Classification

So, according to the place of origin, it is customary to classify sand into the following types:

River sand

River sand is mined from the bottom of the rivers. It is distinguished by its natural purity and good culverts. The size of grains of sand in river sand ranges from 0.3 to 0.5 mm.

This type is used for the preparation of concrete mortars, cement screeds, treatment filters, drainage structures. It is worth noting that when preparing a concrete mixture, this type of sand precipitates quickly, so the solution must be constantly mixed. The cost of river sand ranges from 600 to 800 rubles per 1 m3.

Quarry sand

Quite logically, quarry sand is mined by the open method and includes impurities: dust-like particles, stones. The grains of open-pit sand are much smaller than that of river sand, ranging in size from 0.6 to 3.2 mm.

In its original unprocessed form, the building material can be used for trenching or as foundation sprinkling. Usually the leading manufacturers wash and sift the quarry sand. In this case, it can be used when performing plastering and finishing works, to create an asphalt concrete mixture, to form a screed.

Sea sand

This non-metallic mineral is extracted from the seabed using hydraulic shells. There are practically no foreign impurities in it, and salt participates in the purification.

This type of sand is considered the most demanded. It is used everywhere, from the creation of concrete structures to the formation of finely dispersed dry mixes. But, despite the unique characteristics of this building material, there is a shortage in it, since it cannot be mass produced.

Sometimes construction sand is considered a separate species. But, as a rule, they mean both river and quarry sand. River sand can be of two colors - yellow and gray, and quarry - brown and yellow.

But it turns out that in nature there is also black sand, which shines like metal. It can be found in different parts of the world. And this type of sand is formed as a result of geological processes.

This mineral is composed of dark colored heavy minerals and is formed by washing out light constituents. The main minerals are magnetite, ilmenite, hematite.

Such sands are characterized by high radioactivity - 50-300 microroentgens per hour, but sometimes this parameter can reach a thousand microroentgens per hour. Due to its high radioactivity, this mineral is not used in construction and economic activities.

Artificial sand

It should be noted that the above types of sand are natural, as they were formed by natural destruction of rocks. But, there is also artificial sand on the market, created by crushing marble, limestone, granite.

The most popular among artificial types of sand is quartz. It is made by grinding and dispersing the white quartz mineral until a homogeneous fraction is obtained. It differs from natural types of sand in that it does not contain impurities and has a homogeneous composition. These advantages make it possible to accurately calculate the parameters of a structure made on quartz sand.

It has found its application in the creation of decorative and finishing, welding materials. It is also used in the production of concrete, but quite rarely.

Requirements

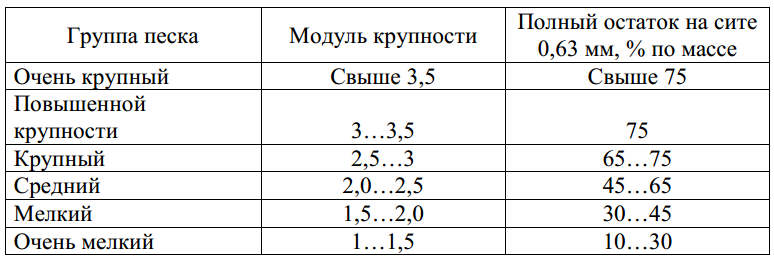

Coarse sand differs in many ways.When using a material in a particular industry, a set of qualities is required that must meet certain requirements. Therefore, the following government standards have been developed.

