The procedure for working with concrete contact

Before applying the concrete contact to the surface, it is recommended to stir the primer composition to evenly distribute its components. If this is not done, the sand can settle at the bottom of the package and thus no positive effect will be achieved.

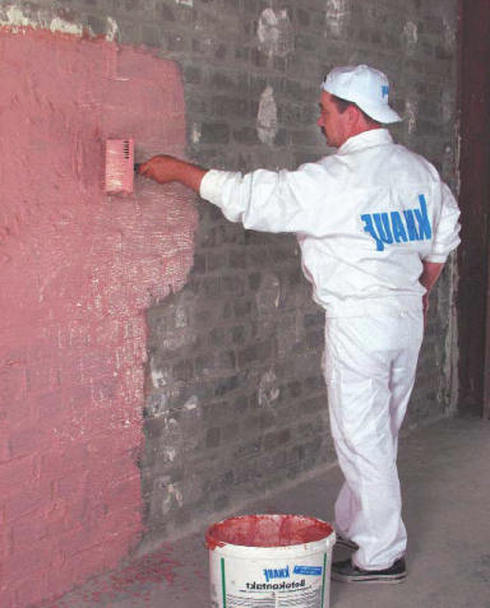

Before treating the surface of the base with a primer, it should be cleaned of dust and other contaminants so that the solution covers the entire available area. It is necessary to apply Concrete Contact with a brush or roller. Also suitable devices for applying solution are spray gun and plastering station.

The base is processed in two layers:

- The first is considered a safety net, and when applied, Concrete Contact can be mixed with an ordinary deep penetration primer.

- The second layer is the main one. Only pure concrete solution is used.

It should be noted that the application of the second layer becomes possible only after the first dries. You can check that the layer is dry by touching it. If the primer stops sticking to your hands, then you can proceed to the second stage.

The application of this type of primer requires compliance with a certain temperature regime.

It is important that the range of permissible temperatures is within the range from +5 to +30 degrees Celsius. The use of concrete contact at low temperatures will affect its consistency, which will lead to difficulty in working with the material

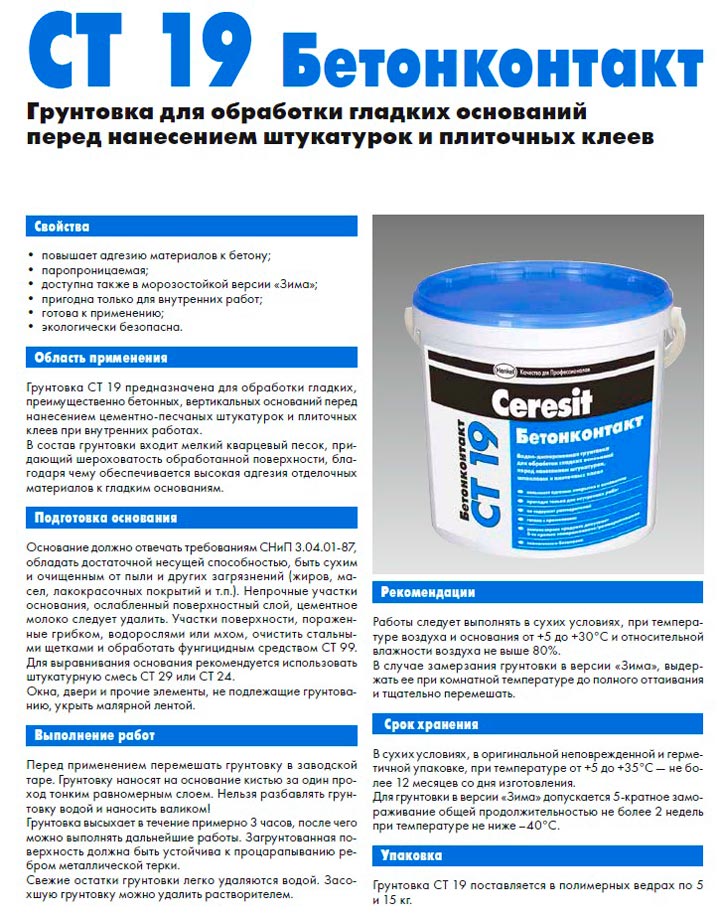

Purpose

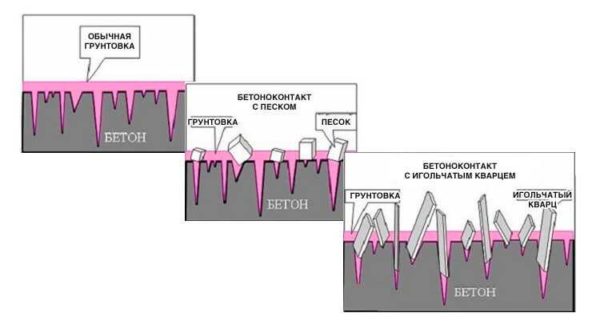

Primer for concrete concrete-contact is a special type of deep penetration soil on a polymer basis, resistant to alkali. It contains a finely dispersed quartz filler in the form of sand. Due to this component, a rough layer is formed, which increases adhesion. The special composition of the contact concrete makes it versatile and suitable for the application of any finishing material.

Also, the features include the absorption of moisture formed on concrete structures. A great advantage over other compositions is that it allows you to exclude the stage of cleaning surfaces from the previous coating from the general work. Even when applied directly to the paint, it forms an adhesion to the surface. This primer material has a waterproofing property. And it is suitable for use in wet rooms.

