Varieties of coatings

For repair and restoration work with your own hands, paint on a brick on a water or organic basis can be used. Water- and organic-soluble formulations have their own disadvantages and advantages:

Organosoluble nitroenamels and oil dyes

They penetrate well into the brick structure, are resistant to UV rays, but create a thin, durable water-repellent film on the surface, which prevents the material from "breathing" and provokes the formation of condensation.

It is not recommended to use organic-soluble mixtures in the interior of a residential building: the walls will become damp, the internal microclimate of the premises will be disturbed. They are well suited for painting the facade, brick balconies and fences, provide full protection from atmospheric agents, do not fade, but are toxic.

Water soluble

These paints are very durable, they are used for painting walls outside. They can even paint a brick pipe for stove heating or gas-heating traction, as well as carry out finishing work inside the house. Suitable for simple, silicate and gypsum bricks or gypsum tiles (imitation brick).

Water-borne facade paint

Water-borne facade paint

They have good vapor permeability, providing full water and gas exchange between the atmosphere and the surface. Non-toxic, fireproof, they can be used to decorate the interior of the premises. They can be produced with heat-resistant qualities.

If the tiling is ceramic, you need to look in the direction of special tile paints.

Epoxy

They have various qualities. Depending on their constituent resins, they can be toxic and non-toxic. They are distinguished by increased adhesive properties and strength, but are poorly resistant to atmospheric phenomena. Painting a plaster brick wall or indoor decoration tile can guarantee the quality and durability of the coating. They can be used to paint a covered balcony from the inside.

These colorants can be varnished to increase their weatherability. For living rooms, it is advisable to select non-toxic solutions, carefully reading the composition and scope of the package.

Mineral

Cement-based brick paint is well suited for facade work, for decorative painting of a facade, balcony or fence. Possesses high water and heat resistance, is able to withstand the onslaught of heavy rains and temperature drops, reliably protecting the fence or building facade from destruction. It is rarely used for interior decoration.

Silicone

When choosing how to paint a brick or decorative tile with low adhesive properties (usually silicate products), it is better to stop at silicone mixtures that fit well on a smooth surface and do not fade for a long time. They can be produced with heat-resistant properties - for decorating stoves and fireplaces in the interior.

Industrial production

How is aged cladding brick made?

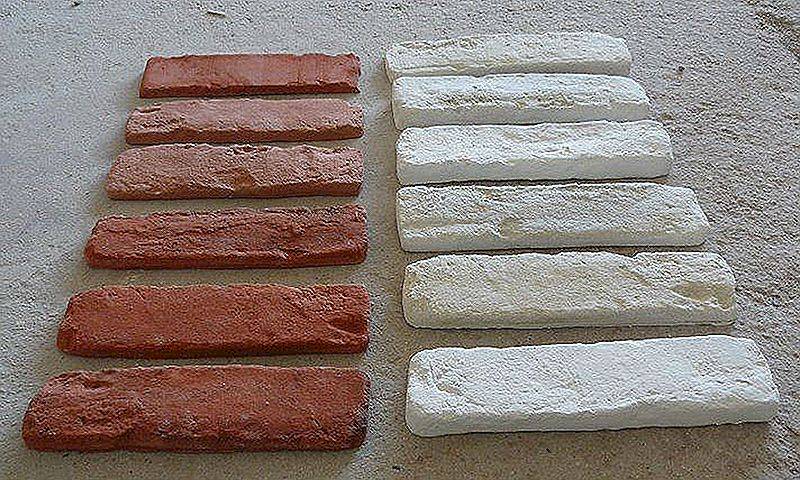

In general, nothing out of the ordinary. The raw material is ordinary clay, the same one used for the production of red building bricks. The uneven surface of one of the faces is imitated during molding; uneven color, imitating efflorescence and darkening of surface areas, is provided by the addition of mineral dyes.

Facing bricks of most manufacturers are fired at high temperatures: from the point of view of production technology, they are clinker bricks. Thanks to high-temperature firing, clay particles are sintered more reliably; as a result, the brick has very low moisture absorption and is extremely durable.

