Mix of grades M125, 150 and 200

The M125 masonry mortar is suitable for the construction of walls made of stone and various blocks. A composition for laying gypsum tiles is often used. The fraction of the used sand can vary from 0.5 to 1 mm. The mixture of the M150 brand is characterized by increased hardness. Suitable material for masonry, and in domestic construction it is used for ceramics and finishing of concrete structures. This mixture is good in that it does not show sensitivity to low temperatures, but requires adherence to a temperature range of +5 to +35 ° C during the work process. Heat-resistant masonry mix M200 is distinguished by refractoriness and water-repellent characteristics. Washed mountain sand without organic compounds should be used for cooking. Among other things, shells and limestone fragments are used, the fraction of which is approximately 3 mm.

How to tell if a solution has been prepared correctly

If the solution is made according to all the rules, then it looks like thick sour cream. It is very simple to check its quality: you need to take a little of the resulting mixture on the tip of the shovel and see how it will spread out (if the solution spreads slowly, this means that it is of high quality).

Requirements for building mixtures

Compliance with its purpose - antifreeze materials must tolerate cold well, and moisture-resistant materials must tolerate dampness. Special properties are created using special additives. You can enter them yourself or buy a ready-made powder that just needs to be mixed with water and sand.

Plasticity - workability depends on this quality. The plastic mass fills the voids of the base and strengthens its structure. It adheres better to its surface.

This property is important not only for construction, but also for filling cracks. It depends on the consistency and amount of the binder.

To improve it, plasticizing additives are introduced. The layering ability allows you to apply thin, uniform layers without significant effort.

Adhesion - adhesion to the surface. It depends on plasticity. To improve it, glue is introduced.

Setting time - you have to adjust to it in order to have time to work out the batch before it hardens. If the lower rows have not yet grabbed, the upper ones can destroy them. There are hardening accelerators and retarders.

Heat and sound insulation characteristics - they are influenced by the porosity of the material. The more voids, the higher these indicators, and the lower the strength. Requirements for heat and sound insulation, as a rule, are not high, but they are taken no lower than that of a ceramic stone. In production, special air-entraining and gas-forming additives are used.

Determination of clay quality

It is necessary to dwell on this point in more detail, there are several simple methods for determining the quality of the mixture and clay.

-

Prepare a small amount of a mixture of clay and sand in various proportions, roll them into balls the size of a tennis ball. Place in the shade to dry. If the ball is badly cracked, then this means that there is a very large percentage of clay in the solution. If sand is poured out of it, then the clay, on the contrary, is too little. If the surface is in good condition, then these proportions should be used for the stove. This is how the optimal proportion of the mixture for laying bricks is determined.

-

Roll the soaked clay, thick as a dough, into a ball about 5 cm in diameter.Place it between two even boards and gradually squeeze, try to notice the moment when cracks appear.If they appeared after compression to half of the original height, then the clay is considered highly plastic. It has excellent astringent properties, more sand can be added to it during the preparation of the solution. If cracks appeared during compression by about 1/3 of the diameter, then the clay has an average plasticity, no more than two parts of sand can be added to it. And the worst clay is skinny, it cracks with insignificant compression parameters, it is better not to use it for a solution. This method is better than the one described above in that it allows you to very quickly recognize the quality of the clay and get an idea of the optimal ratio of components for preparing a mixture.

-

Balls are rolled from thick clay, the diameter does not matter. Leave for a day for slight drying. If, after this time, fingerprints remain on the surface of the balls, the clay is oily, if the prints are invisible, the clay is skinny. The amount of added sand is adjusted according to the properties.

-

Checking clay for lime content. In the oven solution, lime is an unwanted impurity that has a negative effect on the quality of the seam. A piece of freshly dug clay is very carefully cut into two halves. We must use a sharp knife. The cut surface should be as smooth as possible. The cut is left in the shade to dry, and then vinegar or any acid is dripped onto it. If it starts to boil, then the clay has a high percentage of lime, it is better not to use it to prepare the mixture.

It should be understood that in a mixture for laying bricks, clay plays the role of a binder, and sand as a reinforcing agent.

Common Ways to Determine Clay Quality

Common Ways to Determine Clay Quality

Types of masonry mortars

There are several options for masonry mixes. The most commonly used cement-based mortar, which is also called sand-cement. In addition to masonry, it is perfect for rough plastering as well as for concrete floor screed. It all depends on the consistency. A thicker mortar is suitable for masonry, it will not spread during work and will not leave smudges, and the masonry will be even and neat, the bricks will not move.

