Advantages and disadvantages of wood screws

To build a solid, reliable structure, it is important to choose high-quality material and suitable fasteners. Almost all buildings and materials made of wood are assembled using self-tapping screws.

There are different types of fasteners that differ depending on where they are used. Self-tapping screws for wood have an incomplete thread, which gives their advantages when using them:

- A self-tapping screw forms a hole using a thread in which it is securely fixed (unlike nails).

- Due to the incomplete thread, the upper element is securely fastened.

- Multi-purpose indoor use.

- There are various forms of thread: groove, special cutting edges, sawtooth threads at the point. The combination of several elements allows parts to be assembled without cracking. Even when curling close to the edge.

- The presence of special slots under the head, necessary to drown the self-tapping screw, without puncturing the wood.

- A special cutter is provided at the end of the hole, which prepares and drills it.

The variety of fasteners

The variety of fasteners

The disadvantages include the fact that self-tapping screws are not universal, namely:

- Some are used for mounting only small structures. For example, phosphated fasteners are suitable only for fixing lightweight structures (with self-tapping screws, drywall sheets are attached to a wooden crate or metal profile). It is not safe to assemble heavy structures with it. Also, this type is prone to corrosion.

- A self-tapping screw with a press washer and universal self-tapping screws cut wood. It is difficult to pull the parts tightly with them, which leaves gaps. Cracking of the material may occur.

- Self-tapping screw with a hex head (wood grouse). Requires hole preparation for mounting. It is used for fastening wooden blocks of heavy structures. Some of them are equipped with a press washer, if not, then it is advisable to put it. White zinc plated as a corrosive coating.

- Confirmates. Also require hole preparation. They are used in the manufacture of furniture.

With the correct selection of fasteners and skillful use of them, the shortcomings are not only smoothed out, they completely disappear.

Bit types

The screwdriver accessory consists of the following accessories:

- magnetic or conventional bits and holders for them (extension cords);

- drills.

The bit is a rod with six faces, on one side of which there is a working profile, and its other end is intended for fixation in the chuck of the power tool or in the holder. This special nozzle should correspond in size to the type of fastener (self-tapping screw, screw, screw, bolt, etc.).

Drills for a screwdriver represent a separate category of accessories. They are taken from conventional (hammerless) drills. In this case, the maximum diameter of the drills is limited by the largest section of the tail part, which the tool holder can clamp.

The existing types of bits differ in the shape of their working part. On this basis, such groups of this equipment are distinguished:

- basic (standard), which includes straight, cruciform, hexagonal tips, as well as in the shape of an asterisk and for bolts;

- special, for example, bits equipped with spring clips, limit stops (designed for screwing drywall sheets), triangular;

- combined, in which the attachments are equipped with two working parts of different shapes or sizes.

Bit extenders are divided into two types:

- magnetic, holding the inserted nozzle due to the strength of the magnetic field;

- spring, in which the tail is fixed rigidly.

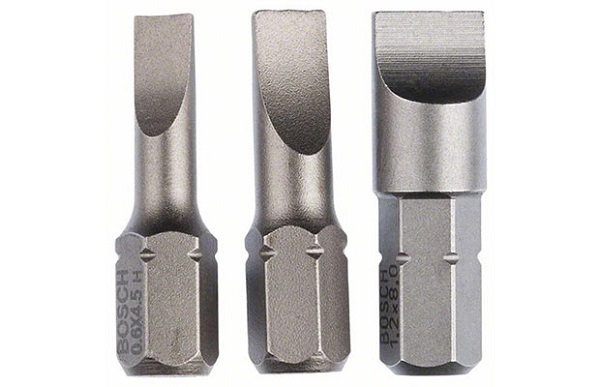

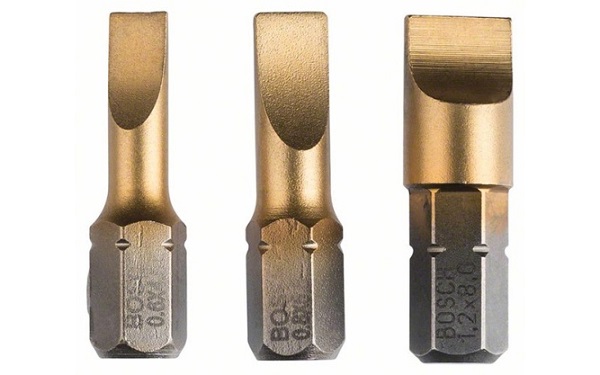

Standard equipment

Standard nozzles are included in any set, they are used most often in work. The very first of all the variety of accessories appeared straight (slotted) bits. This classic version is designed to work with screws or screws that have a straight cut. The slotted equipment is marked with the letter S (from the word slot), next to which a number is placed. The number indicates the slot width, which is between 3-9 mm. Nib thickness is not specified, but is typically 0.5 to 1.6 mm. The marking located on the shank also contains an indication of the material from which the tooling is made.

