The choice of alkyd enamel according to the composition of the solvent

For each specific case, you can pick up alkyd enamel and make the surface not only beautiful, but also protect it from external influences and rapid destruction. Some of the paints are designed for woodworking and others for metal painting.

Alkyd auto enamel is used directly for painting a car, that is, it is already prepared for applying a varnish of a certain tone to a metal surface. Alkyd auto enamel is able to withstand any temperature of unpredictable weather, both in summer and winter. At the same time, the painted surface is comparable in gloss to acrylic painting.

The big disadvantage of alkyd car enamel is that it takes a long time to dry, despite the fact that it contains a solvent. For complete and quick drying, sometimes even special installations are bought, if the painting is done at a professional level, which entails additional cash costs.

Solvents, like alkyd enamels, in this case should be selected according to their properties and characteristics, as far as safety for the human body, since not everything can be used for painting, for example, pieces of furniture in the house.

Solvents for alkyd enamel are of a large variety, but in order to choose the most suitable one, it is better to be curated by its characteristics. Solvents can be added to the alkyd enamel yourself or you can buy paint that contains the desired solvent.

When repairing the garage, they found alkyd enamel, but it froze. How can old alkyd enamel be diluted so that it can be applied?

This case may be useless, it all depends on the degree of solidification, it is even possible that you simply cannot dilute it and waste your money. By the way, diluted enamel will no longer have such good properties and it is best to use it in places where there is no need to obtain quality work.

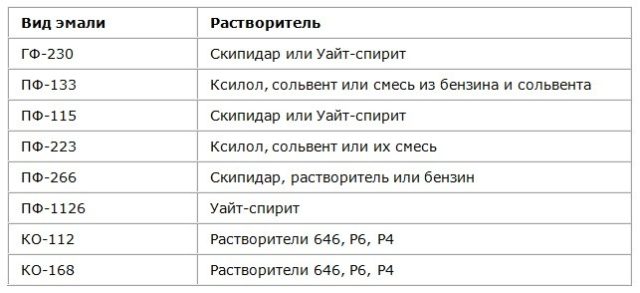

So, if you decide, then first we look at the brand of alkyd enamel and, accordingly, based on the brand, we use the thinner that suits you, or rather the paint.

Turpentine - GF-230, PF-115, PF-253, PF-266.

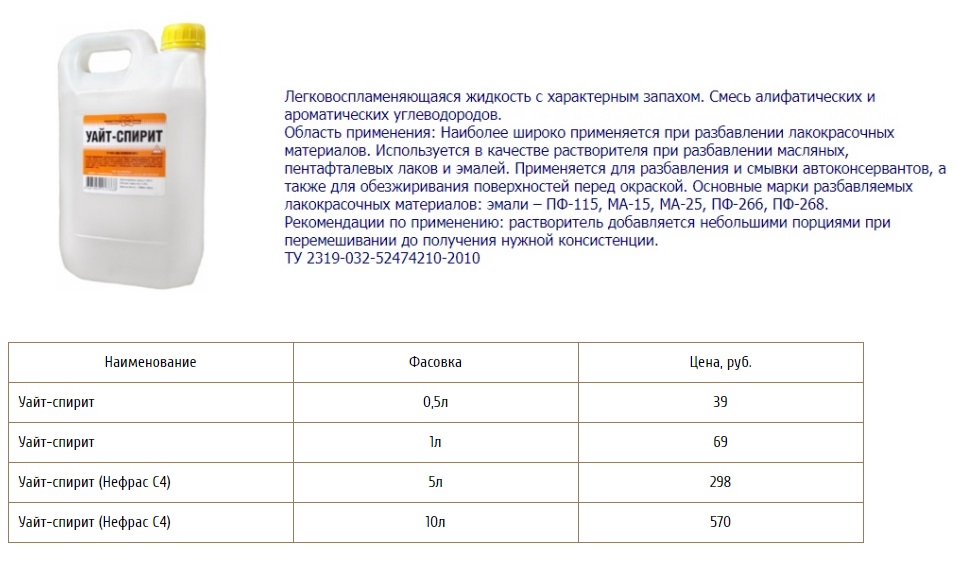

White spirit - GF-230, PF-115, PF-1126.

Xylenes - PF-133, PF-223.

Solvent (it is possible with gasoline) - PF-133, PF-223.

Solvent No. 646, R 4 or R 6 - PF-253, PF-266, KO-168, KO-112.

It must be remembered that no solvent can quickly dissolve the paint (if at all), so pour the solvent into the jar and from time to time just stir the jar without opening it and so on for a day or two with approaches to it, preferably 0.5 hours.

Then shake the jar well and leave for another day. Then stir all the paint. what has dissolved and pass through the filter, you can use gauze.

Yes, a hackneyed phrase that I have already quoted in many answers

But in order to use it correctly, you need to know exactly what you want to dissolve and with what solvent.

It is known that alkyd resins are a part of alkyd paints. In turn, alkyd resins contain aromatic components. For those who have not studied chemistry well or have forgotten, let me remind you that aromatic compounds are derivatives of benzene.

So the solvents must also be aromatic derivatives.

