Alcohol stains: features and scope

Wood is a wonderful natural material, strong and durable. But it also loses its beautiful original appearance over time. To prevent this from happening, the wood should be treated with wood stain. The procedure will not only preserve and emphasize the sophistication of the unique textured pattern, but also significantly increase the service life of wood products.

There are different types of stains and each has its own advantages and disadvantages. The most common type is water-based stain. The composition is sold both ready-made and in powder form for subsequent preparation at home.

This species has the following features:

- has a wide range of colors: from very light tones to deep dark;

- easy to apply;

- economical to use.

However, water takes a long time to dry. In addition, it loosens the wood fibers, and they rise. Then they have to be removed with sandpaper.

The easiest to use is oil stain. She has a wide variety of colors. It penetrates well into the wood without lifting its fibers, protects the material from damage. It can be applied in different ways, it will be evenly distributed over the surface.

Acrylic or wax based products are relatively new. Their advantage is the creation of a protective film on the tree. This look can give wood a wide variety of colors. He will create both natural and vibrant exotic finishes. This effect on wood is called stain. It should be noted that this is a rather expensive type of coverage.

A stain with a whitening effect may be of interest. For its manufacture, acids or hydrogen peroxide are used. With its help, very light shades and even a discolored surface are obtained, on which paint is then applied.

<?php related_posts(); ?>

If you are interested in making a stain with your own hands, then you can use herbal decoctions, tea, coffee, chemicals. With their help, beautiful unusual shades are obtained. Their recipe is easy to find on the relevant Internet sites or in specialized literature.

Alcohol stains are also popular.

For information on how to choose a wood stain, see the next video.

Peculiarities

Alcohol stain is an aniline dye in denatured alcohol. You can buy a finished product or powder, which must be diluted with alcohol. The ratio will be indicated on the package. If a large surface is to be treated, it is necessary to immediately dilute a sufficient amount of the substance so that it is enough to obtain a uniform shade over the entire surface.

The use of alcohol stain has many positive aspects, namely:

- giving an interesting shade, it is an antiseptic and protects the material from decay;

- the alcohol solution does not cause swelling of the fibers, and therefore no subsequent leveling of the surface is required;

- suitable for any type of wood;

- the dye penetrates deeply into the material, which contributes to bright saturated colors.

The procedure for applying the substance is not the most pleasant experience, since it has a pungent odor.

Manufacturers

In order for the coating to be of high quality, you need to choose a worthy manufacturer. Among those available on the today's market are Novbythim and Anles. In addition to quality, these manufacturers will delight you with the price of the product. Their products are perfect for indoor work.The stain will accentuate the textured patterns on the material and will not be washed off the surfaces with water.

Wood treated with Novbytkhim and Anles products is easy to polish and is not subject to inflammation, and the surface does not require subsequent varnishing. Novbythim products can also be used to tint veneer or plywood products.

Scope of use

With the help of wood stain, you can give inexpensive types of wood the look of an expensive material, thereby ennobling the room.

Advice

When applying stain on the surface with your own hands, you should know how to do it correctly, listen to the advice of already experienced craftsmen.

- First of all, any surface should be prepared before applying the product. To do this, the product or surface is inspected, dirt and dust are removed. If it is necessary to remove the old coating, then the surface should be cleaned, remove the previous layer, chips, defects.

- After stripping, white spirit is applied and the surface is degreased. If the work is carried out on coniferous wood, it is treated with a special compound to remove the resin and ensure good adhesion. When using water stain, the wood product should be moistened, and when the fibers rise, sand again.

- In order to understand what the color will be on a certain surface, a color test is done. A little stain is applied to a small area, often hidden from the eyes, and wait until it dries completely. Then another layer is applied if the color is not saturated enough.

- If the store version of wood stains does not work, you can make it yourself. One of the most common methods is to prepare a solution using strong tea or coffee. Depending on what saturation the composition is planned to obtain, the amount of tea or coffee also depends, and for a lighter shade, the infusion can be diluted. After that, you can apply the infusion to the surface and adjust its saturation.

- When applying the stain, there is no need to use special tools; you can take an ordinary brush or roller for work. To apply an alcohol composition, it is better to take a spray bottle, since this composition dries very quickly and stains may remain on the surface.

- A roller or swab is best used when applying the product to a small area, thanks to this application, the stain will evenly penetrate into the depths and create a protective layer.

- Most often, a brush is used in work, it is easy to work with such a tool. When applied with a brush, the stain easily and evenly lays down in the desired direction, thanks to which you can give certain areas of different intensities of color and beat the pattern.

- The product is dyed along the fibers to emphasize the pattern and reduce the consumption of stain.

