Installation calculation

The choice of a dowel is not easy. In order for the fastening to be reliable and of high quality, it is necessary to take into account the base material, its structure, the weight of the structure to be mounted, and its features. Fixing products with a large weight requires the selection of hardware with a fixing depth of at least 8.5 cm.

Lightweight items - wall cabinets in the bathroom, decorative shelves, wall clocks - can be fastened using expansion dowels with a diameter of 7 mm and a length of 3 cm.

For the installation of heavy suspended ceiling structures - multi-tiered chandeliers, massive bronze lamps - you should choose fasteners with transverse notches and spacer antennae

In this case, it is important to observe the correspondence of the diameters of the hole and the hardware itself. For working with drywall, screw drilled models are most suitable.

A metal crocodile dowel is chosen for mounting structures to load-bearing bases made of aerated concrete, foam concrete and other porous materials.

For the installation of heat and waterproofing, manufacturers offer a dowel-stud with a disc head - the features of its head attach the insulating material more tightly and neatly, without the risk of damage

Such products with metal nails are able to withstand a lot of weight, but in the open air they are easily corroded, so it is better to choose the option with a thermal cover.

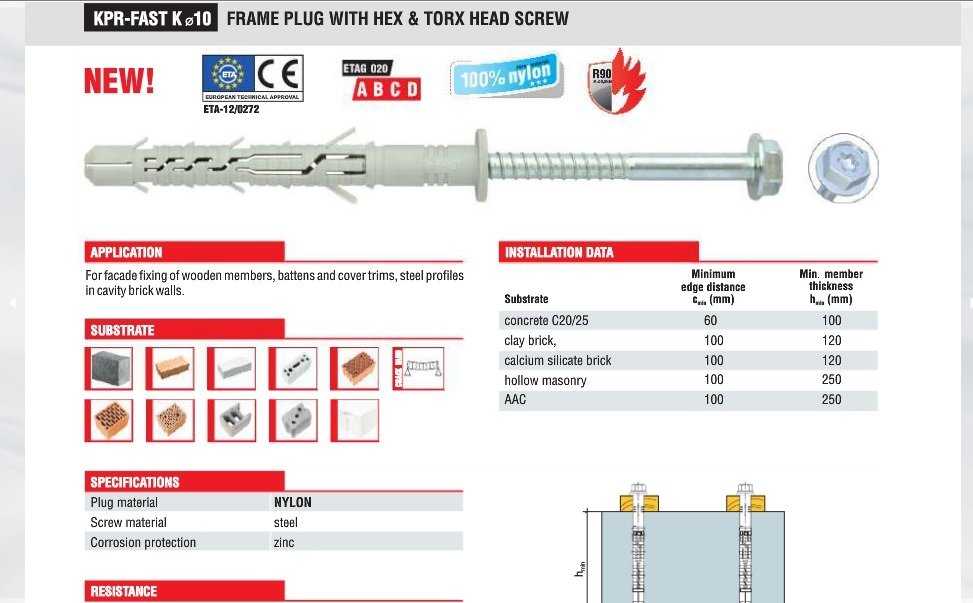

For the installation of brackets or facade profiles, lathing, facade models are selected.

For fixing electrical wires and cables, manufacturers offer the best option in the form of a dowel-clamp. The loop of the clamp firmly grips the wire, and its serrated ends securely fix the entire system to the supporting surface. Excellent replacement for nails and other fixing devices.

Technology

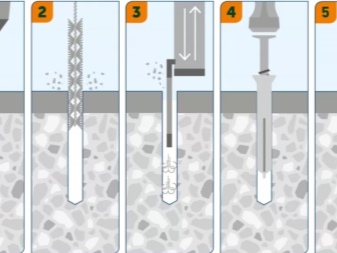

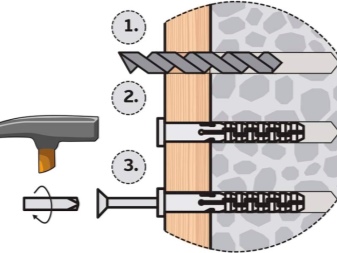

For the correct use of spacer hardware, you need tools, adherence to technology and an algorithm of actions. In addition to the fasteners themselves, it is necessary to prepare electrical tape, a sharp-pointed tool (nail or knife), a hammer and an electric drill with a victorious drill, a screwdriver or screwdriver, a hair dryer or a vacuum cleaner.