Betokontakt is used for various purposes during construction and repair:

- they are treated with concrete bases indoors before plastering;

- cover the facades of buildings intended for covering with decorative materials;

- process surfaces before installing finishing tiles.

Concrete contact is used for finishing works outside, it is frost-resistant. if you intend to carry out outdoor work, please note that the composition should include expanded clay or marble chips, coarse quartz sand. These components are able to reliably hold heavy facade plaster on the concrete surface and protect it from weathering.

Primer: types and properties

The main purpose of using a primer is to give the surface strength and increase the service life of the coating applied to it in the future.

The primer on the walls is indispensable before gluing wallpaper - it is able to penetrate deep into the surface to be pasted and mask defects (cracks and holes).

Wallpaper primer can prevent damage to the roll and the appearance of mold or mildew under it.

A properly applied mixture can improve the adhesion between the wall and the coating, which will lead to a decrease in the cost of finishing materials.

There are several types of primers - acrylic, oil, contact, concrete contact.

Let's analyze each of them in detail:

- acrylic is a universal mixture of deep penetration, capable of imparting strength to a weak base. Most often used in living quarters for leveling walls. However, it can be used on ceilings and floors. Penetrates to a depth of 1 centimeter and, when cured, forms a durable coating with excellent adhesion properties. Not recommended for work on ferrous metals;

- contact primer with the addition of quartz sand enhances the adhesion of the surface and, due to its composition, penetrates deeply into the walls, effectively filling cavities;

- an alkyd or oil primer mixture is used to treat wood or metal surfaces. It can be applied to rust, as it combines the properties of paint and anti-corrosion properties;

- drying oil or alcohol primer is perfect for working on wood - if you preheat the surface to be treated, you can significantly reduce the drying time;

- concrete contact is ideal for walls and ceilings of an ordinary apartment.

Video:

There are also mixtures less popular among ordinary residents, which are most often used only by professionals:

- on concrete or lime-sand walls, they work with a silicone solution, which hardens in 5 hours;

- areas with poor absorbency - utility rooms and workshops - are treated with a polyurethane compound;

- to obtain a neutral color that does not shine through the wallpaper, a pigmented primer is used on the surface.

The drying time of the primer depends primarily on the type. So, oil, contact and primer mixture of deep penetration freeze for about a day. Acrylic primer dries in just 10 hours.

Therefore, before buying a mixture, read the label - the manufacturer always indicates the drying time of the primer mixture.

If we talk about average values, then the mixture dries completely after about 4 hours at a temperature of 25 degrees Celsius and a humidity of 65%.

Remember that the higher the humidity in the room, the longer it will take for the deep penetration primer to harden, so this process can be accelerated simply by opening the windows, of course, if the weather is clear without rains.

If the room has increased humidity, and there is no opportunity to ensure the flow of air, then the time indicated on the box can be doubled.

How long should the primer dry before wallpapering?

There are several factors that affect the drying rate:

- the mixture will solidify slowly if the room temperature is extremely low or, conversely, high temperature;

- the thicker the layer is applied, the longer it will take to dry;

- how much the newly applied primer will dry is also influenced by its composition - the deeper the mixture penetrates, the longer it will take to solidify.

Do not forget about the duration of the action of the primer solution - the interval until the mixture retains its adhesive properties.

Use the primer immediately after preparation, otherwise it will lose its effectiveness.

The primed surface also plays an important role.

If the primer mixture is applied in 2-3 layers on cement-lime plaster, then it will take about 6 hours to wait.

If the primer is applied to a regular wall before the putty, then it will take 2 - 3 hours for the mixture to harden.

After a visual assessment, run your hand over the wall - a smooth and dry surface will indicate that priming was successful.

Primer concrete contact: features and consumption per 1m2

A primer is a unique solution that is used to prepare a specific surface for finishing, such as painting. The use of such a building mixture allows you to level the surface, get rid of any defects on the wall and eliminate small cracks.

One of the most popular types of primer is concrete contact, the use of which greatly simplifies the further finishing works.