- The composition should have a comfortable consistency. When choosing a non-aqueous stain, it should be diluted with white spirit to the desired thickness. This will not do without the specific smell of the solvent.

- The number of application layers is determined individually, depending on the desired effect. Usually 2 or 3 coats are applied, the surface is dried after each application.

It is better to make the first layer thinner, it is necessary to treat the surface carefully. This even layer will be the basis for further application. It takes 2 or 3 hours for water and alcohol solutions to dry, for oil solutions it takes up to 3 days.

By following the tips and tricks, you can easily get the job done and apply the stain to the surface.

Stages of staining a wooden surface with a stain.

If the wood surface is properly prepared for staining, the staining procedure will be fairly straightforward. It is performed in the following stages:

1. First, the stain needs to be slightly warmed up to enhance its penetration into the wood.

2. A brush, rag or swab is moistened with stain.In no case do not allow strong moisture, as streaks may appear and the staining will become uneven. If a spray bottle is used, the stain is poured into the reservoir.

3. The stain is applied along the wood grain. Apply the stain quickly and without interruption to avoid staining. If streaks appear, then the surface must be wiped with a cloth, collecting excess liquid along the fibers. Then the surface is left until the stain is completely dry.

4. Similarly, apply several more layers of stain in order to obtain the desired shade (usually 2-3 layers).

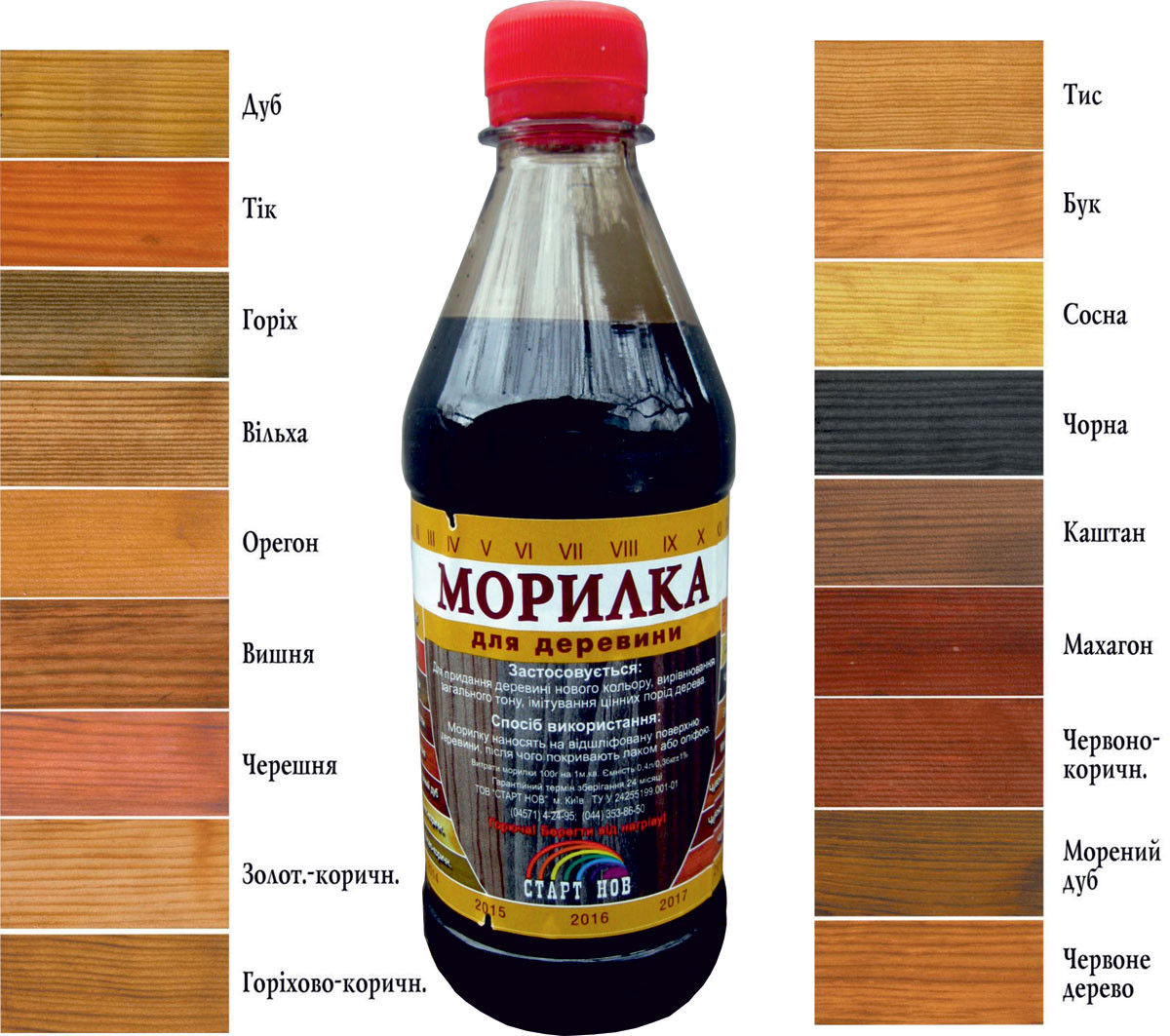

Color spectrum

Stain is a unique agent that helps to give wood a noble shade. The structure of the wood is heterogeneous, different areas are impregnated unevenly, therefore, after the composition dries, an original pattern is created on the surface. The most popular shades of wood stains are in the wood range, their names correspond to different types of wood. There are also other types of wood stains on sale: green, black, red, blue and corresponding to other tones that are usually used to paint furniture. If you cannot choose the right color, stains of the same type and brand can be mixed with each other.

When buying, you should carefully consider the samples on which stains are applied, because the shade on the label and in reality may not match. The finished color will also depend on the following factors:

- the original shade of the tree;

- the degree of porosity of the material;

- density;

- breed;

- the amount of resin.

Hardwoods are impregnated much better than conifers, so the tone will be as close as possible to the declared one. To give a light shade, you can purchase a brightening impregnation, which also tends to emphasize the wood pattern. There are even colorless stains on sale that do not change the color of the wood, but fully have protective properties.

What is the stain for

In a professional environment, wood stain is called "stain". This liquid agent allows you to give the desired color to wood without changing its texture or pattern. On the contrary, stains emphasize the entire aesthetics of natural wood, enhancing it, ennoble simple species: after processing, even pine can be "made" of dark oak or other expensive varieties of material.