On the surface, mark the installation location of the dowel, put a mark with a pencil. Then a small depression is made with a nail, the tip of a knife or other pointed object.

They check the correspondence of the diameter of the drill and the dowel - ideal when the dowel is inserted by force into the prepared socket.

On the drill itself, a piece of electrical tape marks the desired depth of the future hole, a little more than the length of the dowel itself.

A hole is drilled, while the drill should be in a perpendicular position with respect to the bearing surface.

The resulting hole must be free of dust and debris.

It is blown out with a hair dryer or vacuum cleaner.

The hardware is inserted all the way, while it is necessary to exercise the utmost care and accuracy so as not to damage the fastening device.

After that, a screw is screwed into the dowel, a self-tapping screw with a screwdriver or manually - using a screwdriver.

The following video provides an overview of the best wall plugs.

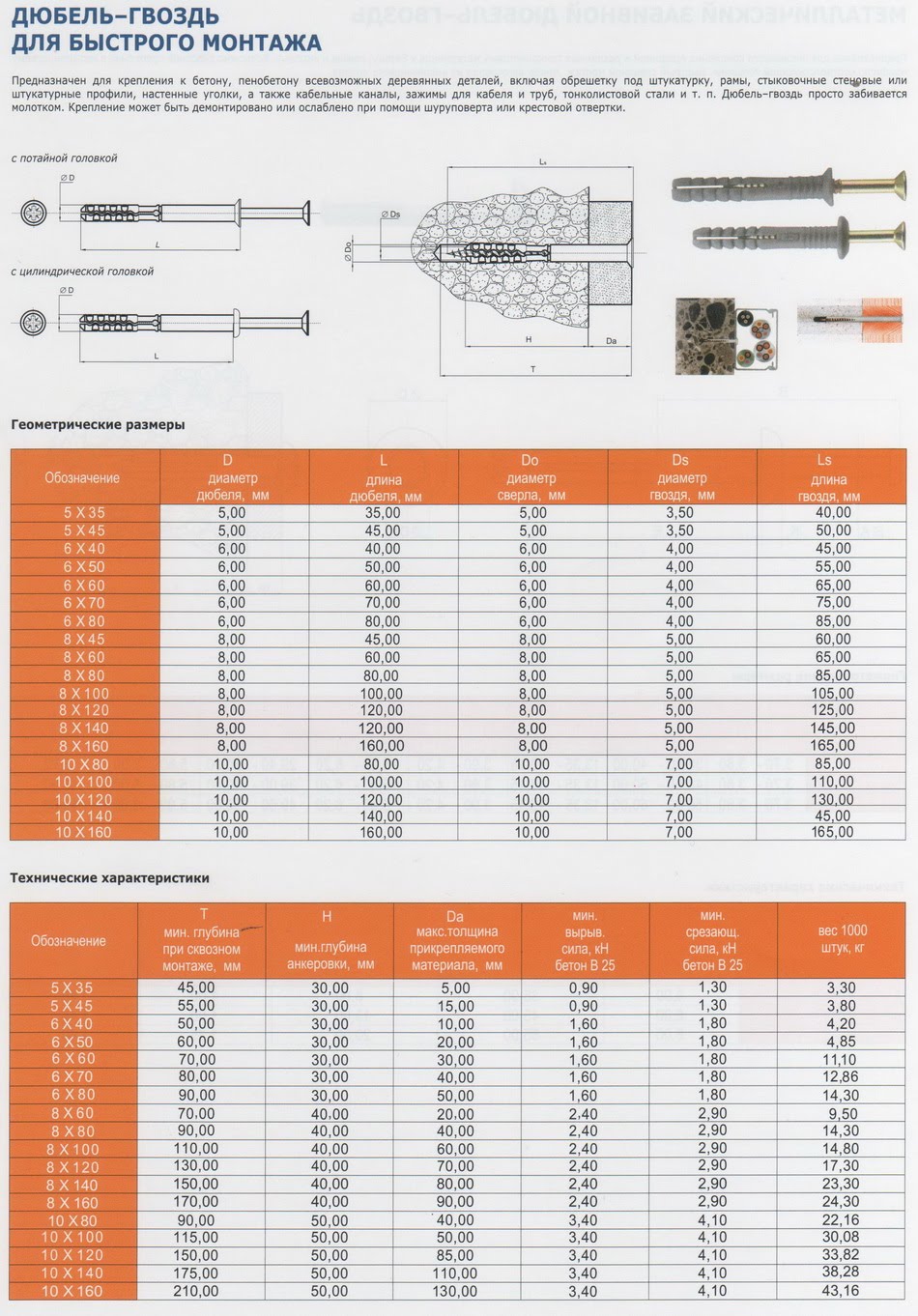

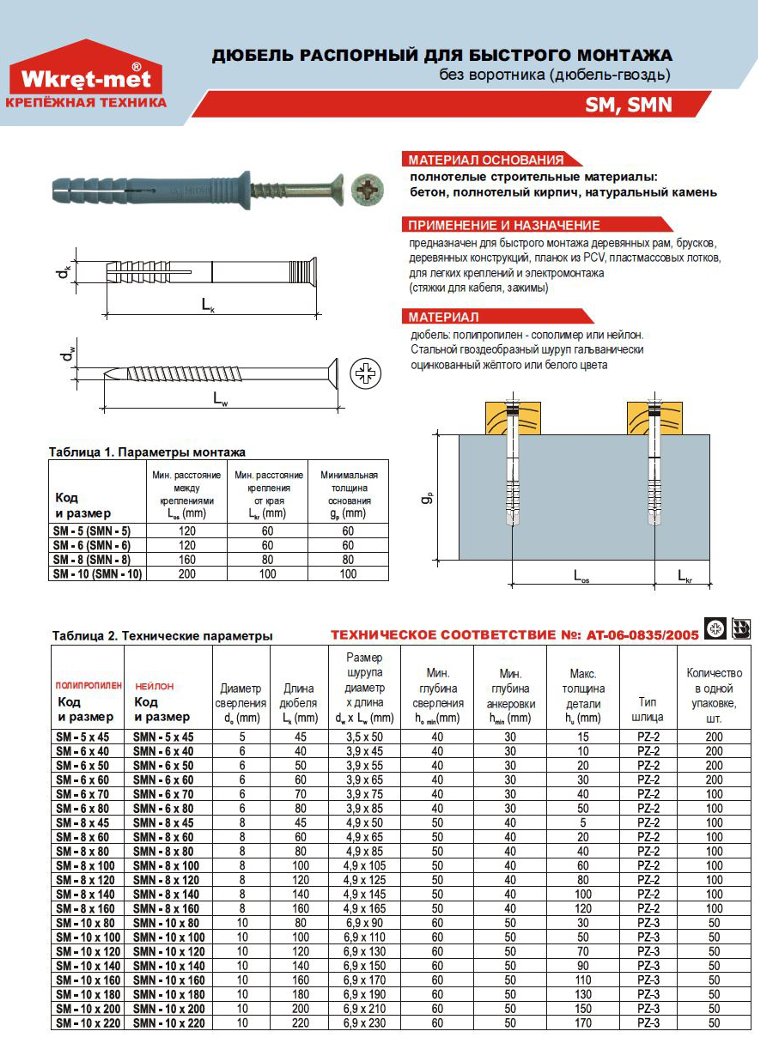

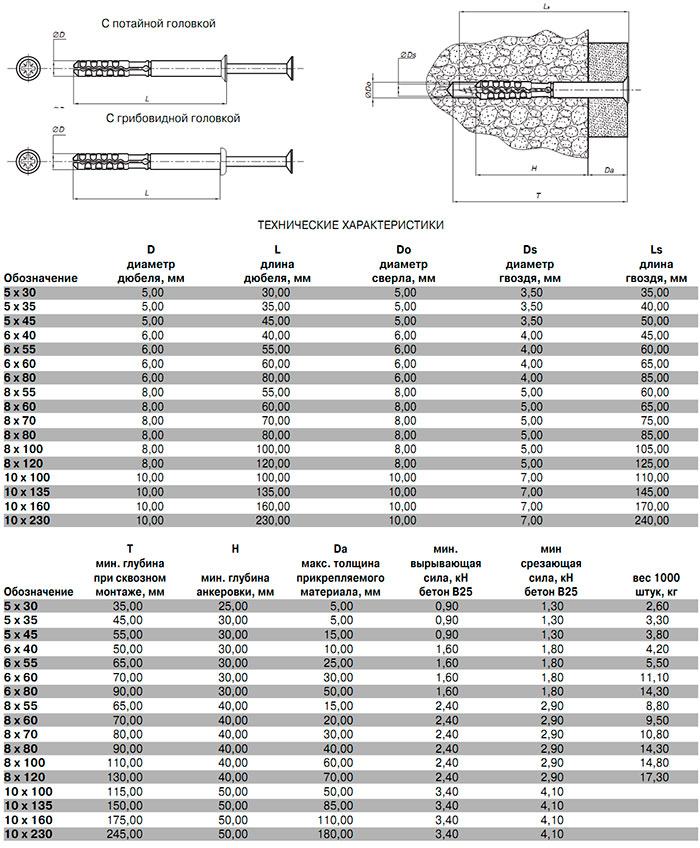

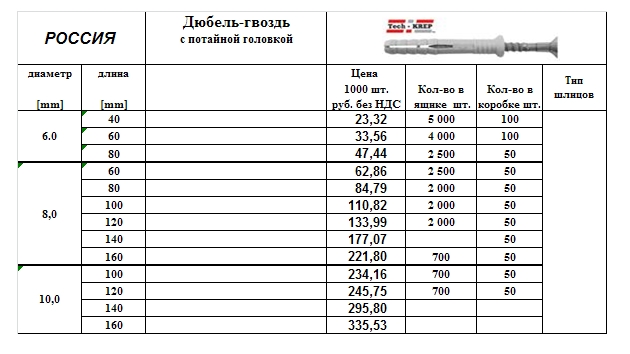

Dimensions (edit)