The best examples of aged facing bricks correspond with their strength to the… M1700 brand. Incredible? However, it is a fact.

Such a high strength is needed so that temperature drops and inevitable mechanical influences do not destroy the complex relief of the cladding. It's funny: the artificially aged surface is made as durable as possible.

But the aged decorative brick for interior decoration is not exposed to extreme destructive influences: temperature drops in the living room are minimal; destruction during crystallization of the moisture that has saturated the material, for an obvious reason, is also not threatened. This material is noticeably cheaper and less durable.

The secret weapon of the Germans

A couple of the technologies they use deserve special attention.

Aged surface can mimic efflorescence

(whitish spots appearing due to the washing out of sulfates and carbonates by rainwater); however, the appearance of real efflorescence means partial destruction of the brick structure. An interesting solution to this problem is the impregnation of the surface layer with a thickness of 2-3 millimeters with a polymer composition, which acts similarly to a waterproofing membrane for a roof.

Water molecules cannot penetrate the front surface of the facade; at the same time, the masonry remains completely vapor permeable.

The addition of wood flour to the clay changes the appearance of the product after firing.

... The surface of the brick is made porous due to the burnout of organic matter; inclusions of coal give the surface an uneven color, the intensity of which can be adjusted by the duration of firing and the percentage of flour in the raw material.

Seams

The joint width should be between 10-12 mm.

Anchors, flexible ties or other elements of fastening the facing masonry to the main wall are laid in the horizontal seams.

After the signs of initial hardening of the masonry mortar appear (“thumb test”), the facial seams are partially cleaned to free up space for grouting (jointing).

Joining is carried out when the masonry mortar is completely cemented. Under normal conditions, this does not occur until the seventh week after the end of the work. The first two weeks, the "fresh" masonry should be covered with a film, if there is a possibility of rain. Before grouting, the remains of the mortar are removed from the brick surface with a brush.

You can not clean off fresh mortar - this will further contaminate the brick.

You can make two types of grout yourself: gray and white. To do this, use Portland cement of the appropriate color. It is mixed with four parts of sand and water is added to a "semi-dry" consistency. The sand fraction is selected depending on the surface of the clinker brick:

- coarse-grained quartz sand is used for “antique” or “rustic” relief textures;

- for smooth - fine seeded river sand.

If it is necessary to achieve special decorative properties, then use ready-made color mixtures for joining masonry.

Professional advice

For fast and neat laying with a seam thickness of 10-12 mm, there are special templates (analogs of the American "Bricky").

If you do the masonry mortar yourself, then use the following components:

- Portland cement M500 of high quality with a minimum salt content;

- washed or river sand without clay and organic residues;

- clean tap water (or from a well with purification to the level of "drinking").

The volumetric ratio of cement and sand is 1: 3, and the water content is considered optimal if the mortar does not slide off the trowel at a slope of 45-60 ° to the horizon. The same amount of water is needed when making a solution from dry mixtures.

Grout is made much "drier". The water content in it should be about 8% by volume.

The vertical seam can be made slightly less than the horizontal (the difference is up to two millimeters). Even a slight decrease or increase in the vertical seam allows you to minimize brick trimming when adjusting the pattern and bandaging the corners.

And in this video, a professional talks about the intricacies of laying facade bricks:

Facade brick laying requires professional skills and knowledge of the characteristics of the materials. The cost of error is much higher here than with tiling or siding.Therefore, it is better to entrust such work to specialists.

How to age a brick wall in a simple way

Work instructions:

Angle grinder or grinder

the outer layer of the brick wall is removed, as in the photo.

With the help of such tools, you can get an increased roughness of the material.

-

Work continues with a hammer and chisel.

They simply break off the excess frozen solution in the seams of the masonry. In addition, the corner edges of the brick are knocked off in different places with different impact forces. -

Further, with natural aging, the wall collapses at the joints between the bricks.

For this, chaotic indentations are made in them with a puncher.