Main characteristics and properties

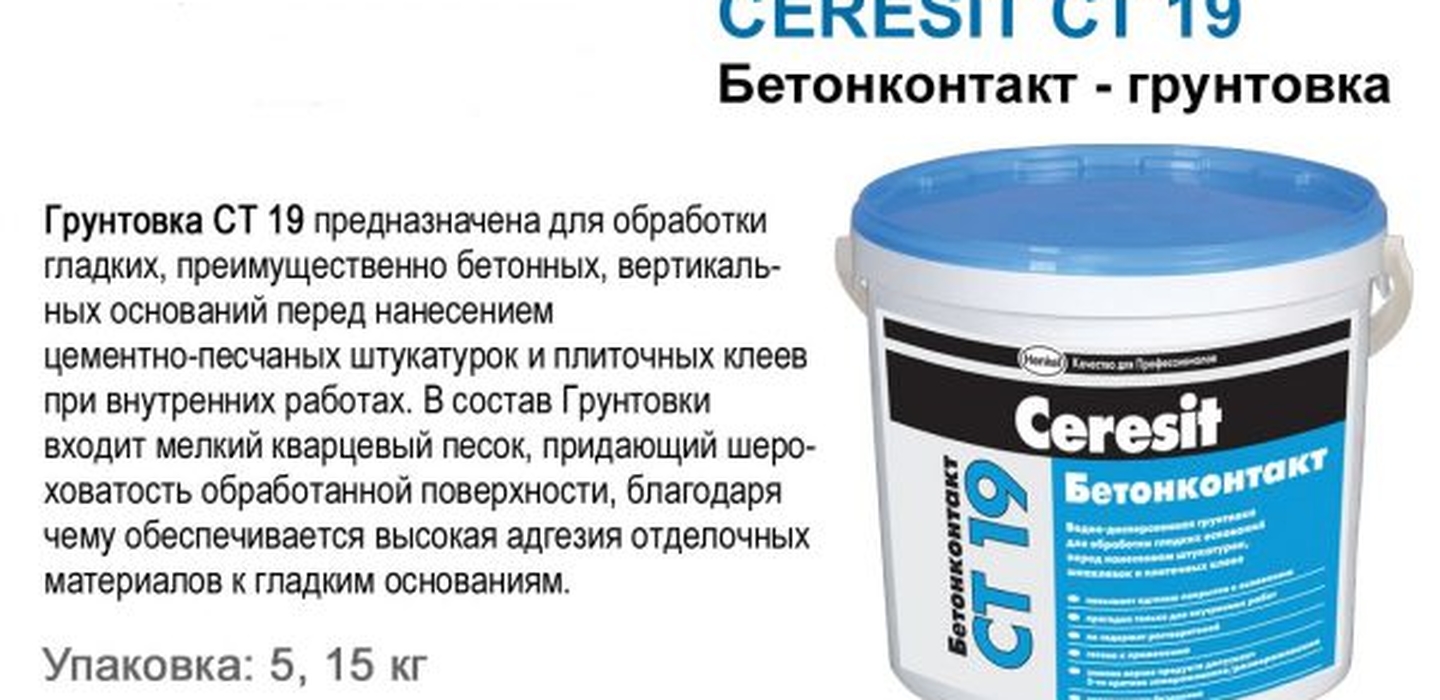

Concrete contact is an acrylic-based building mixture that also includes cement, sand and special additives. This mixture is actively used to increase the adhesion of a surface that does not absorb moisture well, before plastering, laying tiles and other finishing work.

Among its main advantages are the following:

- high drying speed. Further finishing work can be started a few hours after applying the primer;

- moisture resistance. During the drying process, a special film is formed that does not allow water to pass through;

- durability. According to the manufacturer, the concrete contact primer has not lost its qualities for 80 years.

Thanks to its unsurpassed properties, concrete contact has been able to establish itself as a unique material that is durable, does not need a lot of time to dry and does not allow moisture to pass through. It is these properties that allow you not to worry about the quality of the repair done.

How to determine the consumption of concrete contact?

Consumption of concrete contact per 1m2 depends on many factors, among which the first place is occupied by the features of the treated surface

What matters is not the type of surface itself, but the porosity. It determines how much of the primer will be absorbed, which has a direct effect on its consumption per m2

