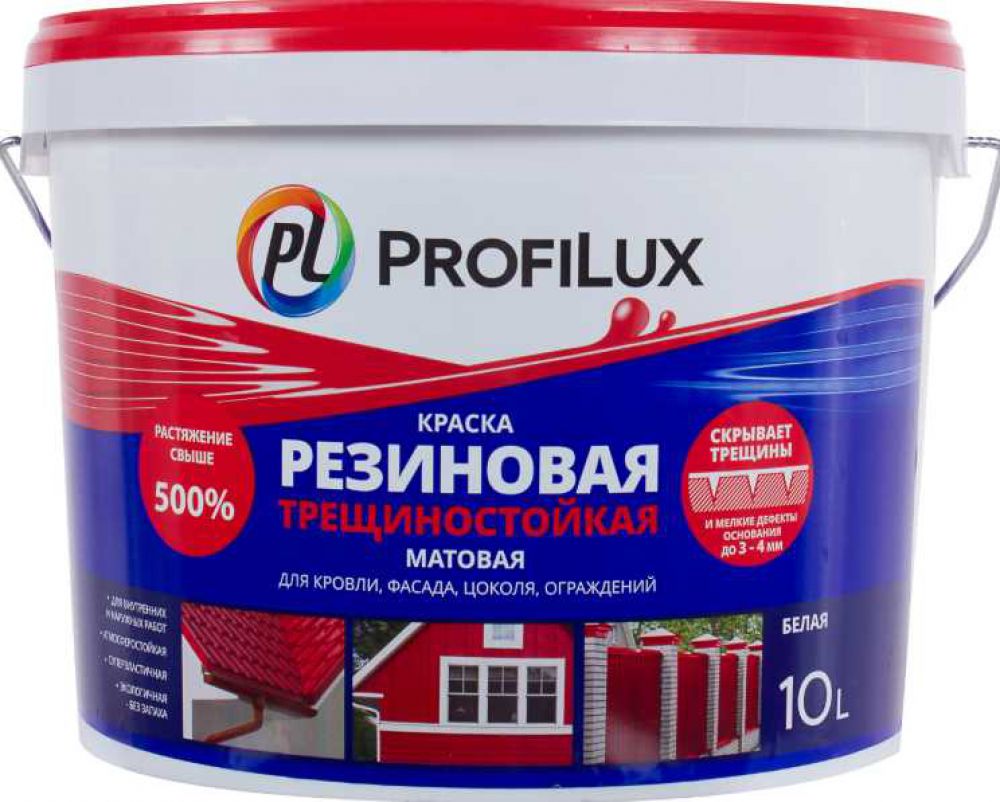

Rubber paint properties and characteristics

The new generation paint has many positive characteristics and properties:

- water resistance;

- strength;

- elasticity;

- ecological cleanliness;

- frost resistance;

- the ability to apply to any original surface;

- simple dyeing technology, which does not require special tools and great qualifications of the worker;

- low cost.

The high degree of water resistance allows the use of rubber paint in rooms with high humidity. Moreover, it can become an excellent waterproofing agent for floors, roofs, artificial reservoirs.

The durability of the paint has been tested on pool bowls and roofs, cycle tracks and outdoor sports grounds, where it stays without loss of its qualities for eight or more years. It also differs in good abrasion resistance and maintainability. When a small part peels off on the painted surface, the defective place is simply covered with a new layer of paint composition.

The elasticity of the rubber paint allows it to be used on surfaces that are subject to periodic movements. At the same time, the coating does not crack or burst, like traditional enamel. For example, applied to a galvanized roof, rubber paint retains its elasticity and strength for a long time, and wooden structures used outdoors are not exposed to moisture and rot.

The solvent is responsible for environmental friendliness - water and acrylate latex, which is used even for the production of children's products. Therefore, the material does not exude unpleasant and harmful odors, does not irritate the skin, and it can be used even in closed rooms, in winter.

Due to the introduction of special additives into the composition, rubber paint, correctly applied to the surface, after drying, can be used in the temperature range from -60 to +50 degrees. The paint composition also easily tolerates short-term drops in temperature. When freezing, the paint thaws naturally in a warm room during the day, after which it can be used for its intended purpose. But the material should still be stored in a tightly closed container at positive temperatures.