-

Blowtorch

dark spots are created, and then these areas are processed with sandpaper, or better with a grinder, achieving more uniform shades. -

The entire surface of the brick wall is processed with coarse-grained sandpaper

to add scuffs.

The main difficulty in processing a wall with a grinder is to ensure a sufficient level of aging of brickwork.

How to use color for aging masonry

When drawing up a work plan for the aging of bricks, it must be borne in mind that the natural process should also be reflected in the coloring.

When performing work, you will need:

- Paint multiple colors to get the desired shade.

- Roller (see).

- Sponge.

The seams on the old masonry are darker in color.

In artificial conditions, to obtain the appropriate effect, you can use acrylic paint of a suitable shade.

For this:

- Apply the coating with a sponge to achieve uneven staining.

- When planning to paint a wall made of bricks or tiles in lighter shades, it is recommended to use a regular roller, and in this case it is necessary to apply paint in small portions, with a semi-dry tool.

- Excess composition is removed with a sponge. In this case, you need to ensure that there are no paint smudges on the wall.

You can get a moss effect on brickwork.

For this:

- The surface is slightly tinted with greenish or earthy paint.

- This should be done with a sponge so that the imitation of moldiness is only partially noticeable.

The final step in all the processes described is to apply a deep penetration primer to the wall surface that mimics old brickwork. This will prevent dust from settling from the brick in the future and will significantly reduce the risk of wall crumbling.

How does a brick wall with plaster grow old?

The methods of aging a brick wall with a blowtorch and paint do not require special construction skills. But they are well known.

A more complex process when creating the effect of a brick old wall is using ordinary or decorative plaster in colors such as:

- White.

- Light gray.

- Beige.

In this case, the brick looks contrasting against its background.

Process technology includes:

- The wall is partially covered with plaster so that it looks like it has been crumbling over time.

- Only those bricks that protrude from under the plaster are artificially aged in the ways described above.

With fallen plaster, brickwork looks original and spectacular. And it is quite easy to make such a wall on your own.

If possible, several bricks can be pulled out of the masonry from above diagonally, then the wall itself will look like collapsed, and the house will be its own ruin. At the same time, aging of bricks can be performed from the front and end parts, and the collapsed wall will look more natural.

Anyone can independently create a work of art on ordinary brickwork using simple methods. It is not difficult to visually age a brick with improvised tools and materials, you only need a great desire, the presence of imagination and free time.

An aged brick wall can be made a separate element of the interior, which can be decorated with paintings, old black-and-white photographs, and an antique mirror can be hung. The parts protruding after the wall collapses can be used as shelves, for example, put indoor flowers on them. The ruins of an ancient temple or castle, which are lost in the jungle, will resemble masonry entwined with a vine.

You can learn more about the process of aging brickwork from the video in this article.

Characteristics of bricks for old masonry

bedroom with brick wall photo

The process of bricklaying itself was the same at all times. The principle was to lay brick products in a specific order and use a special solution.

Antique brickwork has its own individual characteristics, by which it is determined:

- by the method of laying bricks;

- according to the characteristics of bricks;

- on the specifics of the composition of the solution and the method of its application.

Initially, since the bricks were made by hand, they did not have clear geometric shapes and sizes, and the edges were deformed. Only after the invention of special equipment for the production of bricks, this product was slightly modified, and the shape became clearer and more expressive, the surface was even.

Since the 17th century, they began to put a stamp on the surface of the brick, which carried information about the manufacturer of this product. The first stamps depicted animals, and from the 18th century - several letters.

Variety of coatings

Repair and restoration work on bricks on your own is possible if you use organic paint or a water-based composition. Each type of dye has its own advantages and disadvantages, consider them.

Oil and organic soluble nitro enamels

They have the ability to penetrate well into the structure of the stone, protect it from the effects of ultraviolet radiation, but prevent "breathing" due to the strong waterproof film formed after drying. This leads to the formation of condensation under the surface of the paint and has a detrimental effect on the microclimate of the premises in which they were used. But they will be indispensable for decorating facades, the outside of balconies or fences. They are quite toxic, but they will reliably hide the bricks from water, will not fade or crack in the sun.