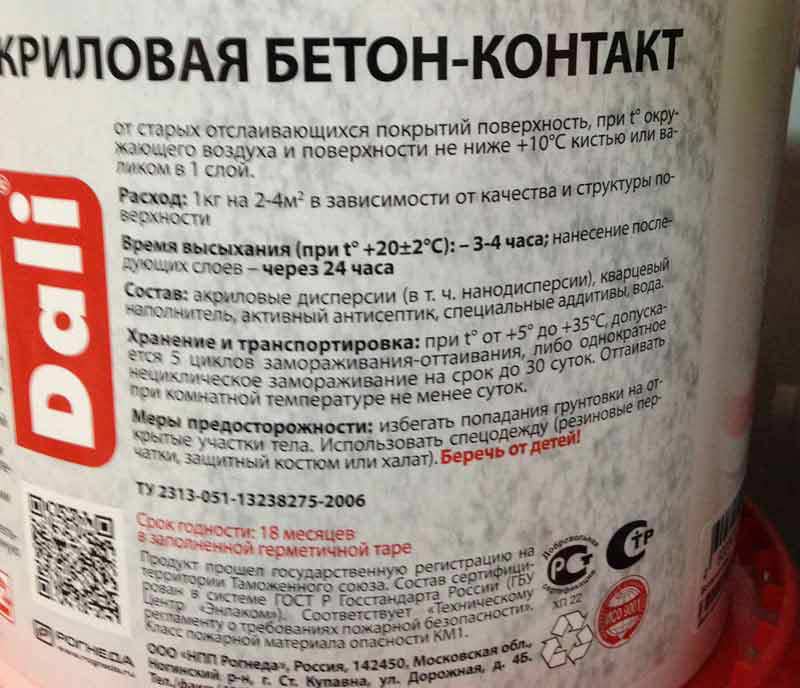

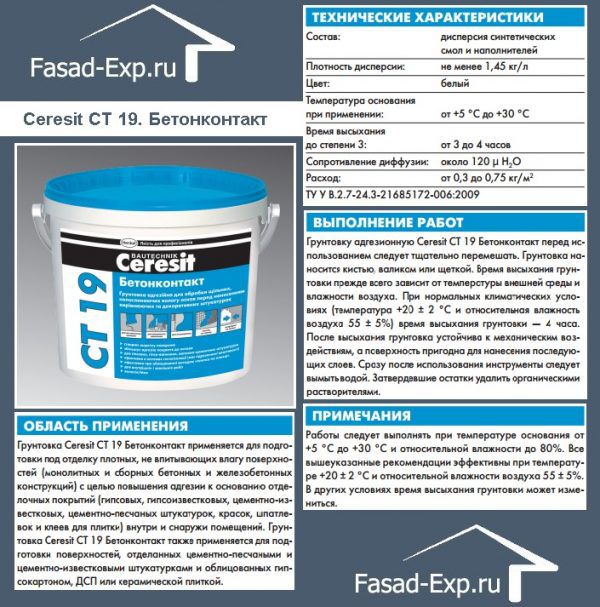

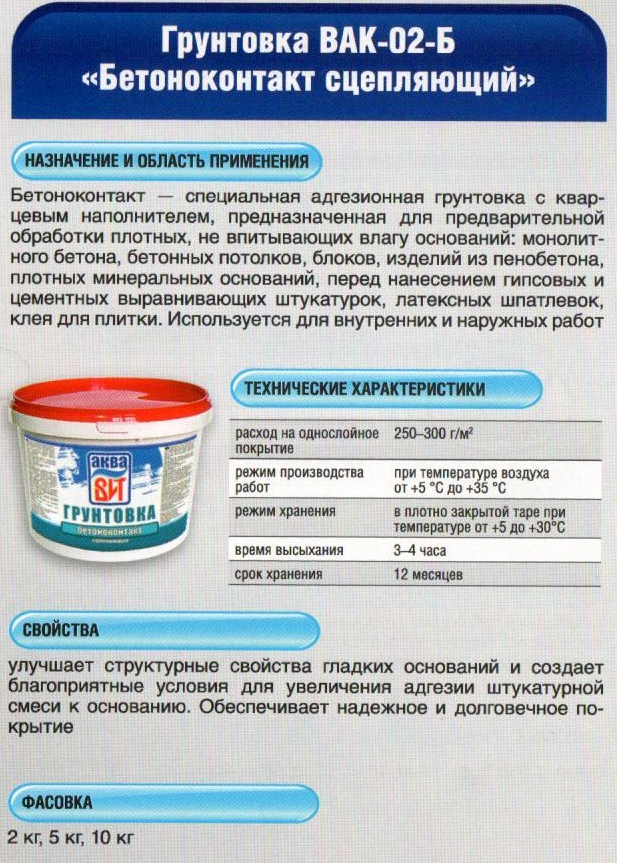

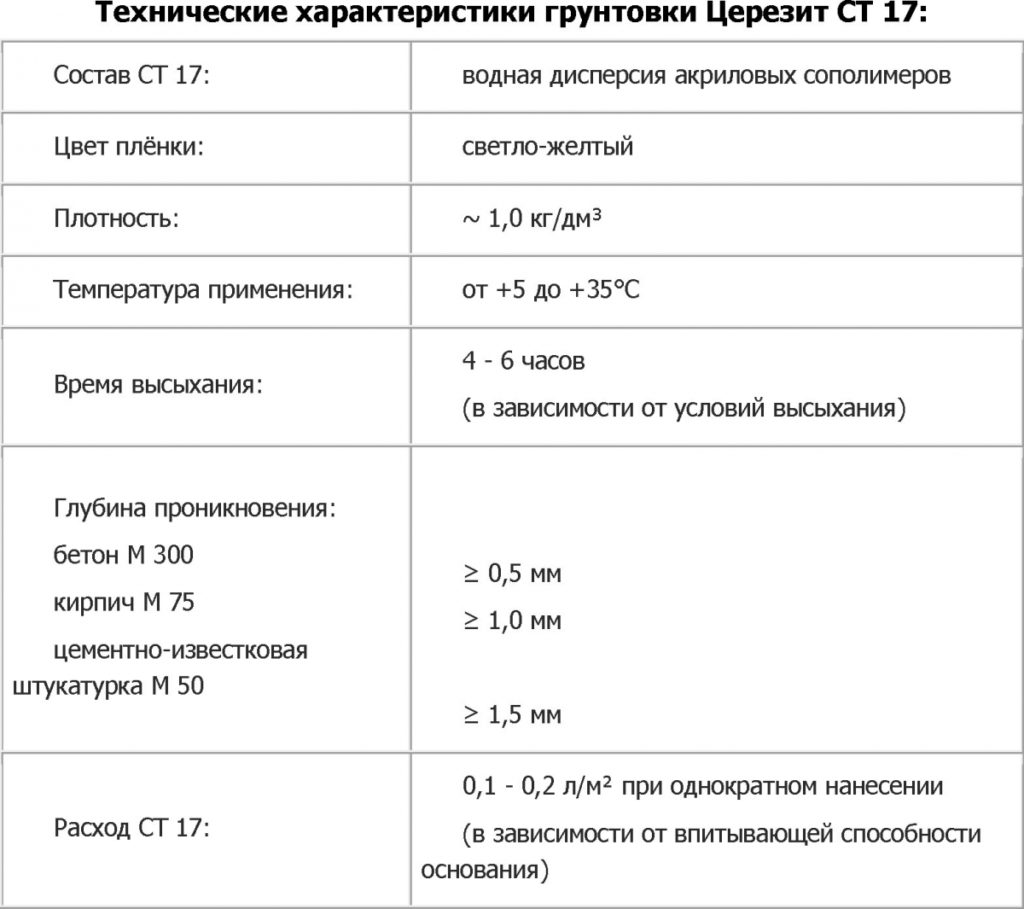

Primer consumption table concrete contact from different manufacturers

Depending on the porosity, the following types of surfaces are distinguished:

- Porous surfaces, which include brick or sand concrete. The primer is absorbed quite intensively, which leads to the consumption of concrete contact up to 0.5 kg per m2. If the porosity is too high, then you will first need to treat the surface with special solutions.

- Surfaces with medium porosity. These include concrete, concrete tiles. Consumption of concrete contact is about 0.3 kg per m2.