There are slotted bits with gold titanium nitride plating. Then the marking contains the TIN designation. In this case, the width of the tips with titanium coating can be from 4.5 to 6,% mm, and the thickness - 0.6-1.2 mm.

There are elongated slotted nozzles. They are 5-10 cm long.

The cruciform (cross) bits are divided into two groups:

Ph (from Philips) - a universal type with a length of 2.5 to 15 cm (there are also 30 cm flexible holders), with a working part of four diagonal ribs;

PZ (Pozidrive) is a rig of different lengths, equipped, in addition to 4 main ribs, with four additional ribs.

Philips accessories are available in four standard sizes: from Ph-0 to Ph-3. The number corresponds to the outer diameter of the fastener.

Pozidrive attachments are available in the following sizes:

- PZ0 are used to work with screws up to 2.5 mm in diameter;

- PZ1 - they are used to tighten fasteners from 2.5 to 3.5 mm;

- PZ2 are designed for screws 3.5-4 mm;

- PZ3 and PZ4 handle large screws and anchor bolts.

The cruciform harness is the most common in comparison with the rest of the varieties. It can also be titanium coated.

Hexagonal bits are marked with the letter H (from the phrase Hex socket). Such nozzles can be:

classic type, size 1.5-10 mm;

hexagonal shape, but with an internal hole (their dimensions are in the range of 1.5-6 mm);

elongated, with the dimensions of the working part from 3 to 8 mm and a length of 5-10 cm.

Asterisk bits are marked with a T followed by a number. They are used in the assembly / disassembly of household appliances, as well as cars. They come in the following varieties:

Torx (classic), sizes T8-T40;

Torx Plus (their rays are less sharp), standard size from T10 to T40;

with titanium coating (TIN), sizes T10-T40;

with an internal hole (standard size T10-T40);

elongated: from T10 to T40 in size, 5-10 cm long.

The attachments designed for tightening or untwisting of fasteners with a hex head (bolts, nuts) have a size of 6-13 mm. The most common of these are 8mm bits.

Special attachments

Special equipment includes the following types of bits:

three-bladed (Tri wing), standard sizes TW0-TW5;

four-bladed (Torq-set, designated Gr), 4-10 mm in size;

classic and elongated tetrahedral (Robertson square, with a square slot), denoted by the letter R;

elongated and classic in the shape of a "fork" (designated Gr).

There are also tips with a different special shape, but they are rarely used.

Recommendations for the selection of roofing screws

Experts advise you to follow these tips when purchasing roof mounts:

The first step is to decide on the material of the roof supporting structure

Each type of material requires different types of self-tapping screws.

Pay attention to the size of the fasteners. Remember that self-tapping screws must be able to withstand the planned load.

When buying branded hardware, check the presence of a stamp on the head

Very often sellers try to foist low-quality material, passing it off as products of well-known brands.

Ask the store to show you certificates and certificates of conformity for roofing fixings. According to them, you can specify the thickness of the zinc layer.For the best self-tapping screws for the roof, this indicator cannot be less than 12 microns.

When buying self-tapping screws, it will not be superfluous to conduct the following experiment. Take one fastener and squeeze its washer with pliers. If at the same time the paint retains its integrity, and the seal remains tightly pressed, then the product is of high quality.

Purchasing fasteners such as self-tapping screws requires a responsible approach. It is necessary to take into account all the nuances in order to get a high-quality result. It is also advisable to buy products from trusted manufacturers - they will not skimp on quality.

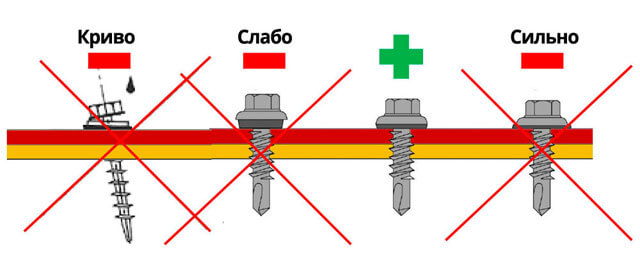

Roof fixing rules

Technological features of the fastening process depend on a number of factors: on the type of products used, their thickness, characteristics of the lathing, etc. However, in all cases, the length of the roofing screw must exceed the total thickness of the fastened products by at least 3 millimeters.