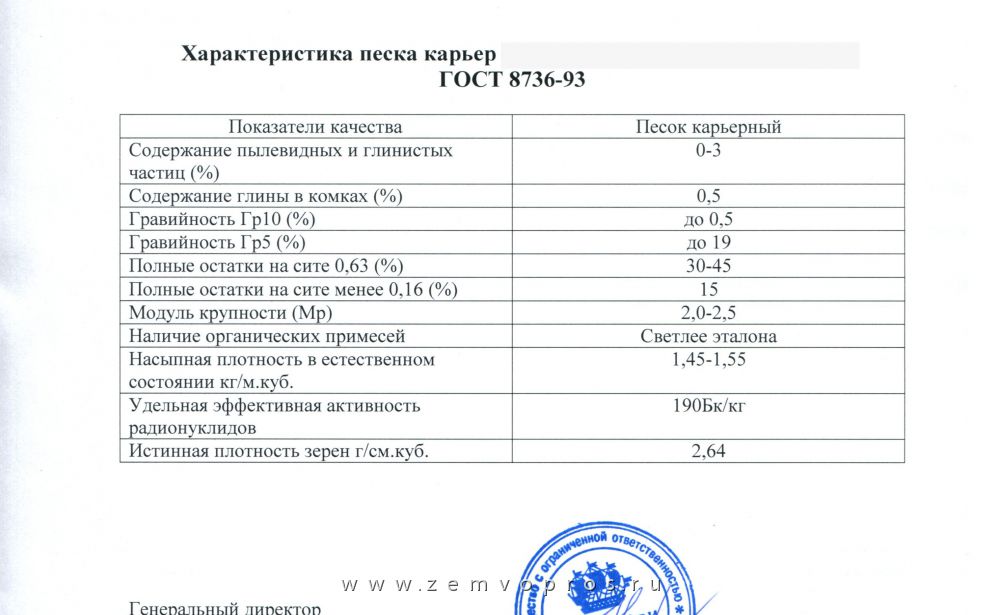

GOST 8736-93

This standard corresponds to a substance predominantly with large grains having a rough surface. Such sand is distinguished by high frost-resistant properties. The grain size is not less than 2.6 fineness module. The presence of impurities up to 9% is allowed. The substance is gray in color.

The material is intended for work in heavy industry. It can be used to fill concrete. In road construction, such sand can be part of asphalt and other bulk materials. Use in monolithic production is also permitted.

GOST 22856-89

This standard corresponds to a free-flowing substance having large and small grains with a smooth surface. Such material is obtained by crushing natural rocks or from river channels. The substance is of high quality. The grain sizes vary from 2.2 to 3 size modules. The presence of impurities of 0.5% is allowed. The substance can have shades of golden, yellow, gray.

Sand of this quality is used as a constituent element of bricks, plaster and other components used in construction or decoration. However, during operation, it is necessary to constantly stir the mixture, since smooth particles quickly settle to the bottom.

Classification

The types of quartz sand determine its purpose. Depending on the shape of the grains of sand and their size, various household or industrial products are made from granite sand. In addition, the material classification is subdivided according to a number of characteristics.

By location

Pure quartz mineral is mined at natural deposits, which are available not only in Russia, but also in other countries. Fractions of small grains of sand are obtained by the natural decay of large pieces of granite rock. In our country, there are such deposits in the Urals, in the Kaluga region, the Volgograd and Bryansk deposits, and even in the Moscow region. In addition, quartz sand is found in the floodplains of the Ural rivers and on the seabed.

Depending on the place of extraction, mineral material is divided into types:

- mountainous - the deposit is located in the mountains, grains of sand have acute-angled edges and roughness;

- river - the most pure, does not contain impurities;

- marine - the composition may include impurities of clay and silty detrital components;

- ravine - the acute-angled edges of the grains of sand have roughness, and the total mass of sand contains silt components;

- soil - lies under a layer of soil and clay structures, has a rough surface.

By mining method

Quartz sand is mined by different methods, in addition to mining, there is also enrichment. Quartz enriched sand is thoroughly cleaned from clay impurities and gravel elements are added. The fraction of such material reaches 3 mm. Quartz in the natural environment is obtained in various ways and, depending on the origin, it is divided into 2 types.

Primary - is formed as a result of natural destruction of granite and is located under a layer of soil or clay. Such decomposed material stays in one place for a long time without the participation of water, oxygen and ultraviolet rays in the process. Sand is extracted using a quarry method, after which the material is transported by transport routes for further processing, where clay deposits are removed by dissolving in water, and then moisture. Dry sand is divided into fractions and packaged.

All quartz sand is subdivided into natural and artificial. Natural sand under the influence of water has rounded particles, and artificial sand is obtained by crushing rock with an explosion, after which sharp small fragments are divided into size fractions.

By grain size and shape

According to the size of the fraction of sand, it is also subdivided into various types:

- dusty - the finest sand, which has a size less than 0.1 mm;

- small - the size of the grains of sand is from 0.1 to 0.25 mm;

- medium - the size of the sand particles varies from 0.25 to 0.5 mm;

- large - particles reach from 1 to 2 to 3 mm.