Any wooden products, despite their strength, are subject to various adverse factors. Wood stain can be used to protect wood from damage by putrefactive fungi. There are different types of wood stains, the properties of which depend on the composition.

The main qualities of the beytsy:

- protection of wood from ultraviolet radiation;

- destruction of woodworms and other pests;

- increased surface service life;

- clarification of wood;

- moisture protective function;

- the possibility of restoration of old products;

- compaction of the material structure;

- preparation of wood for further processing - painting, varnishing.

Some stains should only be used indoors - for covering floors, countertops, furniture, interior doors. Others are suitable for outdoor use - for example, for treating the floor on an open veranda. Some products are used only on the surface layers of wood, others are distinguished by the possibility of deep penetration. Many modern stains can not only be applied to the base, but also perform various interesting effects - combine tones, create shades uncharacteristic for wood.

The difference between stain and varnish, paint, varnish

Stain is a means for imparting texture to wood. It penetrates deeply, tones the wood from the inside, without closing its natural pores and preserving the pattern, while protecting it from decay and destruction. The drying oil also protects the material from moisture and putrefactive processes, but after its application, a film appears on the surface.

Drying oil weakly penetrates into the deep pores of the tree, but clogs them from the outside.If the stain can become an independent finishing agent, then drying oil is used only to prepare wood for further work to improve the quality of staining, reduce the amount of paint.

Varnish is also very different from stain-impregnation. Varnish is a film-forming agent, and a protective film from it is formed after the solvent evaporates from the surface. Oil varnishes form a super strong elastic film that is not easy to wipe off even with white spirit. Again, the varnish layer will have to be updated over time, having previously removed the previous one. Usually varnishes are used where there is a strong influence of atmospheric factors, and the stain will have to be applied too often.

Paint is another popular finishing material for wood. You can paint absolutely any wood product: from the floor to window sills or furniture. After painting, a dense, opaque film forms on the surface, which completely hides the natural wood pattern - this is the cardinal difference from the stain. Usually the color range of paints is far from natural: more often white, black, brown, green paints and varnishes are sold. After 2-3 years, many types of paints lose strength, snap off, after which you will have to completely remove the old layer and apply a new one.

Wood stain ANLES alcohol-containing, oregon, 0.5 l

Specifications

| Chemical basis: | a mixture of acid dyes and nigrosine, surfactants, useful additives, isopropyl alcohol, water |

|---|---|

| Appearance: | homogeneous liquid of the corresponding color, does not become cloudy when shaken |

| Coating color: | Oregon |

| Drying time to degree 3 at 20 ° C: | 20 minutes |

| Mass fraction of non-volatile substances: | not less than 1.5% |

| Consumption in 1 layer: | 250 g / m² |

Application area

Designed for tinting any wood species, giving woody wood shades, in particular, for painting and correcting defects in furniture, parquet and various wood products at home.