In most cases, self-tapping screws can be attached to a particular material without pre-drilling. However, in some situations, through drilling may first be necessary, and then the self-tapping screw is screwed in. This is most often done when working with thick metal products to avoid damaging the screw tip.

Pre-drilling is carried out using a drill, and the diameter of the drill should be 0.5-1 mm less than the diameter of the self-tapping screw. Some experts recommend, when working with thick metal products, to make holes on them that are larger than the diameter of the self-tapping screws.

This is done in order to provide the roofing elements with some mobility, which is important in the presence of serious temperature fluctuations.

For tightening, various tools can be used, depending on the type of screw head, for example, a wrench, screwdriver, screwdriver, etc.

It is worth briefly mentioning in which areas the fastening of certain roofing products is made. Decking or metal tiles are attached where there is the greatest contact with the crate, that is, at the base of the waves. The slate, on the contrary, is fixed in the crest of the wave (in more detail: “What are the slate nails - sizes, rules for using nails and screws for slate”). If the roof is assembled from small elements and parts, then the fastening is carried out in overlaps hidden from the eyes.

What are they?

As with any fastener, the dimensions of a self-tapping screw are their diameter and length. In order to prevent the buyer from purchasing different products for the same marking when buying in different stores, all self-tapping screws must comply with certain dimensional standards. For European manufacturers, these are:

- DIN - German standard;

- ISO is an international standard;

- GOST is a domestic standard.

In many ways, these three standards coincide, although they have their own nuances. The manufacturer in the description of the goods is obliged to indicate the characteristics in accordance with one of them. And in order to make it easier to standardize self-tapping screws by standard size, they are divided into several types.

By wood

The main difference between such self-tapping screws is a rather large thread pitch. This is explained by the low density and hardness of wood, which makes it possible to produce thinner and longer hardware (from the words "metal products"). Their length ranges from 11 to 200 mm, and their diameter ranges from 2.5 to 6 mm. The harder the wood, the larger the size of the fastener has to be selected. Most often, self-tapping screws for woodwork are called universal. For home repairs, the cheapest self-tapping screws with plastic dowels are enough to fix baseboards, socket boxes or hang a shelf on the wall.

In cases where the material is too dense, a hole is drilled before fastening to the self-tapping screw. In order not to spoil the structure, you should carefully select the drill diameter.This can be done using a small table.

|

Self-tapping screw diameter |

Drill diameter |

|

4.0 mm |

2.5-3.0mm |

|

4.5 mm |

3.0-3.5mm |

|

5.0 mm |

3.5-4.0mm |

|

6.0 mm |

4.5 mm |

For metal

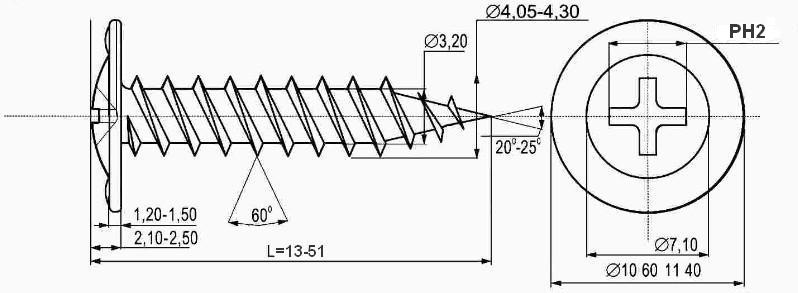

Self-tapping screws for working with metal are somewhat different from those intended for wooden structures. Their length ranges from only 9.5 to 75 mm, and the diameter starts from 3.5 mm and ends already at 4.2 mm.

With press washer

Such elements can be called universal, because they are used to fasten wood, metal, plastic, siding and many other materials. Their distinctive feature is a large cap, which is called a press washer. With its help, it turns out to press the fastened structure more tightly, without using additional washers. Their length is from 13 to 64 mm, and their diameter is always 4.2 mm.

Roofing

The self-tapping screws, which fasten the profiled sheet strips, metal tiles and other types of roofing, have a length of 19 to 100 mm, and the diameter of the rod - from 4.8 to 6.3 mm

Instead of a regular cap, they have a large washer with a rubber gasket, which does not allow water to pass through, which is very important when installing a roof. However, they are often used for fastening other structures, for example, a fence made of a corrugated sheet or a metal garage door frame.