There are quite a few disadvantages of the cement mortar, the main one is its strength. After drying, the mixture has a high rigidity, during the shrinkage of the structure, in which the frame is made of concrete, or thermal expansion, the masonry can burst, thereby reducing the strength of the structure.

The cement mortar is characterized by low mobility, which is not very well manifested in the process of masonry construction. The mobility of the mixture is determined by the factor of its spreading over the surface under its own weight. Mobility can be reduced or increased by adding components to the mixture. This property allows vertical and horizontal joints to be filled evenly.

Lime mortar, in contrast to cement mortar, is more plastic and warm. But it is much less durable and therefore it is rarely used for laying walls that bear a heavy load, it is more intended for low-rise buildings. It is mainly used in dry rooms. Lime mixtures dry longer, which increases the time from masonry to finishing work. Such solutions are rarely recommended.

Cement-lime mortar is a kind of golden mean. It is quite durable, flexible and warm, which allows it to be used for almost all types of masonry. It is easy to apply, which increases the speed of work. Suitable for building walls in dry and damp rooms. Withstands heavy loads and is suitable as load-bearing structures.

Along with the above, a cement-clay mortar is often used, it sets faster than a cement-lime mortar. Great for use in areas with low temperatures. Possesses sufficient ductility and strength.

In addition, there are ready-made dry mixes on sale that you just need to dilute with water in the right proportions. They have all the necessary properties for different types of masonry. Such mixtures are much easier to use, but their price can be much higher than the cost of the same amount of a solution prepared on our own.

Among the ready-made solutions, you can find colored masonry mixtures. They are intended for decorative masonry, but have a sufficient margin of safety and protect the masonry from damage. Such mixtures are resistant to frost and moisture, as they are often used for cladding buildings. The market offers a large selection of colors and shades of the mixture, it can be easily selected for any need.

A color mixture can serve two purposes. In one of the options, a monochrome shade is required and the mixture should not stand out against the general background of the masonry, therefore it is selected to match the main color of the brick. In another option, it is necessary to highlight the structure of the brickwork and the color of the solution is selected contrasting. In such cases, a white solution is often used. There is an opportunity to choose a color for any need.

There are also heat-resistant mixtures. They are used for laying stoves, fireplaces and chimneys. Such solutions do not deform when heated and do not lose their properties.

Rules for the preparation and application of ready-made mixtures

The advantage of preparing masonry material from ready-made compounds is ease of operation. You will need a capacious container, a mixer or an electric drill with a nozzle. A manual kneading method is also possible, but it requires physical effort. It is advisable to avoid adding too much water, as this will reduce the performance of the composition.

The solution must be prepared in parts as work is done. The mixture is not allowed to freeze, because repeated mixing will disrupt the structure of the raw material.

The manufacturer's recommendations for the proportions of water and dry material must be followed. The volume of the liquid is also affected by the temperature in the room. Less water is required in cooler weather.

To prepare the composition, the dry mixture is poured into warm water. The mass is thoroughly mixed, the raw material should turn out to be creamy. The solution is allowed to brew for 1 hour, then thoroughly mixed again.

Ready-made styling compositions have a high water-holding capacity. When laying, additional moistening of the blocks is not required, which speeds up the work process and shortens the drying time.

The elasticity of the mortar allows making thin seams (2-4 mm). The walls acquire an aesthetic appearance and do not form cracks. When applying heat-resistant raw materials indoors, it is required to maintain a temperature of at least + 10 ° С and not higher than + 35 ° С. The mixture is spread on blocks with a layer of 10-12 mm.

Other options

In this case, you will need to stock up on fireclay sand and refractory clay. Both ingredients are mixed in equal proportions. After that, water is poured in an amount of 1/8 of the total volume of the solution. When the mass becomes homogeneous, it can be used for its intended purpose.

In this case, you will need to stock up on fireclay sand and refractory clay. Both ingredients are mixed in equal proportions. After that, water is poured in an amount of 1/8 of the total volume of the solution. When the mass becomes homogeneous, it can be used for its intended purpose.

It is permissible to make the composition from loams. In this case, you will need to prepare 10 different options for a sample in a small amount. The first is taken:

- 10 parts of loam;

- 1 - cement;

- 1 - sand.

The finished sample is thoroughly kneaded until smooth, gradually adding clean water. It is necessary that as a result there are no lumps left.