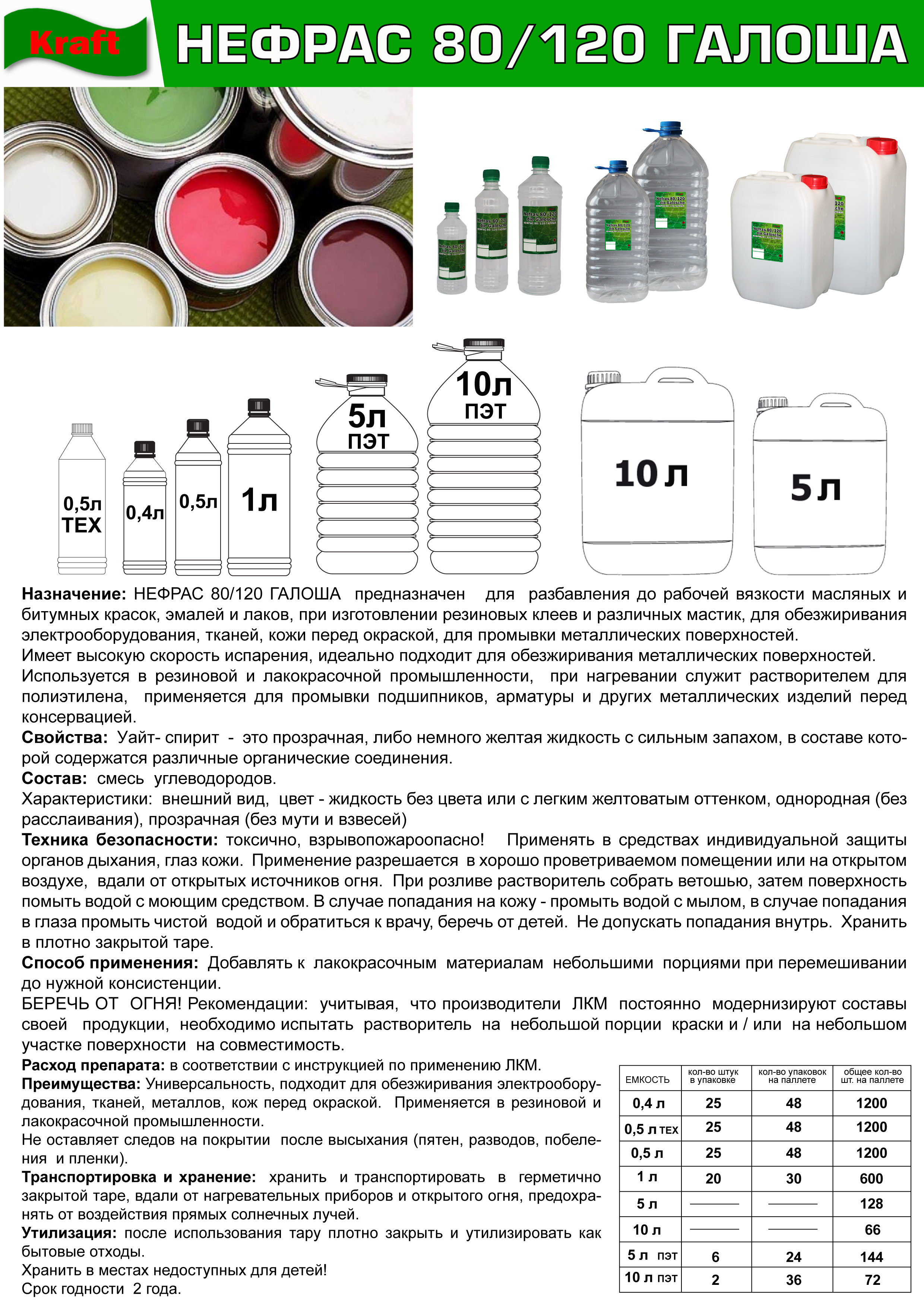

So, although there is information on the Internet that the best solvent for dissolving alkyd paints is white spirit or nephras, or a solvent, which is actually the same thing, namely a mixture of aliphatic liquids of hexane and heptane.

