Main characteristics

Solvent 650 is valued for its low water content (no more than 2%), high coagulation (up to 60%), the composition is based on butanol, contains xylene (obtained by distillation of coal tar or petroleum products), characterized by high solubility and volatility. Chemical properties limit the scope of use of the product, the liquid is quite poisonous and aggressive. The acidity does not exceed 0.1 mg KOH / g, the volatility index is –25. The clarity is ideal, the mixture of hydrocarbons should be free of suspended matter and solid inclusions.

Chemical properties limit the scope of use of the product, the liquid is quite poisonous and aggressive.

Solvent R 4

Composition and properties

P 4 is an organic solvent containing aromatic hydrocarbons, ketones and ethers. It consists of 62% toluene, 26% acetone, 12% butyl acetate. A mixture of these components effectively dissolves and liquefies various paints, varnishes, resins and other organic substances.

There is a variety of it - the R-4a solvent, the peculiarity of which is the absence of butyl acetate in the composition.

This tool is manufactured in accordance with GOST 7827-74. R-4 GOST is produced with the following technical characteristics:

- looks like a clear liquid without color or yellowish, without suspension (P-4 and P-4a look the same);

- water content - 0.7%;

- volatility - from 5 to 15;

- acid number, mg KOH / g - no more than 0.07;

- coagulation number - not less than 24%.

Application

This tool is used to dilute and dissolve varnishes, putties, enamels, primers, paints marked with XB, XC, HSL, EP, Vinicolor, Vinicor, Evikor, Evinal, HS-500 primer-enamel.

Also, R-4 is used for washing dishes, hands and arms after working with paints and varnishes.

This solvent is suitable for dissolving and thinning enamels, varnishes, primers and putties with markings XC, XB, PVC, MS, EP-0020, except for XB-124 gray and protective enamel. The R-4a modification of this solvent can also dissolve the gray and protective enamel XB-124.

It is volatile, and its use is based on this: after adding a solvent to the paint and applying it to the surface, it quickly hardens and forms a film.

Important! Do not allow water to get into solvents R-4 and R-4a. This will lead to whitening of the paint film, since water mixes easily with acetone, which is part of the product.

Security

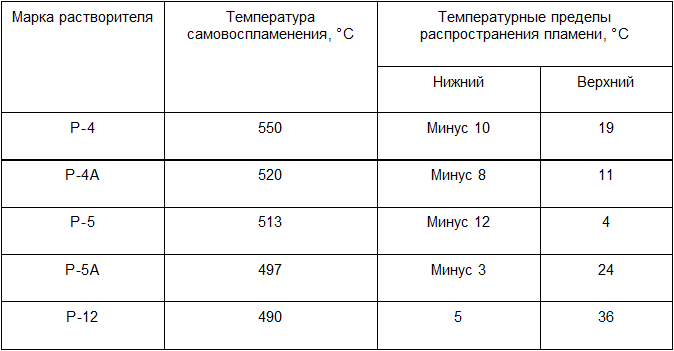

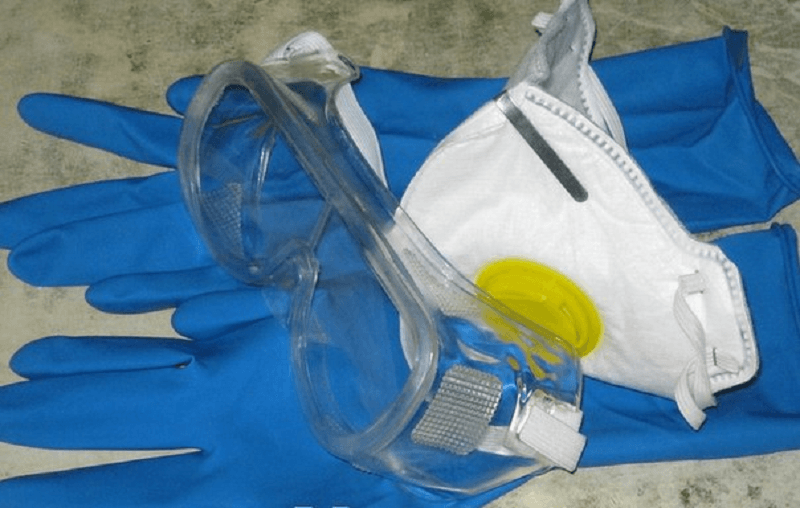

Solvent R 4 is toxic, fire and explosive, therefore, when working with it, safety precautions must be observed.