Further, from time to time, the proportion of loam is reduced, but the sand content is increased by the same volume. In the last portion of the first, you need to leave 1 scoop, and the content of the second will grow to 10.

The finished samples are placed in separate boxes and left for a week. When time passes, they are examined. The composition is suitable for the furnace:

- containing a maximum of clay;

- not cracked.

It will absolutely calmly withstand heating and up to 600 degrees, without deforming or crumbling.

Preparation of masonry mortars

Since various types of mixtures can be used for the masonry composition, we will consider in more detail how to prepare a mortar for laying bricks.

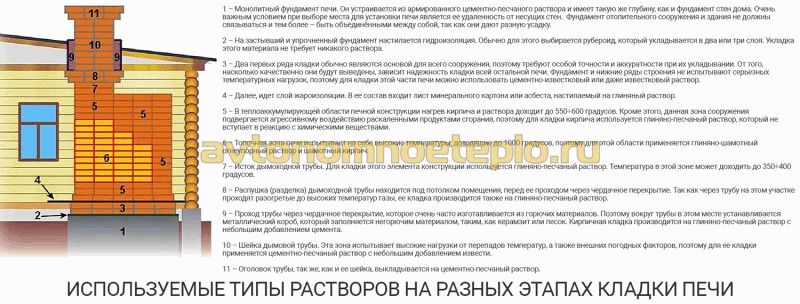

Cement slurry proportions

Sand-cement compositions are widespread in capital construction and other areas where increased requirements are imposed on the strength characteristics of brickwork.

Before preparing a masonry mortar, it should be remembered that an excess of cement in the working mixture does not increase its strength, and in some cases even worsens its characteristics. Only strict adherence to the dosage will ensure the optimal performance of the masonry mixture. The proportions of the most common cement-based compositions are given in SP 82-101-98, which clearly regulates the percentage of ingredients in various types of cement masonry mixtures.