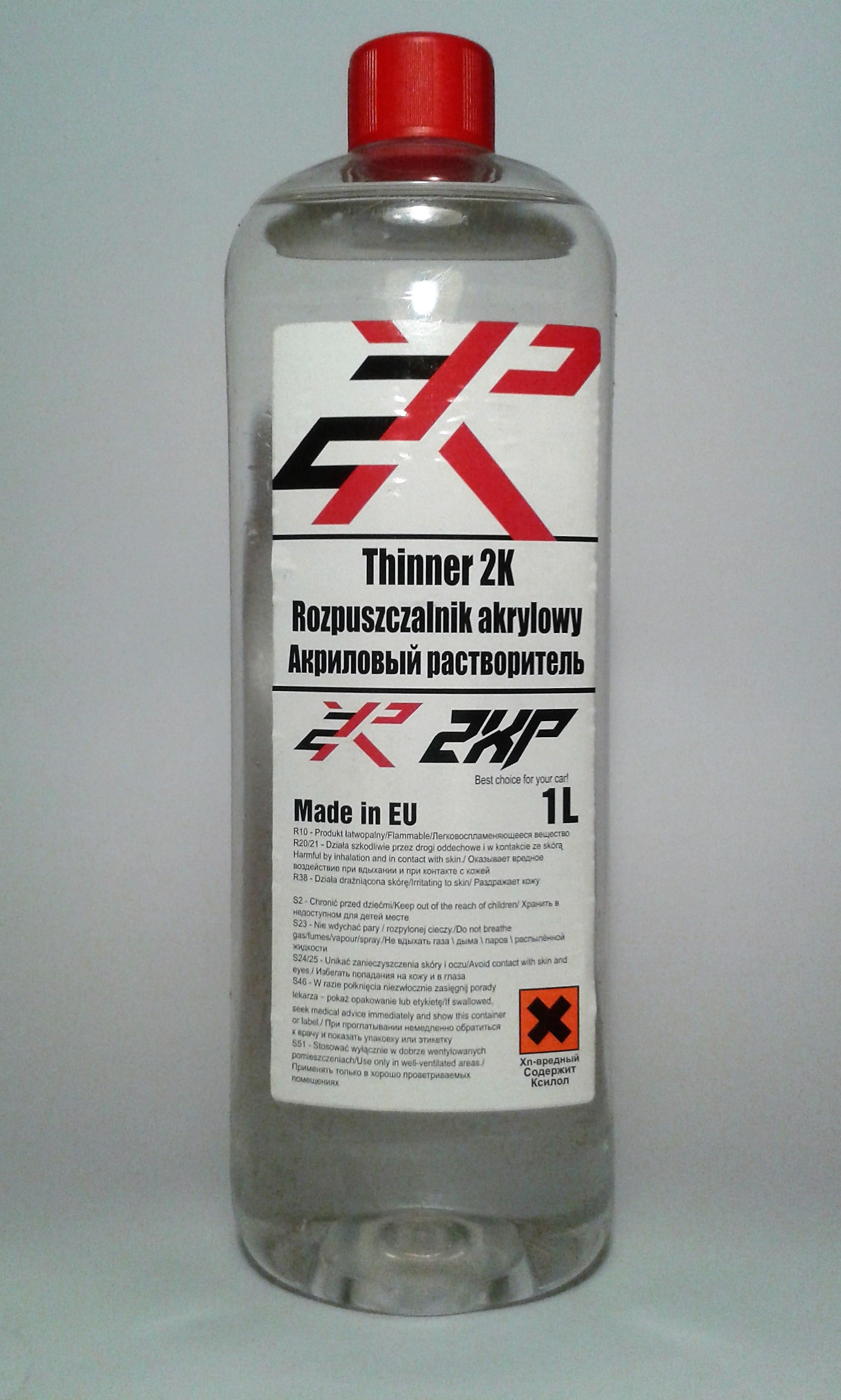

So such solvents are not the best choice, but it is better to use toluene, but it is used in factories and you will not find it on sale, so xylene is suitable, which is a homologous analogue of toluene, but less harmful and slightly weaker in dissolving power.

Dilution of alkyd paint is a necessary procedure when carrying out painting work.

In some cases, how and with what you dilute the alkyd paint will have a decisive influence on the quality of the paint.

For automotive enamels, it is also often necessary to thin the paint to obtain the desired consistency, but this is required less often.

TOP-3 leading manufacturers

When choosing enamel, first of all, pay attention to the products of such manufacturers:

LLC "LKM-Line"

... Moscow company operating since 2000

... The assortment includes the most common enamels and paints and varnishes, special compositions for waterproof and fireproof coatings.

"Khimprom-M"

... It is one of the leading suppliers of paints and varnishes to the domestic market and country. CIS

... The assortment includes enamels for interior and exterior use, compositions used in shipbuilding and for cars.

There are special offers for the application of anti-corrosion and chemically resistant coatings.

Factory "Enamel"

... It is a scientific and production company operating in the market since 1994

... The enterprise is located in Chuvashia, production facilities allow producing up to 10,000 tons

paints and varnishes monthly.

All manufacturers work in accordance with the requirements GOST

, the manufactured products undergo a multi-stage quality control.

This agreement governs the use of the Matrapac website.

This website is operated, operated and owned by Matrapac GmbH. Access to the materials and functions of the site is provided to the user if he accepts the current Terms of use of the site and agrees with them. The fact that the user uses this site indicates his acceptance of these Terms. If the user does not agree with the current or other rules of using this resource, he should leave the site.

Matrapac has the right and ability to revise and change the current Terms of Use at any time without notice to the user. The user agrees that in order to have complete and up-to-date information regarding the rules for using the resource, he should periodically review this section. The user's work with the site and the use of its capabilities after the publication of changes to the current Terms indicates the user's consent to the changes that have come into force.

The user does not have the right and ability to interfere with the organization of the site's security, or in any other similar way to unlawfully use the site or other system resources, networks and services that are available or may be associated with this site. The user undertakes to use the site only to the extent permitted by law.

physical or electronic signature of a person who is authorized to act on behalf of the entity - the owner of copyright or other discussed intellectual property;

a description of the work or other type of intellectual property belonging to this owner, the rights to which, in the user's opinion, have been violated;

a description of the place on the site where this material was located;

the email address, telephone number and physical address of the user;

a statement by the user confirming that there is a reasonable expectation that the use that was the subject of the proceedings was not authorized by law or by the copyright owner;

a statement, consistent with an affidavit, that the information provided by the user is true, correct and that the author of the statement is the person who is authorized to act on behalf of the copyright owner or is directly the owner of the copyright.

Disclaimer: The original legally binding version of this document was written in Russian and translated into other languages for the courtesy of our non-Russian speaking users. If there is any discrepancy between the Russian version and the translated version, the Russian version will override the translated version.

Selection Tips

Different types of solvents interact with different types of paints - this factor is the most important when choosing materials, otherwise it can negatively affect the result of the repair.