- Low-porous surfaces, for which the consumption of the primer is minimal - 0.1-0.2 kg per m2.

Is it possible to reduce the consumption of primer?

Most people wonder if it is possible to reduce the consumption of concrete contact primer. The answer is definitely no. First of all, this building mixture is notable for its affordable price, so there is no point in saving on it. In addition, this can lead to a decrease in the strength of the material, which over time will begin to crack or flake off.

It should be remembered that the quality of the primer and the work done on its application has a direct impact on future finishing work and the quality of the entire repair in general. If you reduce the amount of concrete contact primer per m2, the surface will lose its adhesion properties. In the future, this may cause the coating to separate from the base.

Reduced primer consumption may result in loss of surface adhesion.

The primer plays an important role in the process of ensuring the waterproofing of the surface, which can be disturbed when the amount of mortar per m2 decreases.

Do not forget about an important feature of some finishing materials, which is that some coatings can dry out. The fact is that gypsum or Portland cement is present in their composition, and drying out becomes a natural reaction to a decrease in the amount of water.

Thus, the use of concrete contact is essential for the future of the entire renovation.

All the nuances of using this building mixture should be taken into account. The level of concrete contact consumption per m2 depends on the type of substrate and its porosity

It is not worth saving when using a primer, as this can negate all further finishing work.

It is interesting: DIY repair of a small kitchen in Khrushchev

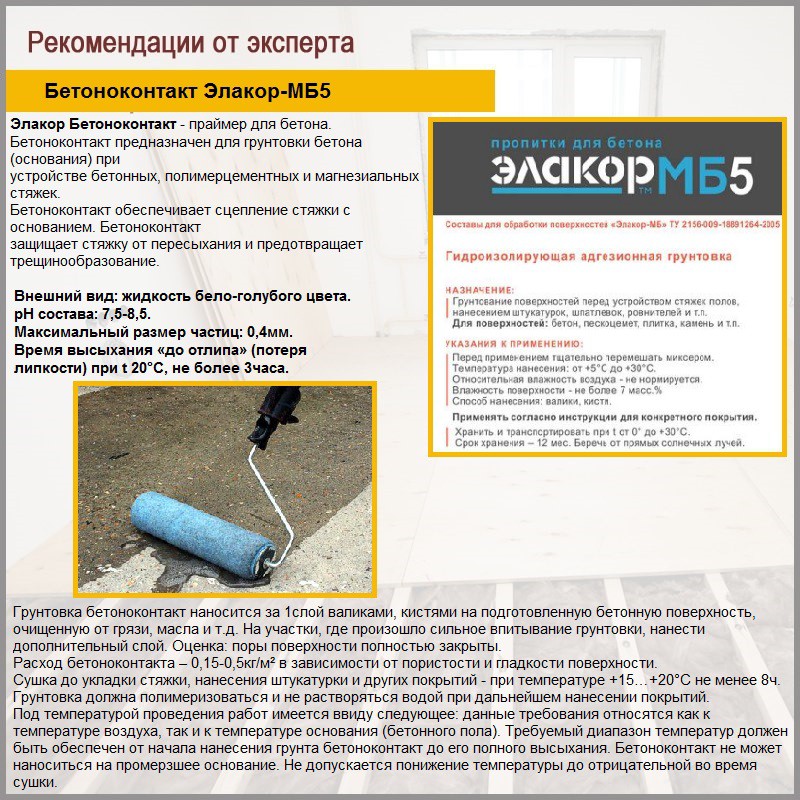

What is a primer Betonokontakt

Primer concretekontakt - polymer alkali-resistant dispersion. The composition includes:

- Quartz sand. It is used as a filler that creates a certain surface texture.

- Acrylic. Binder.

- High strength adhesive. Provides a strong bond to the treated surfaces.

- Some types contain additional additives such as cement or other compatible materials.

This combination is not quite common for a primer, but the purpose and method of its use suggest otherwise. It acts as an intermediary between surfaces that are incompatible from the point of view of the finisher.

It makes it possible to glue tiles, for example, on glass or metal.

During repairs, problems of this kind are often encountered - it is required to use cement, gypsum-cement, gypsum or some similar type of mortar on the surface, the material of which is not capable of absorbing water and, as a result, does not hold the mortar at all. This is helped by the primer, the technical characteristics of which speak for themselves.

How to apply

It is necessary not only to know what Concrete Contact is needed for, but also how and with what to apply it. It just seems like there is nothing complicated about it, but try it first. The composition is often thick, approximately like kefir, and sometimes thicker. Moreover, it contains grains of sand, crystals, which are very desirable to be evenly distributed over the entire surface, and not collected in one place. In general, it is not that simple. There are some tips:

-

It is best to work in protective clothing, and it is advisable to cover everything. It is washed from the skin with big problems, it is removed from the hair only together with the hair. To make it easier to rinse off unprotected skin, cover it with a greasy cream or some kind of oil. When processing the ceiling, it is advisable to protect the face, even if the skin is smeared with cream / oil. At least glasses are required.

- For large areas, it is easier to apply with a roller. It is more convenient to take it in such a size that it fits into a bucket. It is better to work with a fleecy - with a pile of 12-18 mm. Yes, a certain amount of the composition is absorbed, but it is really more convenient to work this way than foam rubber, which very quickly becomes "wooden". Moreover, even in this case, after a while the pile will become clogged with sand. In the process, remove sand on the edge of the bucket, you can try with a spatula. In general, clean up. If it is not already cleaned and "does not work", take a new one.