By color

Natural granite quartz - transparent or pure white. In the presence of impurities, quartz sand can be colored in shades ranging from yellow to brown. Quartz bulk material can often be seen as a painted look - this is a decorative option that is used for design purposes. Colored quartz is dyed in any desired color: black, blue, light blue, red, bright yellow and others.

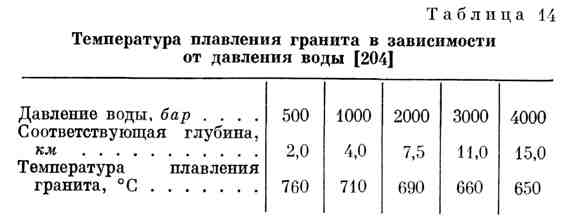

Density indicator

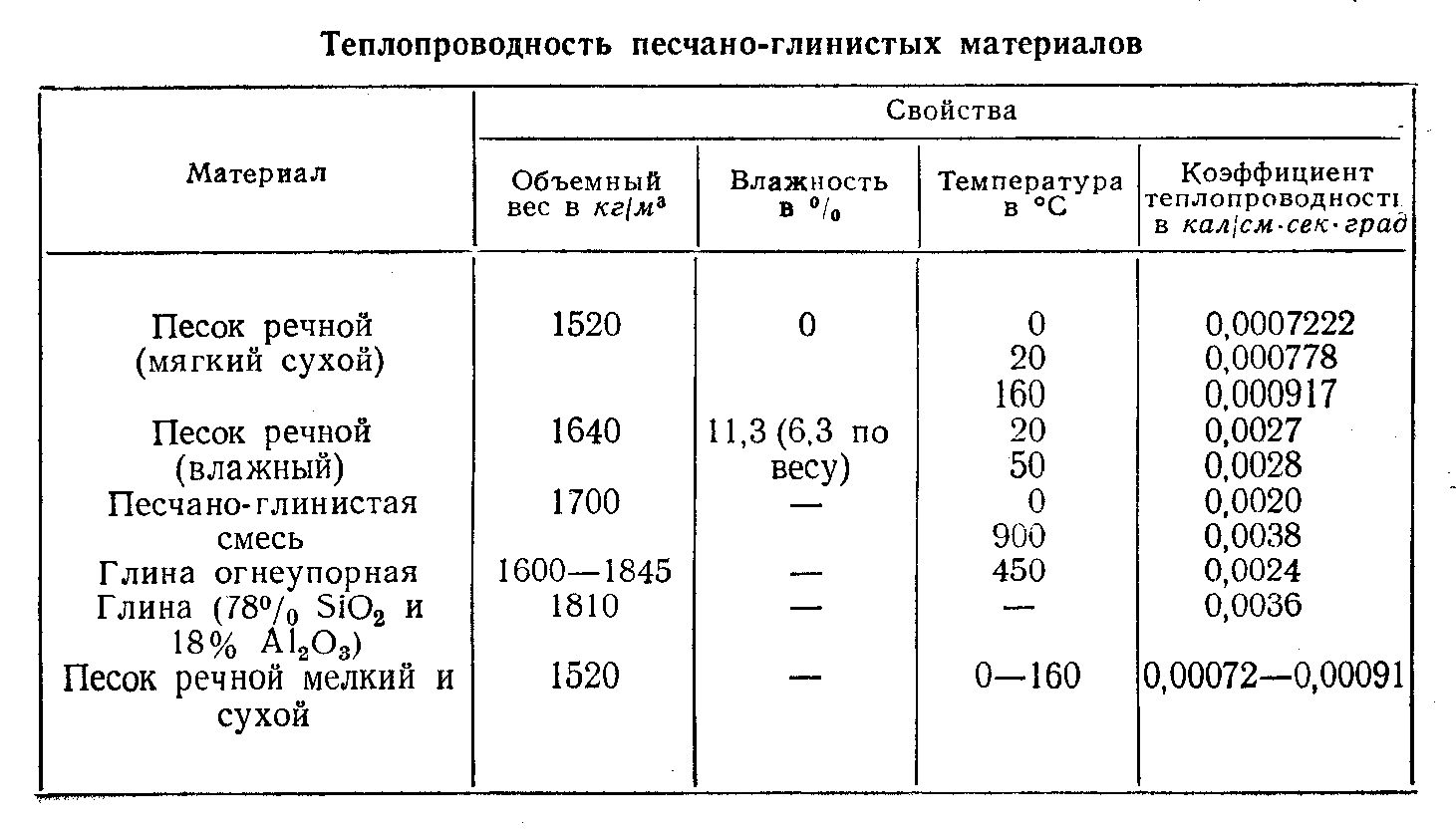

It determines the quality of this material, but depends on the moisture and porosity that it possesses. For construction work at home, the density of sand is not particularly important and its average value is taken for calculations. And in the industrial sphere, the density calculation is interconnected with the strength and service life of the buildings being erected.

