How to glue fiberglass: work algorithm

Before how to glue fiberglass for painting, it is necessary to provide optimal working conditions. The walls should be inspected for visible imperfections such as cracks, potholes and other defects. They must be removed with a plaster mixture or putty. Further, the base is treated with a special primer, which must have good penetrating ability. This mixture helps to level the surface structure, bind dust and fill microcracks.

Before gluing the fiberglass, the surface must be primed

After applying the primer, it is necessary to withstand the time for its complete drying.

This is very important, since the formation of a fine crystal lattice with high adhesion occurs. This film will be broken if you do not wait until the base has dried.

Before gluing the fiberglass to the ceiling or wall, you need to prepare the material. It is very inconvenient to work with long solid panels. They are cut into elements that are convenient for work. In this case, the presence of allowances (1-2 cm) at the edges should be observed. Next, the glue is prepared. It is applied to the back side of the strip of material along the width and sides, distributing it in a thin layer - 1-1.5 mm.

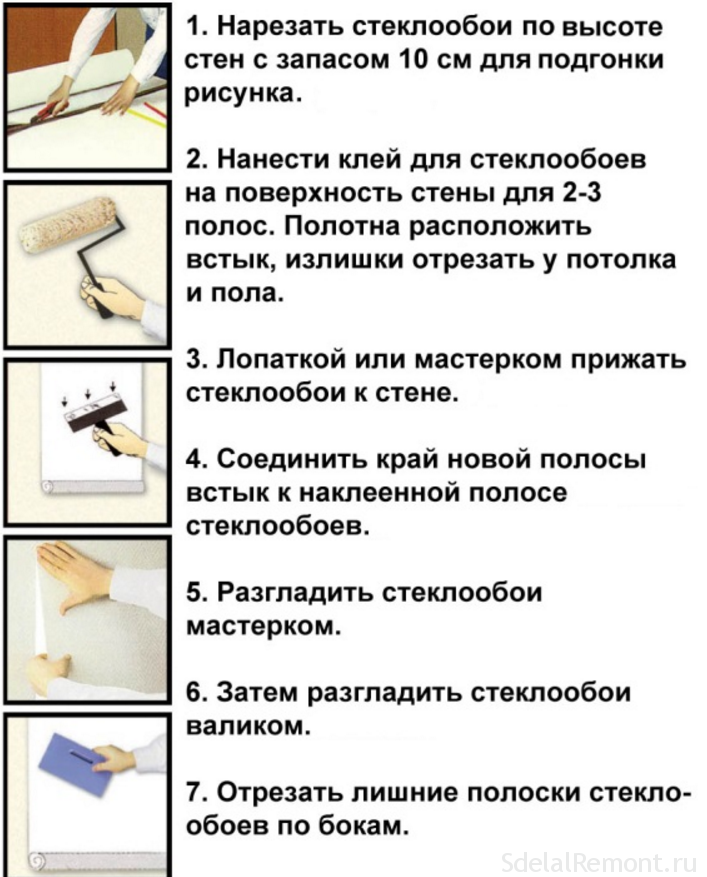

Fiberglass for painting: installation technology

When performing work, it is important to consider how to properly glue the fiberglass. The process starts from the corner of the plane

It can be a wall or a ceiling. After gluing the first strip with an overlap, the second element is fixed, which is subsequently trimmed. The pile on the material should point to one side. Otherwise, the surface after painting will be unaesthetic. In this way, the remaining parts of the finish are mounted.

Before gluing the cobweb, you need to wait until the surface is completely dry.

The price of gluing the fiberglass depends on the plane of the finish. The cost of lining the ceiling will be slightly higher compared to the cost of pasting the wall.

When gluing fiberglass to drywall, the material should be positioned so that its butt joints do not coincide with the seams between the drywall sheets. To exclude such a moment, it is necessary to first mark the base.

An important step is the careful joining of adjacent strips. The joints should be additionally impregnated with glue and pressed well with a spatula. The finished finish should dry completely, which will take 2 days. You can stick the material yourself or invite a specialist to finish the surface with fiberglass. Price per m2 starts from 150 rubles.

For ease of installation, the fiberglass is cut into separate canvases, taking into account the allowance

Painting technology

The very last step in putting the surface in order is painting the glass fiber wallpaper. This process is completely do-it-yourself, and it does not require extensive knowledge. You just need to follow simple rules and recommendations, then your decoration will look great in any interior.

The technology of painting glass wallpaper, as well as gluing them, is practically no different from painting other types of surfaces.

The main difficulty here lies in choosing the right paint. According to construction experts, the best option for painting this type of finishing material will be water-dispersion compositions in which acrylic resins act as a binder.

The advantages of such compositions include the following points:

- do not hide the texture of the wallpaper;

- retain all the qualities and properties of glass fiber;

- are environmentally friendly products;

- are resistant to open flame;

- characterized by vapor permeability and moisture resistance.

It is worth noting that if you are pursuing a desire to create passively maximum fire protection in the house, then you should give preference to a special acrylic fire-resistant paint. At the same time, you must not forget to process all metal communications in the room with a special fire-resistant compound.

In addition to the properties described above, water-based paints have the following advantages:

- water is used as a solvent, so they are devoid of a sharp and unpleasant odor (such solutions practically do not smell);

- fast drying of the painted surface;

- paint can be applied in any way;

- affordable cost.

When choosing paint for glass wallpaper, you should give preference to washable types. This will greatly simplify the wet cleaning of the room and keep the appearance of the wall or ceiling decoration beautiful for a longer period of time.