Water soluble

They have increased strength, which is why they are often used for painting external walls. Even a brick fireplace (heating) pipe or draft from a gas boiler can be painted with water-borne paints. They are also suitable for interior work when decorating simple or sand-lime bricks, as well as gypsum surfaces (bricks or tiles that imitate full-fledged brickwork). They remove steam and moisture well, ensuring a sufficient level of gas and water exchange between the surface and the air. They are fireproof, do not have toxic components, such dyes can be used indoors. There are also heat-resistant compounds. Ceramic tile material must be coated with special compounds designed for tiles.

Epoxy

They contain resins, depending on which they can acquire toxic properties or not, have different properties. They have increased adhesion and strength, but they do not tolerate weather conditions. They can be used to process the balcony from the inside, as well as decorate plaster tiles or bricks in order to ensure the long-term preservation of the coating. To improve the weather-resistant qualities of such dyes, it is customary to cover them with a layer of varnish. The choice of interior paint for residential premises is made taking into account its non-toxicity (you can verify this by carefully reading the composition).

Mineral

They are based on cement and are ideal for treating external walls, balconies or brick fences.Resistant to moisture and temperature fluctuations, withstand the onslaught of precipitation, reliably preventing the facade of a building or fence from destruction. They are extremely rarely used in interior work.

Silicone

The composition for painting surfaces made of silicate composition must cope with its low adhesive properties. Therefore, it is customary to cover smooth bricks with silicone mixtures. They are heat-resistant (for finishing fireplaces or stoves) and do not fade for a long time.

Internal wall surfaces

In this case, for obvious reasons, the requirements for "external" analogs are irrelevant. Vapor permeability is not important, and there is no special need for hydrophobicity. The most important thing in this case is aesthetic possibilities.

The material of the home walls will help with the exact choice:

- "white" brick (silicate) - acrylic paints are optimal for it. Their distinctive features are absolute harmlessness, acceptable cost and sufficient strength;

- "red" brick (ceramic) - any dyes are suitable: silicone, acrylic, latex, polymer or acrylate. The latter option is preferable, since such a coating is wear-resistant, outwardly very beautiful and easy to clean.

It is worth highlighting the transparent varnishes, which are great for any brick, especially when creating a creative interior, implying the presence of "bare" sections of the walls.

History of brickwork

Even primitive people were engaged in the construction of their homes. Over time, a person discovered new materials and methods for holding this event for himself. The first brick was made from river clay, resin and mud. The product, after its molding, went through the process of drying in the sun. But firing in kilns began to be carried out a little later. Even in Ancient Egypt, brickwork was widely used for the construction of various buildings.

But in America, as well as Mexico, adobe was one of the most popular materials for construction. Its components were resin, quartz additives and porous lime clay. The resulting material was particularly resistant to various factors, which proves the presence of buildings of that time, even in our time.

Temples, houses, fortresses in Russia began to be erected from bricks somewhere in the 4th century AD. The brick, which looked like a bar, appeared in the 15th century and was called "Aristotelian". Many ancient architectural masterpieces were erected from the above bricks. You can view photos of old brick houses on the Internet on special resources. We will also present the reader with the most liked photo:

The reign of Peter I was a breakthrough in the world of brick production. Special factories were opened that produced this building material. And already in the 19th century, the first kiln appeared, in which brick blanks were fired.

Today, almost everyone who regrets to change something in their life prefers a bedroom with a brick wall, because it is not only convenient, but also beautiful. It is also important that the presence of a designer is not required, since you yourself will be able to appreciate the beauty of your choice.

Installation of tiles under bricks

The technology of mounting decorative material consists of several stages:

- preparatory work;

- preparation and application of the solution;

- installation of decorative tiles;

- grouting.

At the first stage, the preparation of the base is carried out. The surface to be lined is pre-cleaned, leveled and primed if necessary.