Properties

- Forms a moisture-resistant, light-resistant protective coating.

- Abrasion resistance.

- It is used both independently and as a durable stain for subsequent varnishing.

- Retains and enhances the texture of the wood.

- Can be used for hardwoods.

- For indoor and outdoor use.

- Dries quickly, does not swell wood.

- Does not lift wood grain, creates a leveling effect.

- Penetrates deep into the pores, providing better protective properties than others and the possibility of subsequent sanding.

- Unlike non-water wood stains, they do not require perfect drying of the wood.

Directions for use

- Before painting, it is necessary to prepare the wood: carefully sand with a sandpaper, clean it from dust, oil stains, old varnish.

- Apply 1-3 coats of stain with a swab, roller, brush or spray.

Storage and transportation conditions

The stain should be stored in the manufacturer's packaging in covered warehouses at temperatures from -10 ° C to + 40 ° C. Transportation of the stain can be carried out by any type of transport in covered vehicles in accordance with the rules for the carriage of goods in force for this type of transport. Shelf life is 2 years.

Not fire hazardous. They belong to the 3rd class of hazardous substances - low hazardous. All work should be carried out in rubber gloves. Avoid ingestion. Keep out of the reach of children.

The highest level of service: Our specialist managers are professionals in their field and if you need help in choosing the right product, they will be happy to advise you.

Types of wood stains

All stains according to the main material used for their manufacture are divided into 3 categories:

-

The base of the stain is water.The product is produced in several varieties: ready-to-use, as well as in the form of a powder, which must be dissolved in water. This variety is the most common and allows you to paint surfaces in any color shades, mostly wood shades. The disadvantage of water-based stains is that when applied, the material lifts the grain of the wood. This fact emphasizes the structure of the tree, but at the same time, the expanded fibers perfectly absorb moisture. To avoid such a phenomenon, it is necessary to moisten the tree with water before applying the stain, keeping it in water for some time. Next, the product is rubbed with an abrasive material and the last step is stained. The advantage of water-based wood stains is that they do not have any odors, which does not harm human health;

-

The main component of the stain is alcohol. In this embodiment, the stain is a solution of the dye of aniline in denatured alcohol. The described variety is produced in the same way as the stain with a base of water, in two versions - a ready-made product for use and in the form of a powder. The disadvantage of this variety of wood stains is their rapid drying, which is the reason for the appearance of stains. The application of such a material by hand is difficult due to the uneven color of the resulting coating. The best result will be observed when using spray guns;

-

The base of the stain is oil. This base allows you to give the processed object any of the available color shades of wood. This is made possible by mixing dyes that dissolve in oils. To prepare wood stains for consumption, they must be diluted with white spirit. This variety presents no difficulty in applying them. The treated surface dries quickly, the coating is applied evenly, without swelling the wood fibers.

There are also acrylic and wax based stains. These types are designed in such a way that they do not have the disadvantages that are described in the above listed varieties: they do not swell wood fibers, do not leave stains, and the applied coating protects the wood from moisture. When water is poured onto surfaces treated with acrylic and wax stains, water droplets scatter.

Acrylic wood stain

Acrylic-based stains do not have specific odors and are also fireproof. When applying them, it is necessary not to "go over" with the thickness of the applied coating

Wax wood stain

Wax stains add brightness to surfaces, and are applied to the surface using a flexible or non-coarse fabric by rubbing, applying little effort.

But in addition to the fact that these varieties protect surfaces, they themselves also need protective treatment. Wood varnishes are used as a protective coating for wood stains. Only acrylic and wax based stains have different color tints, ideally highlighting the structure of the wood surface. For this reason, both varieties are called rustic.

The use of stains based on soluble dyes

When working with stains based on soluble dyes, keep in mind that these dyes are absorbed into the wood together with solvents (there are no binder resins in the formulation of such stains), they take the place of air in the microscopic pores that penetrate the wood. In this case, the color of the wood becomes the most saturated, the volumetric texture of the wood appears.

In areas of wood where absorbency is overestimated, more dyes are concentrated, these areas get the darkest shade.

These are stains with an accentuating effect.

Soluble dye-based stains produce colors that are closer to natural wood colors, but it is difficult to obtain rich and pastel colors (for example, pink, green) with their help.This is due to the fact that a significant part of the dyes goes deep into the wood.

The depth of wood staining depends on the used thinner (the slower - the deeper), as well as on the type of wood. Softwoods can absorb accent stains up to a millimeter or more, so that shallow scratches may not be visible.