Detailed information about the properties of the paint can be found on its packaging.

Before direct painting, a primer must be applied to the surface of the fiberglass, but not an ordinary one, but a special one. It is similar in composition to glue. The glue must be diluted with water. Carrying out priming at this stage will increase the adhesion of the coating to the paint, and will also allow several times to reduce the consumption of glue, which will not be absorbed into the finishing surface, but will be evenly distributed over it.

Remember that before priming you need to wait until the fiberglass is completely dry, and also remove the dust left after gluing from their surface. Usually, dust removal is carried out in situations where the wallpaper has already served as a final finish for some time before painting. To remove dust from them, it is enough to walk over the entire working surface with a slightly damp cloth.

Now everything is ready for painting. This procedure is carried out as follows:

- We prepare the inventory. Use a brush, roller or spray gun to apply paint. The way you apply paint is determined by the tools you have in your home, as well as your desire. Most often, the paint is applied to the glass wallpaper using a roller.

- We open the paint and stir it well until a uniform color is obtained.

- Pour the coloring composition into a special tray and dip a roller into it.

- After the roller is well saturated with paint, we survive it on the embossed area of the pallet and start applying the coloring composition to the surface of the fiberglass.

Please note that you need to apply the paint in a thin and even layer. The joints between the stripes are best painted over with a brush.

The second coat of paint should be applied only after the first coat has completely dried. Several layers will allow you to get an even and rich color of the walls or ceiling.

Simultaneously with the walls and ceiling, the communication should be painted (radiators, etc.).

As you can see, in many respects glass wallpaper is a modern and most practical material that will allow you to quickly and effectively complete interior decoration of premises. The key to the success of gluing and painting them is strict compliance with the instructions and rules, without which it is impossible to properly glue the wallpaper and apply a finishing layer to them. Remember that with high-quality painting and the correct selection of paint, this process can be repeated many times.

What to glue the fiberglass: choosing the right composition

Two types of glue can be used for gluing on the glass fiber surface: dry powder and ready-mixed

It is important to choose formulations designed specifically for this material. Glue for paper wallpaper will not work

This is due to the fact that the fiberglass is heavier than paper, so the usual composition may not withstand this weight.In addition, fiberglass fabric has a structure of woven fibers that wallpaper glue will not bond.

Adhesive composition for fiberglass for painting on the ceiling or the wall contains high quality components that do not have a negative effect on the human body. This glue is characterized by anti-fungal properties.

When buying ready-made glue, the date of manufacture of the composition is checked without fail. Expired goods will not provide the desired result. The surface may swell, causing the web to peel off. Opened containers must be used up as soon as possible. Therefore, when buying a ready-made composition, one should focus on the surface area and material consumption required to fill it. The cost of the finished mixture is in the range of 450-600 rubles. for 10 kg.

Dry mixes or ready-made glue are suitable for fixing the fiberglass.

What fiberglass is glued to: other composition options

Dry powder glue is more advantageous to use. The finished composition can be prepared in the required volume. The powder should be diluted with warm water, which is carried out in accordance with the instructions. Dry composition can be bought for 400-450 rubles. for 0.5 kg.

You can glue the fiberglass with PVA glue. However, here it should be borne in mind that the material has a low density, therefore, it transmits a large amount of ultraviolet radiation. After some time, the glue will turn yellow, which will affect the decorative effect of the final coating. Therefore, when gluing fiberglass to PVA glue, paint should be chosen in dark shades.

Experts recommend using only special glue for fiberglass for gluing

You can make the glue yourself. Before gluing the canvas with gelatin, a composition is prepared at the rate of 25 g of substance per 350 ml of water. After the gelatin is soaked for 1 hour, add ½ tablet of crushed aspirin and 1 tsp. glycerin or castor oil. The mixture is heated to a temperature of 40-45 ° C and removed from the fire. When the glue has cooled, it will have a medium-soft jelly consistency.

What is a "cobweb"