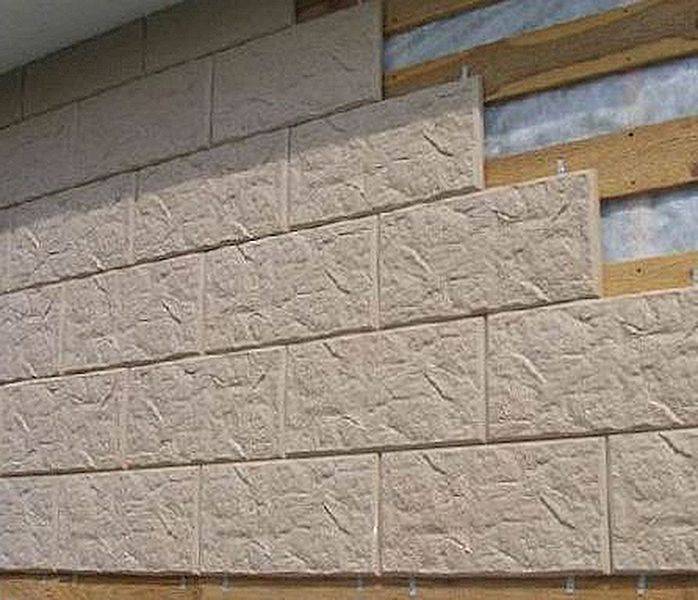

Installation of the cladding on the base can be done in two ways:

- on special glue;

- on a sand-cement mortar.

You can apply glue or solution directly to the decorative element or directly to the base itself. Both installation options are acceptable. In the second option, the solution is applied to the area sufficient for the installation of 4-5 decorative elements.

The thickness of the adhesive layer is up to 0.5 cm. If the back side of the product is embossed, a straight spatula is used to apply the adhesive; a notched spatula should be used to apply the adhesive on a flat surface.

You need to lay bricks in the direction from the corner to the center. The laid element is pressed against the base, its position is corrected. In order for the gaps between the elements to be of the same width, plastic spacers are used. The mortar protruding between the seams is immediately removed with a rubber trowel.

Having laid out the first row, proceed to the installation of the second and subsequent rows, shifting the bricks by half the length relative to the previous row.

After the tile with imitation of brickwork dries up and firmly attaches to the base, proceed to the final stage of work - mashing the seams.

You can see how decorative bricks are laid in this video:

ATTENTION PLEASE

important information on the handling of antique brick tiles, the rules for working with them, their transportation and storage (after an introductory-explanatory article)

To save space, time and effort, the workshops of the Brothers NemceV developed their own techniques 10 years ago to recreate authentic old masonry from elements of old bricks. It was the Workshops who were the first to come up with PLATES and CORNERS

They are applicable to the creation of old walls and partitions, window dawns and vaulted ceilings indoors, and in the cladding of facades of houses and buildings, completely reproducing old masonry, conveying their original temporary textures and moods. our own author's invention of fifteen years ago, namely, on the manufacture of its lightweight Elements from real old bricks: plates and corners.

In stone-cutting workshops located twenty kilometers from Moscow, ancient bricks are skillfully cut with large mechanical diamond saws, getting thin plates and corners from it. Filigree, and very difficult in technical processes, fine faceting of old bricks allows architects and creators to save such necessary centimeters, significantly relieve floors and walls. But at the same time, to achieve a convincing effect of genuine old masonry, in a newly created brick wall, or reproduced vaults of Monier, which no longer raises doubts about their historical origins.

After diamond sawing, the plates and corners of the old brick are checked, dried, and carefully and carefully packed in corrugated cardboard boxes prepared for these procedures, thus storing a piece of the future real old brick wall.

The packed boxes are ready to be delivered to the Site on time. The boxes do not provide the necessary safety of the Plates. The material is more than 150 years old, and it is very fragile. Below are the rules of handling, transportation and storage of antique material. Photos are active Open

Please read CAREFULLY:

prepared plates from old bricks material is very old, thin and fragile

General principles

The laying should be done in order not more than 5-6 rows in one day, so that the mortar does not "squeeze out" under the weight of the brick. It must be carried out in dry weather and with dry bricks - at high humidity, the rate of hardening of the solution decreases.