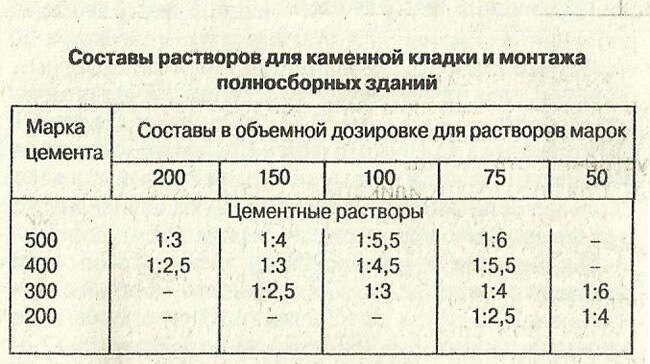

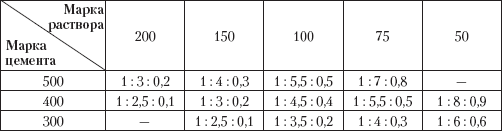

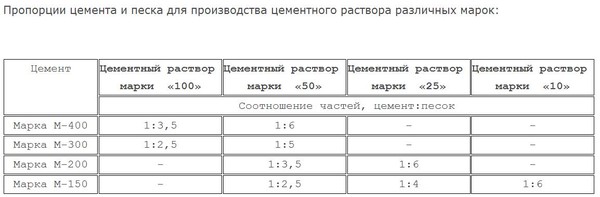

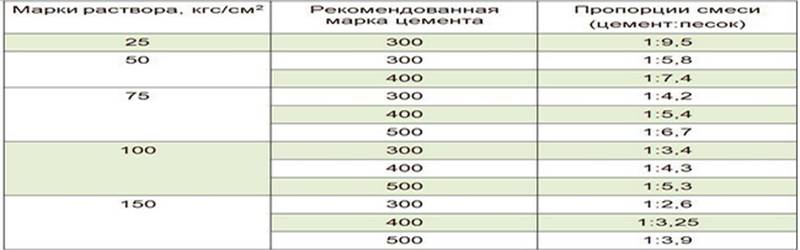

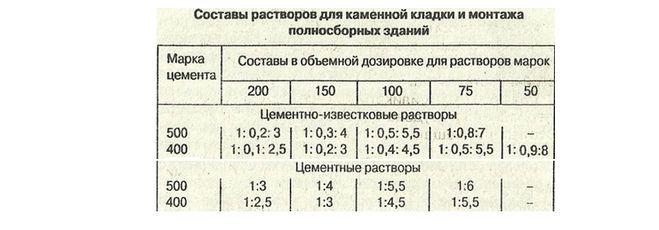

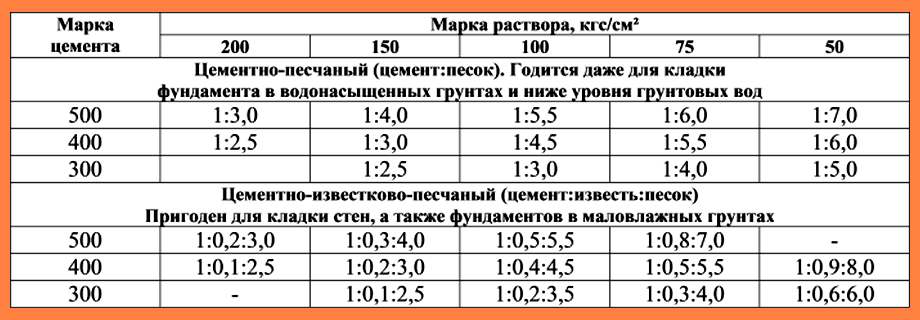

The table shows the percentage of ingredients in the masonry mortar, depending on the grade of cement used.

|

Masonry mixture brand |

Cement grade |

Ratio cement / sand |

|

M25 |

M300 |

1/9,5 |

|

M50 |

M300 |

1/5,8 |

|

M400 |

1/7,4 |

|

|

M 75 |

M 300 |

1/4,2 |

|

M 400 |

1/5,4 |

|

|

M 500 |

1/6,7 |

|

|

M 100 |

M 300 |

1/3,4 |

|

M 400 |

1/4,3 |

|

|

M 500 |

1/5,3 |

|

|

M 150 |

M 300 |

1/2,6 |

|

M 400 |

1,3,25 |

|

|

M 500 |

1/3,9 |

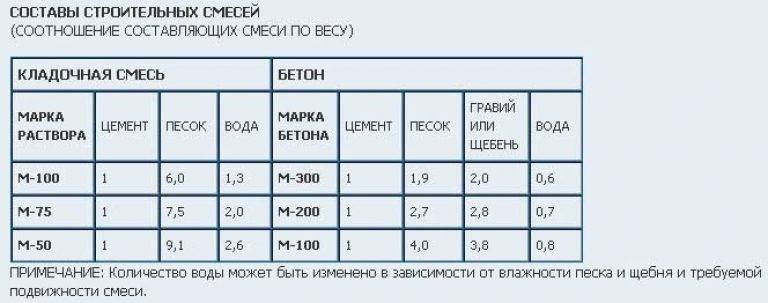

Scope of application of cement mortar, depending on the strength characteristics

Below is the scope of application of various grades of masonry mortars.

- M25. Used for plastering and floor screed. The composition does not contain any additional ingredients.

- M 50. It is used for brick and masonry in the construction of low-rise buildings and structures. May contain plasticizers, colorants and other additives.

- M 75. It is used for laying concrete slabs, installing reinforced concrete structures, erecting internal partitions and installing a concrete floor screed.

- M 100. It is widely used in monolithic construction, masonry work and pouring lightly loaded strip foundations.

- M 150. It is mainly used for foundation work on loose soils.

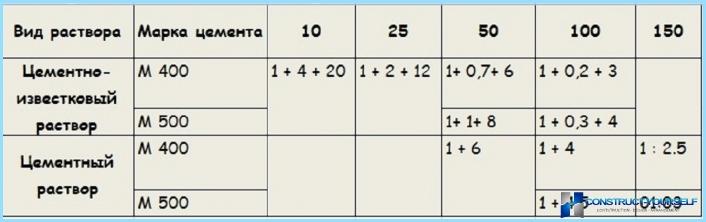

Proportions of cement-lime mortar

The percentage of cement, lime and sand in the cement-lime mortar is shown in the table.