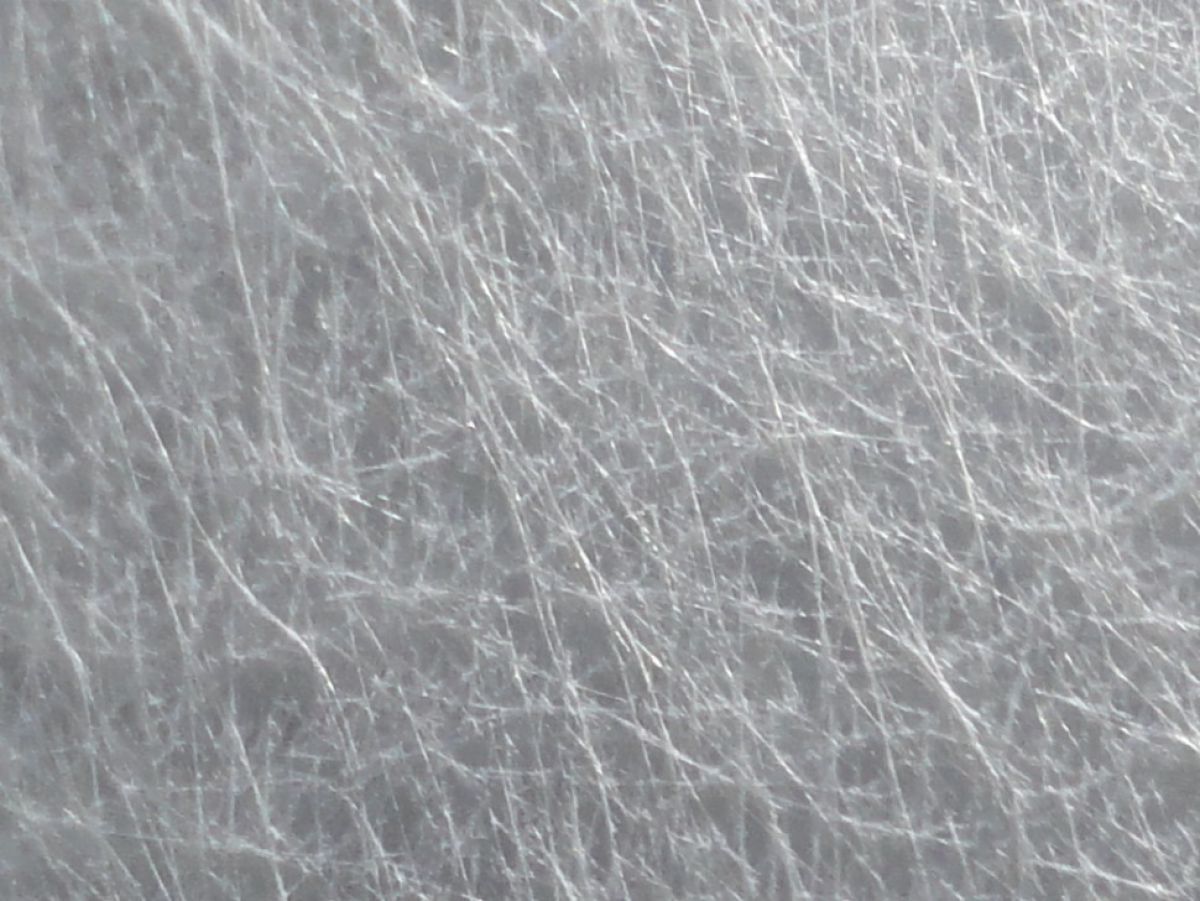

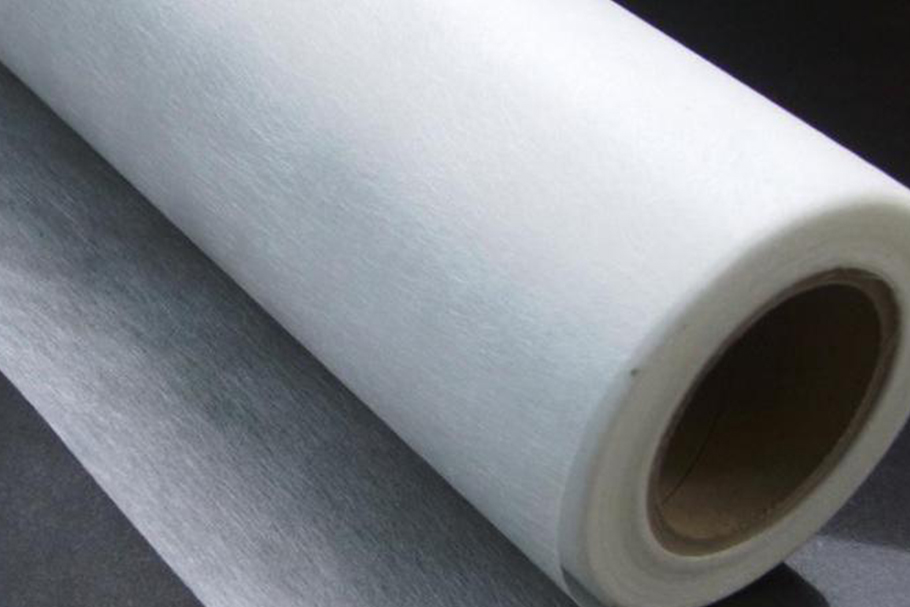

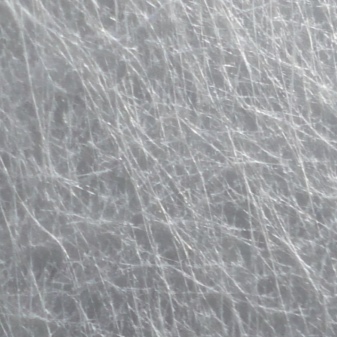

Painting fiberglass is called an environmentally friendly and lightweight material created on the basis of fiberglass and organic resin. It is a non-woven fabric that is very tear-resistant and does not have a clear pattern. The surface of the canvas consists of fibers, which, unlike fiberglass, do not intertwine and are arranged in a chaotic manner. And the material got its name due to its soft and pleasant to the touch texture.

Depending on the thickness, the "cobweb" is divided into classes. On the market, you can find options with a density of 25 to 65 gsm. m. The higher this indicator, the stronger the glass-fiber-finished surface will be. However, for ceilings, on the contrary, it is recommended to choose a lighter version that adheres better to a horizontal surface.

Benefits of fiberglass

To buy quality material, it is advisable to choose products of well-known brands - such as the Finnish company Wellton, the Dutch brand Spektrum and the Swedish manufacturers Samtex and Oscar

It is worth paying attention to domestic production - for example, to the fiberglass spider web X Glass, produced in various regions of Russia. Depending on the brand and density, their price may differ significantly - from $ 100 to $ 250 and more per roll of 50 m2

Such materials as Oscar spiderweb fiberglass, which are distinguished by wear resistance and an affordable price, have proven themselves quite well. You can cut or tear it only on purpose, using sharp objects. For fiberglass of this brand, a minimum of paint is required - even if the painting work is carried out without putty. And you can paint it, in contrast to the products of lesser-known brands, you can repeatedly.