During the storage and transportation of bricks, condensation may have formed under the packaging film. One day before the start of laying, it is necessary to remove the film from the pallets, the bricks from which will be laid during the working day.

In the work should be at the same time from three to five pallets. This will help to more evenly "mix" different shades on the surface of the facade.

The first row should be laid on top of the basement waterproofing layer. The unevenness of the surface of the base should not exceed 2 cm.

When it rains, the masonry and open pallets should be covered with foil.

Types and features

Based on the production technology, brick-shaped tiles are divided into the following types:

- clinker;

- ceramic;

- concrete;

- plaster.

Clinker tiles

Clinker is a material produced from special refractory grades of shale clay by firing at high temperatures. The raw material composition and production technology provide the unique properties of the finished product. The molding of the product can be carried out in automatic or manual mode. Hand-molded clinker tiles are in demand when decorating semi-antique facade walls; ceramics made in Belgium, England and Holland are very popular. Handcrafted antique brick tiles give the building a medieval look.

The key advantages of clinker products are the following characteristics:

- frost resistance;

- UV resistance;

- low coefficient of water absorption;

- high strength;

- ecological cleanliness.

The main disadvantage of facing material:

high price.

Clinker tiles brick can be attached to surfaces made of brick, concrete, wood, drywall. The scope of application of clinker products is quite extensive:

- facade cladding of residential and public buildings;

- interior surface finishing;

- decorating fireplaces, stairs, stoves, etc.

- finishing of fences, terraces, balconies;

- landscape design (paving paths, decorating flower beds, gazebos, ponds, etc.).

Brick effect ceramic tiles

Ceramic products with imitation of brickwork are mainly used for interior finishing work, the scope of its application is practically unlimited - living rooms and bathrooms, kitchens, offices and hallways. A wide range of decorative products allows you to bring to life a wide variety of design ideas.

The decorative tile material is characterized by a long service life, which can be up to one hundred years. The composition of ceramic tiles with imitation of brickwork contains clay, quartz sand and mineral additives.

Production

The production technology consists of the following stages:

- formation of products;

- high temperature firing;

- glaze.

Specifications

Key technical characteristics of decorative ceramic products:

- water absorption - over 6%;

- frost resistance - up to 60 cycles;

- density - up to 1700 kg / m3.

Advantages and disadvantages

The advantages of ceramics:

- moisture resistance;

- resistance to temperature extremes;

- UV resistance;

- ease of care.

Main disadvantages:

- not reusable;

- tends to crack under mechanical stress.

Concrete tiles

Concrete brick tiles for the facade are a popular finishing material. Concrete products are based on a mixture of Portland cement, quartz sand, organic fillers and special additives. Manufacturers often use expanded clay as a filler; this material helps to reduce the weight of the finished product. The front side of concrete tiles completely imitates the structure and appearance of natural bricks, the back of the products is characterized by a smooth and even surface.

Material advantages:

- variety of colors;

- durability;

- frost resistance;

- resistance to moisture;

- long service life;

- attractive price.

The main performance characteristics of concrete tiles:

- frost resistance - 200 cycles;

- water absorption - 4-9%.

Disadvantages:

decorative concrete elements are not recommended for use in areas with sharp and frequent temperature changes.

Gypsum brick tile

Material advantages:

- light weight;

- good heat and sound insulation;

- environmental Safety;

- fire safety.

Disadvantages of gypsum products:

- low frost resistance;

- high degree of water absorption;

- difficulty in cleaning products with a relief surface.

Brick interior decoration

Old brick tiles are a relatively new finishing material that appeared on the market less than 10 years ago. Initially, this finish was used for the exterior cladding of buildings. Thanks to the accurately reproduced color and texture, this material allows you to create truly original and stylish facades, ideally imitating aged building bricks.