Furniture

Such self-tapping screws are called "confirmations", they are used when assembling various furniture. Their length is from 40 to 70 mm, and their diameter is from 4.72 to 6.05 mm. Such self-tapping screws always require preliminary drilling of the marked holes with a special confirmation drill; screw them with a special hexagon, and not with an ordinary screwdriver.

"Capercaillie"

Such fasteners are used for the installation of heavy structures, where high strength and reliability are especially needed, for example, in the construction of interfloor ceilings. Their length is usually 40 mm, and the diameter starts at 6 and ends at 10 mm. The hexagonal head is tightened with an ordinary wrench or a special attachment for a screwdriver.

Galvanized metal-to-metal 4.2 mm. with a press washer

The most common self-tapping screws for metal. As the name implies, they are used to screw metal to

metal. To be more precise, for screwing thin (no more than 0.9 mm.) Sheet material to the same

thin metal base. This is if without preliminary drilling, when drilling the thickness of the contracted

sheets can increase significantly.

These self-tapping screws are available with or without a drill. Length from 13 mm. ("Bugs") up to 51 mm. Fine pitch threads promote

good fixation in sheet metal, and also holds well in not too loose wood and plastic. Standard, products without

drills are designed for mounting in metal up to 0.9 mm., equipped with a drill on the tip - up to 2 mm.

Despite the fact that products with a drill according to German DIN standards are designed for screwing into metal up to 2 mm. without

pre-drilling - in fact, they often break when screwed. Perhaps it all depends on the quality of the screws.

and from a specific manufacturer, however for metals thicker than 1.5 mm. I highly recommend pre-drilling

hole with a drill, more on this below.

I would also like to note that for fastening in metals thinner than 1 mm. It is better not to use self-tapping screws with a drill bit.

In thin metal, this self-tapping screw holds weakly. As an example, you can consider the attachment of the suspension to the profile during cladding.

drywall - the self-tapping drill is scrolled and dangles. By the way, hardware with sharp tips, without a drill, also

should be carefully twisted into thin profiles, fearing overtightening.

If there is a question of choosing between a sharp tip and a drill for universal tasks, then it is better to dwell on

option without drill.Anyway, with thick metal, you need to pre-drill holes, and in the drilled holes

A sharp tip and a drill work equally well. Self-tapping screws with a drill will be good, for example, with multiple

twisting into sheets of 1.5 mm.

Another argument in favor of the versatility of the sharp tip is that the screws are perfectly twisted into plastic dowels. A

here the tip with the drill fits very badly with the dowels.

All products of this type are equipped with a slot for a bit PH2 (Philips). Since the hardware is coated with a layer of zinc, they are very

firmly tolerate a humid environment and do not require additional painting. In addition, zinc plating looks good enough.

and in many cases there is no need to close the caps of these screws.

| The size | L length, mm | Weight 1000 pcs, kg without drill | Weight 1000 pcs, kg with drill |

|---|---|---|---|

| 4,2×13 | 13,0 | 1,66 | 1,85 |

| 4,2×14 | 14,0 | 1,73 | 1,87 |

| 4,2×16 | 16,0 | 1,89 | 2,05 |

| 4,2×19 | 19,0 | 2,04 | 2,26 |

| 4,2×25 | 25,0 | 2,45 | 2,61 |

| 4,2×32 | 32,0 | 2,87 | 3,05 |

| 4,2×41 | 41,0 | 3,60 | 3,71 |

| 4,2×48 | 48,0 | 3,78 | No |

| 4,2×51 | 51,0 | 3,87 | 4,10 |

In fact, in stores, products with a different length may be found. The table only lists common

values. There are even screws 75 mm long., but this is rather an exception.

The main types of self-tapping splines

There are the following types of self-tapping splines:

- direct, the most traditional, but lately it has been used less and less;

- Ph or H cruciform (Phillips) displaced the straight slot and significantly accelerated the screwing process;

- cruciform Pz or Z (Pozidrive) due to the smaller corner at the top and the improved shape of the internal recess is able to transmit more torque without breaking the tool;

- Torx torx allows even greater effort, but is less convenient due to the complex shape of the tool;

- internal hexagon, used to a limited extent, in particular when assembling furniture on screeds (the so-called "Confirmat").

What is the diameter of the drill for the self-tapping screw

What materials are usually used at home? Items made of wood, metal, plywood, drywall - their installation is not complete without the use of self-tapping screws. Of course, without practice, you can bend the screws, break them, and that's all due to the lack of knowledge of how to work with these fasteners. Therefore, it is better to know in advance how to screw in the screws.