The painting fiberglass cobweb Wellton is also in demand when carrying out repair and construction work, the advantages of which include:

- increased fire safety due to the incombustibility of the material;

- resistance to high temperatures, humidity and aggressive environments;

- hypoallergenic;

- long service life;

- high density.

Regardless of the brand of "cobweb", among its advantages are the following characteristics:

- environmental friendliness, which is expressed in the ability of the walls finished with fiberglass to "breathe", letting in water vapor and maintaining an optimal level of humidity;

- lack of static on the surface;

- easy cleaning - even stained fiberglass is easier to clean than other finishing materials.

An insignificant disadvantage of using the "cobweb" is the danger of being injured by small particles of the material when cutting it. For this reason, it is best to work with fiberglass by wearing personal protective equipment - hand gloves, respirators, goggles, rubberized and tight clothing.

Painting fiberglass - what is it and why

When the building shrinks or the plaster / putty dries out, small cracks form on the walls and ceiling. They spoil the appearance of painted surfaces very much. To prevent their formation when plastering, use a paint net. It reinforces the finishing materials preventing the formation of large cracks. Microcracks are fought with glass fiber painting. It is a thin nonwoven fabric made from many glass fibers of varying thickness. The fibers are interconnected chaotically, which prevents the appearance of cracks. There may be microcracks, but they are not visible. This determines the area of application of the glass-fiber painting - to improve the quality of the finishing of walls and ceilings.