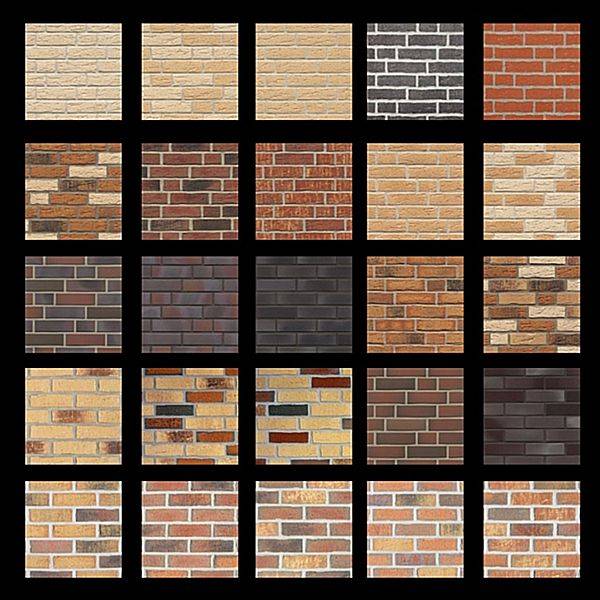

Manufacturers were able to achieve such believability that it became possible to imitate almost any type of brick, including double silicate brick M 150. Today, the material is produced in various colors: white, yellow, red, gray, etc.

The use of decorative brick tiles in the interior of your home

Let's consider several options:

White brick tiles. Due to its high aesthetic qualities, such cladding is often used in interior decoration in such historical styles as Gothic, Russian antiquity, Provence, etc. The material looks very harmonious with wallpaper, stone, plaster, clapboard.

Red brick looks bright and realistic. Cladding with a loose structure is an excellent solution for finishing mantels and fireplaces. A variety of shades and textures allows this type to "fit" into any interior.

Very often, artificially aged bricks are used to decorate the hallway, which looks very impressive and impressive.

The use of such tiles in the kitchen design creates an atmosphere of romance and comfort.

This type of cladding works well with natural materials.

Glossy tiles with brick texture are a peculiar novelty. It is an excellent solution for kitchens with country and modern styles.

How to work with tiles

This material has both advantages and disadvantages.

Among the advantages should be highlighted:

- Durability.

- Ease of care.

- Resistance to external influences and aggressive environments.

- A wide variety of textures and colors.

- The price of certain types of material is quite acceptable.

- Ease of installation, as a result of which any home craftsman can do it yourself.

Application of the solution

photo of old brick wall

If you study the photos of old brick walls, you can see that there is a special way of applying mortar and processing the seams. Lime was used as a grout, which was filled between the brick space, and then the plane was rubbed to a smooth state so that the seams did not become invisible.

Beginning in the mid-18th century, the one-sided straight trimming method began to be used. This method also assumed the presence of small depressions in some places. Both methods were periodically used in the construction of structures.

brick old house photo

Some old brick houses, the photos of which were studied, are still located on the territory of Kaluga.

There is also another way of surface treatment - this is a scraper. The principle of this method is the presence of both processed and untreated joints between bricks.

You can also find a slot on old masonry. This is when a clear seam is extremely rare. The old brick wall, photo of which was taken in the city of Ostashkov, confirms this.

Material features

Plasterboard structures have long ceased to cause delight, on the contrary, they have become an architectural and design stamp. Therefore, they are replaced by a more recent design solution: antique brick. It is increasingly being used to decorate interior walls. This solution is recommended when decorating halls, corridors, as well as when decorating kitchens. You can cover the wall with old brick both in a city apartment and in a suburban cottage.

It should be noted that laying out walls with old bricks in small-sized housing is illogical and inconvenient. There, she only absorbs a lot of space, which is always not enough. But this does not mean that you need to give up your plan completely. A good replacement for a full-fledged brick wall is a specially designed tile. It is distinguished by its low thickness and allows realizing the most daring aesthetic ideas.