- It is necessary to store the composition in fireproof ventilated rooms, away from sunlight, in sealed containers;

- it is also necessary to work with the solvent in rooms with good ventilation;

- avoid contact with eyes;

- work in protective gloves, avoid contact with skin, in case of contact with skin, wash off with plenty of warm water and soap.

Due to the fire hazard of the solvent in the room where it is stored and worked with it, sparks, open fire, and smoking must be excluded. In case of fire, P-4 is extinguished with foam, carbon dioxide, sprayed water. It should be remembered that vapors of the solvent and its components (butyl acetate, acetone, toluene) are heavier than air, can accumulate near the floor and are explosive.

The toxicity of the drug is manifested by narcotic effects (dizziness, headache, disorientation, blurred consciousness with prolonged inhalation), irritation of the eyes and other mucous membranes, and coughing. With prolonged inhalation of vapors, poisoning is possible, similar in symptoms to food, toxic damage to the nervous system.

Therefore, when working with a solvent, you should use protective equipment (goggles, gloves, respirator), work only in a well-ventilated area. If the product comes into contact with the skin, it must be washed off, if in the eyes, rinse them and seek medical attention.

Solvent brands R-4 and R-4a are also fire and explosive, forms explosive compounds with acids and oxidants (acetic, nitric acid, hydrogen peroxide), reacts with chloroform and bromoform, reaction products are fire and explosive. In relation to some types of plastics, they are aggressive.

Only "relatives"

But the fact is that the same liquids can behave differently with different paintwork materials: for some resins, they can be thinners, and for others, they can be aggressive solvents. Therefore, the use of unregulated thinners can lead to incompatibility with the diluted material, with all the ensuing consequences.

Sometimes this property of a "non-native" diluent can very effectively lower the viscosity of a material, but God forbid it will negatively affect the film formation process ... And when "kinship" is violated, this is often what happens.

The fact is that each diluent is developed strictly for a specific material, taking into account compatibility with the base and additives in its composition. The developer of paintwork materials, adding certain liquids to the formulation, calculates the sequence and speed of chemical reactions, therefore, the process of drying the material and the quality of the final paintwork (hardness, gloss, etc.) depend on the correct choice of the diluent.

That is why it is so important to use only the liquids recommended by the manufacturer to dilute paints and varnishes. By replacing a branded product with some "leftist", we initially doom ourselves to failure.

Meanwhile, such a replacement is practiced quite often: painters choose high-quality expensive primers, paints and varnishes, but instead of the recommended thinner, they pour the cheapest domestic liquids, and after problems arise, they begin to blame the paintwork manufacturer for everything.

Solvent 647

Composition and specifications

Another inexpensive and popular solvent has the number 674. It differs from 646 in composition and scope. This thinner does not contain acetone, therefore it is less aggressive, including to plastic.

The technical characteristics of the P 647 are as follows:

- looks like a clear liquid, yellowish or colorless, free of suspension, homogeneous,

- water content - no more than 0.6%,

- volatility - 8-12,

- acid number - does not exceed 0.06 mg KOH per 1 g,

- coagulation number - not less than 60%,

- density - 0.87 g / cc.

When diluting nitro enamels, the film should not turn white when the solvent evaporates. Streaks and scratches on the enamel surface should be smoothed out.

It includes:

- ethyl acetate,

- butanol.

- toulol,

- butyl acetate.

Application

Also 647 is used to increase the viscosity of materials containing nitrocellulose. What is the difference between solvents 646 and 647 by application?

P 647 is less active, therefore it does not damage plastic, and therefore it can be used for bodywork, degreasing various surfaces, removing varnish and paint films, if respect for the surface is important. This solvent is introduced into soluble paints and varnishes, constantly stirring, in the proportions indicated in the instructions for a particular paint or varnish.

This solvent is introduced into soluble paints and varnishes, constantly stirring, in the proportions indicated in the instructions for a particular paint or varnish.

Security

Precautions when working with it are the same as when working with the P 646

- Solvent 647 must be stored in closed containers in a fireproof room, away from direct sunlight.

- The room where the work is carried out must have good forced ventilation. The solvent is toxic and dangerous to inhale.

- Avoid contact with eyes. You need to work with gloves, in case of contact with the skin, wash with soap and water.

Like P 646, P 647 is sold for domestic use in cans ranging from 1 to 10 liters, and for industrial use in steel drums.

Storage

Before using solvent 647, you should definitely familiarize yourself with the basic rules of operation and storage.