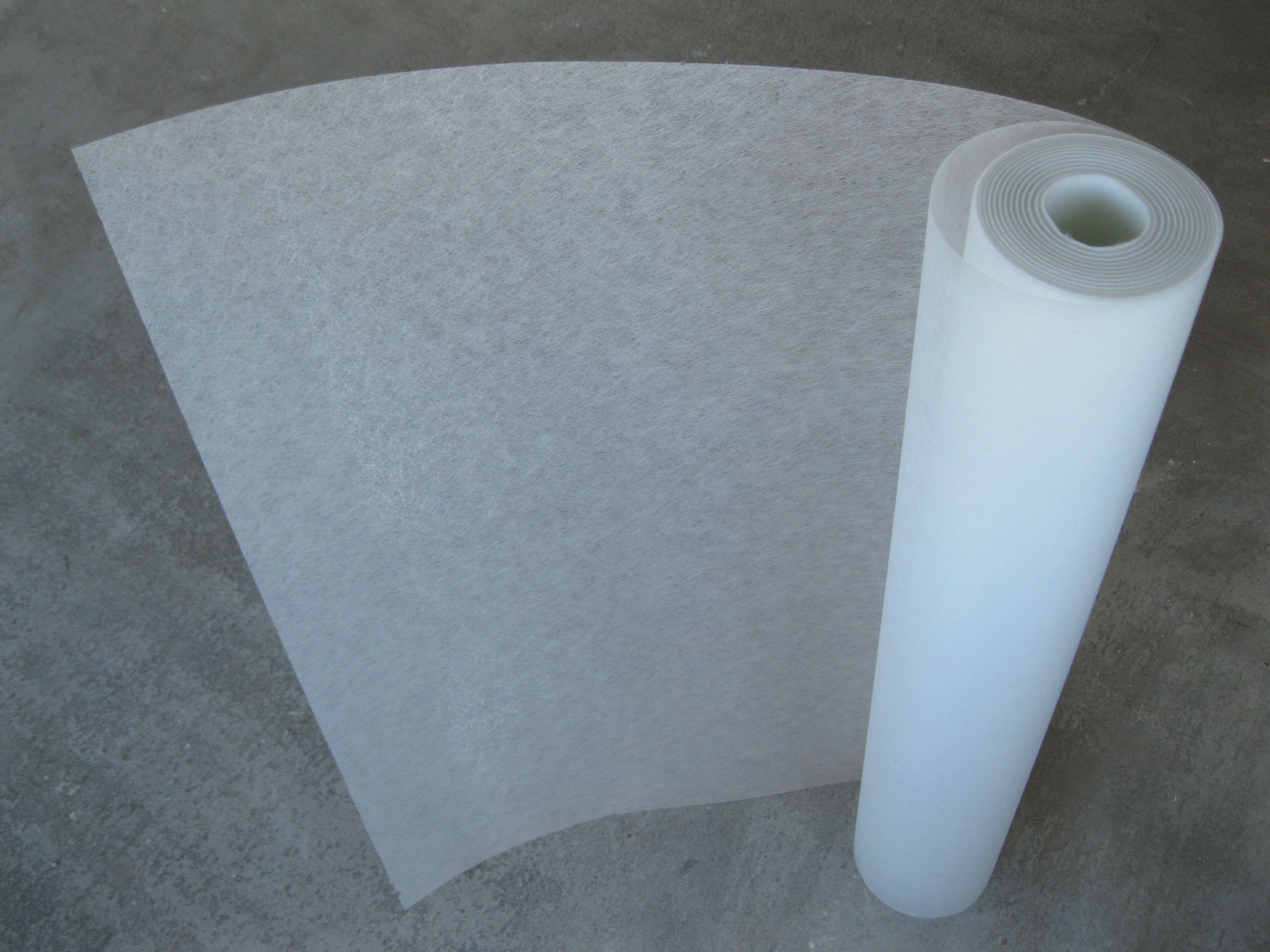

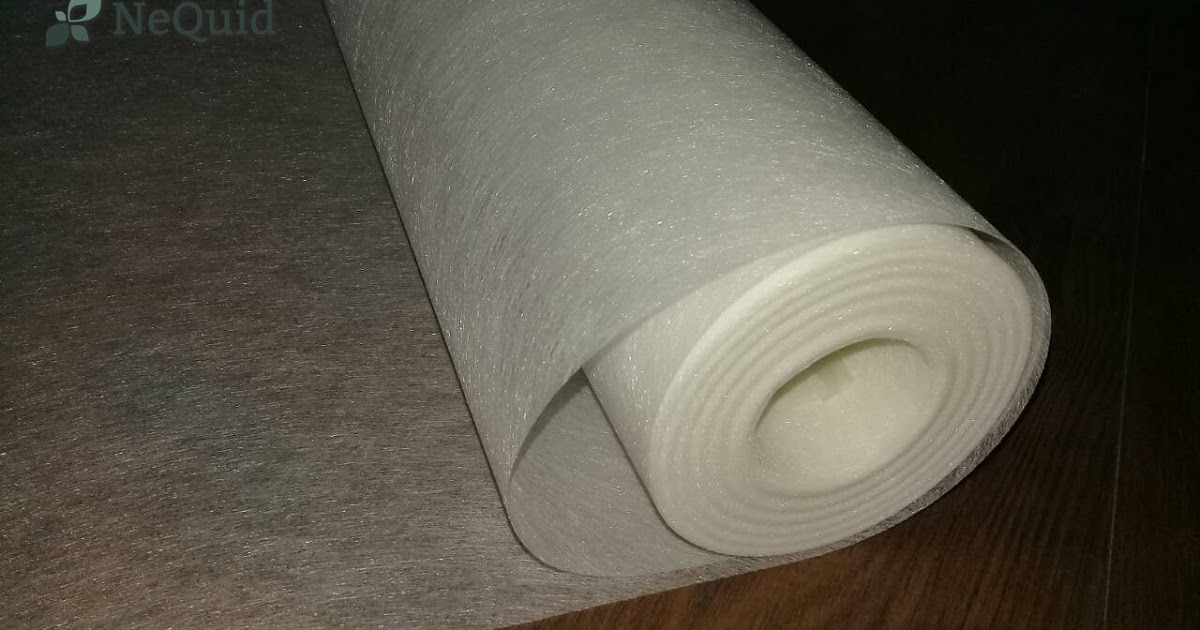

To keep the painted surfaces even and smooth, use a "gossamer"

The thickness of this material is small - it is translucent. Due to its appearance, it received the name "spider web". Sold in rolls 1 meter wide, has a different density - from 20 g / m2 to 55 g / m2. The density is selected depending on the area of application. For interior work, 30-40 g / m2 is more often used.

Fiberglass is glued with glass fiber glue on more or less even walls. It successfully masks small cracks (up to 0.5 mm wide) and irregularities, creating an even surface. Therefore, this technology is becoming more widespread - it simplifies the preparation of walls for painting (putty), and the result is no worse. The same material can be glued to drywall. It successfully masks the joints and prevents the formation of cracks in these places. The main thing when gluing the seams of the fiberglass should be located away from the joints of the gypsum board.

It looks like a fiberglass cobweb

Painting fiberglass is inconvenient to work - fiberglass is pricked, its smallest particles can get into the lungs. Therefore, it is necessary to work in protective clothing and, preferably, in a respirator. After it is glued and hidden with several layers of finishing materials, there is no talk of any migration of fiberglass. In this state, it is absolutely harmless.

What and how to paint later

The dried wallpaper is subjected to a finishing operation - painting. For this, water-based or water-based acrylic paint is best suited.

You need to paint after the wallpaper is completely dry (the time is indicated on the glue package). But before that, it is necessary to prepare the room so that paint splashes do not fall on the floor and furniture, apply a primer on fiberglass - it will reduce paint consumption and improve its adhesion to trellises. You can prime it with a special primer or highly diluted wallpaper glue.

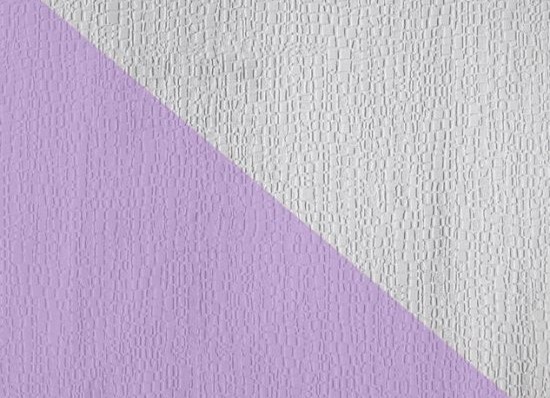

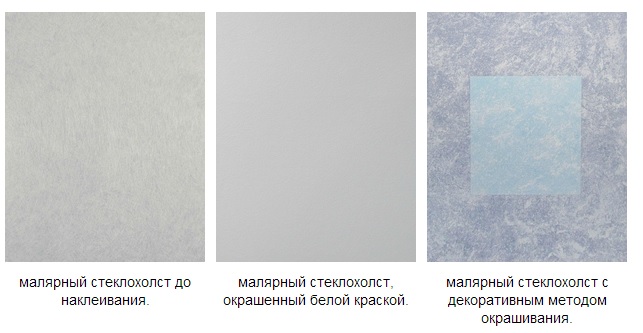

Painted cobweb.

Painted cobweb.

Painting is carried out with a small paint brush, initially in hard-to-reach places, such as corners and joints of the wall with the floor and ceiling, and only then with a roller along the entire canvas. The streaks are removed with a used roller.

