Size range of species

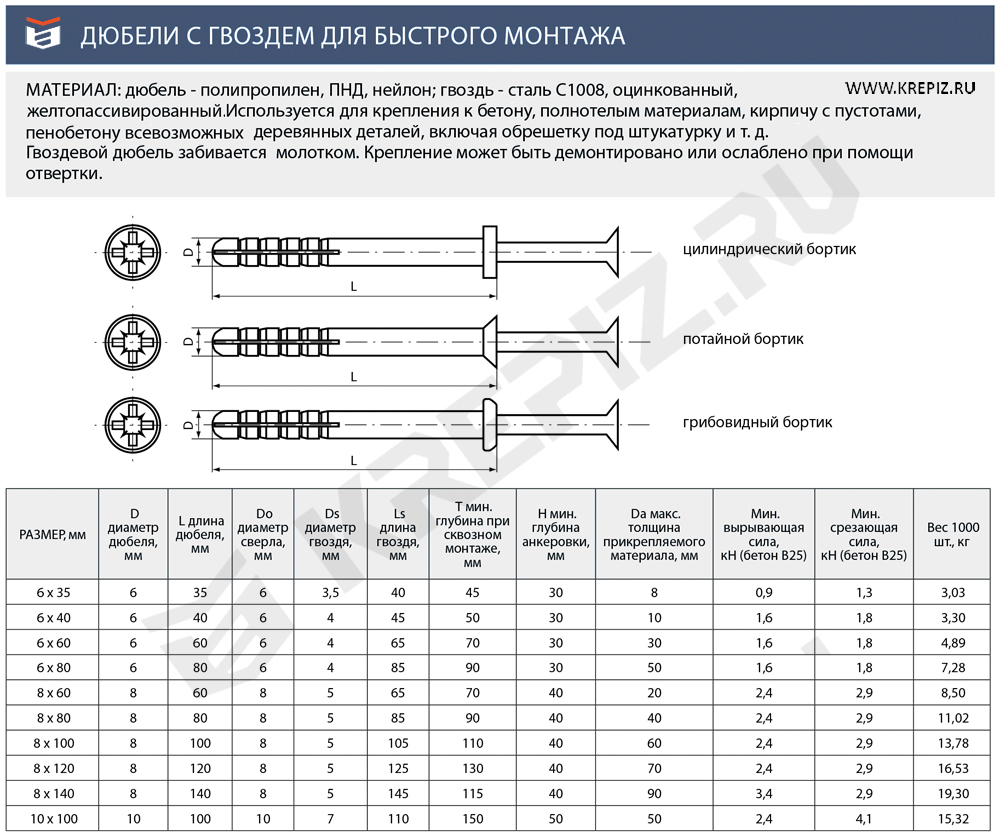

According to the standards, the dowels are made with a diameter of 5, 6, 8, 10 mm. There are also less common ones, for example 4 mm. The length varies from 20 to 150 mm, The size of the dowel-nail is selected according to the design parameters. For a symbol, two values are indicated in the marking, the first is the diameter, the second is the length. The most popular size range of fasteners is 4x20, 4x40 mm, 5x30, 5x40 mm, 6x30, 6x35, 6x40, 6x50, 6x52, 6x60 mm, 6x70 mm, 6x80 mm, 6x100 mm, 8x40, 8x50, 8x60, 8x80 mm, 8x100 mm, 10x50, 10x60, 10x80, 10x100 mm, 10x120 mm, 10x160 mm, 12x60, 12x70, 12x80 mm.

Dowel-fasteners are divided into types.

- Umbrella (or front). Differs in a cap of a large size and length. Designed for fixing large layers of insulation. The nail can be made of steel or impact resistant plastic.

- Chemical. Fastening takes place by means of a glue capsule. There is a chemical dowel of ampoule and injection types.

- KBT (or fasteners for aerated concrete). During installation, threading occurs, but the base material itself is not destroyed. It can withstand loads from 400 to 600 kilograms.

- Universal. Designed both for surfaces with voids and for solid surfaces. When installing the nail, the sleeve "twists" and forms a kind of knot, which provides reliable adhesion and fixation.

- Molly (or folding spring) dowel. It is made of steel and when installed "folds", it is mounted in thin and hollow walls. Also popularly it can be called a butterfly dowel.