|

Cement / lime / sand ratio |

|||||

|

Cement grade |

Masonry mix M 50 |

Masonry mix M 75 |

Masonry mix M 100 |

Masonry mix M 150 |

Masonry mix M 200 |

|

M 300 |

1/0,6/8 |

1/0,3/4 |

1/0,2/3,5 |

1/0,1/2,5 |

|

|

M 400 |

1/0,9/8 |

1/0,5/5,5 |

1/0,4/4,5 |

1/0,2/3 |

1/0,1/2,5 |

|

M 500 |

1/0,8/7 |

1/0,5/5,5 |

1/0,3/4 |

1/0,2/3 |

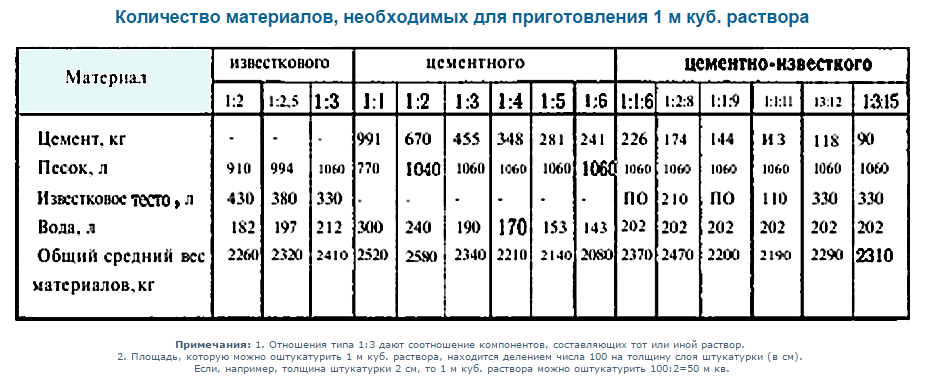

The solution is prepared in the following sequence:

- Lime-fluff is diluted to the consistency of kefir, after which it is filtered.

- A dry sand-cement mixture is prepared separately.

- The strained lime is added to the cement-sand mixture and thoroughly mixed until a homogeneous mass is obtained.

Proportions of cement-clay mortar

The ratio of cement, clay and sand in the cement-clay masonry mixture is shown in the table.

|

Masonry mixture brand |

Cement M 500 |

Cement M 400 |

Cement M 300 |

|

Cement / clay / sand ratio |

|||

|

M 300 |

1/0,15/2,1 |

1/0,07/1,8 |

|

|

M 200 |

1/0,2/3 |

1/0,1/2,5 |

|

|

M 150 |

1/0,3/4 |

1/0,2/3 |

1/0,1/2,5 |

|

M 100 |

1/0,5/5,5 |

1/0,4/4,5 |

1/0,2/3,5 |

|

M 75 |

1/0,8/7 |

1/0,5/5,5 |

1/0,3/4 |

|

M 50 |

1/0,9/8 |

1/0,6/6 |

|

|

M 25 |

1/1,4/10,5 |

The addition of clay increases the moisture retention capacity of the masonry mix.

The low strength of the lime mortar prevents its widespread use in masonry work. Most often, lime mixtures are used for plastering work. The proportions of the working solution depend primarily on the fat content of the lime and can range from 1/2 to 1/5.

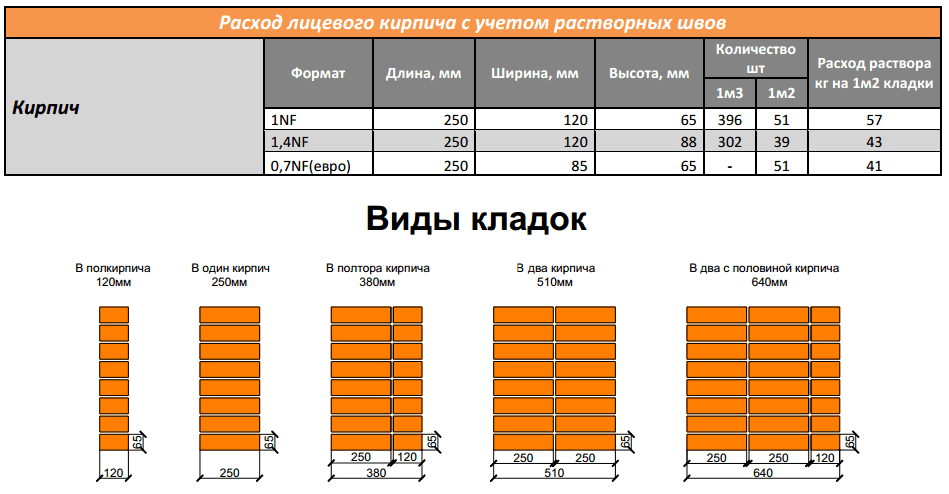

Composition and proportions

The proportions of any type of solution are calculated based on the load that will fall on them. The composition of the cement slurry includes cement and, as a rule, quarry sand. It initially contains a small percentage of clay, which adds plasticity to the solution. For these purposes, river sand is not suitable due to its coarse fraction and a large amount of impurities - it has to be carefully filtered. Cement acts as a binding element, the more of it, the stronger the result will be after drying. This is also influenced by the brand and freshness of the cement. Over time, unused cement tends to deteriorate.