This indicator is also taken as the basis for determining the total amount of bulk building material.

It changes from the moisture content of this substance. If the moisture content increases, water flows into the voids between the grains of sand, filling them. Thus, the bulk density indicator grows upwards.

The greatest loosening of sand occurs at a moisture content of 4-7%. Bulk density in this case will decrease by 10-40%. Density is controlled using special devices - density meters or penetrometers, humidity - moisture meters. The average density of sand is considered to be a coefficient of 1.3 t / m3.

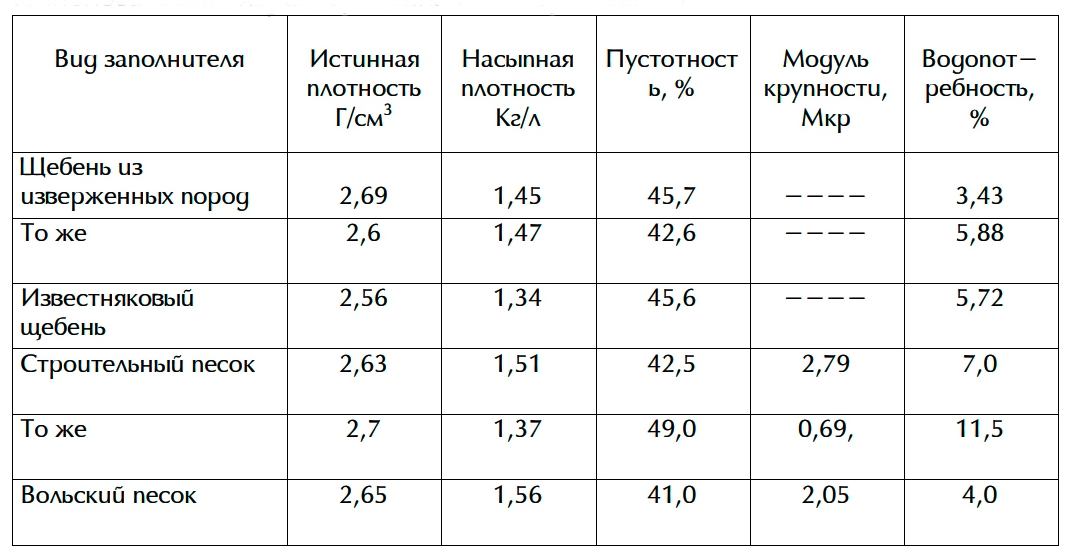

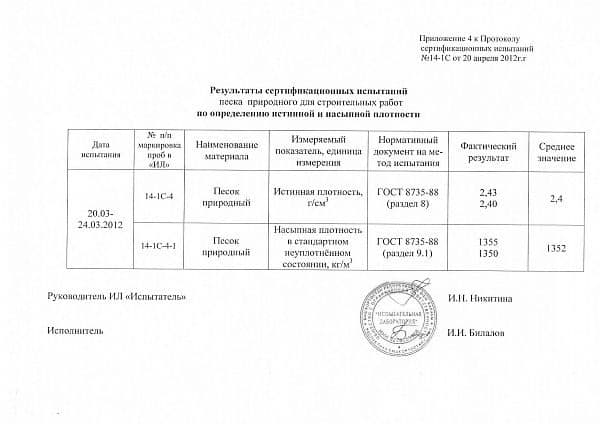

Density

The actual specific gravity of the sand is usually not used. It is calculated by laboratory assistants of special institutions.

Thus, the density of river sand (kg per m3) ranges from 1.5 t / m3 to 1.45 t / m3. It is taken into account when dosing for the preparation of concrete mixtures (volume determination). The specific gravity of river sand is 2.65 g / cm3.