For latex paint used for facing surfaces made of concrete, wood and plastic, solvents such as R-4, R 646-648 are best suited. Organic substances are hidden under these abbreviations.

They must be used with great care, especially if there is a need to remove stains from the parquet, otherwise it may remain burned out from the solvent.

Diluted latex paint combined with a solvent will create a long-lasting coating that is water repellent.

When using oil and alkyd paints, you should pay attention to the following thinning substances: butanol, kerosene, turpentine, white spirit and gasoline. Since in the production of these types of dyes, not natural linseed oil is used, but artificial, many craftsmen are afraid that solvents can enter into chemical reactions with them, but this can be easily avoided if proportions and safety precautions are observed

The varnish, which is used as a base for alkyd paint, determines the use of solvents with indices: PF 115, KO or R-6. In order to achieve the desired effect and a coating that is resistant to mechanical damage, it is necessary to observe the proportion - when using a mixture of white spirit and turpentine - 1: 1, otherwise the solvent can destroy the previous primers.

Nitro paints are usually used for painting metal, because the main feature of this type of paints is the strength and durability of the coating, which can often be glossy. It is also important that such a material has a strong pungent odor that does not disappear for a long time - it can last up to two days.

The best solvents for this type of paints are compositions numbered 645-650 - they will effectively act not only as solvents, but also as a degreasing agent.

For epoxy paints, it is worth choosing compositions such as R-14, R-40 and R-83. They can even remove dried stains on the surface, because epoxy materials dry very quickly and are highly resistant to mechanical damage and abrasion. However, on the other hand, this can be a clear advantage over similar paints.

Polyurethane materials are widely used not only in construction, but also in many other areas, since this paint interacts well with any type of surface and fits well on it. In addition, it is durable and does not emit any toxic substances during work. This is its main advantage, since it will interact well with solvents without creating chemical reactions. To dilute this type of paints, you need to refer to solvents under the numbers R-189, R-1176, RL-176 and RL-277.

But water is not able to wash off an already dried stain, so you need to know what solvents to use for this type of material. Acetone is best suited for this purpose, because it is gentle enough and can gently remove paint residues without damaging the surface of the coating.

It should be noted also powder paints, which have become widespread in the building materials market in recent years. This happened because it has a large color palette, low cost and is an environmentally friendly material that does not create detrimental conditions for working craftsmen.

As solvents, special washes are used, which can be found in the building goods store under the numbers P-7 and P-11

However, they contain harsh chemicals, so be very careful when handling these solvents.In addition to them, turpentine, gasoline and white spirit can also be used.

Hammer paint can be diluted with compositions R-645, R-647 and R-650, as well as universal white spirit. Dry stains can be difficult to cope with as hammer enamel is quite tough and adheres quickly to the surface. However, if you use the above materials, you can avoid negative consequences after the repair.

Types of coatings

Consider the main types of paints and varnishes.

Water-dispersive

Water based acrylic paints

widely used for interior work. They have high decorative qualities. Despite the fact that water is used as a thinner, a strong layer appears on the surface after drying. Fresh paint smudges can be easily removed with a cloth moistened with water. If the coloring matter on the brushes has time to dry, then it can be wetted with a warm solution of water and soap.

Latex paint

it is used to cover surfaces of various materials. Such a product forms a strong and dense layer. To obtain the desired viscosity, the paint is diluted with water. After completing the painting work, the tools and drops on the objects are immediately washed with water.

Polyvinyl acetate paint

applied to plastered, wood or plasterboard surfaces. The coloring matter is quite easily removed with a regular sponge soaked in a solution of warm water and soap. Individual drops are simply removed mechanically using a knife or a special spatula.

Old dirt is removed with acetic acid, white spirit, acetone, benzene.

Silicone paint

forms a reliable layer that is not afraid of water. Remove fresh stains with a dry and damp cloth. For dried drops, mechanical means are used. Old contaminants are cleaned with hydrocarbon-based solvents or ether and ester components

These chemical fluids should be used with caution on plastic surfaces.

Oil-alkyd

Oil paint

- the most affordable type among these products. Wipe off fresh drops with a cloth soaked in oil paint thinner. White spirit, turpentine, kerosene, refined gasoline (nefras), butanol or ammonia are excellent for these purposes. Since the paint forms a fairly durable coating, it is difficult to remove old dirt. Numbered compositions P 647, 651 can be used as solvents for old paints.

Alkyd paint

is able to penetrate deeply into the surface structure, due to which a strong, resistant layer is formed. Drops of GF enamels are easily removed with turpentine or white spirit; PF - xylene, solvent or gasoline, as well as their mixture 1: 1; KO - R-4, R-6, solvents N 646, 649, 650. For old dirt, you can use special means - removers. Care should be taken when working with them, as their effect may not be limited to the paint itself. The active substance can also dissolve all the original layers of the primer or putty.

Nitroenamels

Nitro paint is used to paint various surfaces, primarily metal structures. The best paint thinners NTs are combined compositions N 645, 646, 647, 649, 650

... They are used as thinners for thickened enamel, as well as for degreasing surfaces, removing paint residues from construction tools. The contamination can be cleaned with a cloth soaked in acetone, ethyl acetate and other similar products of the ether and ester group.

Epoxy materials

Epoxy paint has a number of advantages. However, its excellent strength and resistance to many chemicals has another side - a well-dried material is almost impossible to remove. Remove fresh stains as quickly as possible with a clean, dry cloth.