- For processing not too large surfaces or in corners, it is more convenient to work with a brush. Pile - medium or even short. Here as it is more convenient to whom. Only the long one is hard to manage when there is a lot of sand. In the process of application, the sand must be periodically removed (on the edge of the bucket). The brush is quickly erased, therefore, with large volumes of work, you will have to change it several times.

There is one more trick - attach a brush or roller to a stick with a meter in length - and a stepladder is not needed when processing walls, and away from yourself - fewer drops fly to clothes and to your face.

Features and characteristics

Before starting work, you need to understand what concrete contact is, how to use it correctly. Many people think that concrete contact is a conventional primer or its substitute. This is wrong, although they are similar in function: concrete contact improves conditions for working with any surface.

Before the appearance of concrete contact building materials on the market, the process of plastering ceilings was complicated and took a long time. It was required to use a large number of different materials, but this did not guarantee a successful job.

When using a concrete contact, the time of work was reduced, the quality of plastering increased. This composition is used for interior work, facade decoration.Without the use of such a solution, decorative plaster can peel off within a year, which is not included in the plans of most consumers. Concrete contact can be applied to any surface. In this case, you can not remove the old coatings: this solution will increase adhesion in any case. The composition includes:

- base made of polymers;

- quartz or quartzite;

- cement;

- special additives.

When using a concrete contact, a rough layer is formed, to which any glue and material can be fixed. The main characteristics of the finished composition include low consumption and good waterproofing. All components that make up the concrete contact are allowed to be used with dusty substrates. Quartz sand increases adhesion (especially with wood surfaces), creates a rough layer.

Many additives that are included in the composition prevent the formation of mold and mildew. When used correctly, the composition retains its properties for several decades. The parameters that may vary from operating conditions include the consumption of the composition and the drying time. Average consumption ranges from 250 to 450 g per 1 sq. m of surface.

Drying time depends entirely on the humidity in the room, an average of 150 minutes.

There is a large selection of ready-made concrete contact compounds. Due to carefully selected proportions, all components fulfill a specific role. After purchase, you only need to mix the contents: the solution will be ready to be applied to the surface.

Some people believe that you can prepare this composition yourself. However, given that it is difficult for yourself to accurately calculate the proportions, the need to purchase various materials and the time to prepare the solution, it is worth considering several times whether such a procedure would be beneficial. The price for a ready-made concrete contact is acceptable, it does not need to be adjusted before application.

What is concrete contact: purpose and features

Concrete contact is a cohesive acrylic primer with the addition of quartz. This type of primer is used to roughen the subfloor to provide greater strength to the fastener. In addition, it has increased moisture resistance.

BC is of two types:

- under the putty;

- for plastering works.

A distinctive feature of this composition is its versatility, which gives ample opportunities to use it for working with concrete, brickwork, plasterboard, porcelain stoneware, tiles, painted surfaces, wood, metal, glass.

Concrete contact: composition and properties

This polymer blend is not a deep penetration primer

The exact composition of the concrete contact is a secret behind seven seals, since manufacturers are not inclined to share important information with competitors. However, its main components are well known: they are acrylic or latex, glue, gypsum, quartz sand, talc, cement mixture or marble chips.

Modifiers must be added to any primer. Their task is to impart a certain property to the surface: they must impart increased strength, frost resistance, etc.

Polymer materials guarantee reliable adhesion, cement is responsible for the hardness and strength of the primer layer. Quartz sand provides it with a roughness. The diameter of its grains of sand depends only on the purpose of the composition: small ones are added to the mixture for finishing, larger fractions - under plaster, putty. This primer is usually pink in color, so untreated areas are easy to spot.

The ratio and composition of the components differs depending on the type of concrete contact: some of them are intended only for work inside buildings, others “specialize” in outdoor operations, and still others belong to universal primers. The task of the material is to ensure excellent adhesion of dissimilar materials.Applied to the surface, the concrete contact creates a rough layer, thanks to which it easily holds any finishing material. Another feature of the primer is the ability to absorb excess moisture that appears on concrete structures.

The universal type of concrete contact gives the chance to get perfect adhesion to any surface. They are treated with:

- concrete;

- drywall;

- wood;

- ceramic tiles;

- brick;

- metal;

- painted surfaces;

- glass.

The rough layer of this primer guarantees a strong connection of materials that are completely different in structure: tiles and metal, wood and glass. The concrete contact holds firmly, does not crumble, does not crack. The biggest advantage of this primer is that the work does not require the tedious step of getting rid of the old, but still reliable coating: treated with this compound, it is able to stick almost tightly to the new type of finish.

This is the most common question regarding this primer. If we talk about normal room temperature (about + 20 °) and humidity, then the average setting time is 3 hours (2-4). But this work has some peculiarities. Those who have already come across this material know that the surface looks completely dry within an hour after applying the mixture. However, even the eyes are sometimes deceiving.

To check the base, carefully rub it with a metal spatula. You can omit this operation, since any damage to the layer threatens to lose the material's remarkable properties.

Experts with extensive experience of "communication" with concrete contact advise to apply the mixture in the evening, and start the next work in the morning. It makes no sense to wait any longer, since the treated surfaces literally attract dust.

The only exception is small bathrooms, where high humidity is common. It is best to try to provide the room with excellent ventilation. If such a mission is not feasible, then the drying primer is left alone for 24 hours.

Sometimes force majeure circumstances arise that do not give a lot of time for work. In this case, there is still a way out: wet surfaces are covered with a deep penetration primer, waiting for it to dry completely. Then they proceed to finishing the premises.