Fasteners are divided into many types. Most often, there is a division into "for metal" and "for wood". They differ from each other even in appearance. The difference lies in the ball of the thread, that is, the distance between the threads. The thread of self-tapping screws for wood has a greater distance between the threads of the thread (for metal - a smaller distance).

If you confuse the screws and twist the self-tapping screw on wood, for example, into a sheet of metal, then the mount will either bend or break altogether. A self-tapping screw for metal in wood will not hold at all, since the wood will not penetrate between the turns and actually does not hold.

As for self-tapping screws for metal, you can find 2 varieties - with a drill at the tip and without.

Drill diameter for self-tapping screws for wood

It is quite easy to determine a self-tapping screw for a tree - it has a large distance between the turns (than a self-tapping screw for metal). Why is that? The reason is quite simple - wood is a less dense material than iron.

These screws can be of different colors - black, white, gold. Color does not affect functionality, that is, it is not some kind of special marking, but simply different colors for matching fasteners to match. Of course, if you have white furniture, then it is better to use a white self-tapping screw.

It is impossible to determine what this self-tapping screw for wood or metal is for by colors, only by the distance of the thread.

Self-tapping screws can be of different lengths and you need to choose the smallest ones for your tasks - a little more than a centimeter in length and there are long ones, more than 20 centimeters in length.

Black self-tapping screws are usually 3.5 and 4.2 mm in diameter. And yellow ones are from 2.5 to 5.5 millimeters.

Of course, there should be no problems with soft woods, but difficulties with oak or acacia can arise (plus do not forget that the tree can split). Therefore, in order not to spoil the whole structure, it is better to first drill a hole of a smaller diameter in the material. The hat must be drowned flush in the material (for this, a recess is drilled in advance with the same diameter as the hat).

With a small diameter of the self-tapping screw, preliminary drilling is not necessary, but if the diameter is more than 4 millimeters, then you need to drill in advance with a drill 0.5 - 1 millimeter less than the self-tapping screw itself.

Drill diameter for metal self-tapping screws

If the metal to be drilled or the self-tapping screw in the metal is less than 0.5 millimeters thick, then there are no problems, it does not even need to be pre-drilled. But if the thickness of the metal is greater, for example 0.8 millimeters or 1 millimeter, then you must first drill a hole for installing a self-tapping screw. Usually the thickness of the drilled hole depends on the thickness of the material. If you guess with the size of the drill, then the self-tapping screw can be tightened even with a regular screwdriver.

Below is a table of recommended drill diameters for a specific metal thickness.

The most common drill diameter is 3.4, the rest are less common.

In the case of self-tapping screws (+ press washer) up to 1.5 mm of metal thickness, you can not drill a hole, and higher - you cannot do without this, since the drill itself from a self-tapping screw cannot cope, there is almost no sense from it.

Correspondence table of the diameter of drills for sharp self-tapping screws and metal thickness

Table data can change a lot due to:

- The quality of the material itself;

- The quality of the screws;

- Screwdriver power;

- What reliability is needed for fastening.

So, in general, if you have a thick, dense wood or a thick sheet of metal, you first need to drill it (smaller diameter than the diameter of the screw) and then screw it in.

Selected for you:

Classification

Self-tapping screws are classified into separate groups depending on different criteria - type of head and coating, type of tip, material.

By head type

Types of fasteners:

Self-tapping screws for metal with a press washer. Designed for joining metal sheets up to 1 cm thick. Thanks to the large head, the parts are securely fixed.

Hemispherical. Large fasteners that are designed to fix various metal workpieces.

Cruciform. They are considered the most reliable and versatile. For tightening, you can use standard Phillips bits for a screwdriver. They fit tightly into the material without breaking its structure.

Self-tapping screws with a straight slot. Such fasteners are more often used to connect wooden parts.

Hex head. Screwed into different materials. To tighten, you need a special wrench or screwdriver bit.

Countersunk head. To tighten the self-tapping screw, you must first drill a hole with a smaller diameter.

It is important that the cap fits snugly against the material, does not protrude outward.

Reduced countersunk bonnet. Small diameter head

It is easy to hide it in the material to be joined.

Self-tapping screws with a press washer (Photo: Instagram / anna_schelepneva)

By tip type

Depending on the type of tip, there are several types of fasteners:

- Self-tapping screws for metal with a drill. The tip of such fasteners is a drill consisting of two feathers. Suitable for fastening metal sheets up to 2 mm thick.

