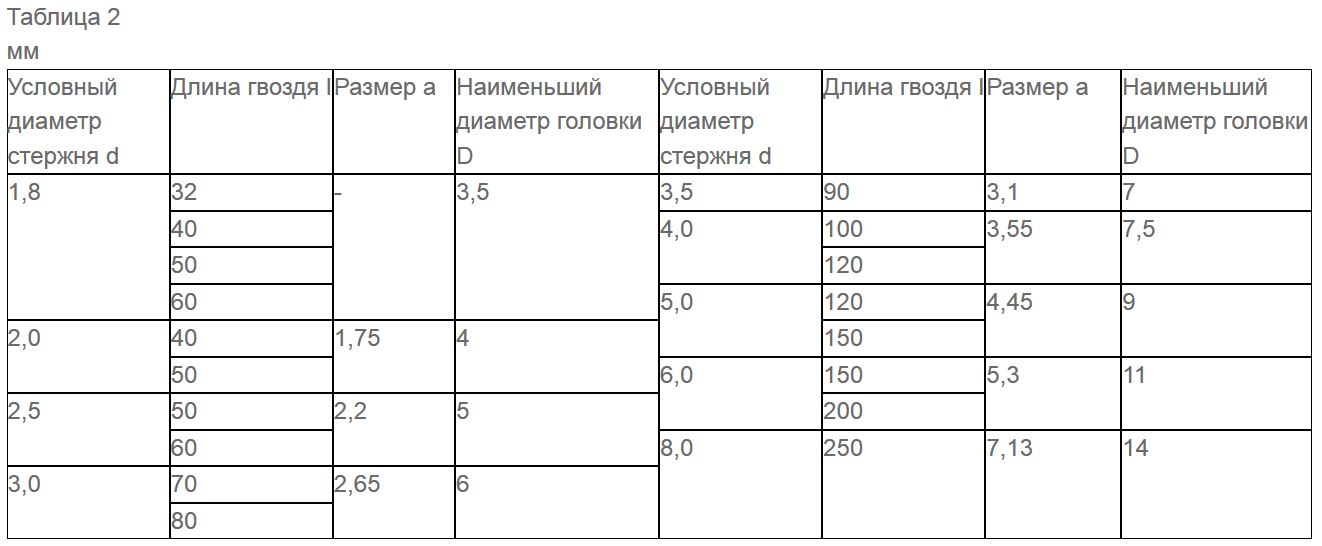

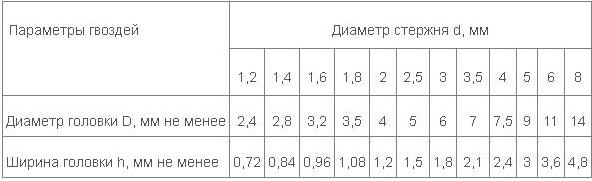

table 2

mm

|

Conditional |

Length |

The size a |

Least |

Conditional |

Length |

The size a |

Least |

|

1,8 |

32 |

— |

3,5 |

3,5 |

90 |

3,10 |

7,0 |

|

40 |

4,0 |

100 |

3,55 |

7,5 |

|||

|

50 |

120 |

||||||

|

60 |

5,0 |

120 |

4,45 |

9,0 |

|||

|

2,0 |

40 |

1,75 |

4,0 |

150 |

|||

|

50 |

6,0 |

150 |

5,30 |

11,0 |

|||

|

2,5 |

50 |

2,20 |

5,0 |

200 |

|||

|

60 |

8,0 |

250 |

7,13 |

14,0 |

|||

|

3,0 |

70 |

2,65 |

6,0 |

||||

|

80 |

Note. At the request of the consumer, round nails in size

1.8 x 32 are manufactured with a flat head.

Conventional designation of conical head construction nails

round, 2.5 mm in diameter, 60 mm long:

Nails K 2.5? 60 GOST 4028-63

The same, of clubs:

Nails T 2.5? 60 GOST 4028-63

The same, of clubs with jumpers:

Nails TP 2.5? 60 GOST 4028-63

(Modified edition, Amendments No. 1, 2).

3. Technical requirements for nails - by

GOST 283.

Note. Unilateral uniform deflection of the bar in the middle

parts of a nail with a size of 1.8 × 60 should not exceed 0.7 mm.

(Modified edition, Amendments No. 1, 2).