Subtleties of application

All concrete contact manufacturers write a short instruction on the packaging. Be sure to read it before starting work. The use of a primer solution does not require special skills and abilities

When reading the manufacturer's recommendations, pay particular attention to the temperature range. Too high and low temperature values of air not only harm the composition, but completely render it unusable

Overcooling and overheating reduce the adhesion properties by several times.

Concrete contact is more often found on sale ready-made. You can start finishing the walls, floor or ceiling right after you return from the store. Before starting, you should still mix the contents of the bucket thoroughly. Visually, this primer resembles a pastel paint with small solid blotches. Before starting the priming work, make sure that the room is warm enough (more than +15 degrees).

It is categorically impossible to apply the composition to frozen walls. Low temperature prevents adhesion of the compound to the surface. After decorative treatment, the primer will simply fall off the wall under the influence of the heavy material. If there is a wiring in the wall, then be sure to de-energize the room before starting work. Otherwise, the surface can absorb moisture and act as a conductor of electricity.

To apply a primer composition, use:

- wide brush;

- wide and narrow spatulas;

- paint roller.

A wide brush helps to minimize material consumption, and on the contrary, a lot of composition remains on the roller.Apply concrete contact in an even layer over the entire surface of the substrate. If you are working on a surface that will absorb liquid, it is best to apply the primer in two coats. You will also have to reapply the solution if the base has serious defects and intricate relief.

Sometimes it makes sense to slightly dilute the primer mixture. To do this, add 50 ml of water to 1 kg of the product. The water must be at the same temperature as the room air temperature.

What not to do

If you wish, you can find reviews or videos stating that the plaster / tile fell off Betonkontakt. To prevent this from happening, apply primer only on recommended substrates. Also, don't do the following:

- Dilute the plaster or filler with more water than indicated on the package. Yes, it is easier to work, but as a result, the putty can fall off.

- Do not apply the composition to frozen ground.

- Do not apply Concrete Contact on an unprepared surface (remove all loose parts, degrease, remove dust).

-

Do not apply BC to wet surfaces. Only dry.

- When working, do not forget to periodically stir the contents, as sand particles (granules from some manufacturers) sink down.

- Do not continue work until the primer layer is completely dry (indicated in the instructions).

- Do not work at temperatures below + 5 ° C. This does not mean that it cannot be used for outdoor work. It is possible, only it must be applied at positive temperatures.

- Do not allow dust to enter. It adheres very well to the adhesive surface, but then falls off along with the plaster. If the surface is dusty, another treatment is necessary.

-

Do not use the composition with an expired expiration date, frozen. The exception is frost-resistant compounds (there are some). Before use, they must be defrosted, wait until the temperature rises above + 5 ° C, then you can work. By the way, the inscription "frost-resistant" does not mean that it can be applied at sub-zero temperatures. It can only endure several defrost / freeze cycles before application without loss of properties.

- Do not add water, even if it seems that the composition is too thick. Unless the manufacturer described such a possibility in the instructions. But so far they have not seen one.

And for Betonokontakt to work, it must be "real". There are a lot of fakes, so you need to be careful. And to be sure, you can check. Pre-process a small piece of the wall with the BC according to the instructions. Apply a planned layer of plaster / putty. Wait until it dries and try to tear it off. If done correctly, nothing will work out for you. They say that high-quality Betokontakt allows you to apply plaster even on glass. By the way, you can try.

How to choose concrete contact correctly

The question arises: how not to make a mistake when buying?

Choose a primer made by reputable companies that are respectful of their reputation. If you see a concrete contact of an expensive brand at a too low price, this is a reason to be wary.

The quality of the primer can be assessed visually. A quality material always has a pink, blue or purple color to control the evenness of the coating. If the primer is almost white, it may have been heavily diluted with water.

Video Primer: types, mistakes, how to cheat? Secrets of materials and advice from a professional

Betonkontakt is one of the types of primers that you cannot do without when implementing finishing work. In addition to adhesion, it gives surfaces additional characteristics: strength, waterproofing properties, resistance to mold and mildew damage, and also provides dedusting of concrete surfaces. The use of concrete contact allows finishing work not only on new surfaces, but also on those that have already been previously painted or tiled.

To obtain a reliable and durable coating, it is important to use high-quality material and not try to save money by diluting it with water

Purpose and scope

Concrete Contact is a special type of primer for substrates that do not absorb water. If such bases without preliminary preparation apply plaster, it will most likely fall off when it dries, since the surface of these bases is usually smooth and the plaster simply has nothing to cling to. To prevent the plaster from falling off, use Beto-contact. And it really works, but you just need to know when it is needed.

The principle of operation of Concrete Contact

The composition is not cheap, but it is advised to use it anywhere. In order not to waste money, you should know him for sure properties and scope... In general, there is information on every bank, but sellers (and some builders) advise a different application. But not everyone should be believed.

What surfaces to apply

Concrete contact forms a sticky, rough layer with abrasive inclusions on the surface. Plaster / putty also adheres well to this layer. Abrasive particles - grains of sand or crystals - provide additional support for the finish layer. In general, the task of Concrete Contact is to increase adhesion to difficult substrates. But not to everyone.

What should Betonkontakt be applied to? As already mentioned, it is intended for substrates that do not absorb water. There are not so many of them:

-

Smooth concrete with almost no pores. Usually these are concrete panels in panel houses, columns in modern monolithic ones. If the concrete is loose and porous, a different primer is needed.

- Ceramic tile. It is not necessary to knock down the old tiles before laying new tiles. Although, if possible, it is better to shoot down. If for some reason this cannot be done, go over the top of the tile twice with concrete contact and you can continue working.