Rubber paint adheres well to any surface:

- concrete and brick;

- wood and metal;

- tile and stone, as well as other materials.

The main thing is to properly prepare the base. Simple work with this material requires only a brush or roller and hardworking hands.

The positive properties of this material include its protective function. Surfaces covered with several layers of rubber paint are reliably protected from moisture and microbes, rust. The film coating does not tear when the wood is moistened, then dries, and the metal changes its size when heated and cooled.

However, one cannot fail to mention the negative properties inherent in this material. Although it is difficult to call a disadvantage that the coating can peel off from the base surface if the latter is poorly prepared. And besides this, the coating does not shine after drying, but this is difficult to attribute to a disadvantage.

Main characteristics

Composition of rubber paint

So what is unique about rubber paint? The homogeneous mass resembles in appearance the popular mastic, however, after application and complete drying, the material creates a plastic film, similar to a thin layer of rubber.

The composition of the paint contains important components:

- Water acts as a solvent and makes up one-twentieth of the total volume of the solution.

- Acrylate latex provides the material with strength and proper elasticity.

- Coalescent is a film formation catalyst.

- Antifreeze makes the surface covered with a rubber compound resistant to sub-zero temperatures.

- Thanks to the preservative, the shelf life of the product in a closed container is significantly increased. Also, the preservative protects the plane from the appearance and development of fungi and mold.

- Special additives, pigment substances improve the functional and decorative parameters of the composition, help to achieve the saturation of the shade.

With regard to storage, it is advisable to adhere to temperatures from 0 degrees and above. This rule can be neglected only for a short-term period, for example, during the transportation of the vehicle. If the enamel is still frozen, storage of containers in a room where the air temperature reaches 25 degrees will help to achieve a liquid form again.

Benefits of using

Due to its unique composition, rubber paint has a number of advantages:

The material fits perfectly on wood and metal, is combined with plastic, aluminum, gypsum and steel surfaces, it is well fixed on asphalt, aerated concrete, corrugated board.

The composition is intended not only for internal work, because it can withstand a stable minus 50 degrees, therefore, it is possible to paint planes with a product on the street.

When applied to natural materials, it is important that the natural component still allows air and steam to pass through well, which is exactly what rubber paint provides, for example, when it comes to wooden objects.

Experts note the fast drying time - just a couple of hours is enough.

From tools when painting it is convenient to use both a roller and a brush. If you don't want to get your hands dirty, rubber paint is sold packaged in spray cans.

Such a bottle is especially relevant if it is necessary to apply drawings using stencil techniques.

By using a surface covered with the specified agent, you will be convinced of the anti-slip effect, which reduces the likelihood of injury.

The high level of wear resistance allows the active use of surfaces from 8 to 10 years, without losing the original appearance.

As part of the manufacturer, no toxic substances are declared.

Another unusual property is that the rubber film can stretch three or even four times the entire painted surface.

Purpose of rubber paint

It's time to get acquainted with the areas in which the tool is used:

- Allows you to carry out high-quality repair of the facade of buildings and roofs. The material is distributed even in the smallest seams and cracks, thereby thoroughly leveling the structures and providing the structure with an almost perfect appearance.

- The dye solution is used in the treatment of the interior surfaces of artificial pools and ponds.

- Gyms, courts, stadiums and playgrounds are covered with latex film.

- If you need to update a fence at a summer cottage, regardless of what it is made of - metal, concrete or wood - use rubber paint.

Professionals recommend applying at least 2 layers of coloring agent; for uniform coverage, it is advisable to arm yourself with a spray gun. But for this, it is preferable to have the skill in working with the equipment, because the slightest delay in one area can disrupt the uniformity of the surface.

What is rubber paint

This tool is considered a versatile product, since it can be used on almost any type of surface.

General information

To begin with, it is advisable to understand the features of the composition.

The composition by its characteristics resembles a water-dispersion paint.

Dignity

Main Strengths of Rubber:

- Elasticity.After 2-3 coats, the coating becomes rubber-like. An excellent option for a playground, as it will protect children from injury.

- Good adhesive properties. With a well-carried out processing of the base, peeling and flaking are absent.

- No burnout. The color does not fade even after 10 years of use.