- The composition must be stored in a tightly closed container. The direct rays of the sun must not fall on the packaging. The room must have a high level of fire safety. Store the solvent out of the reach of children and animals. The ideal location is a dark, dry environment that maintains room temperature.

- When using it is necessary to ventilate the room. If there are no windows, and ventilation cannot cope with the volatility of the solvent, fans should be installed in the room.

- The product packaging must contain instructions for using the product.

- Thinner 647 is sold for both industrial and domestic use. The choice of buyers is presented in packages ranging from 0.5 to 10 liters, as well as large steel drums for bulk purchases.

Household chemicals as a replacement

There are many alternative products on the market in Moscow. And in the kitchen, any housewife has a couple of packages of household chemicals for cleaning kitchen utensils.

However, using it to remove difficult stains will take many times longer and harder. At the same time, the quality of the result will not be guaranteed.

Recommendations for use

Consider the purpose of the P-4 solvent and other compounds. Use them in situations where you cannot do without them. Follow the basic rules for interacting with such products, excluding amateur activities. In other cases, use other, less aggressive means.

Working with such substances should not be harmful.

Ignoring safety precautions is dangerous and often leads to an explosive situation.

Adding solvent to the gas tank of a car

Given the physicochemical properties of solvent 646, some motorists use a solution with gasoline to clean engine parts by pouring it into the tank. On the internet, you can find recommendations on how to use the mixture correctly in order to get a good result. The substance is added to the fuel tank and additionally refueled with gasoline to the required proportion.

Goals

The main goal is to improve performance and restore the function of the machine mechanism. The liquid in the gasoline, flowing through the system, gradually dissolves scale and specific plaque on the elements of the car. As the engine runs, parts are cleaned and technical performance improves.

Effects

According to the experts, the composition significantly increases the work of the machine. After such manipulation, the following result is observed:

- cleaning of inaccessible parts and nozzles inside the engine;

- gaps disappear when shifting the gearbox, which does not require intensive pressing on the gas pedal;

- stable engine operation is noted;

- speed increases;

- the mechanism warms up faster;

- reduced fuel consumption.

Recommendations

If a decision is made to improve the technical characteristics of the vehicle with a gasoline-based mixture, this issue must be investigated in advance. The use of a solvent as an engine cleaner remains controversial today.

Therefore, it is better to adhere to the following recommendations.

- Adhere to the proportion - gasoline from 20 to 40 liters, liquid form 646 - 1 liter.

- When working with a multi-component mixture, observe safety precautions.

- Pour the substance into the gasoline tank through a special funnel.

- Clean the engine no more than once every three months to avoid damaging the rubber seals.

The combination of gasoline and 646 blend helps to significantly improve vehicle performance. However, you should take into account the peculiarities of vehicle operation and use approved substances.

Storage and safety rules when using the R-646

For industrial use, solvent 646 is poured into special metal containers, and for household use - into bottles, cans and small barrels.

During transportation and storage, certain rules must be strictly observed, remembering that the substance is volatile and flammable:

- the container in which the solvent is located must always be tightly closed; moisture, exposure to high temperatures and direct sunlight must not be allowed;

- the room in which the containers with the solvent are located should be equipped with a ventilation system or simply be constantly ventilated. It must be ensured that there is no sunlight and that all fire safety rules are observed.

To protect yourself as much as possible when working with a solvent, the following standards must be observed:

- it should always be remembered that the substance is extremely toxic;

- in no case should it be allowed to get into the eyes;

- during work, overalls and personal protective equipment, such as glasses, gloves, respirator, should be used;

- in case of contact with the skin, rinse immediately with soapy water.

Refusal to use protective equipment entails the following troubles:

- irritation of eyes and respiratory tract by vapors;

- damage to the central nervous system, kidneys, liver, stomach, intestines;

- solvent vapors are able to penetrate the body not only through the respiratory system, but also be absorbed by the skin;

- with prolonged contact with the skin, dermatitis develops;

- also, long-term exposure to the substance can affect the condition of the blood and bone marrow.

Fire safety rules when working with solvent 646:

- the substance has a high fire hazard class, therefore, it should not be allowed to be near the places of its use and storage of open flames, sparks, heat sources, lighted cigarettes;

- a mixture of vapors and air has explosive properties;

- the accumulation of a dangerous concentration of vapors in the air can occur quite quickly if the container with it is kept open;

- since vapors are heavier than air and can be directly above the ground or floor;

- fire can occur at a distance;

- on contact with acetic and nitric acids, as well as with hydrogen peroxide, explosive mixtures may form;

- there is a reaction with substances such as chloroform and bromoform, which can lead to fire and explosion;

- Thinner 646 is corrosive to several types of plastics.