- Wooden fragments. There is simply no other way to apply plaster to wood. But the wood must be dry.

- Metal. This base is 100% non-absorbent and, in order for the plaster to stick to it, a BK layer is needed.

That's what Betonokontakt is for. There are no other recommended surfaces. Tips to apply on plaster under putty, under decorative plaster - all this is superfluous. There is no need for this processing, because only the cost rises, and the result is not affected or only worsens the situation. On fresh plaster, the putty will go down with a bang, like other finishing materials.

Option from the Prospectors - Concrete-Contact

Moreover, the advice to apply Betokontakt on wooden and metal surfaces is precisely on the fragments. For example, beams, protruding parts of structures. This is again the moment where the bookmaker is needed. There are other technologies for plastering wooden walls, and if there is only a fragment, it is advisable to use this composition.

Do I need a concrete contact over oil paint

Finishers also use Betonkontakt on oil paint. Most of them advise to peel off the paint, because both with concrete contact and without it, the plaster under its mass can separate from the paint. If the composition has eaten tightly and is not removed by any means, it is necessary:

- Be sure to thoroughly degrease the surface.

- Remove smoothness by abrasive processing - with coarse sandpaper, a metal brush. It doesn't matter what, as long as it works.

-

Make notches with a chisel, ax.

- Dust off. You can wash, you can vacuum. The main thing is carefully.

- Apply the first layer of concrete contact.

- Dry.

- Apply a second layer of concrete contact.

- Dry.

- You can putty, plaster, lay tiles.

In this case, it is also clear why Betonokontakt is needed and how it works. But it is quite possible to stop before the first application of Concrete Contact. If there are notches of sufficient area, both plaster and tiles will stick.Use a suitable primer to treat “chips” in the wall and, after drying, apply the following material.

Olimp designated its Contact-Grunt as an agent for decorative plasters and ceramic tiles.

Many people assume that with the sticky surface that Betokontakt leaves, it will stick better. In general, it works, but only if you do everything as written. And yes. Drying is complete and final. The term is indicated on the bank and differs depending on the manufacturer. The shortest drying period is 3-4 hours for Betonkontakt Fedal, the longest is about 24 hours for some cheap one.

What is it and why?

Concrete contact, in fact, is a soil, but more advanced. It contains sand, polymer, cement and other additives. The use of this composition implies a desire to increase the adhesion of materials. It is an intermediate layer between the main surface and the finishing material. By applying concrete contact on a smooth surface, you can make it rough, like sandpaper. And on such a coating, any coating material will lay down more reliably.

The use of the presented solution, due to its technical characteristics, is possible on any surfaces: walls, ceilings, concrete slabs, whitewash or painted partitions. The application of concrete contact, taking into account its consumption per 1 m2, should be carried out immediately before the application of the finishing material. On the construction market, concrete contact is presented in the form of a ready-made solution in buckets of 20 kilograms and in the form of a mixture for preparing soil in packages of 3 and 5 kilograms. To prepare the soil with your own hands, it is enough to read the instructions presented on the package and adhere to it exactly.

Features of preparation and application

After it became known what it is, you can consider how to use concrete contact correctly. The use of the ready-made solution is quite simple, because it does not need additional preparation. It is enough just to open the bucket with the mixture and mix it thoroughly. Before applying the primer mixture to the surface, it must be cleaned of dust, dirt, oily traces, as well as old paint or wallpaper. In the process of work, the solution must be stirred from time to time.

The concrete contact that needs to be prepared has slightly different characteristics than the ready-mix. For its manufacture, it is necessary to use the basic rules for the preparation of a primer mixture. The choice of this or that composition will completely depend on your own preferences and financial capabilities.

Concrete contact can be applied roller or ordinary brush, to whom it is convenient. You can also use special equipment to apply it, but at the same time, you must definitely read the warnings that are described on the package. The drying time of the mortar will depend on its characteristics, as well as the level of humidity in the room, air temperature and wall decoration material. Under standard conditions, primer mix usually dries in about 3.5 hours. It is recommended to apply ceramic tiles, wallpaper or paint only after the mixture has completely dried, because otherwise the adhesion may not be so good.

How to calculate the flow rate correctly?

How much concrete contact is required to process one room? Consider the consumption per 1 m2 using an example. For example, it is necessary to use the mixture in a room 4 meters long, 3 meters wide and 2.5 meters high. First, you need to calculate the total surface area that needs to be processed. So, they have two walls with an area of 10 square meters, two walls with an area of 7.5 square meters and a ceiling with an area of 12 square meters. As a result, the total area to be processed is 47 square meters.Such an area can be easily processed with one bucket of ready-made primer mixture, and even with a margin.

Primer consumption calculations may vary based on additional factors. When applying the mixture, it is necessary to take into account the absorbent properties of the surface, the number of layers to be applied, etc. When applying a concrete contact to a brick, the consumption per 1 m2 can be up to 500 grams, on concrete or for leveling the floor - up to 300 grams, on low-porous surfaces - up to 200 grams. The best method for determining consumption per m2 is a test application.

Is there a health hazard?

Concrete contact is an environmentally friendly solution that can be used for both external and internal work. It does not in the least interfere with the surface "breathing", thus preventing the appearance of mold, mildew, and, accordingly, pathogenic bacteria. As a mixture, the soil can be stored for up to 1 year, but this is provided that it is in a sealed package and at a positive temperature. Freezing of the soil mixture is strictly prohibited.