- Fasteners with a sharp tip. There is a thread on the rod for easy screwing. Suitable for fastening metal sheets up to 0.9 mm thick.

By type of coverage

Types of self-tapping screws:

- Phosphated - black hardware. Manufactured from carbon steel. They undergo additional processing with phosphates. Suitable for fastening parts in high humidity conditions.

- Oxidized - made of carbon steel, black. A protective film is applied to metal surfaces.

- Galvanized - carbon steel is used for manufacturing. The surfaces are coated with a zinc layer. They are used for the installation of metal parts outside, indoors.

- Galvanized yellow - products similar to standard galvanized fasteners, but different in appearance.

- Uncoated - suitable for indoor work at normal humidity levels.

Self-tapping screws of different types (Photo: Instagram / stroi_s_nami82)

By material

Material:

- Carbon steel is an alloy based on carbon and iron, which is not supplemented by foreign impurities. They are distinguished by a high strength indicator.

- Brass is an alloy based on copper and zinc. To change the technical characteristics, manganese, lead, nickel, tin, iron can be added. Brass fasteners stand out for their high wear resistance and reliability. The material is immune to prolonged exposure to moisture, temperature changes.

- Stainless steel is a material that contains about 10.5% chromium. The stainless steel has an increased strength index. The material is resistant to rust formation.

Which one is suitable for different types?

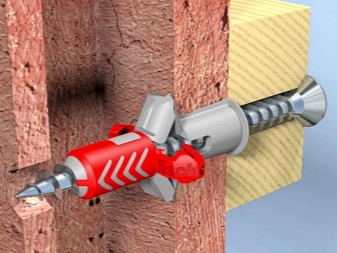

The selection of the dowel is determined by several factors.

Its appearance depends on the material in which it will have to be fixed. Dowels for solid brick or concrete have serious differences from consumables used for porous or hollow materials. Correspondence of the design to the material for which it was developed significantly increases the reliability of the fasteners.

So, a simple spacer consumable with two petals can be driven into concrete, and it will be quite enough to hold the corresponding size of the self-tapping screw.

Such a dowel may also be suitable for fasteners in solid brick, but given that it is still a more fragile material, fasteners with 3 or 4 petals, and even with additional holding devices in the form of various kinds of thorns, may be more suitable for a brick.

For fasteners in a hollow or porous material, you will have to select a consumable with several active zones, with special complex spacers that allow you to cling to the harder parts of the drilled material. Very popular in the case of a hollow material is a fastener called a "butterfly", which, when tightening the self-tapping screw, forms a complex knot that expands it in the pores of the material.

Dimensions (length and diameter) are determined by the load that the fastener must withstand. To hang a picture or a photo frame on the wall, you can get by with a very small dowel of a simple device with a diameter of 5 mm. The length does not really matter in this case, so you do not need to drill a deep hole. The maximum size of such consumables is 5x50 mm. Dowels under 6 mm differ in a variety of lengths: 6x30, 6x40, 6x50 mm.

Securing heavy equipment or exercise equipment will require more powerful fasteners with a diameter of 8 mm or more. The most popular in terms of sales is the size group 8x50 mm. Often these dowels are marked as 8 x 51 mm. They can be successfully used for the installation of lightweight structures, and used for serious installation work.

The correct size of the dowel allows the use of a self-tapping screw corresponding to the load. The dimensions of modern plastic dowels are standardized in terms of the ratio of length and diameter.

The table clearly shows the existing variety of dowel sizes:

|

Diameter (mm) |

Length (mm) |

Self-tapping screw diameter (mm) |

|

5 |

25, 30 |

3,5 – 4 |

|

6 |

30, 40, 50 |

4 |

|

8 |

30, 40, 50, 60, 80 |

5 |

|

10 |

50, 60, 80, 100 |

6 |

|

12 |

70, 100, 120 |

8 |

|

14 |

75, 100, 135, |

10 |

When choosing the length of the self-tapping screw, it is important to add the thickness of the material to be fastened, since it is important that the self-tapping screw reaches the bottom of the plastic sleeve when screwing in - only in this case the fastening properties will appear in full. The wrong diameter of the self-tapping screw can also cause poor-quality fasteners: either the petals will not open and wedging will not occur, or the sleeve will be torn, which is also unacceptable, since the adhesion to the material will be broken

The dimensions of the dowels and self-tapping screws determine the maximum loads allowed for the fasteners.

Small dowels with a diameter of 5 mm at any length cannot be used to fix bulky items. They are ideal for hanging a picture, photo frame and similar objects of light weight on the wall.

