The paradox: price, quantity and quality

When considering the cost of bits, it is important to understand that when buying cheap products, even in specialized stores, you can not save money, but lose it. It is no longer a secret that the market is filled with fake goods that are created only for sales and profit by unscrupulous manufacturers by deceiving gullible consumers.

Buying such products means simply losing your money.

It is no longer a secret that the market is filled with counterfeit goods, which are created only for sale and profit by unscrupulous manufacturers by deceiving gullible consumers. Buying such products means simply losing your money.

The production of high-quality nozzles is associated with material costs that should pay off from the manufacturer and the buyer. They are priced based on the optimal combination of these requirements.

The manufacturer makes a profit due to the rapid and massive sales of products, and the buyer - thanks to the long and reliable operation of the purchased screwdriver bits, which save working time and greatly facilitate the installation of fasteners.

Therefore, buying quality beats means investing money correctly, saving your nerves.

A quality bat costs about $ 1.50. It bears the stamp of the manufacturer indicating the type of shape and size. PVD coating will cost a little more.

A master who regularly uses a screwdriver, performing various actions with it, can save on the purchase of bits. To do this, they are bought in large quantities, but at a wholesale price. Due to this, the cost of a single item is reduced.

Once again, I draw your attention: each bit is selected for a certain fastener with specific characteristics. A good tool cannot be cheap, but it justifies its purchase in the process

I consider it useful to recommend watching the video of the owner of the autom "Why screwdrivers deteriorate" on the topic under discussion.

It is possible that you still have questions about the choice of bits or there are disagreements with the material provided. Use the comments, and I will answer them.

The screwdriver is widely used by both home craftsmen and professionals at the construction site and in other fields of activity. It is used to tighten screws, self-tapping screws, screws, bolts, and also drill holes in different materials. For each type of fastener, you need a suitable bit for a screwdriver. Working attachments for the power tool used can be purchased in sets or individually: it all depends on the variety of types of fasteners with which to work.

If you only need to connect parts occasionally, then it is enough to purchase a few of the most common bits. It is more convenient for professionals to buy attachments in one set for different fasteners. The classification of products by size and type, as well as recommendations for manufacturers, will help you navigate the extensive range without any problems.

Asterisk Bits (Torx)

Sprocket-shaped nozzles are used in mechanical engineering and in the production of household appliances, for tightening fasteners with an appropriate head shape. They are called Torx (torx) and are designated by the letters TX or T. Next to the letter is a number that indicates the size of the bit. It corresponds to the distance between the beams of the hexagonal sprocket.

Torx was first used in 1967 by Textron in America.Today, different types of bits are used for this type of screwdriver. So, there is a vandal-proof version equipped with an internal hole. For its designation, the letters TR are used, which stands for Torx Tamper Resistant. There are also five-beam bits called Torx Brigadier Pentahedron.

Classic bit "Asterisk" (Torx)

In European countries and the USA, the Topx nozzle is the most popular of all existing slot shapes. This is due to its high performance. This bit is distinguished by the presence of six faces, with the help of which there is contact with the screw or screw.

The design feature of the nozzle improves the adhesion to the surface of the fastener. As a result, it does not take much effort to generate torque. The likelihood of the device slipping is also reduced, since the load is distributed immediately over 6 faces. This in turn reduces wear and tear. Consequently, the operational period of the bit is significantly increased. The Zvezdochka nozzles are produced in various standard sizes. The most common models are from T8 to T40. In this case, there are bits of smaller size.

Bit "Asterisk" Torx Plus

The Torx Plus is distinguished by the fact that its sprocket has less sharp beams, which are also shorter. These types of bits for a screwdriver require a master of increased accuracy during the execution of work. High-hardness steel is used for their manufacture. The sizes of these nozzles are T10-T40.