- Long period of use, immunity to weather changes. The average period of use is 8 to 10 years. Technical properties are more dependent on the product brand.

- Wear resistance. Thanks to this quality, the coating is used for concrete floors, sidewalks and parking spaces.

- Moisture resistance. The material does not allow liquid to pass through, which is why it is used to cover reservoirs, blind areas and plinths.

- Environmental friendliness. The product is odorless, water acts as a solvent. When used, no harmful substances are released, therefore, the product is applicable in schools, kindergartens and sports youth complexes. Works can be carried out even indoors.

- Fast drying speed. Often this figure is equal to several hours. After this time, you can start applying the next layer.

- Water vapor permeability. When painted indoors, it allows the walls to "breathe".

- Wide scope of application:

- brick;

- concrete;

- metal;

- wood;

- stone;

- tile, etc.

After painting, a strong film appears. It not only improves the appearance of the coating, but also protects it from destruction, preventing the appearance of microscopic cracks.

disadvantages

The disadvantages of rubber-based coating include high cost. The minimum price for 1 kg is from 200 to 300 rubles. Oil paint costs 2-4 times less. But this option is inferior in all characteristics.

The material is well tinted, so it is recommended to acquire white color and make the desired shade out of it. This method will save money on a large painting area. The larger the container volume, the cheaper the cost of 1 kg. The second disadvantage is poor covering ability.

To obtain an even color, concrete paint has to be applied several times. There is no gloss after drying. The composition practically does not adhere to the uncleaned surface and begins to move away.

Properties

Rubber paint for concrete floors has found wide application due to its qualities:

- impact resistance;

- slip resistance;

- lack of organic solvents in the composition;

- lack of smell (during work and after drying).

This product is used to reduce the accumulation of dust on floors or other substrates. If the room is kept at a constant temperature (+ 20 ° C), it will take only 1 hour to dry.

Rubber is presented on sale in a variety of colors, which allows you to choose a shade for any interior. The treated surface prevents the appearance of defects as a result of mechanical damage or transport loads.

Specifications

The main parameters of the paint and varnish material:

| Specifications | Options |

|---|---|

| Minimum and maximum temperature conditions, ° С | -55…+60 |

| Optimum temperature for painting, ° С | +5…+30 |

| Consumption, g / m2 | 180-230 |

| Density, kg / l | 1,4 |

| Dry residue,% | Not less than 45 |

| Drying time to touch, minutes | 30-60 |

| Final hardening time, hours | 12 |

| Film stretch,% | 400 |

Price

The cost of the most demanded coatings:

- Superdecor (1100 rubles per 6 kg).

- "Prosvet" (2500 rubles per 12 kg).

- Rezolux Universal (2800 rubles per 7 kg).

- Tikkurila Novasil (2000 rubles for 2.7 liters).

The first 3 products are produced domestically and the last one is produced by a Finnish company. Rubber paint for concrete floors "EkoROSS", Moscow (255 rubles per 1 kg) is of good quality and fast drying speed (30 minutes at 20 ° C).

Rubber paint for wood: areas of use

Modern frame house in black

Rubber paint is a unique way to paint wood. But in fact, it is universal, as it can be used on plaster, metal, plasterboard, brick, stone, asphalt and other surfaces. The unique technological characteristics allow the use of rubber paint in a variety of construction works:

- Roof and facade finishing. On such surfaces, the paint allows you to ideally hide cracks and cracks, eliminate roughness. It is very easy to give a building a completely new look with a water-based rubber product. Thanks to the paint, any structure can be turned into a colorful house that will become the pride of the whole family.

- Pool decoration. The paint is ideal for these types of work and adheres plastically to concrete. But most often it is used as a multifunctional tool. On the one hand, a unique design is created with the help of paint, and on the other hand, rubber paint serves as a waterproofing.

Rubber paint is a great option for painting a pool

So that the facade does not lose its brightness, it is better to paint it with rubber paint.

- Finishing of metal products. With the help of paint, it is very easy to extend the operational period of the product. The agent is a reliable protector of steel elements from corrosion damage.

- Finishing paths in the garden, sports courts. The unique paint is resistant to temperature extremes and does not interact with the environment. It has a beneficial effect on the base, significantly extending the service life.

Due to its merits, rubber paint is often used to paint tennis courts.