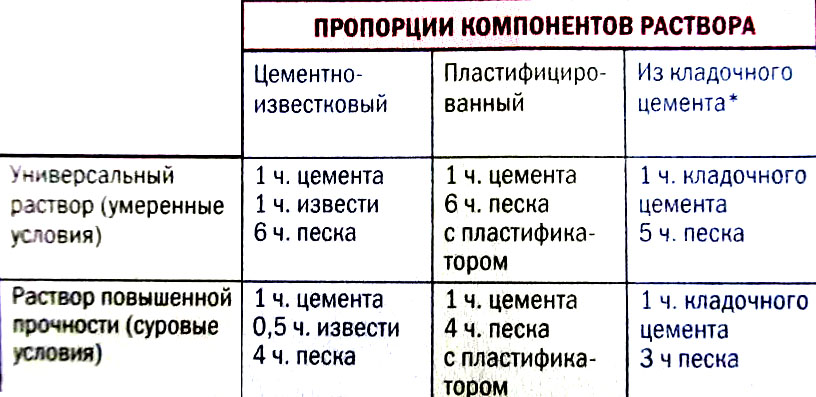

For masonry, the ratio of cement to sand should be 1/3. Since the mortar is suitable not only for masonry, the proportion can vary from 1/3 to 1/6, depending on the type of work.

Cement-lime mortars consist of cement, hydrated lime, sand and water. As a rule, the proportions are 1/1/6 (cement, lime and sand). The recipe for such a solution is quite simple, it is prepared according to the same principle as lime. Such solutions can be used for plastering work.

The composition of the finished masonry mortar can be different depending on the type of material from which the brick is made. Basically, it consists of a binder, which can be cement or lime, as well as a filler and a plasticizer - they are most often sand and clay. In some cases, the composition of the mixtures may contain special additives to increase the drying rate or frost-resistant for work at low temperatures.

The proportions, as a rule, are indicated on the package in the ratio of water to the mixture itself. In the production of such mixtures, all ingredients are brought to a homogeneous mass, ground and packaged in packages. The consumer can only follow the instructions.

To obtain colored solutions, the necessary mineral pigment is added to the mixture. They are not subject to fading. The mixture can be colored on request. Otherwise, these solutions differ from the previous ones only in their cost.

Heat-resistant mixtures are created on the basis of cement, lime or clay. In some cases, the base may be gypsum. They have a number of special additives, the cost of which may be too high for self-preparation of the solution.

Due to the high cost of ready-made mixtures, the task often arises to prepare them yourself. for heat-resistant solutions, the components can be sand and clay. The clay is resistant to high temperatures. The main criterion is its fat content, the use of non-greasy clay is contraindicated, the excess of fat content can be compensated for with sand. From this type of mixture, the body of the furnace should be laid out. Facing is best done with a cement-based or lime-based mortar. The use of colored masonry mixture is allowed.

Quality control and readiness

Several techniques and methods are used to determine the quality and readiness of the solution. The easiest is manual and visual. When using the second method, it is evaluated how well the prepared composition adheres to the brick and its fluidity.

A small dent is made in the composition and, if it is preserved, the mixture is considered ready for use. In addition, a small container with a solution is tilted forty-five degrees, and the mobility is checked. A properly prepared mixture should not leak out of the container.

From special means, a cone with dimensions in height and circumference of fifteen centimeters is used, while its weight should be three hundred grams. The cone is lowered into the composition under its own weight and the penetration depth is controlled.

Depending on the type of composition, the cone sinks to a certain depth. For a mortar on which a full brick is placed, it is about ten centimeters. If a composition is being prepared for a hollow brick, then the cone should be immersed in it by no more than seven, eight centimeters.

Testing cone for mortar or concrete

It is worth noting that when preparing masonry mixtures, it is necessary to strive for optimal proportions, especially the water contained in the solution. If the amount is insufficient, the solution will turn out to be dry, which will reduce its adhesion to building materials.

Excess moisture will lead to spreading of the mixture over the surface of the brick and that, as a result, will give a poor-quality seam. The mobility of the solution also depends on the fraction of the sand used - the coarser the sand, the more mobile the mixture.If, when scooping, the solution sticks to the trowel, then it is necessary to add dry components and mix the mixture again.