Bit "Zvezdochka" with TIN coating

Thanks to the titanium nitride coating, the tip has increased wear resistance. Its surface is rough and adheres well to steel. Also, the nozzle is characterized by increased durability, because it is made of solid material. The attachment is sold in sizes T10 to T40.

Bit "Star" with a hole inside

This bit is often used in assembly plants. When tightening the fastener, the bit fits snugly into the fastener. As a result, the reliability of the twisting process is increased, for the implementation of which you do not need to exert special efforts. Bit sizes range from T10 to T40.

Long bit "Asterisk"

This attachment is convenient to use when performing certain types of work. Its dimensions are the same: from T10 to T40, the length can be from 50 mm to 100 mm.

How many screws are needed for 1 sheet of corrugated board for a fence

Before installing the profile fence, it is necessary to calculate the number of self-tapping screws. You can perform this action using a special formula. In order to determine how much self-tapping screws for 1m2 of profiled sheet need, you need to calculate the total area of the fence.

Fastening the profiled sheet to the fence

For 1 m² of corrugated board fence, 10 to 15 screws are required. This takes into account how often the posts are installed. The consumption of self-tapping screws for a profiled sheet, the width of which is 110 centimeters, is 10-15 pieces. Along the edges, the installation of the sheets is carried out with an overlap, so one self-tapping screw holds two sheets together at the same time. Screws must be screwed into the pillars and logs made of wood. 1-2 fasteners are screwed into each post, and 6-8 into the lag. This is the consumption of self-tapping screws for 1m2 of profiled sheet.

In order to calculate the number of sheets of corrugated board for the fence, the length of the fence is taken, which is divided by the width of the sheet. The number of sheets is multiplied by 10-15. This will make it possible to make the necessary calculation of self-tapping screws for corrugated board and buy them in the optimal quantity.

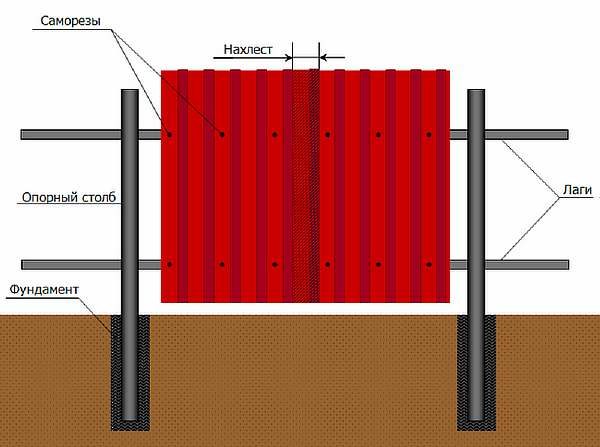

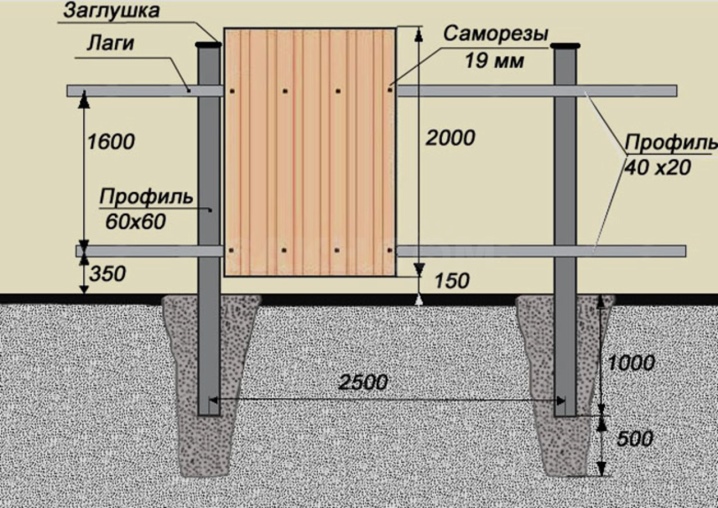

Fence installation diagram

For the installation of a corrugated fence, it is recommended to prepare the following materials in advance:

- Professional sheet. It is recommended to purchase sheets for the entire length of the fence. The thickness and height of the waves are selected depending on the strength characteristics. The pillars should have a height of 20 cm more than the length of the profiled sheet, since they are dug into the ground.When counting sheets, you need to take a larger number, since there are overlaps of 8 centimeters between the sheets.