- Spacer. It has additional fastening whiskers, it can be three-spaced, four-spaced and six-spaced. A threaded nail is driven in with a hammer.

- Frame. Its distinctive feature is the shape of the non-expansion part, it is elongated.

- Metallic for concrete. It is best to use a special gun for fasteners, but manual installation can be done. Holes must be prepared in advance.

It is worth noting that some models come with a sealing washer.

Specifications

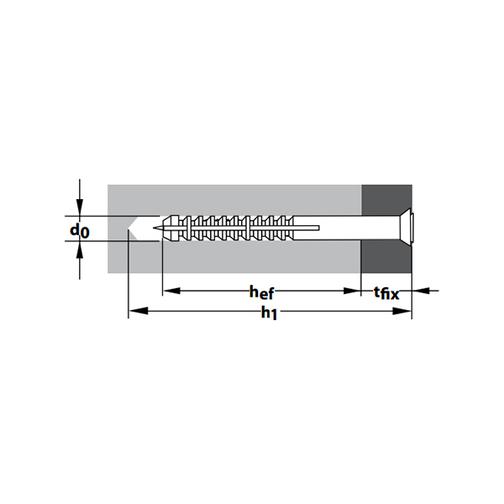

The dowel-nail design consists of two parts - a nail and a sleeve (dowel). The liner looks like a cylinder made of plastic or steel. On the sides there are spacer mustaches, which are straightened when the nail is installed. The technical characteristics of the dowel-nail correspond to the GOST standards, while minor deviations of the parameters are allowed - changes in the size of the diameter, weight, length or structure of the fastener. Dowels are made from a steel rod, the alloy of which must be resistant to various loads. The hardness of the product varies from 54 to 56 HRC (according to Rockwell).

The permissible curvature of a rod less than 5 centimeters is 0.1 millimeter, a rod greater than 5 cm - up to 0.15. The tip of the screw should evenly and smoothly pass into the rod, not have chipping, cracks or chips, and its dullness should be no more than 0.8. On the surface of the fastener, traces from the clips used in processing are allowed.

The surface of the nail is treated with a protective layer of zinc, at least 6-7 micrometers thick. The load, depending on the diameter, the length of the fastener and the material into which the dowel was driven, may be different. It is necessary to take into account the density of the base with which you have to work, as well as how and in what plane the installation will take place - vertical or horizontal (floor, wall, ceiling). There is an asymmetrical thread on the nail, which should not make it difficult to insert it into the sleeve, but thanks to it, the nail cannot be pulled out or unscrewed.

The dowels themselves are made of plastic - polypropylene, nylon, polyethylene. They withstand surfaces made of concrete - 200-450 kilograms, of brick - 150-400 kilograms.Just like nails, they can be produced from a steel bar, such fasteners are used as heavy ones and can withstand a load of up to 5 tons. The color of the plastic can be white, black, gray, blue, red and orange.

Selection rules

Before you purchase the dowel fasteners, you need to find out in which surface it will be mounted. An important parameter when choosing is the diameter and length of the fastener. The larger they are, the more load it can withstand. It also takes into account the thickness, surface density and the presence of voids.

For example, the most popular universal dowels with a diameter of 0.6 centimeters and a length of up to 8 centimeters are suitable for a plinth. This is one of the reliable fasteners, but if the dismantling of the structure is required, problems can arise. It must be remembered that before installation, all the necessary markings are applied for mounting on the wall and under the holes on the baseboard, which will be drilled out in advance in the future. The diameter of the holes must be equal to the diameter of the dowel.

For a toilet with small dimensions, installation with dowels will be the most practical option. Complete with hardware should be rubber washers or gaskets. Here you also need to measure the surface and apply a markup where the fasteners will be inserted. Next, a hole is drilled in the tile with a drill, and then with a construction perforator in concrete. For insulation and foam, facade specimens are suitable, at their base there is a special toothed thread, thanks to which the dowel-nail is securely attached to the base.

As a fastener for a TV, for a wall hallway, for hanging a kitchen, shelves and other furniture that will be installed in a vertical plane, it is better to use metal nails for aerated concrete or frame nails.

In the next video, you will learn about the types, characteristics and features of the installation of dowel-nails.