About solution

The clay-based composition is mainly used for the construction of stoves in a private house. Its properties make it possible to ensure the strength and durability of the masonry.

In the bath, it is unacceptable to build a base (and even more so a chimney) on this masonry mixture. It is much better to use a solution here:

- lime;

- cement-sand.

Neither one nor the other is afraid of condensation, which usually forms on these elements of the furnace.

It depends on it as a result:

- plastic;

- the degree of final shrinkage;

- high temperature resistance;

- the strength of the entire masonry.

In total, experts distinguish between three types of solution:

- skinny is very fragile and has low plasticity - when it dries, it often cracks;

- oily - pliable, but after hardening it may begin to crumble;

- normal - ideal for masonry.

The latter variety has the following properties:

- does not give significant shrinkage;

- withstands strong heat;

- have excellent plasticity.

It is a pleasure to work with him. Using a normal solution, the oven can be easily folded even by an inexperienced master.

How to choose quality clay

Fireclay clay called "Kaolin" and ready-made mixtures are sold in hardware stores. There are good reviews both about Russian and foreign manufacturers of this heat-resistant material. The best is considered to be chamotte produced at enterprises in Western Europe.

When choosing materials, pay attention to the year of production and its quality. High-quality mixture and clay do not contain particles exceeding the size of the fraction indicated on the package

The mixture for the preparation of the solution should not contain crushed stone or sand with a size of more than 2.5 mm.

The letter "U" on the package says that the fireclay is made of recycled material. The letter "Ш" says that the material has not been recycled, it is better suited for laying the firebox.

Building materials are stored in specially equipped warehouses. If chamotte is stored in a dry room, in sealed bags, at temperatures from plus 40 to minus 40 degrees, then the shelf life of mixtures and clays is not limited. Long-term storage (more than three years) in high humidity conditions will lead to deterioration of the material properties due to moisture saturation.

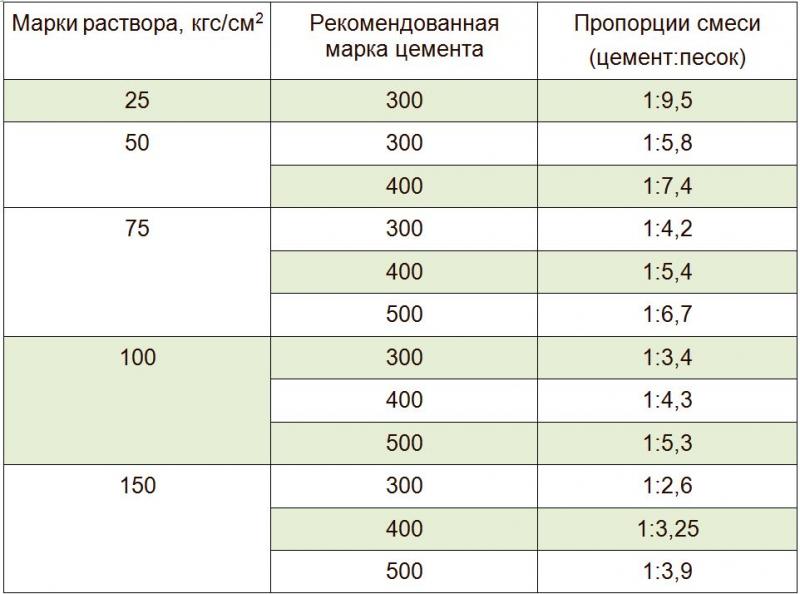

Features of the construction of the furnace, affecting the choice of solution

During the construction of furnace structures, there are peculiarities that affect the choice of a particular solution. Let's consider in more detail each stage of the construction of the structure:

- The foundation is the base of the furnace, in the event of a malfunction of which, it becomes necessary to re-lay the entire furnace structure. During the operation of the furnace, the foundation practically does not experience thermal loads, therefore, a sand-cement or cement-lime mix is suitable for its construction. If the structure has large dimensions, you can simply use a lime mortar for masonry.

- The heat storage part of the furnace structure, its heating reaches 700 degrees, and it is also exposed to the chemical influence of flue gases, with the precipitation of acid condensate. For the construction of this site, ordinary clay mortar is used, the quality of which has been tested for centuries.

- A brazier or furnace firebox can heat up to 1200 degrees. It is recommended to use a clay-chamotte, refractory masonry mixture.