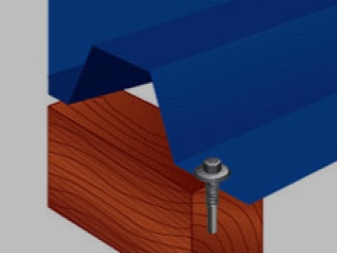

- Screws. For the installation of the fence, a roof bracket or a device with a press washer can be used. When choosing it, the requirements of waterproofing are taken into account. The bracket is selected in accordance with the material of the batten, which is mounted between the posts. It can be wooden or metal.

- A screwdriver or drill that has a matching bit for a hexagonal head. Installation of thin sheets of corrugated board can be carried out with wrenches.

- A hacksaw and scissors for metal. The grinder is used for work, after which the material is painted.

- Cord, level.

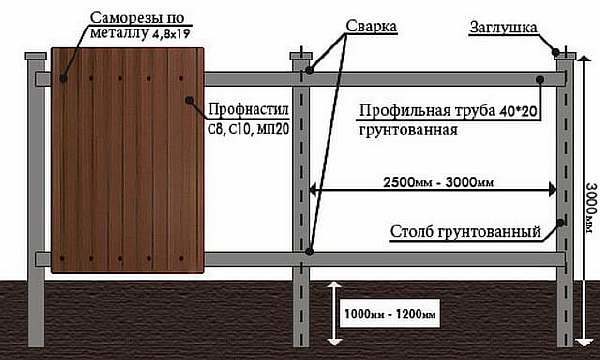

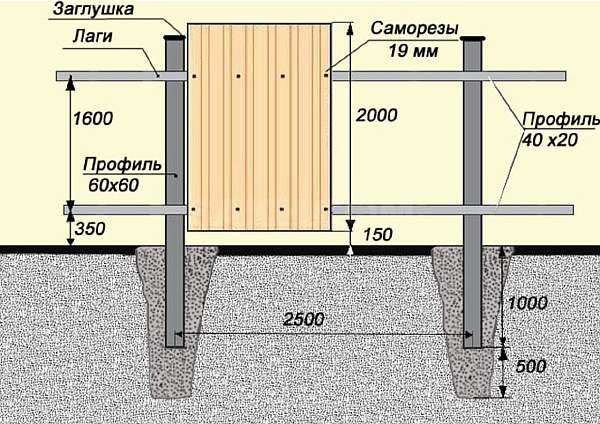

Sheet fastening drawing

After purchasing the material and preparing the necessary tools, you should proceed with the installation work. When installing the fence, it is recommended to use self-tapping screws for the corrugated board measuring 4.8x29 or 5.5x19 millimeters.

They must have a rubber gasket to ensure a tight fit. Fastening the sheet to the lags is carried out with self-tapping screws, which are located at a distance of 25-30 centimeters from each other.