- Finishing of fences, gates, windows, wickets. With the help of paint, it is very easy to create a fabulous harmony on the site.

- Painting floors and walls. With the help of rubber paint, sophisticated interior solutions can be created.

Rubber-based paint for wood is a unique material with a wide range of uses. It is successfully used by builders, it is preferred by highly qualified designers and simple home owners who strive to create a beautiful interior and reliably protect the surface.

Rubber paint will last for many years, bringing pleasure with its unchanged appearance, because it does not crack, fade or deform. This is a new generation material that deserves attention.

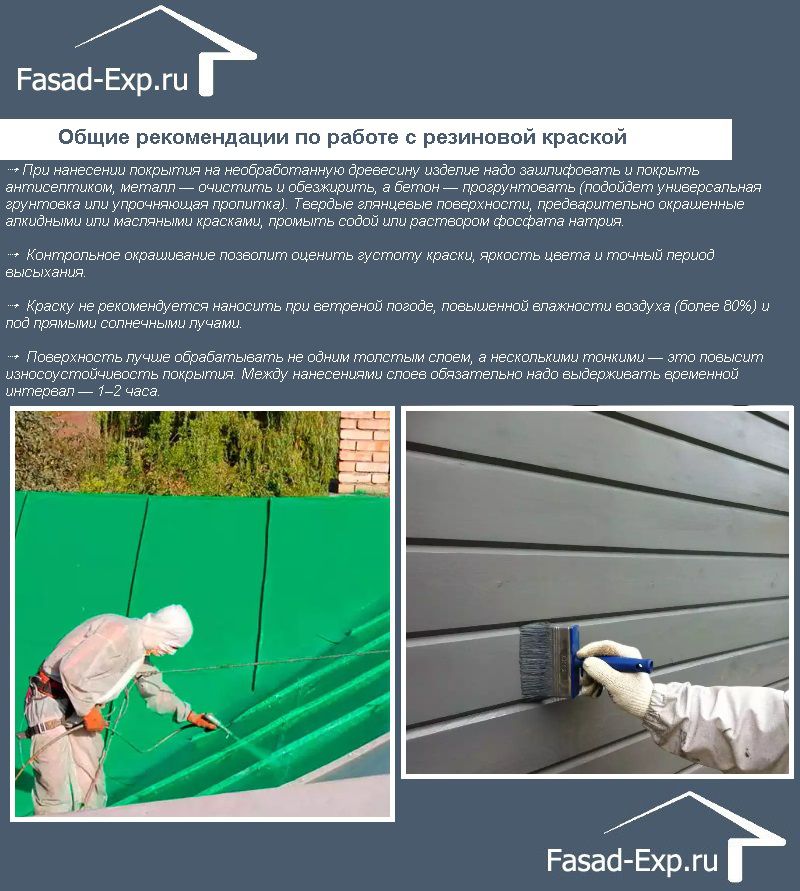

Stage I - preparatory work

Graphite painted facade

Rubber paint for wood floors and walls not only makes the surface beautiful, but also makes you feel reliable and safe on it. The treated floor is non-slip. But before starting the staining process, you need to prepare the wooden surface. This requires:

sand the surface to a smooth and even state;

Prepare the surface before painting

treat with a special antiseptic and allow some time for absorption;

Treatment of a wooden surface with a special antiseptic

- apply a test stain. This is necessary to assess the density of the paint and determine the color shade;

- measure external indicators of temperature and humidity. You can work with the paint at a humidity of no more than 80%;

- applying a special putty to eliminate cracks;

- applying a certain type of primer.

Primer application

The prepared surface must be clean and dry. For the application of the base, it is recommended to select formulations that are compatible with rubber paint.

Waterproof pool paint - long lasting protection

It used to be that paint would not withstand constant exposure to water, but modern chemists have refuted it, creating a wonderful paint for swimming pools. Such a coating is particularly resistant to impact and abrasion, and it also absolutely does not allow water to pass through.

When it comes to finishing the pool, many are inclined towards painting, because this type of finishing will cost much less than tiles or mosaics and will last a fairly long period.

Why do most builders choose pool concrete paint?

The most popular type of pool has become a reinforced concrete pool. Firstly, because concrete is a fairly strong and durable material, and secondly, a reinforced concrete pool can be of any shape and depth. A special paint for concrete pools was developed, which has already managed to show itself only on the good side.