For paint work on metal surfaces, hammer paint is often used, for which solvents such as xylene (orthoxylene) or solvent are used. The composition of polyurethane varnishes includes a solution of a polyurethane oligomer in a mixture of organic solvents.

Surface preparation

Thorough surface preparation before painting is one of the main conditions before any painting work. Depending on the type of surface, the following preparatory steps must be taken:

- Remove dirt from wooden surfaces with powder or soda solution and dry the painted parts thoroughly. Cycle and degrease if necessary. To reduce the consumption of enamel, apply a layer of drying oil or universal varnish.

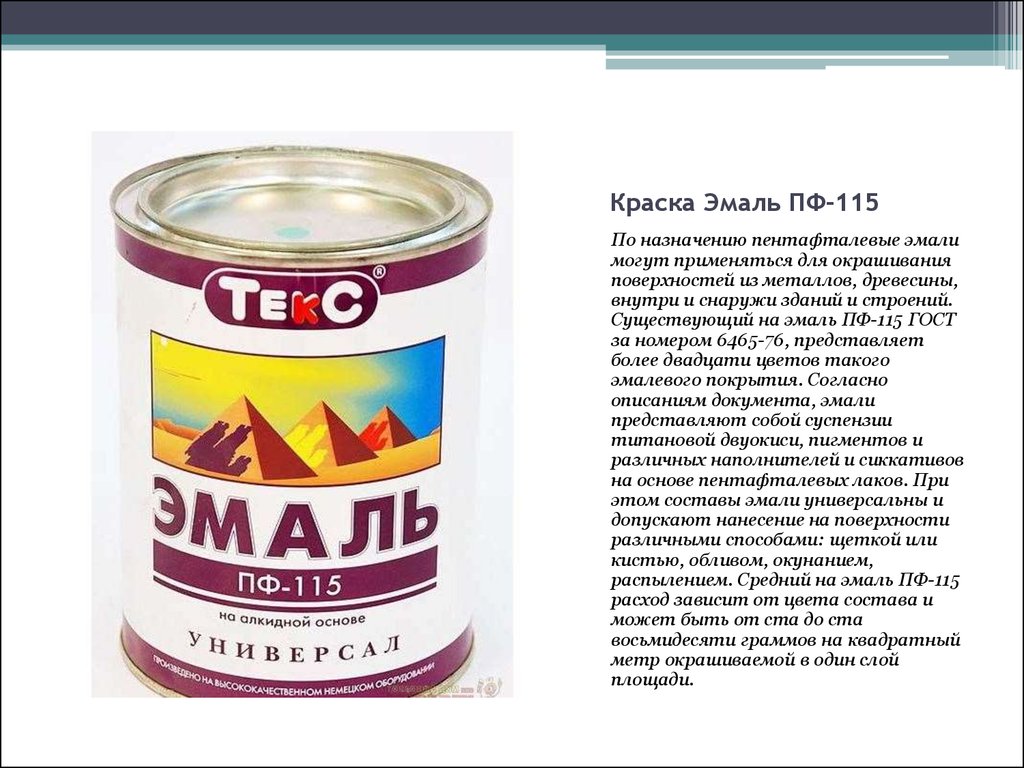

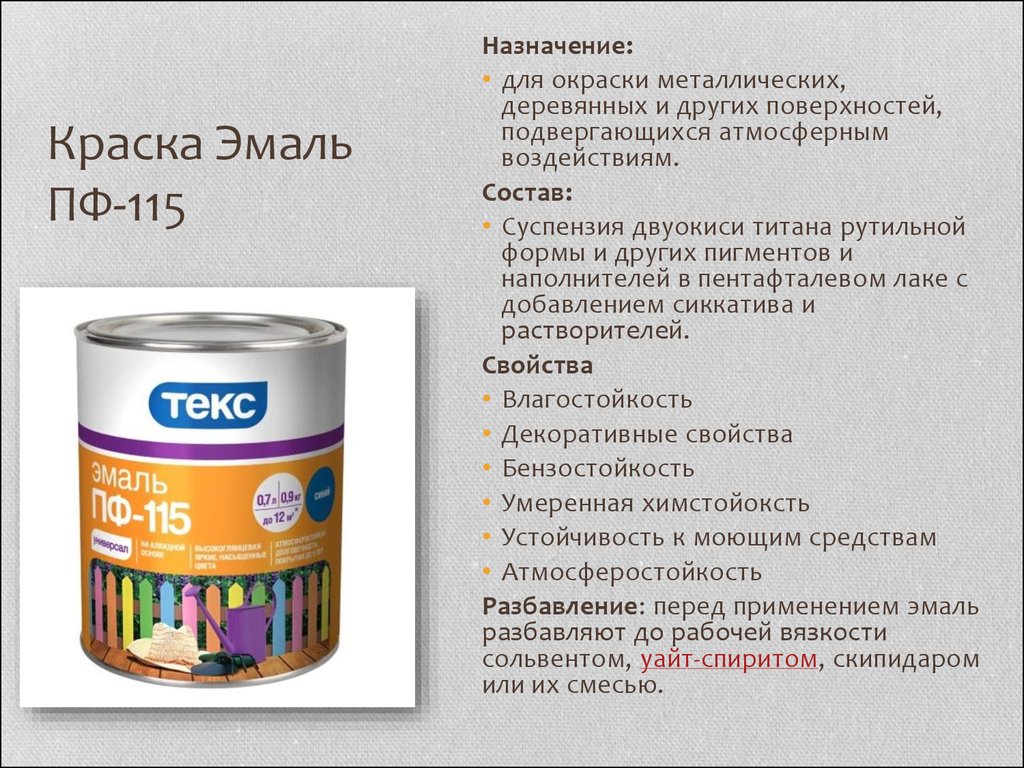

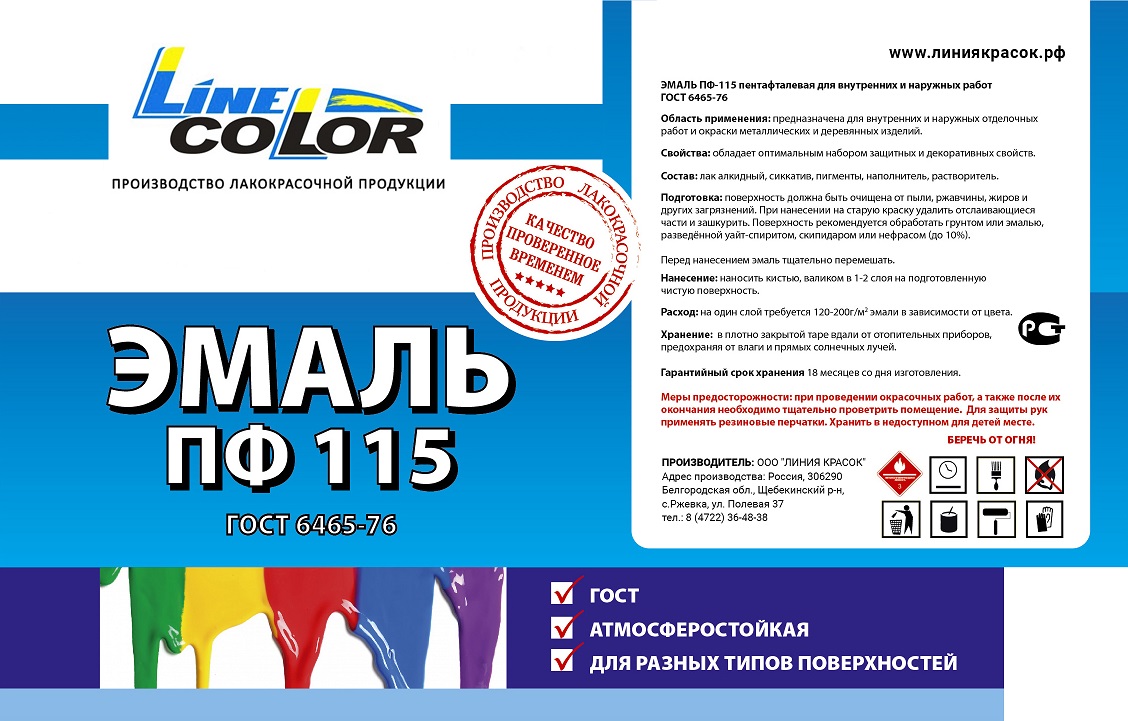

- Before using enamel, rust and burrs must be thoroughly removed from metal products, dust and dirt must be washed. A prerequisite is the priming of metal surfaces, while the composition of the soil should be pentaphthalic