When passing the joints of the canvases, it is imperative to grab the next sheet in order to avoid visible seams. After the first layer has dried, the second is applied.

In conclusion, the use of fiberglass wallpaper for the decor of an apartment or house allows you to create a durable finish with the possibility of regular interior renovation (if all operations are performed correctly, the glass wallpaper will last more than 30 years).

The technology of pasting and painting does not contain anything complicated - the work can be done on your own.

Fiberglass sticker

Before deciding whether it is possible to paint the fiberglass and putty it before this or not, the material must be glued to the wall. In this case, the surface to be glued must be prepared - leveled with a putty, leaving cracks no more than 1 mm thick. It is possible to refuse leveling only in cases where the wall is already sufficiently flat and strong.

Video:

The main nuances that arise during the preparatory work:

- wide cracks are sealed with a special compound for joints or ordinary putty, but in several steps;

- when using drywall sheets, the joints between them must be putty and reinforced with a self-adhesive fiberglass mesh ("serpyanka"); so that the already pasted wall is as even as possible, it is desirable that the seams between the drywall and the glass fiber canvases do not coincide with each other, otherwise cracks may appear in these places;

- dried "patches" on the wall need to be leveled with a putty and sanded until the surface is almost perfectly flat;

- before the fiberglass spider web for painting is glued to the wall, it should be cleaned of dust and thoroughly primed.

Due to the fact that the glass cloth is glued with an overlap, when determining its area, not only the surface of the walls should be taken as the calculated value, but also a small margin (at the level of 5-10%). And as an adhesive, it is advisable to use not ready-made, but dry glue, the characteristics of which are the same, and the price is much lower. In the process of work, special clothing is used - pants, long-sleeved shirts, gloves, a respirator and a hat. All this will help to avoid getting fiberglass particles on the skin and in the respiratory tract.

Other nuances that are taken into account when gluing include the correct laying of the canvas. Fiberglass sheets have a smoother face - usually located on the outside of the roll. It is she who should look inside the room, while the outside should be applied to the wall or ceiling. You should also position the canvases so that the pile on them is directed in one direction. Otherwise, the paint applied to the material will have different shades.

The main stages of gluing glass fiber for painting are as follows:

- The roll is rolled out and cut into sheets of the required size, which is selected for the walls taking into account a small overlap. For the ceiling, it is recommended to choose canvases up to 1.5 m long, which are easier to fix on a vertical surface.

- Glue (prepared according to the instructions or ready-made) is applied in a thick layer to the surface, starting from the corner of the room. The width of the strip should be slightly larger than the size of the fiberglass itself, that is, about 1 m.

- The first sheet of canvas is glued end-to-end to the corner of the room, pressed with hands and smoothed with a wallpaper spatula along the entire length from the middle of the canvas to the edges.

- The excess part of the fiberglass is cut with a knife along the ruler.

- The canvas already glued to the surface is coated with glue until the material is completely impregnated. It is possible to determine that the canvas is completely missed by its color, which should become uniform by the end of the procedure.

The rest of the sheets are stacked in the same way, but with a slight overlap on the previous ones. After gluing and aligning, both canvases are trimmed along the joint using a ruler. The trimmed parts are removed, and the resulting even seam is again greased with glue and pressed with a wallpaper spatula.When pasting corners, they try to get an even joint before trimming - the corner blade breaks more often than others, and an ideal cut will help to avoid tears and cracks.

The rest of the sheets are stacked in the same way, but with a slight overlap on the previous ones. After gluing and aligning, both canvases are trimmed along the joint using a ruler. The trimmed parts are removed, and the resulting even seam is again greased with glue and pressed with a wallpaper spatula.When pasting corners, they try to get an even joint before trimming - the corner blade breaks more often than others, and an ideal cut will help to avoid tears and cracks.

After the room has been completely pasted over with fiberglass, it is left closed until the glue is completely dry. Usually this period lasts at least a day. At this time, drafts should not be allowed in the room, otherwise the movement of air will lead to a lag in the material and the need to glue it or even re-glue it.

The procedure for gluing fiberglass

The procedure for gluing fiberglass

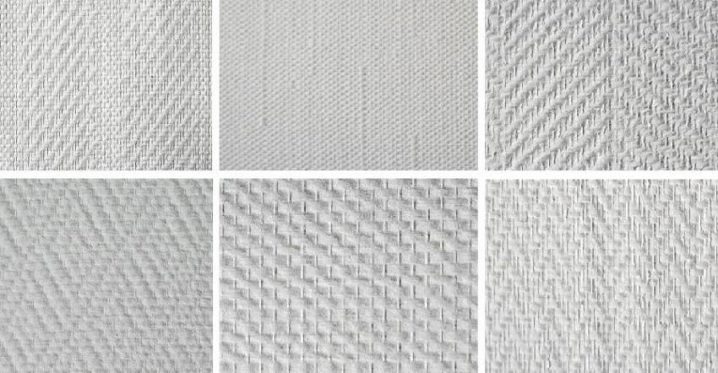

Types of fiberglass for floors and walls

Everything is clear with the walls and ceiling, but is fiberglass needed for painting the floor? Not worth it, it has a different purpose. Fiberglass is classified according to two functional characteristics:

- Painting.

- Reinforcing.

Rolls perform a reinforcing and decorative function, but they can also be recommended for strengthening the self-leveling floor. A thin spider web for walls can serve as a self-sufficient paint base where additional processing is not needed.

Rolls perform a reinforcing and decorative function, but they can also be recommended for strengthening the self-leveling floor.