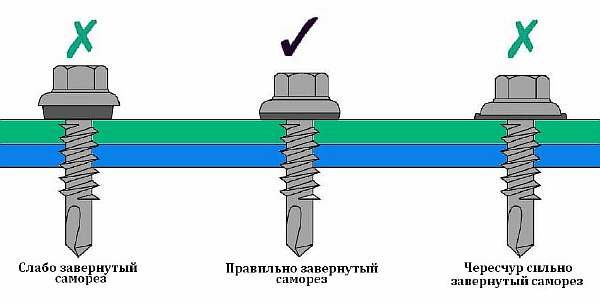

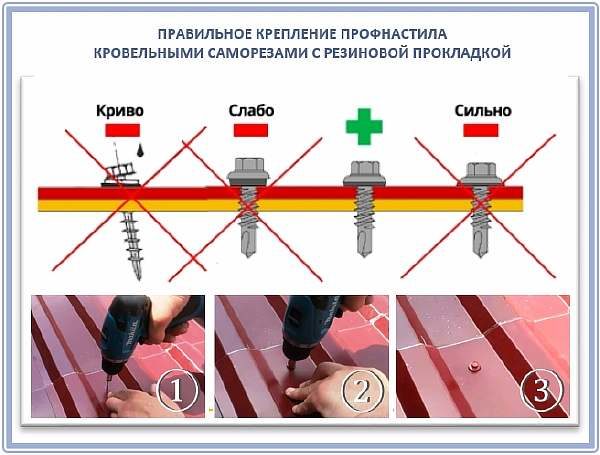

Correct fastening

Initially, it was recommended to install the supports for the fence made of corrugated board into holes pre-drilled with a drill. They should be equidistant from each other. When installing a fence made of corrugated board, a distance of no more than 2.5 meters must be observed.

At the next stage, the horizontal transverse lags are fastened to the fence posts made of corrugated board. These can be metal profiles or wooden beams, which are installed on poles in several rows.

Fence installation drawing

The profiled sheet is screwed to the logs with self-tapping screws. After screwing the first sheet, the next one is positioned so that the edge of the previous one overlaps the previous one by 8 centimeters. The connection point must be treated with silicone sealant, which provides additional insulation and is characterized by resistance to moisture.

At the corner joints and ends, you need to mount special strips, that is, cover strips. To ensure long-term operation of the corrugated board, it is recommended to treat the ends with an anti-corrosion compound.

When fastening the screws, use rubber pads that match the color of the fences. The screws are screwed in vertically in accordance with the surface of the profiled sheet, which eliminates the possibility of skewing. After screwing in the screws, this place is primed or coated with paint, which is combined with the profiled sheet in color.

Mounting scheme

How to calculate

Self-tapping screws for a profiled sheet, if they are made according to GOST standards, have a rather high cost, therefore it is necessary to correctly determine the number of hardware that will be required to complete the work. In addition, it is necessary to determine the parameters of the hardware, based on what materials you will have to work with.

Determination of the number of self-tapping screws depends on the type of construction and the number of fasteners.

The calculation of hardware for a fence from a profiled sheet is as follows.

- On average, 12-15 self-tapping screws are consumed per square meter of corrugated board, their number depends on how many horizontal lags will be involved in the construction of the fence - on average, there are 6 self-tapping screws for each lag, plus 3 pieces must be kept in stock for unforeseen situations.

- When two sheets of corrugated board are joined, the self-tapping screw has to pierce 2 sheets at once, overlapping each other - in this case, the consumption increases - 8-12 self-tapping screws go to the corrugated sheet.

- You can calculate the required number of corrugated sheets as follows - the length of the fence must be divided by the width of the corrugated sheet without taking into account the overlap.

- The number of horizontal lags is calculated based on the height of the fence planned to be made, while the lower lag should be located approximately at a distance of 30-35 cm from the ground surface, and the second support lag is carried out already stepping back 10-15 cm from the upper edge of the fence. In the event that a distance of at least 1.5 m is obtained between the lower and upper lags, then for the strength of the structure it will also be necessary to make an average lag.

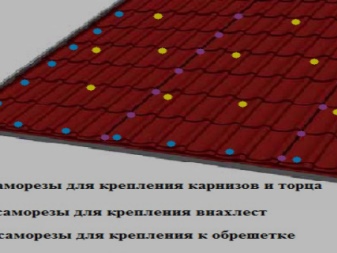

The consumption of hardware on the roof is determined based on the following data:

- for work, you need to purchase short self-tapping screws for the lathing and long ones for attaching various elements of accessories;

- hardware for fastening to the crate take 9-10 pcs. for 1 sq. m, and to calculate the pitch of the lathing take 0.5 m;

- the number of self-tapping screws with a greater length is calculated by dividing the extension length by 0.3 and rounding the result upwards.