, the best option would be GF 021. - Brick walls, concrete products are also washed from all kinds of pollution. In this case, PF 115 enamel can be used to cover previously painted surfaces.

- If the surface to be painted has a porous structure, then a layer of alkyd primer must be applied to it.

Beginning of work

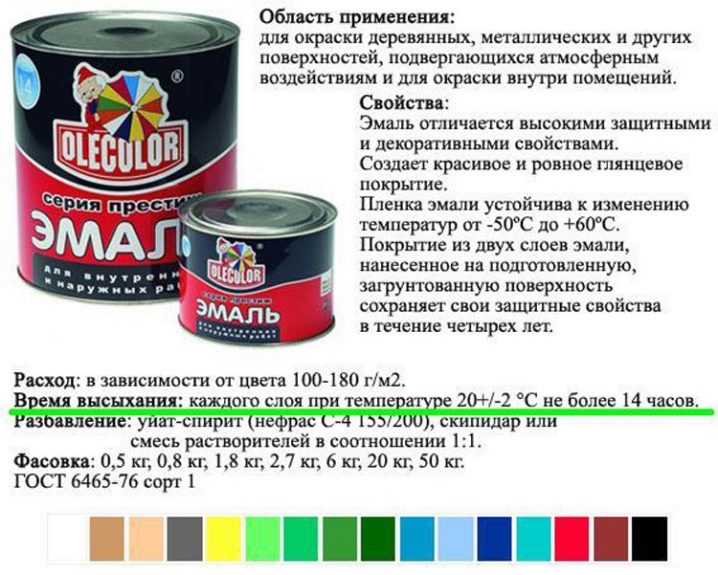

Before starting work, the enamel must be thoroughly mixed and, if necessary, brought to the desired consistency with white spirit, solvent or other solvent. The paint is applied by spraying, roller, brush. Depending on the thoroughness of the preparation, the absence or presence of primer on the painting surface, it is chosen whether the enamel will be applied in one or two layers. Material consumption varies from 100 to 180 g / m2 with one layer of application.