One of the most commonly used types of paint is acrylic pool paint. This paint is characterized by high water resistance, elasticity and mechanical strength. It is used for decorative and protective painting of the underwater and above-water parts of the pool. The waterproof paint has proved to be excellent in operation. Acrylic paint for pools, reviews of which are only positive, of course, if you buy quality paint in a specialized color studio.

Also, quite often, for painting swimming tanks, rubber pool paint is used. Rubber paint is used for swimming pools, as it covers the concrete walls of the pool with a breathable, waterproof film. Concrete pool rubber paint works well. You can apply such paint directly on concrete, and if necessary, it can be used to cover tiles that have lost their appearance.

What properties should a pool paint have?

Of course, first of all, when thinking about what to paint a pool with, you must understand what to expect from a good paint. Pool paint should be a good sealant and water resistant. It should be resistant to both frost and heat, and the scorching rays of the sun should not change its colors.

Since people swim in the pool, the paint should not cause allergies. As a rule, so that the water does not get contaminated, various chemicals are added to the water that are not harmful to humans, but deadly to bacteria, therefore, the paint should not be destroyed under the influence of chlorine and alkaline solutions. Also, the paint itself should protect the pool surface from mold and mildew. Only two-component epoxy paints for concrete and metal pools meet these high requirements.

Where to get this material and what does its cost depend on?

We highly recommend purchasing pool paint from specialist shops or color studios. Our color studios observe special conditions for the storage of paints and varnishes, under which all paints retain their properties.

Properties and characteristics

The mixtures produced at the present time are the most widespread. The popularity of rubber paints among consumers is provided by such properties as:

- Water resistance... Acrylic-based compounds can be used in conditions of high humidity, in addition, the paint can be used as waterproofing of pools, floors, roofs, etc.;

- Strength... The use of paint on summer sports grounds, outdoor stadiums, bicycle paths has shown that such a coating does not lose its original properties for 8 years or more. In addition, delamination in a small area can be easily removed by applying a new coat of paint;

- Elasticity... This property makes it possible to apply the composition on surfaces subject to vibrations and minor periodic movements. The ability to deform prevents cracking and peeling of the coating, which is an indisputable advantage over traditional paints and varnishes;

- Environmental Safety... The use of water as a solvent completely eliminates the harmful effects of paint on the human body, and the acrylic base does not cause any allergic reactions. It is allowed to work with the composition even in unventilated rooms.

- Frost resistance... With full compliance with the dyeing technology, rubber coatings can be used in the temperature range from -65 to + 55C without losing their original characteristics. In case of freezing, it is enough to place the jar in a warm room for a day, after which the composition can be used again.

- Versatility... Rubber paint can be applied to almost any surface, both indoor and outdoor. You can paint concrete, brick, metal surfaces, wood, tiles and ceramic tiles.

- Affordable price... The purchase will not cause serious damage to the family budget. The cost of a can of paint, depending on the manufacturer, ranges from 350 to 450 rubles.

When using the material, its main technical characteristics should be taken into account:

- Use of thinners allowed only if absolutely necessary;

- Primary polymerization time is from 30 to 60 minutes, complete hardening can last from 1.5 to 3 hours, depending on humidity and temperature;

- Dry residue is 45% or more;

- Specific gravity 1 liter of paint, depending on the consistency, can vary from 1 to 1.2 kg.

- Resistant to washing high. The coating can be washed using cleaning agents and a medium-hard brush;

- Tool cleaning can be produced with soda solution, water and soap, household detergents;

- High resistance to weathering, even in aggressive environments;

- Storage of the composition should be carried out in tightly closed containers, avoiding freezing, the guaranteed shelf life is 2 years from the date of issue;

After complete drying, the surface has a characteristic semi-matt shine.