To find out the mass, the following formula is used: m = V ∙ p (m - mass, V - volume, p - density). Let's find out its quantity in 20 m3: m = 20 ∙ 1.3 = 26 tons (1.3 is the average density coefficient).

When preparing a solution, you always need to know that at low density, voidness can be increased. Therefore, it is necessary to double the amount of binders. Raising the consumption of binders is not profitable for construction, because it increases waste and, consequently, the cost of concrete.

Ultimately, all this is reflected in the return on costs, which is very important for construction companies and firms. For household use, such a rise in price does not play a significant role, because the scale of work is much smaller.

As mentioned above, the higher the humidity, the lower the density. Moreover, its decline continues until it reaches 10%. Then the density begins to grow due to the increase in the volume of the liquid. Changing this parameter affects the quality of the concrete.

The density of the sand can be calculated by yourself. They do it like this: sand is poured into a ten-liter bucket from a height of 10 cm. The container is poured full with a slide. Then it is cut off so that in the end a guaranteed flat surface comes out.

The remaining amount of sand in the bucket is weighed, then the density is calculated: the kilograms that have been received are converted into tons and divided by 0.01 m3. To refine the result, it is good to repeat this procedure twice. Then the received data is summed up and divided by two.

You can also define voidness on your own. Pour a sample of sand into a liter container and weigh it.

By the way, the measured values can be converted into the desired values.

Features of the main varieties of sand

The sand, the GOST of which was mentioned in the article, is classified according to the processing and origin.For example, river sand is mined from river beds, it is characterized by a high degree of purification and the absence of stones, clay impurities and foreign inclusions. Washed quarry sand is mined in a quarry by flushing, as a result of which dust and clay particles are removed from it.

Seeded quarry sand is mined in a quarry, cleared of stones and large inclusions. It is widely used in the manufacture of mortars for foundation work, masonry and preparation of plaster. Quarry seeded sand often becomes the basis for asphalt concrete mixtures.

Building sand is an inorganic bulk material that is formed by the natural destruction of rocks. Artificial heavy sand is a loose mixture that is obtained by crushing rocks according to the type:

- limestones;

- granite;

- marble;

- slags.

The shape of the grains is acute-angled, and the surface is rough. This material is used as a filler and when carrying out plastering work, when there is a need to achieve the effect of a tangible texture of the covering layer.

Artificial sands can become part of any plaster layer, the fractional content can be different, depending on the solution and the requirements of the project.

Artificial sand is made from coal slag, and burnt coal is processed. As a result, a low sulfur content is obtained in the material, which determines the quality of the cover layer. When implementing decorative plaster using artificial sand, crushed stone, powder and crumbs of this breed can be used to save money.

Other sand specifications

The specific gravity (density) of the sand mass directly depends on the grain size. Specific gravity is subdivided into bulk and true. The average true density is 2.5 tons / mᶟ. In practice, the bulk specific gravity is mainly used in the calculations (that is, the amount of raw materials in a free-flowing, unconsolidated state contained in one cubic meter). When determining this value, in addition to the volume of particles, the voids between them are also taken into account: as a result, it turns out that the bulk density is slightly less than the true value. Bulk specific density of river sand - 1.3 ÷ 1.5 tons / m2.

The main advantage of river sand is the absence of clay, silt and dust-like impurities (they make up about 0.7% of the total weight), which has a good effect on the properties of ready-made dry mixes, which include this bulk material.

As for radiation safety, almost all natural raw materials belong to the first class: that is, they are radiation safe and suitable for all types of work.

In the production of construction work, not only such characteristics of sand as particle size, the presence of clay components, specific gravity are important, but also the filtration coefficient (expressed in the distance that the liquid overcomes in the thickness of the material during the day), which characterizes the ability of the sand mass to pass water. The value of this indicator largely depends on the structure of the material, as well as on the amount of certain impurities in it: the cleaner and coarser the sand, the higher its water permeability. Raw materials with clay have low water permeability, since clay practically does not allow liquid to pass through. Consequently, the field of application of such a material is significantly narrowed. Sand filtration coefficient (particle size - 2 ÷ 2.5 mm) is 5 ÷ 20 m / day; and material with a granule size of 1 ÷ 2 mm - varies from 1 to 10 m3 / day (for comparison: for open pit sand the filtration coefficient is 0.5 ÷ 7 m3 / day).

Advice! If you want to increase the filtration coefficient: remove clay impurities from the material.