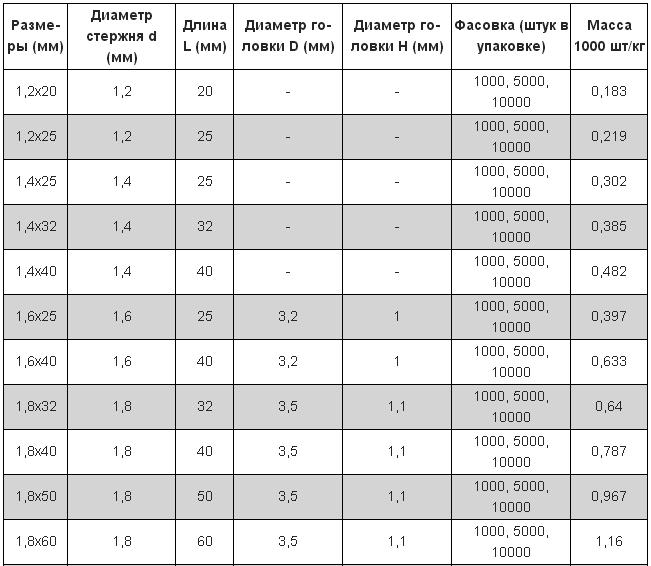

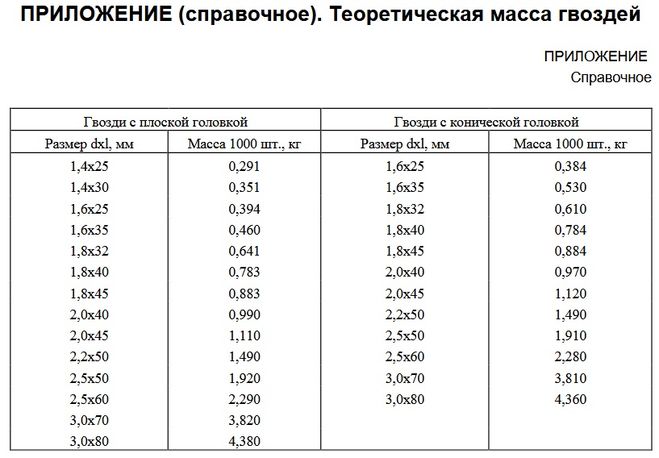

4. The theoretical weight of nails is indicated in the datasheet.

application.

(Introduced additionally. Amendment No. 2).

APPLICATION

Reference

Theoretical weight of nails

|

Size of nails d? l, mm |

Weight of 1000 round nails, kg " |

Size of nails d? l, mm |

Weight of 1000 round nails, kg " |

|

0,8?8 |

0,032 |

1,8?60 |

1,160 |

|

0,8?12 |

0,051 |

2,0?40 |

0,949 |

|

1,0?16 |

0,100 |

2,0?50 |

1,190 |

|

1,2?16 |

0,147 |

2,5?50 |

1,870 |

|

1,2?20 |

0,183 |

2,5?60 |

2,230 |

|

1,2?25 |

0,219 |

3,0?70 |

3,770 |

|

1,4?25 |

0,302 |

3,0?80 |

4,330 |

|

1,4?32 |

0,385 |

3,5?90 |

6,600 |

|

1,4?40 |

0,482 |

4,0?100 |

9,500 |

|

1,6?25 |

0,397 |

4,0?120 |

11,500 |

|

1,6?40 |

0,633 |

5,0?120 |

17,800 |

|

1,6?50 |

0,791 |

5,0?150 |

21,900 |

|

1,8?32 |

0,640 |

6,0?150 |

32,400 |

|

1,8?40 |

0,787 |

6,0?200 |

43,100 |

|

1,8?50 |

0,967 |

8,0?250 |

96,200 |

Note. Weight of 1000 nails of clubs by 15%, and of clubs with

with jumpers 12% less than the weight of 1000 round nails of the same

size.

APPLICATION. (Modified edition, Amendment No. 1 -

3).

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Ferrous Metallurgy

the USSR

2. APPROVED AND INTRODUCED INTO ACTION by the State Committee

standards, measures and measuring instruments of the USSR dated 06.08.63 No.

567

3. REPLACE GOST 3886-47, GOST 3887-47, GOST 4028-48, GOST

4031-48

4. REFERENCE REGULATORY AND TECHNICAL DOCUMENTS

|

Designation of NTD referenced |

Item number |

|

GOST 283-75 |

3 |

5. The limitation of the period of validity has been removed by protocol No. 5-94

Interstate Council for Standardization, Metrology and

certification (IUS 11-12-94)

6. edition (February 2009) with Amendments No. 1, 2, 3,

approved in October 1965, November 1980, December 1987.

(IUS 11-65, 2-81, 4-88)

Table 3. Thickness of wood, depth of face and permissible load on nails.

| Sizes of nails, d x l, mm | Minimum wood thickness, mm | Minimum bottomhole depth, mm | Permissible shear load N1, H | ||||

| without pre-drilling | pre-drilled | 12d | 8d | for softwood | for oak and beech | ||

| without pre-drilling | pre-drilled | always pre-drilled | |||||

| 2.2 x 45 2.2 x 50 |

24 | 24 | 27 | 18 | 200 | 250 | 300 |

| 2.5 x 55 2.5 x 60 |

24 | 24 | 30 | 20 | 250 | 310 | 375 |

| 2.8 x 65 | 24 | 24 | 34 | 23 | 300 | 375 | 450 |

| 3.1 x 65 3.1 x 70 3.1 x 80 |

24 | 24 | 38 | 25 | 375 | 460 | 560 |

| 3.4 x 90 3.8 x 100 4.2 x 110 4.6 x 130 |

24 24 26 30 |

24 24 26 28 |

41 46 51 56 |

27 30 34 37 |

430 525 625 725 |

540 650 775 905 |

650 780 930 1090 |

| 5.5 x 140 5.5 x 160 |

40 | 35 | 66 | 44 | 975 | 1220 | 1460 |

| 6.0 x 180 7.0 x 210 7.6 x 230 8.8 x 260 |

50 60 70 88 |

35 45 46 53 |

72 84 91 106 |

48 56 61 70 |

1120 1450 1640 2060 |

1400 1800 2050 2575 |

1680 2170 2460 3090 |

Species overview

Even before starting the construction of the structure, it is worth deciding on the number and type of construction nails, without which it is impossible to do in this matter. Currently on the market you can find a wide variety of hardware of this type. Often found black, flat-headed, tapered, and others.

Construction nails are of the following types.

Slate. As mentioned earlier, these hardware are used during the installation of slate and its fasteners to a wooden surface. The nail has a round cross-section of the rod, as well as a flat rounded head with a diameter of 1.8 centimeters. This device is characterized by a diameter of 5 millimeters and a length of up to 10 centimeters.

Also, this type of product is divided into the following types, according to the material of manufacture.

- Stainless.

- Galvanized.

- Brass.

- Plastic.