Advantages and disadvantages of the tool

Summarizing the advantages of p-646, they highlight its high efficiency and guaranteed result. Thinner 646 does not leave hard-to-remove marks on the treated surface, which cannot be said about its analogues. Therefore, even transparent or colored coatings are cleaned with them without the risk of spoiling them.

Thinner 646: safety measures

Before starting work with the P646, carefully read the manufacturer's instructions. It indicates the principles of work and the rules for using the composition with a guarantee of safety for the health of the master.

Arm yourself with gloves, a respirator so that the substance does not damage the skin of the hands and respiratory tract. The work area must be well ventilated.

Peculiarities

Solvents include rapidly evaporating reagent mixtures consisting of several active components. They dissolve organic substances and form homogeneous compounds with them.

The main task of the solvent is to dilute paints and varnishes, giving them the required working consistency, therefore, certain requirements are imposed on them:

- lack of any reaction with paints and varnishes;

- high evaporation rate;

- the composition must be non-hygroscopic;

- the interaction of the solvent and the coloring composition should take place without any effort.

The solvent affects the paint only at the moment of its application, after which it evaporates without a trace. Each paint and varnish product corresponds to a certain type of solvent.

Thinner number 646 is a universal composition with a wide range of uses.

The active components of P646 are:

- toluene - 50%;

- butanol - 15%;

- butyl acetate - 10%;

- ethyl alcohol - 10%;

- ethyl cellosolve - 8%;

- acetone - 7%.

The latter does not contain acetone, it is considered not so active, due to which it is used on coatings that require the most careful and delicate handling, for example, when working with plastic. In all other cases, it is worth giving preference to the 646 brand.

Today, solvent manufacturers are conducting research aimed at reducing the concentration of toluene and acetone in the reagent. This is due to the fact that these substances are often used in the manufacture of synthetic drugs.

Security measures

The manufacturer of Solvent 646 reminds you that this is a flammable liquid and must be handled and stored with extreme care. It is recommended to use a closed sealed container for this.

Store the substance away from any sources of heat, electrical devices and sunlight, out of the reach of children.

Solvent vapors are toxic! When working in closed rooms, it is imperative to create good air ventilation. Work should be done in a respirator, protective gloves and goggles.

Prolonged skin contact can cause dermatitis. If the substance comes into contact with the skin (mucous membranes), thoroughly wash the contact areas with warm water and soap.

solvent 646

Solvent 646

Composition and specifications

This composition is used for dissolving and diluting various paints and varnishes, removing stains, cleaning surfaces and tools from paints and varnishes. The GOST standard describes its composition:

- acetone - 7%;

- ethyl cellosolve - 8%;

- butyl acetate - 10%;

- ethyl alcohol - 10%;

- butanol - 15%;

- toluene - 50%.

Also, solvent 646 is made according to TU, with the differences that the content of toluene and acetone is reduced in it. This is due to the fact that toluene and acetone can be used in the production of drugs.

The description of solvent 646 includes the following specifications:

- appearance - a clear, colorless or yellowish liquid without suspension, not stratifying, without precipitation,

- boiling point - 59 С,

- flash point - -7 С,

- autoignition temperature - 403 С,

- the density of the solvent is 646 - 0.87 g / cc, due to this it mixes well with other solvents and paints and varnishes,

- specific gravity - 0.68 kg / l,

- water content - 0.09%,

- acid number - 0.06 mg KOH / g,

- coagulation number - 40 g / o,

- volatility (ethyl ether) - 12,

- does not freeze

- does not leave dull or whitish spots.

Application

The solvent R 646 is used to dissolve and dilute various varnishes and paints. It was originally intended to dilute nitro paints and nitro enamels. Later it was found that the 646 solvent is also effective in relation to other types of paints and varnishes, as well as epoxy or glyphthalic primers, melamine amide, alkyd, epoxy paints and varnishes, putties, and the film was distinguished by gloss and strength.

It is used to bring paints and putties to the desired viscosity, dilute thickened paints, putties, film-forming varnishes, and gives shine. After drying, the whitish film and the smell of the solvent do not remain. Paints and varnishes with the addition of solvent 646 form a film faster than paints and varnishes without it, have a beautiful gloss. Also used in the production of nitro paints, nitro varnishes, nitro enamels.