- The chimney source is heated up to 300-400 degrees, allowing the use of clay mortar.

- The chimney fluff is the connecting link between the chimney and the ceiling. The edges of the overlap in this place rest on the fluff, thereby preventing it from sinking. In this area, increased strength is required, which is achieved when using clay-lime or simply lime mortar.

- Special requirements are imposed on the construction of a chimney above the roof covering, since this area is exposed not only to internal thermal effects, but also to external atmospheric loads and temperature changes. The best option would be to use a lime mortar.

Cement mortar for brickwork

Stove-makers use it for the foundation and chimney that rises above the roof. Such masonry does not get wet from water. Cement has increased strength, it is not afraid of not only atmospheric, but also soil moisture that appears at the base of the house during long rains and melting snows.

Photo 1. Pouring the foundation for the construction of the kiln using cement.

Composition

Several brands of Portland cement are suitable for preparing the mixture: M 300, M 400, M 500. Cement is sold in bags of 25 and 50 kg, after purchase it is mixed with sand. For work, take only fine-grained sand with a particle diameter of 1.5 mm or less. The sand collected from the quarry requires cleaning, which includes the following steps:

- Manual sampling of large stones, crushed stone, pebbles, plant residues and roots.

- Sifting the material through a metal sieve with a mesh diameter of 1.5 mm.

- Sand washing. For this procedure, a net is made from a linen burlap stretched over a frame. A small amount of raw materials is put into it and poured with water from a hose, which is supplied under pressure. Dust and clay particles come out of the material. Rinsing is continued until the water is clear.

Reference. For the preparation of the masonry mixture, quartz sand or sand of a mixed composition (containing quartz, feldspars, and other hard minerals) is suitable.

Manufacturing: procedure and proportions

The composition of the masonry mixture, in addition to cement, includes sand and water. For work, you need a large container (tank, trough, bath). In order to knead the ingredients, you need a wooden or metal spatula, a construction mixer. Large volumes of cement, sand and water are prepared in a concrete mixer. For different brands of cement, different amounts of sand are used:

- 1 measure of cement M 500 and 3 measures of sand;

- 1 measure of cement M 400 or M 300 and 2.5 measures of sand.

Chamotte sand and chamotte crushed stone are needed for the preparation of mixtures with increased heat resistance. Similar solutions are used in the laying of the bottom of the combustion chamber and the walls of the furnace. The mixtures include:

- cement grades M 300 or M 400 - 1 measure;

- fine-grained sand and broken brick (chamotte crushed stone) - 2 measures;

- 0.3-0.5 measures of chamotte or ordinary sand.

Stoves use tap, melt, river or spring water. It should be "soft", the high content of mineral salts will lead to the fact that white traces and streaks will appear on the walls and chimney after drying the masonry. They also appear on the chimney after heavy rains.

The procedure for preparing a cement-sand mortar:

- The calculated amount of cement and sand is poured into the container.

- Mix the ingredients with a spatula.

- Water is poured into the mixture, the mass is mixed in a concrete mixer or a construction mixer. Manual mixing with a spatula is allowed if the volume of the solution is small.

When choosing materials, you should focus on their quality. Caked, lumpy, long-stored cement, not sifted and unwashed sand are not suitable for mixing.

What to do if the mixture is dry

After hardening, the cement paste resembles natural stone in strength. It cannot be dissolved with water or chemicals. When the mixture hardens, water enters the structure of the cement and gives it high strength.

If the solidified mass is broken and ground, you get a powder similar to the original cement from the factory packaging. "Reclaimed" material loses its quality and becomes unsuitable for such important work as laying the base and chimney of the stove.

For the complete recovery of cement with the removal of bound water, special plant equipment is required.This process takes place at a high temperature, and it is impossible to carry out it yourself at home.

Important! At an air temperature of 20 degrees, the cement begins to "set" in 2 hours. At a temperature of 30 degrees, the mass hardens faster (in 1-1.5 hours)

The mixture is too thin or too thick

If the cement-sand mass is too thick, add water to the container in small portions and mix the contents. If there is a lot of water in the mixture, it is made thicker by adding calculated portions of dry cement and sand (for example, 1 measure of cement and 3 measures of sand are added at the same time).

Reference. The quality of the cement-sand paste is checked using a trowel. A properly made solution does not run off and does not fall in pieces from its working surface when tilted at 45 degrees.

Building compounds made with cement and water cannot be stored. Intensive stirring helps to slow down the hardening process.