Dyeing technology

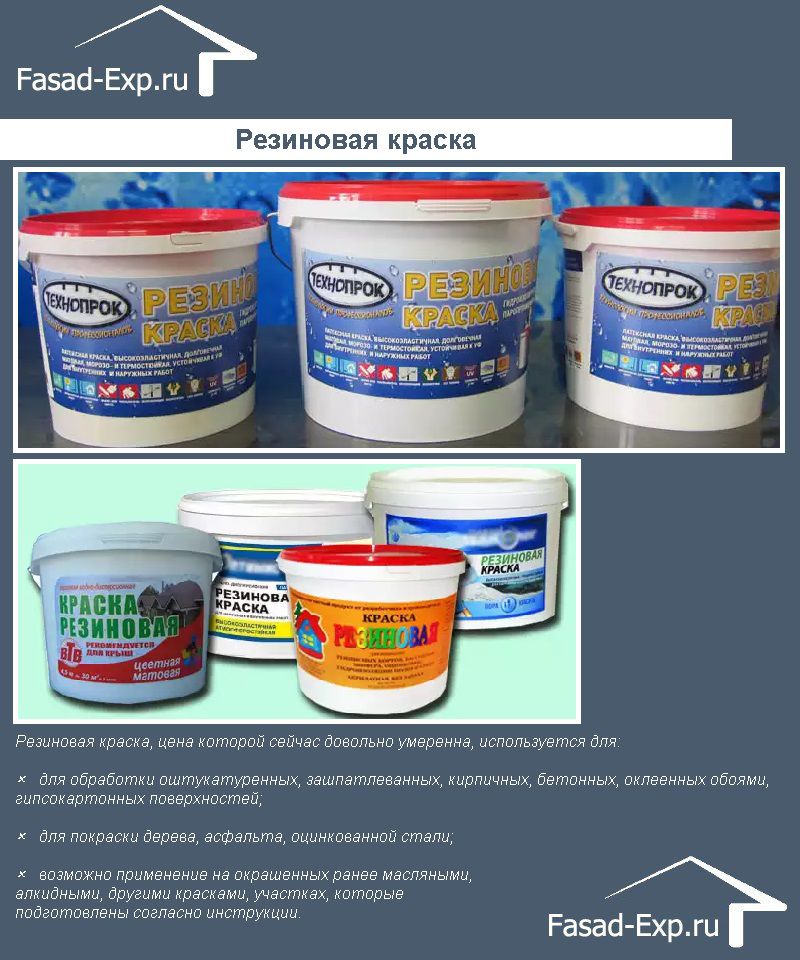

A rubber-based colorant on the market can be found under the following names:

- "Optimist"

- Farbex

- "Chief Technologist"

- "Super decor"

The first two are great for outdoor painting, while the rest are great for indoor use.

Painting technology involves preparatory work:

It is very important to thoroughly clean the working base, otherwise it will not be possible to achieve the desired result. To do this, all debris is removed from the surface.

If there is any adhering dirt, it must be scraped off.

Next, sanding is carried out using a grinder or sandpaper.

Now the surface can be rinsed with a soda solution and dried thoroughly.

Be sure to use a vacuum cleaner to remove dust residues.

It is advisable to degrease.

In some cases, putty and subsequent primer are required. After all, ZhRK (liquid rubber paint) adheres perfectly to the putty.

To reduce the consumption of rubber paint, it does not matter whether it will be used for roofs, floors, stairs or something else, the surface must be putty and primed.

Description of rubber paint

Rubber roofing paint - paints and varnishes based on acrylic water dispersion with the addition of latex and other ingredients. Its peculiarity lies in the fact that a universal flexible layer is created. It, like roofing sealants, protects the surface, but at the same time gives it a beautiful appearance.

This paint does not contain organic solvents, therefore it is safe for the environment and humans. No toxic substances are emitted, there is no unpleasant smell.

Types of paint

This paint was named for its property of becoming a soft film resembling rubber. It is similar to polymer mastic, which is used for self-leveling floors.

There are several types of rubber paint.Depending on the scope of application, the following are distinguished:

- For outdoor use. According to its performance characteristics, it is suitable for use in extreme conditions, with sudden changes in temperature. This type is recommended for roofing. It can also be used on sports fields, swimming pools, exterior walls and plinths.

- For interior work. It is suitable for floors, windows, interior walls, various objects. It can only be used in a dry room - it is not suitable for the street.

- For wood. Such formulations contain fungicidal and antiseptic additional components. Thanks to this, such a coating of the acrylic variety protects the wooden surface from mold, mildew, and microbes. The product will not rot.