Rolls perform a reinforcing and decorative function, but they can also be recommended for strengthening the self-leveling floor.

But still, which fiberglass is better to choose on the walls for painting, if today 3 types of products are offered:

- Light cobweb for painting walls and ceilings.

- Medium density fiberglass (for walls).

- Dense fiberglass for deformed walls prone to cracking. A high-quality panel can withstand tensile strength up to 4.5 units.

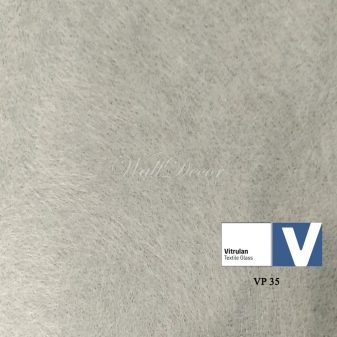

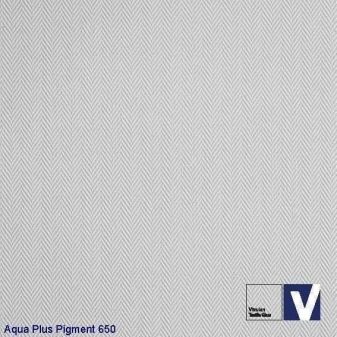

As a rule, the reinforcing base is rarely used as a decorative topcoat. Manufacturers offering fiberglass cobwebs produce all types of fiberglass. The Vitrulan brand from Germany produces almost weightless rolls with a weight of 35 g / m2, complementing the range with fabrics with a weight of 200-230 g / m2.

In the niche of the German manufacturer Virtulan, there are rolls on a sticky base that are easy to glue on a smooth wall. It is enough to wet the canvas, the glue swells and becomes functional.

There are proposals with primer impregnation. Such fiberglass for painting by technology is laid on the walls with a plaster layer. Vitrulan VPP200 possesses these properties. The savings in time and materials are obvious. If the rolls were glued evenly, it remains to paint the wall in 2 layers.

The Vitrulan brand from Germany produces almost weightless rolls.

The Vitrulan brand from Germany produces almost weightless rolls.

So, which one to choose paintable fiberglass to reinforce the walls and at the same time enhance the aesthetics of the surface? Experts recommend separating these functions. When it is necessary to strengthen the surface as much as possible, a dense "cobweb" is better. For textured surfaces for multiple color changes - non-woven or fiberglass.

For a textured surface for multiple color changes - non-woven or fiberglass.

For a textured surface for multiple color changes - non-woven or fiberglass.

Preparing a fiberglass spider web for painting

One day after the glue dries, you can proceed to further processing. It is allowed to immediately start painting, having previously cleaned the glued fiberglass from dust, but it is recommended to first prime it. It can be primed with a special compound or highly diluted glue.

The primer will reduce consumption and improve paint adhesion to the coating. The "gossamer" can be putty with a fine-grained putty, for example, latex or shitrok, then, after drying, sand it with the finest sandpaper, prime and paint.

Fiberglass is a high-tech material that improves performance and extends the life of the finish coat.

Features of the "cobweb" sticker

There are several nuances that allow both to properly glue the fiberglass, and to do it with a minimum consumption of materials. First of all, before performing work, you should definitely make sure that certain conditions are met - temperatures within 15-25 ° C and humidity not higher than 60%.During the gluing process, the fiberglass should not be exposed to a draft or direct sunlight. Approximately the same requirements are indicated in the instructions for Bostik glass fiber glue, which is one of the best options for performing work.

The process of sticking the "cobweb" begins with the preparation of the surface, which must be free of dust and completely putty, except for the smallest cracks. At the same stage, it is chosen which glue for the fiberglass will be used. First of all, one should abandon the usual solutions and mixtures with which wallpaper is glued - substances based on starch do not hold such a canvas well. A more suitable option may be to use Bostick glue for fiberglass, which contains PVA with a strength several times higher than that of a starch base.

It is not recommended to choose plaster as a base - due to its high density, it cannot be saturated with glue and it will not be enough to hold the canvas firmly. Liquid putty is also not suitable, and after trying to stick a "cobweb" on it, bubbles may appear in places that are not sufficiently saturated with adhesive. All this can be avoided only by using glass fiber glue - ready-made or in the form of a mixture.

It is advisable to use your own adhesives for each type of "cobweb":

- Oscar fiberglass glue will be the best option for gluing material of the same brand with a density of 40 g / sq. m;

- a similar adhesive is best suited for Wellton fiberglass;

- at the same time, Cleo's glue for fiberglass, which is also used for non-woven wallpaper, is compatible with any brand of canvas.

It is possible to achieve the optimal consumption of the mixture, counting that 10 grams is enough for 1 sq. m of fiberglass. And one 300-gram pack is enough for a 25-meter roll. The time for preparing the solution, if it is purchased not ready-made, but dry, does not exceed 10-15 minutes. And the setting takes place within 12–48 hours, depending on the brand of glue and fiberglass - you can specify the specific value on the package with the mixture.

The technique of how to glue the fiberglass consists of several stages:

Surface putty.

Treating walls or ceilings with a deep impregnation primer.

Application of pre-prepared glue

Using this method, how to glue the fiberglass to the ceiling or walls, it is important not to miss a single non-impregnated area. At the same time, no excess adhesive should be left, which can be removed with a spatula.

Bonding the first sheet, starting from the corner, and smoothing the edges of the material to improve the reinforcing qualities.

Applying the next portion of glue with an approach to the already glued part (the canvases are glued with an overlap).