Disadvantages of enamel

One of the disadvantages of PF enamels is a rather long drying time. It is about a day for each layer at a temperature of (20 ± 2) ° С. Also, many do not like the reluctance of paint to be washed off from hands and tools used when working with PF enamels. Experienced painters even throw away the brushes after painting the surface. The unpleasant smell of paint for many also becomes one of the disadvantages of this enamel.

Advantages of enamel

One of the most important advantages when choosing enamel 115 is, of course, an affordable price. The resistance of alkyd paints to temperature drops, to aggressive environmental influences, the durability of the coating is also an undoubted advantage of this paint. The retention period of the enamel on the surface is on average 4 years. The temperature at which this type of enamel will retain all its properties is from minus 50 to plus 60 degrees Celsius.

Repeatedly, when preparing for surface painting, it is found that the consistency of the coloring material does not correspond to the working condition. What should be done in this case? Is there a way out or is it better to buy a new can of paint? Most often, it is necessary to purchase a solvent for PF 115 paint and add it to the composition. But, you need to figure out how to choose the right solvents for alkyd paints from all the abundance in hardware stores. This is what will be discussed in this article.

Do not flatter yourself and look for a universal solvent. It doesn't exist. There are corresponding solvents for each type of colorant. How to figure it out? The main rule should be remembered: the bases of the dye and the solvent must match.

Basically, solvents are divided into the following types:

Petroleum based (gasoline, solvent, white spirit, orthoxyrol). Most often they are used to dissolve oil-based paints and varnishes.

On organic components (acetone, xylene). The most common types of solvents, since they rarely violate the structure of the dye.

With chemical additives.Solvents of this type are divided by marking: P-4, 646, 647, 650.

It should be borne in mind that the higher the number in the marking, the higher the degree of fat content, which means that the paint will dry much longer.

Types of coloring materials

This is the main factor that determines which paint thinner can be used.

Acrylic enamel

Consists of several components. Before painting, it is mixed with a hardener and diluted with a thinner to the desired consistency. Suitable diluents for dilution:

- P-12;

- 650 (soft enough, therefore suitable for many dyes);

- 651.

The diluent content should not exceed 10-15% by volume. The exact consumption must be clarified when buying from a specialist.

Alkyd enamel

A versatile material, it is used not only for painting surfaces of various materials, but also used as a primer against rust.

- toluene;

- xylene;

- P4;

- white spirit (it is better to use artistic white spirit, since the usual one may contain impurities that precipitate).

Alkyd enamel can still be primed against rust

It should be noted that there are types of alkyd enamels that do not require dilution, for example - PF-15 and "Extra". As an alternative to alkyd, oil-phthalic enamel can be used. In terms of properties, it is similar to PF-115, but at the same time it does not have a pungent odor. This type has excellent flow, bright colors and resistance to chemical and weathering.

Nitroenamels

Any type of solvent is suitable for this paint option, but it is better to use the one recommended by the manufacturer. When diluting nitro enamels, you can use 646 (it is also suitable for soil), however, it should be noted that this is a very aggressive type of diluent and must be used carefully.

Water based paint

The water emulsion can be diluted with water, alcohol or ether

It is important to remember that in this case the water must be distilled, since in ordinary water, even in fresh water, there is a large amount of impurities of a salt nature, which, when the coating dries, can give a white bloom. Alcohol may not be compatible with the dye, therefore, it is necessary to test for a small amount before diluting the entire volume, if the test paint does not coagulate after dilution with alcohol, then the substances are compatible and this diluent can be used

If, when adding alcohol to the paint, it curls up, then this paint is not suitable for divorce with alcohol.

Filler

The filler is a primer, the preparatory material is no less important to properly dilute than the coating that is supposed to be after it. The main task of the soil is to smooth out the surface roughness before painting, which is not only necessary for painting, but also further protects against rust

If the soil film is too thin, then it will not be able to cover all defects and depressions and will have to be recoated, which leads to additional costs. In the case of a soil that is too thick, its penetrating and rustproofing ability will decrease, and again it will not be able to fill irregularities on the surface. The material will begin to flake off and will not be able to spread, as a result of which shagreens will form, which will have to be removed by grinding.

Solvents that can be used for primer:

- solvent;

- xylene;

- a mixture of solvent or xylene with white spirit.

It should be noted that 20% of a thinner is added to one-component soils, and two-component soils are diluted in the proportions indicated by the manufacturer (2 kg to 1 kg, 3 kg to 1 kg, etc.).

Application and recommended paint schemes

Waterproof alkyd enamel PF 115 can be applied with any type of painting tool - brush, roller, spray

When calculating the amount of paint required, it is imperative to take into account the peculiarity of the surface to be painted and the color of the paint.

Concrete, brick, unpolished wood absorb paint quite intensively and its consumption will be higher than when covering planed wood, metal or previously painted surfaces.

Selection of the amount of paint by color

Depending on the color, the consumption of a standard paint is quite large. At room temperature, to paint 1 m2 of the same type of unprimed surface, you will need:

0.1-0.14 kg - white paints

0.05 - 0.06 kg - black paints

0.07 - 0.1kg - blue paints

0.07 - 0.08 kg - brown paint

0.1 - 0.2 kg - red colors

The calculation is given for a single coat. When determining the real, the number of layers is multiplied by the given figures and again multiplied by a factor of 0.9 - for each subsequent layer there is less paint than the first. The second coat can be applied no earlier than 24 hours after the completion of the previous coat.