- Car paint. Used for processing metal bodies. The composition has increased wear resistance and a wide range of colors. Can also be applied to interior parts, wheel rims.

Composition

The properties of rubber paint are determined by its composition. It contains the following components:

- Acrylic latex. It makes the material strong and flexible.

- Preservative. It is used to last longer.

- Antifreeze. Thanks to him, the composition can be used for outdoor work. In addition, the layer remains flexible, elastic, even if the temperature drops to -50 ° C.

- Coalescent. This substance is used to form a film.

- Water. It is used as a solvent.

- Chemical additives. Dyes are used, various substances that give shine or dullness.

Volume and form of release

Rubber paint is sold as a liquid in buckets, cans, aerosols, and drums. Available in containers of 1.2 kg (about 1 l), 3.5 kg (2.5 l) and 6 kg (4 l). There are also larger containers - 12, 14 and 40 kg.

Aerosol paint is the most expensive, but this option is considered the most convenient. Available in 325, 390, 450 and 520 ml cans.

Colors

Black and white paint is versatile. She is diluted with other colors to get different shades, even the most unusual ones. Many companies produce ready-made colors: green, blue, yellow, red, etc.

As a standard, the line contains from 5 to 15 tones. For painting buildings, there is a special tool with the effect of the presence of crumbs. Many more options are produced for cars - with metallic, mother-of-pearl, glossy and matte, with shimmer, glowing.

Storage and transportation conditions

Store the paint at temperatures from 0 to + 40 ° C. The container must be tightly closed. This applies to both new products and used residues. During transportation, freezing is allowed for a short period, but only up to -20 ° C maximum. After that, you need to keep the paint in a warm place for a day, then it is allowed to use it.

Water emulsions

Due to their liquid consistency, these paints quickly penetrate into the structure of the tree, and after drying they form a protective coating.

As part of these paints:

- water;

- pigment (substance that provides color);

- a binder component (responsible for the quality of the formed film);

- fillers that give the composition some additional properties, such as fast drying, moisture resistance, and others;

- organic solvent (usually white spirit).

- The drying process is completed in 2-6 hours. Several types of water emulsions are produced, so when buying, you should carefully read the information on the label.

PVA emulsion

The coating is slightly porous in texture. PVA-based water emulsions have the following advantages:

- burnout resistance;

- fire safety;

- lack of unpleasant odor and components harmful to health;

- ease of use;

- elasticity;

- good adhesion to wood;

- resistance to alkaline solutions.

Negative:

- vapor permeability (coating "does not breathe");

- lack of water-repellent properties (washed off with water);

- low resistance to dirt.

- Conclusion: this paint is an economical way of finishing wooden ceilings or walls in warm ventilated rooms, utility blocks and storage facilities.

Do not use PVA-based water-based solutions as coatings for wooden surfaces subject to constant mechanical contact; the appearance of walls or doors will quickly lose their appeal. Window frames also require a more durable and moisture resistant paint material.

Latex based water emulsions

Styrene-butanediene polymers in the form of an emulsion, plus pigment and fillers, is a latex water-based emulsion. Odorless paint, quite suitable for interior finishing work on wood. In the package it is in the form of a paste, requires dilution with water.

- high moisture resistance,

- vapor permeability (prevents damage to wood by fungus),

- elasticity and the ability to fill fine cracks on a wooden surface,

- quick-drying,

- non-toxic composition.

There are also disadvantages:

- the coating fades, turns yellow and loses its attractiveness when exposed to sunlight;

- when working, it is advisable to use a spray gun or paint roller, since shading with a brush is unacceptable for latex water emulsion.

Conclusion: paint for interior decoration of a wooden house is ideal, it can also be used for repairs in rooms with high humidity. Coating wooden window frames and facades requires materials with different technical characteristics.

Water-based paints have good hiding power, therefore, the consumption of compositions during finishing is low: for applying two layers of solution (to obtain an even tone), an average of 200 ml of material is required per 1 square meter. In the case of woodwork, it may take a little more due to the porous texture. The range of colors is very diverse.

In the composition of aqueous emulsions, silicone, silicate and alkyd components may be present, which to some extent affect the properties of the dye. These interior paints perfectly interact with wooden surfaces, but they are inferior in wear resistance to other painting materials and are not suitable for covering the outer walls of a log house.