It is quite aggressive, especially against plastic, so it should not be used on plastic surfaces. Solvent 646 can be used for degreasing, and it is one of the most effective formulations for this purpose, but due to its activity, the surface properties must be considered.For plastic, use less aggressive products.

Consumption per 1 square meter for degreasing is approximately equal to:

- for outdoor surfaces - 0.147 kg;

- for metal and wooden surfaces indoors - 0.12 kg;

- for concrete - 0.138 kg.

For surfaces that will be affected by water and other aggressive factors, the consumption per square meter is 0.169 kg.

Security

Solvent 646 is toxic, its environmental hazard class is 3. When inhaled, it causes a narcotic effect - headache, dizziness, disorientation, as well as irritation of the eyes, respiratory tract, effects on the gastrointestinal tract, liver. With prolonged inhalation, toxic damage to the liver, bone marrow, changes in the composition of the blood are possible, which lead to serious consequences. Therefore, it is necessary to work with P 646 solvent in a room with good supply and exhaust forced ventilation or outdoors. To protect the respiratory system, use a respirator (such as a "petal").

If it comes into contact with the skin, it does not cause burns, but with prolonged interaction with it, contact dermatitis is possible. Do not allow it to get into the eyes, work must be carried out with gloves and goggles, and in contact with the skin, the substance is immediately washed off with soap and water.

It is volatile and flammable, so care must be taken when handling it. The flammable solvent is extinguished with sand, foam, sprayed water

It is stored in an airtight container, in places where the direct rays of the sun do not fall, at a temperature of -40 to +40 degrees. You cannot store it outside. In the room where the composition is stored or work is in progress, the occurrence of any sparks must be excluded. Do not smoke near containers with the substance.

P 646 is sold in metal drums for industrial use and in 1-10 liter canisters for domestic use. It is completely ready to use, no additional preparation is required. The warranty period during which the composition retains its properties is 12 months.

This is interesting: Wooden ceilings in the apartment - the pros and cons

Storage and safety rules for use

Since the characteristics indicate that the product is highly flammable, then its use near sources of fire, smoking and the presence of sparks is unacceptable. Also, the danger of a blast wave can be caused by air mixtures and product vapors. The air is polluted with diluent vapors at a rapid rate when the temperature is above +20 degrees. If a substance is sprayed, then this process occurs more quickly.

So you can also highlight the following rules for working with this tool:

- Storage can only be carried out in a tightly closed container, which should not be near heating appliances and sources of fire. It is not recommended to expose containers to direct sunlight;

- It must be stored in a place where children or animals cannot find it;

- As stated earlier, the vapors are hazardous and can be harmful if inhaled by humans. Therefore, work with it should be carried out in a room where good ventilation is provided, or powerful ventilation is carried out;

- Do not allow the composition to come into contact with the skin and eyes. For this purpose, rubber gloves are put on hands, upon contact with the skin of a solvent, this place is washed with plenty of water and soap. Eyes should be protected with special goggles;

- With prolonged contact with vapors, many human organs are affected. Moreover, this process can also occur through the skin, in this regard, the washing of the skin area, where the solvent has got into, should be done immediately;

- The compound of the composition with oxidants is explosive, their content nearby is unacceptable;

- Also, mixing with chloroform and bromoform may cause fire or explosion;

- Spraying thinner is dangerous, with this type of air pollution, it can catch fire, even if it is located at a distance from sources of fire;

- It is advisable to protect the master with special protective clothing.

Storage can only be carried out in a tightly closed container, which should not be near heating appliances and sources of fire.

Storage can only be carried out in a tightly closed container, which should not be near heating appliances and sources of fire.

Types of compositions

Solvents can be of different compositions, they are used for different types of surfaces. So you can distinguish several categories of compositions:

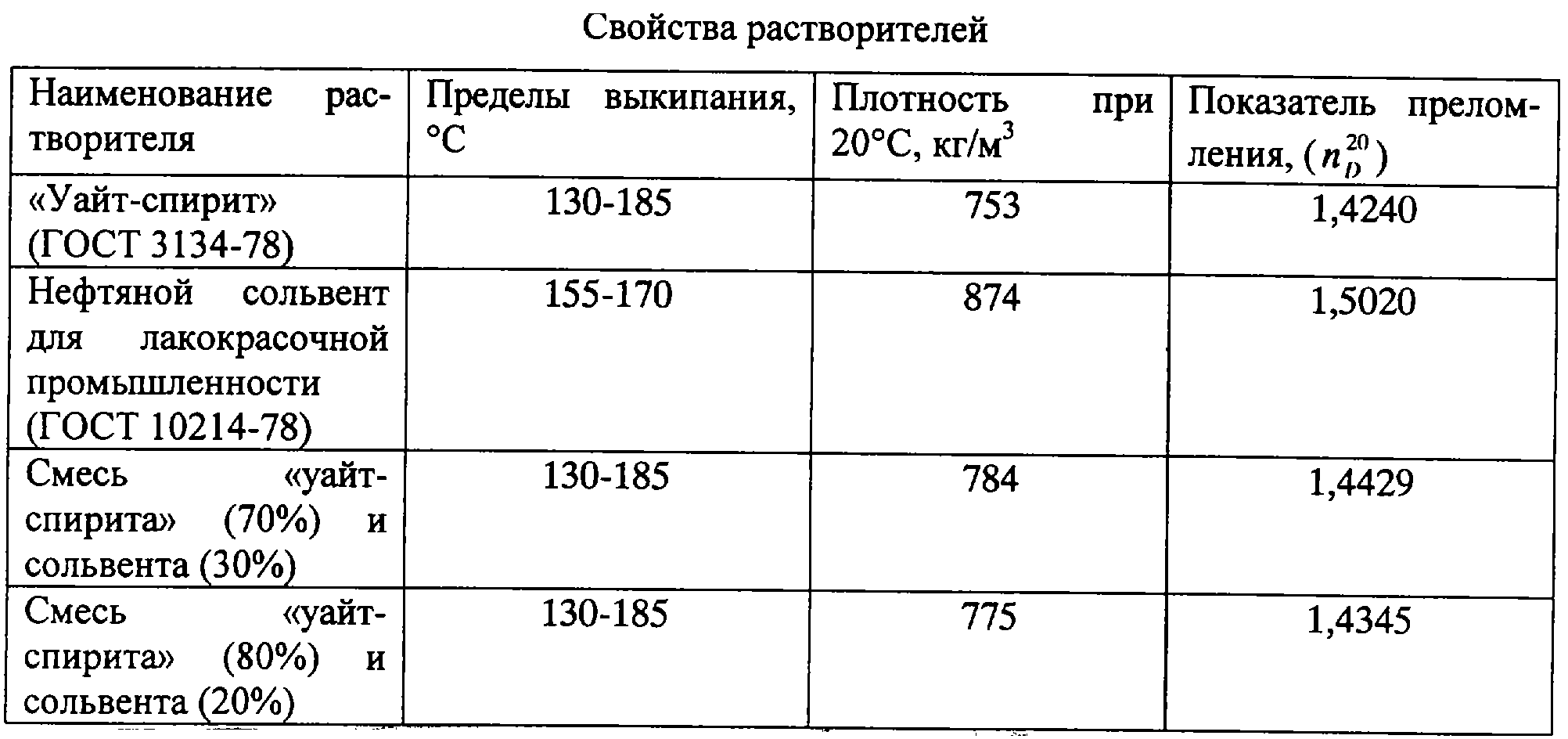

- For oil paints. The formulations are made gentle so that they can be diluted with coloring materials in order to improve their characteristics. Most often, in this case, white spirit, turpentine or gasoline are chosen;

- Thinners suitable for thinning bituminous paints as well as glyphtal-based paints and varnishes. These are xylene and solvent;

- Composition for perchlorovinyl dyes. For them, acetone is selected as standard;

- Thinners for glue and water dispersion coloring agents;

- Weak compositions for household needs.

Solvents can be of different compositions, they are used for different types of surfaces.

Solvents can be of different compositions, they are used for different types of surfaces.

Basic security measures

The use of a solvent provides for strict adherence to the relevant sanitary standards and safety rules. All of these compounds found on store shelves irritate the eyes, skin and respiratory tract.

If proper ventilation is not provided, the solvent will cause a severe cough, and the following negative consequences are also possible:

- loss of creation;

- headache;

- dizziness;

- clouding of mind:

- food poisoning;

- state of narcotic intoxication;

- weakness;

- irritation;

- nausea.

Special work clothes and accessories will help protect yourself from the above and other negative consequences. You cannot do without protective glasses, gloves and masks, which will prevent the ingress of toxic substances into the respiratory organs.

The solvent can even infect the bone marrow and blood. If the solvent comes into contact with open skin, it is necessary to urgently wash the affected area with soap or other foaming composition. Otherwise, direct contact may cause dermatitis.

The vapor generated by the volatile components in the formulation is highly irritating to the respiratory tract and eyes. Poisoning is possible due to improper handling and neglect of safety rules.