Only ideally dry surfaces are painted, heated to a temperature of at least +5 C. It is optimal to carry out painting work using PF 115 in dry, windless weather at an outside air temperature in the range of +15 ... + 22 C. In this case, the paint will maintain optimal viscosity, solvent - do not evaporate too quickly from the surface, and the risk of sagging is minimized.

The method of application also affects the paint consumption. When using a roller, it will be larger than a brush, and a spray may lead to some overrun. Also, the average consumption directly depends on the quality of surface preparation for painting and compliance with standard paint application schemes.

Painting schemes with enamel PF-115

1. Coloring of metal.

Metals of all types are painted with enamel only after priming with compositions GF 0119, VL 05, GF 021 or their analogues compatible with pentaphthalic paints. In the index of primers, the number 0 must be first. If there are no primers, and the surfaces are not very critical, then for the primer you can use the PF 115 enamel itself, diluted with white spirit to 50% of the original density.

Surfaces bearing traces of corrosion are treated with Unicor rust inhibitors (converters) before priming. These compounds are applied after mechanical cleaning of metal from rust and grease. They transform the products of corrosion into strong and tight joints, which do not differ in hardness from the solid metal. Metals are painted with PF 115 enamel in two layers.

2. Coloring the tree.

On wood, the enamel is applied without a primer in 2 - 3 layers. If necessary (recommended), treat the wood surface with fire retardants, antiseptics and fungicides compatible with pentaphthalic paints. Manufacturers of paintwork materials offer a wide selection of such compositions, but when using them, you must carefully study the instructions - some of them are designed for acrylic paints, some act as an independent coating.

3. Plaster, concrete, brick.

These materials are painted with enamel in 2 - 3 layers without a primer. But it is advisable to use anti-mold preparations - the enamel forms a dense surface with low vapor permeability and residual moisture can cause favorable conditions for the development of mold and mildew in the bulk of the material if pest spores remain there.

When painting any of the materials, the surface must be thoroughly cleaned of dust and dried. Residual moisture should not exceed 10 - 15%. Fresh concrete walls and foundations, as well as brick structures, can be painted no earlier than six months after the end of the installation. The interval between applying the next coat of paint is at least one day.

In most cases, the paint is sold ready-to-use in its original container. But after opening the can, the solvent begins to evaporate intensively and the density of the enamel increases. To bring the paint to a working consistency, white spirit or solvent is used, as well as their mixtures.It is not recommended to use gasoline and kerosene - although they dissolve the enamel, they significantly change its shade and shine.

When preparing the paint for work, it must be thoroughly mixed by adding the solvent in small portions. In the process of work, the paint also needs to be mixed periodically.

The better to dilute the paint PF 115

To understand the nuances of dilution, you need to learn about the components that make up the paint, and its features. PF 115 is an alkyd enamel, its field of application is wide, it can be used to paint wooden, metal, plastered, concrete surfaces.

Its popularity is also due to its low cost. It includes:

- Alkyd varnish;

- Solvents;

- Pigments;

- Pentaphthalic varnish (precisely because of the presence of this varnish in the composition, the abbreviation PF is present in the name). This varnish is a mixture of resin with vegetable oils, rosin, glycerin.

By mixing varnish with alkyd enamel, PF 115 is obtained.

In addition to its low cost, it has good characteristics and is able to protect metal surfaces from rust formation and from harmful atmospheric influences.

The paint has good characteristics and is able to protect metal surfaces from rust formation.

Before thinning the paint PF 115, you need to read the instructions on the package. Where the recommended solvent will be indicated. This is due to the fact that the production of different brands may differ slightly. In production, they go through some stages of preparation, but they are often released for sale with the addition of solvents. In such cases, a specific type of diluent may be written on the packaging, which is compatible with the type already added.

Which solvent for PF 115 is suitable:

- Turpentine;

- White-spirit;

- Solvent.

You can also use a number of other types, they will be discussed later.

They begin to dilute immediately before the start of staining, you should not do this in advance.

How PF 115 alkyd enamel differs from acrylic paints

When choosing a coloring agent, there is a desire to compare it with others to make sure that it is the one that is best suited for specific work. Now two types of paints and varnishes that are popular will be disassembled.

The composition of alkyd paints includes:

- Drying oil;

- Glyphthalic and pentaphthalic varnishes;

- Oil-phenolic varnish.

For a better understanding of the differences between alkyd and acrylic paints, it is worth understanding the positive and negative qualities of both.

The main difference, of course, lies in the basis of the composition. So, speaking about alkyd enamel PF 115, the following advantages can be distinguished:

- Has good performance in protecting surfaces from harmful effects;

- Complete drying occurs in a day;

- Budgetary price;

- Large assortment of colors and shades;

- When painting, it is enough to apply two layers, sometimes you can limit yourself to one, which also makes it more economical;

- Resistant to moisture, temperature extremes.

The disadvantages are:

- Toxicity and fire hazard, however, after drying, the paint ceases to be harmful. During drying, it is better not to enter the room where the painting work was carried out and the painted object is located for a day;

- The service life is lower than that of acrylic.

Has good performance in protecting surfaces from harmful effects.

Acrylic paints also have their positive properties:

- Long service life;

- Non-toxic;

- High UV resistance;

- Able to withstand high temperature performance.

The downsides are:

- High price;

- It takes a long time to dry completely;

- It's hard to choose a good lineup.

Also, to dilute alkyd paint, you need to use solvents, and for acrylic paint, plain water is suitable.

Able to withstand high temperature performance.