It is not recommended to purchase self-tapping screws in a strictly limited quantity, according to the calculations performed. You always need to have a small supply of them, for example, to strengthen the side mounts when installing a profiled sheet or in case of loss or damage of a small number of hardware.

How to choose wood screws

It is not worth using self-tapping screws for metal or universal screws for fixing wood. Universal ones are good when you need to twist wood and metal. And when twisting two pieces of wood, they work worse. In the sense that specialized fasteners will hold the wood better. That is, we consider only wood screws. Believe me, there will be plenty to choose from.

Wood screws are better than yellow (yes, expensive) or white (a little cheaper)

As already said, wood screws have a rarer thread with a higher profile (the grooves between the turns are deeper). They are used not only for wood, but also for all types of sheet materials: gypsum fiber board, plywood, OSB (OSB), fiberboard and chipboard. Now about which ones work better.

Thread and other "bells and whistles"

First you need to choose the type of hat. Secret or with a press washer, cylindrical, hemispherical - select based on what kind of connection you need to make. It is also recommended to choose a spline of the TORX type, since it best transfers the torque from the power tool. Further in order.

- It is necessary to determine whether the thread should be applied to the entire rod or not. If you need to fasten two pieces of wood and pull them tightly together, take a self-tapping screw with an incomplete thread. This means that there must be an unthreaded area under the head. The length is equal to the thickness of the attached part or slightly more. Due to this zone, one part is "attracted" to another.

How to choose self-tapping screws for wood: a few chips for quick and high-quality work - To make it easier to screw into hard rock or sheet material, there are wood screws with a router or mill. The cutter is available only on self-tapping screws with an incomplete thread. It looks like a few screw-type notches, which are applied before the start of the thread. The notches soften the wood, after which the self-tapping screw "goes" better.

- In general, wood screws have a thinner point and thus prevent wood cracking. But there are also special "lotions" against cracking. It can be:

- grooves;

- cutting edges in the form of notches on the screw body;

- notches on several lower threads.

Are these bells and whistles necessary or is it wasted money? Incomplete threads are nothing new. One detail "sits" on top of another much more densely. And try the rest. Only from your own experience you will understand whether it works or not, and what exactly suits you best.

And practical advice on choosing wood screws

It is important that the thread runs straight from the tip itself. If the first turn is too far or the tip is blunt, do not take

There will be continuous torment, not work.

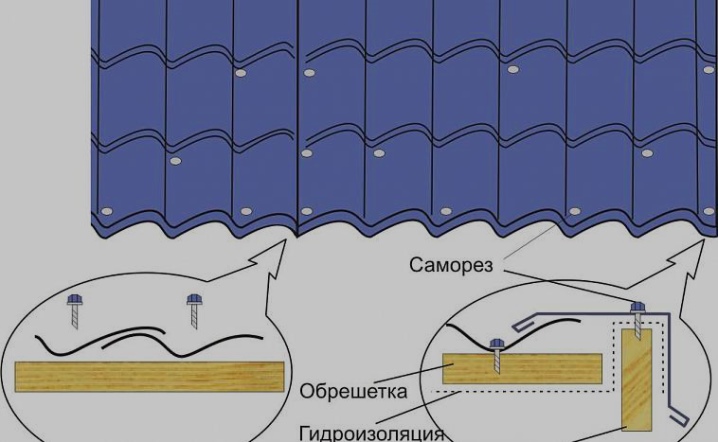

How to fix

Reliable fastening of the corrugated board implies the preliminary production of a frame structure from a metal profile or wooden beams.In order to tighten the screws in the necessary docking points correctly, on the roof or on the fence, you need to have a wiring diagram according to which the whole complex of work is performed. The installation process is not just about twisting the screws - it is necessary to complete the preparatory, and then the main stages of work.