Fasteners with a diameter of 8 mm can withstand higher loads than 5 and 6 mm dowels. With such fasteners, you can install shelves, wall cabinets, fix furniture. Reinforced consumables with a diameter of 10 mm or more can successfully perform the functions of installing not only decorative materials, but also partitions, large items or household appliances, scaffolding and others.

Another criterion on the basis of which you can choose a fastener is the material of the dowel. Of course, a classic self-tapping screw is screwed into a plastic dowel, more precisely, in its variety: polyethylene, polypropylene, nylon (polyamide).

If you need to mount anything outdoors, it is best to use a nylon plug, as this material retains its properties at high temperature ranges. Any plastic dowels are suitable for interior work. But polyethylene has much higher plasticity.

In special cases, the use of self-tapping screws, in general, will have to be abandoned. For example, for fastening frame structures (windows, doors), gratings, awnings, heavy equipment and in some cases when reinforced fasteners are required, it is necessary to resort to using a steel dowel.

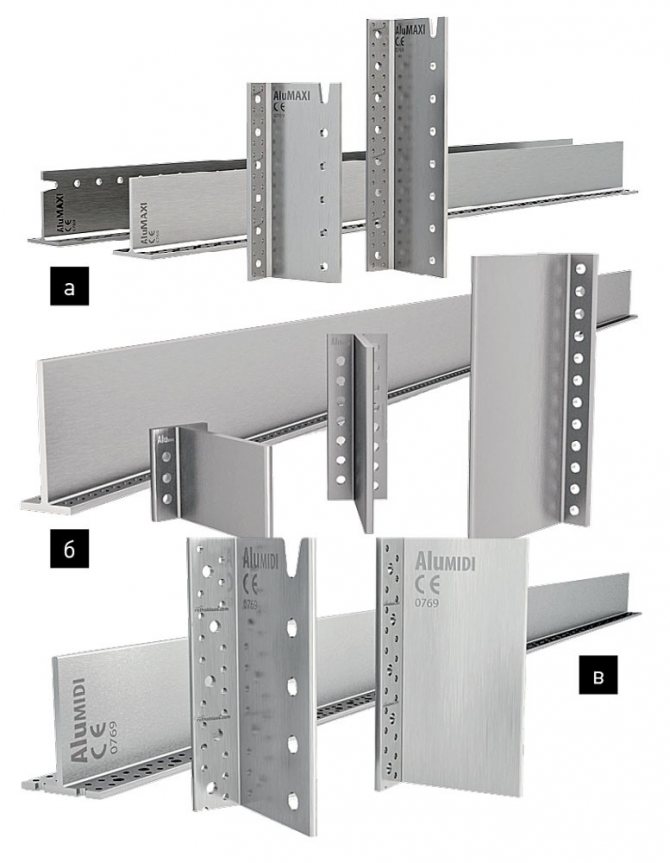

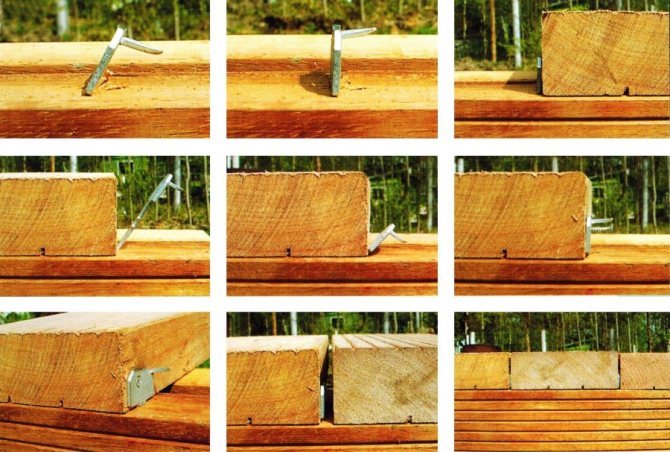

Reiki three-dimensional

The modern Italian firm produces fasteners that are placed perpendicularly and vertically at an angle, using T-type rails, created by extrusion from a high-strength steel alloy. They are produced in several modifications designed for multilevel loads.

The fastening system should be selected according to the size range of cross-sections of the beams to be combined and the dynamic and static loads acting on them.

During installation, the rack base is attached to the beam by means of self-tapping screws. Then, on the end part, attached to the base of the log beam, a groove is created of the same size as the rack shelf. In the absence of perforation, the shelf is equipped with a lag and the connection is fixed with self-tapping screws.