Laying the next piece of fiberglass.

Cutting canvases with a clerical knife clearly at the junction and removing the cut parts.

Repeating the same actions until the end of the surface.

Regardless of whether the walls or ceilings will be covered with wallpaper or painted, after the fiberglass has completely dried, they are treated with a finishing putty. And the already putty surface is cleaned with an abrasive mesh (N150 or N120). It is not recommended to skip this stage, since it will be possible to glue the fiberglass for painting without additional leveling only with a large overspending of paint.

Video:

We glue the fiberglass to the ceiling

Renovation in a modern apartment requires the use of the latest technology and advanced materials. For work on decorating the ceiling, such an unusual material as fiberglass (cobweb) is increasingly being used. Fiberglass on the ceiling helps to reinforce its surface, thereby preventing cracking and making the base much stronger. This effect is achieved due to the fact that the fiberglass is extremely difficult to tear, although it is made of non-woven material.Fiberglass is moisture resistant, does not undergo corrosive processes, and is environmentally friendly.

Usually it is used for those ceilings that need plastering. Work with fiberglass begins after the plaster on the ceiling has dried sufficiently. At this stage, a rough putty is carried out. Special care is not required in its application, since it acts as a preparatory layer. After that, the surface of the ceiling is primed

When choosing a primer, note that it must be deeply impregnated. It is advisable to use the brands of companies that have positively proven themselves in this market segment.

Fiberglass on the ceiling should be cut into sheets

The length of the sheets is calculated depending on the width of the ceiling and a margin of 5-10 cm, the surface of the ceiling is treated with a special glue, but it is not recommended to apply it to the cobweb itself. It is necessary to glue the fiberglass, starting from the corner of the ceiling, the subsequent sheets are glued with an overlap of 3-4 cm. Then, the cobweb should be smoothed out with a rubber roller, trying to avoid the appearance of air bubbles. In the place where the sheets are connected, using a paint knife, it is necessary to remove unnecessary fragments of fiberglass. Pay special attention to the places where the spider web may peel off. The material dries completely within about a day, at this time you should not open the windows, since drafts can interfere with the high-quality gluing of the canvas.

Once dry, you can proceed with the final filler. Then the surface is cleaned with an abrasive mesh No. 150 and primed. It is better to use the same primer as in the preliminary stage of work. The ceiling is painted with acrylic paints in two layers.

This completes the repair of the ceiling, and, thanks to the use of fiberglass, new repairs will not be required soon. Processed

Manufacturers

Today in the construction market you can find glass wallpaper of various brands. We offer you a selection of manufacturers who have won the trust of buyers.

Vitrulan

The German company occupies a leading position in the production of fiberglass. Vitrulan is engaged in the production of wallpaper, including water-active, the assortment is replete with materials and tools for painting work, as well as variations of fiberglass. The manufacturer also produces already painted canvases, fiberglass, which imitates fabric textures, has a varied relief.

Buyers note the high performance properties of the material and, importantly, the absence of fiberglass chips when cutting and installing the canvas. Finally, the manufacturer produces material with a wide variation in density - from 25 to 300 g / m2,

The company regularly updates its assortment offering innovative solutions. So, those who do not want to bother with glue can purchase glass cloth from the Agua Plus collection. It already contains an adhesive composition. It can be "activated" by wetting it with plain water. After that, the glue appears on the surface of the "spider web", it is ready for gluing.

The disadvantage of the product can be considered a high price. The cost of even unpainted canvases starts at 2,000 rubles per roll.

Wellton and Oscar

The products are manufactured by the Alaxar production group, which unites leading companies from Germany, Finland, and Sweden. The main activity is the production of wall and ceiling coverings. In addition, related products and tools are produced.

The brand boasts a wide range of premium materials as well as more affordable options. Of the features - a wide selection of material in terms of density (from 40 to 200 g / m2), the ability to purchase material by footage, as well as its high performance properties, including the possibility of multiple staining.

Together with the fiberglass, you can pick up glue for fixing it from the same manufacturers, which is very convenient.

The cost of the material is lower (about 1,500 rubles per roll), but it tends to crumble, and therefore requires overalls for installation. There are minor defects on the surface of the fiberglass.

Of the domestic manufacturers, the products of the companies "Technonikol", "Germoplast", "Isoflex" deserve attention. The first manufacturer offers increased strength fiberglass, which is successfully used for the decoration of industrial premises, roofing insulation, as well as heavily damaged surfaces. The advantage of the majority of domestic glass fibers is their affordability.

The Russian manufacturer X-Glass is one of those who manufacture glass non-woven liners in accordance with European requirements. It is distinguished by its versatility of use, perfectly reinforces surfaces, hiding small and medium cracks and preventing the appearance of new defects. The brand's collection is not as diverse as compared to European competitors, but X-Glass products are notable for their affordability. In other words, this is an excellent option for low-cost repairs without compromising on the quality of the coating.

Peculiarities

Fiberglass is nothing more than a new generation of building material that prepares the base surface for finishing. This is not fiberglass, as those who are unfamiliar with this material mistakenly believe. This raw material is in the form of a spider web, which is sold in rolls with a length of 50 m at a meter width. It appeared on the construction market relatively recently. However, the quality of the material allows what was previously difficult to do when finishing.

The raw material for the production of fiberglass is quartz sand. The density of the preparatory material for painting can vary from 25 to 50 g / m2. It matters when choosing raw materials for different planes. Usually, for vertical surfaces, varieties with a lower density are used. For the walls, the one that is denser is needed. With an increase in density, the mass of the fiberglass becomes larger.