Preparation

For high-quality performance of the work, you will need to correctly select the diameter and length of the self-tapping screw. There is a single rule here - the heavier the metal profiled sheet weighs, the thicker the diameter of the fastening hardware must be chosen to ensure the reliability of the fastener. The length of the fastener is determined based on the wave height of the corrugated board. The self-tapping screw length should exceed the wave height by 3 mm, especially if 2 waves overlap.

The diameter of such holes is taken 0.5 mm more than the thickness of the self-tapping screw. Such preliminary preparation will allow avoiding deformation of the sheet in the place of fixing it with a self-tapping screw, and will also make it possible to more tightly fix the profiled sheet to the support frame. In addition to these reasons, a slightly larger hole diameter at the attachment point will make it possible for the profiled sheet to move during temperature changes.

Process

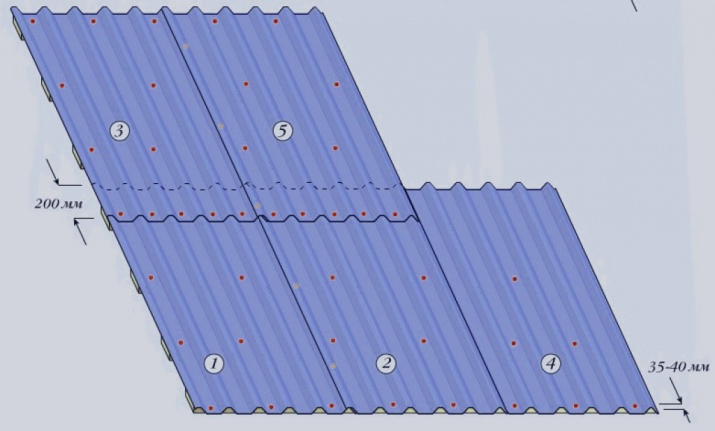

The next stage in the installation work will be the process of fastening the corrugated board to the frame. The sequence of actions in this case is assumed as follows:

- to align the bottom edge of the profiled sheet along the bottom of the fence or roof, pull the cord;

- the installation starts from the bottommost sheet, while the side of the direction of work can be any - right or left;

- sheets of the first block, if the coverage area is large, are installed with a small overlap on each other, first they are attached to 1 self-tapping screw in the overlap places, after which the block is leveled;

- then self-tapping screws are introduced into each low part of the wave along the bottom of the sheet and after 1 wave - on the remaining sheets of the vertical block;

- after the end of this stage, the self-tapping screw is also placed on the remaining low sections of the waves;

- self-tapping screws are introduced only in the perpendicular direction relative to the plane of the frame;

- then proceed to the installation of the next block, overlapping it with the previous one;

- the size of the overlap is made at least 20 cm, and if the length of the crate is not enough, then the sheets of the block are cut and connected together with hardware, introducing them in a row into each wave;

- the overlap area for sealing can be treated with a moisture insulating sealant;

- the step between the attachment nodes is made 30 cm, the same applies to addons.

To protect against the effects of corrosion, the metal in the trimming area can be treated with a specially selected polymer paint.

To fasten the ridge element, you will need to use self-tapping screws with a long working part.

When installing a profiled sheet for a large area fence, it is allowed to fasten the elements of the corrugated board end-to-end, without overlap. This approach will help reduce the structure's exposure to strong wind loads. In addition, it is necessary to mount profiled sheets in each wave and to each log, without gaps, and for installation it is recommended to use only hardware equipped with a sealing washer.

The choice of metal corrugated board is a budget option for a building material that can be quickly and easily installed. With proper installation work using high-quality self-tapping screws, such material can retain its operational properties for at least 25-30 years without repair and additional maintenance.

The video below tells about the design, application features and tricks of installing self-tapping screws for corrugated board.