With cross recesses

Such a screw is used for finishing work in internal or external repairs. By the shape of the screw of a self-tapping screw (i.e., the tip of a hardware), you can find self-tapping models (like a self-tapping drill) and just a sharpened end. There are also small, medium or large species in length. It is recommended to strengthen the fixing of the hardware in the plane with special dowels for a self-tapping screw.

They are easily mounted on any surface, on boards, gypsum board or metal surfaces, for which they have received special popularity and universal status. But, due to additional anti-corrosion treatment with brass or zinc, they are more expensive building materials.

Safety precautions and tips

When working with screws, not only screwdrivers are often used, but also power tools such as drills and screwdrivers, and such tools should be handled with great care.

In no case should you work without safety glasses. Hardware can break and fly off into an unprotected area. If this happens, you should immediately seek help from a doctor.

Fasten your sleeves when working with power tools, as the fabric may be pulled into the appliance.

Move children out of the work area. All hardware is very sharp, and the child can be attracted by these small objects. As a result, he will injure himself or swallow them.

Always use the correct bit when working with a screwdriver. If this is not done, then the head of the hardware will deteriorate, and all the notches for engagement will simply be erased. In this case, the screw will have to be thrown out, but at first this is complicated by the fact that it will be difficult to get it out of the attached surface.

And also apply sufficient force when tightening, because if you press lightly on the screwdriver, then the same incident described above will occur.

Pay special attention to marking work. No one will be pleased if the inaccuracy of the markup becomes noticeable only after the main part of the work done.

Follow all the above rules and tips, and then the repair or any kind of construction activity will take place without complications.

If you carefully study all of the above characteristics, then you can easily find exactly that version of the self-tapping screw that is suitable for a specific situation. With the help of self-tapping screws, you can provide very good fastening, but if it is used only for a specific purpose.

As already found out above, a metal screw can be very easily distinguished from the option for a tree. The self-tapping screw for wood has a much larger pitch than for metal. This is due to the fact that the density of the wood is less, it is softer, and the structure of the fibers is porous. Screws for wood products are usually made with sharp and narrow tips, and therefore the holes that are made with them have smooth walls. And it is also worth noting that hardware for wood has a much lower price than those elements that are made for fastening metal products.

Thanks to the information about self-tapping screws for wood, dimensions, a table with a thread pitch, you can fully consider yourself prepared to buy the right tools for a successful construction.

The main types of screws were presented. On the Internet they are called more popularly, and therefore you can find the names "wood grouse", "seed" and the like. It is best to use official "names" in a store to avoid confusion.

What are they?

There are several types of possible self-tapping screws that are widely used in the market.

- Wood.

- On concrete.

- For special steel sheets where drill work is to be done.

- For speakers.

- For fastening windows and doors.

- Galvanized self-tapping screw for logs and rails.

- Self-tapping screws for plumbing (most often, in narrow circles, they are called so - plumbing).

- Self-tapping screws with a cylindrical head.

- For roof fastening.

- For working with drywall, taking into account coarse threads.

Fasteners for wood are mainly used in the production of cabinet furniture and any other wooden structure. This self-tapping screw has a double-shaped hex head. The thread in this case is very wide, so that it can be screwed in rather securely. Fittings, loot, wooden profiles on windows and much more are installed with such fasteners, their scope of application is quite wide. The end result will often depend directly on the task at hand.

Self-tapping screws for working with metal profiles, pipes or sheets are distinguished primarily by their unique design features. The head of such self-tapping screws can be in the form of a hemisphere, hexagon or pressed washer. The material for the manufacture of such self-tapping screws is carbon steel, specially treated for a longer service life. Such self-tapping screws are usually galvanized, they are marked with markings by which the user can easily recognize the diameter and length of the bolt.

Hexagon self-tapping screws, in principle, are often used for fastening wooden products. Its twisting is possible with a wrench with the required diameter. If the kit includes a dowel, it is twice the diameter of the screw itself. In concrete walls, a hole for such fasteners is drilled exactly according to the diameter of the dowel. With their help, steel corners and steel profile guides are fixed. The self-tapping screw is screwed into the dowel itself after a hole of the required diameter has been drilled. Self-tapping screws, unlike screws, have a wider scope and are considered a more reliable option for fasteners, with which you can work with stone, concrete or brick.

If you need to secure something really heavy, then an anchor bolt is used. They also have dowels, but they are most often metal. Due to the tighter connection, the product will firmly and reliably adhere to the wall, even if it is made of natural stone.