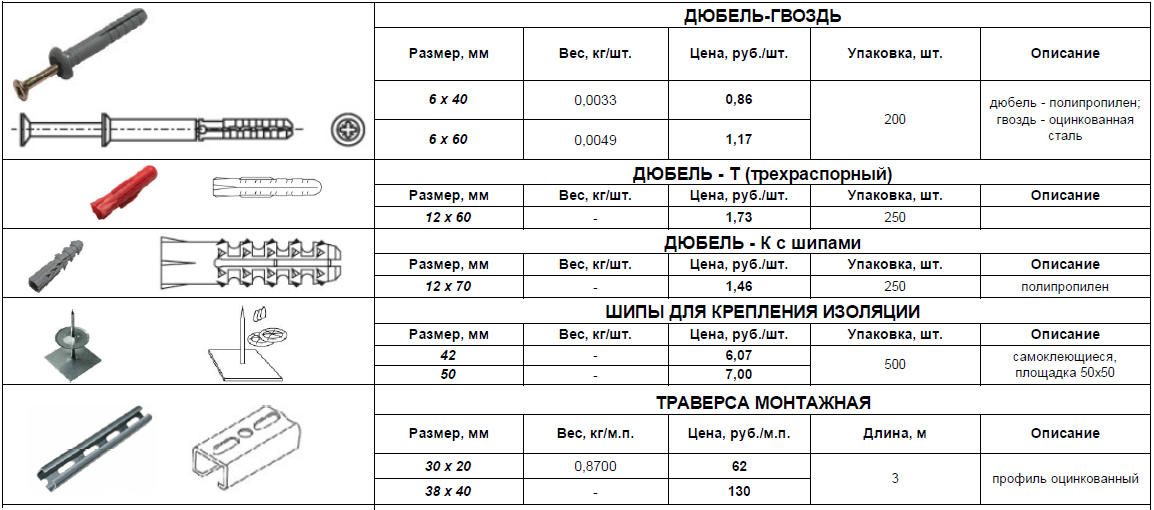

The size of the dowel is the diameter or width of the product and the length. A wide range of spacer models offers several lengths - from three or more options. The most popular sizes are 6x30, 10x50 and 6x37, the diameter of the dowel should correspond to the diameter of the hole.

-

Four-spaced dowels are used for working with solid bases, they have sizes from 5x25 to 20x100. The greatest demand among them are 6x35, 6x50, 8x80, 10x100.

-

Polypropylene, plastic universal models have dimensions 5x32, 6x37, 6x42, 6x52, 8x52, 8x72, 10x61, 12x71.

-

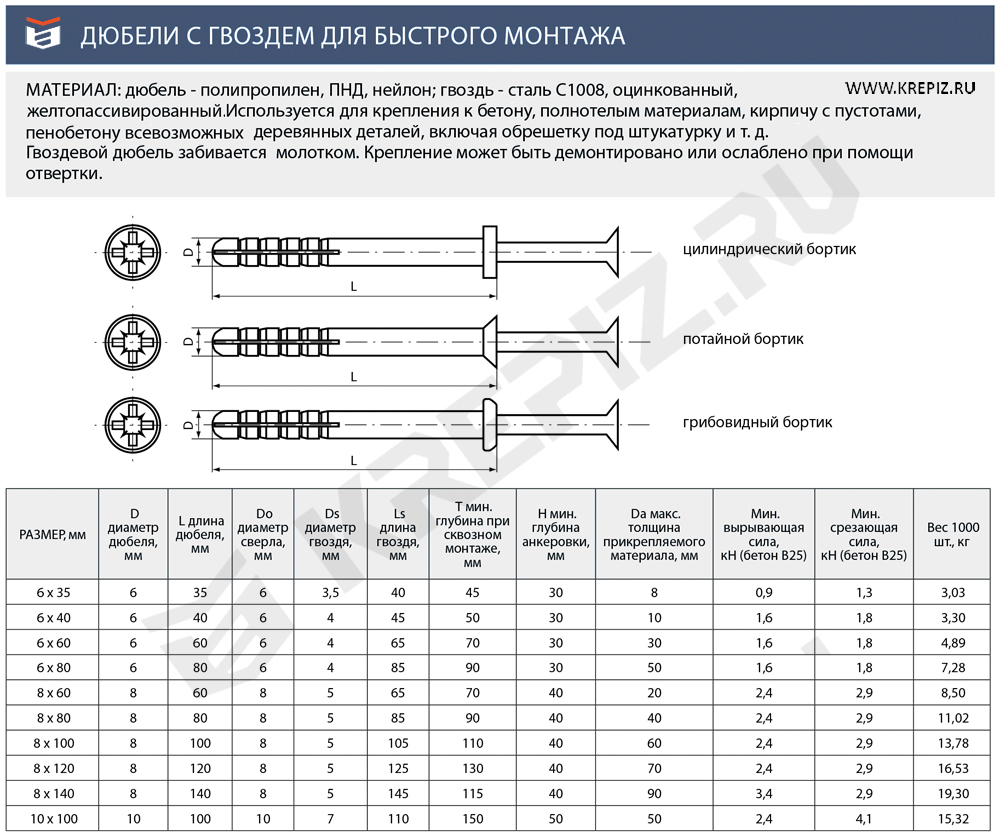

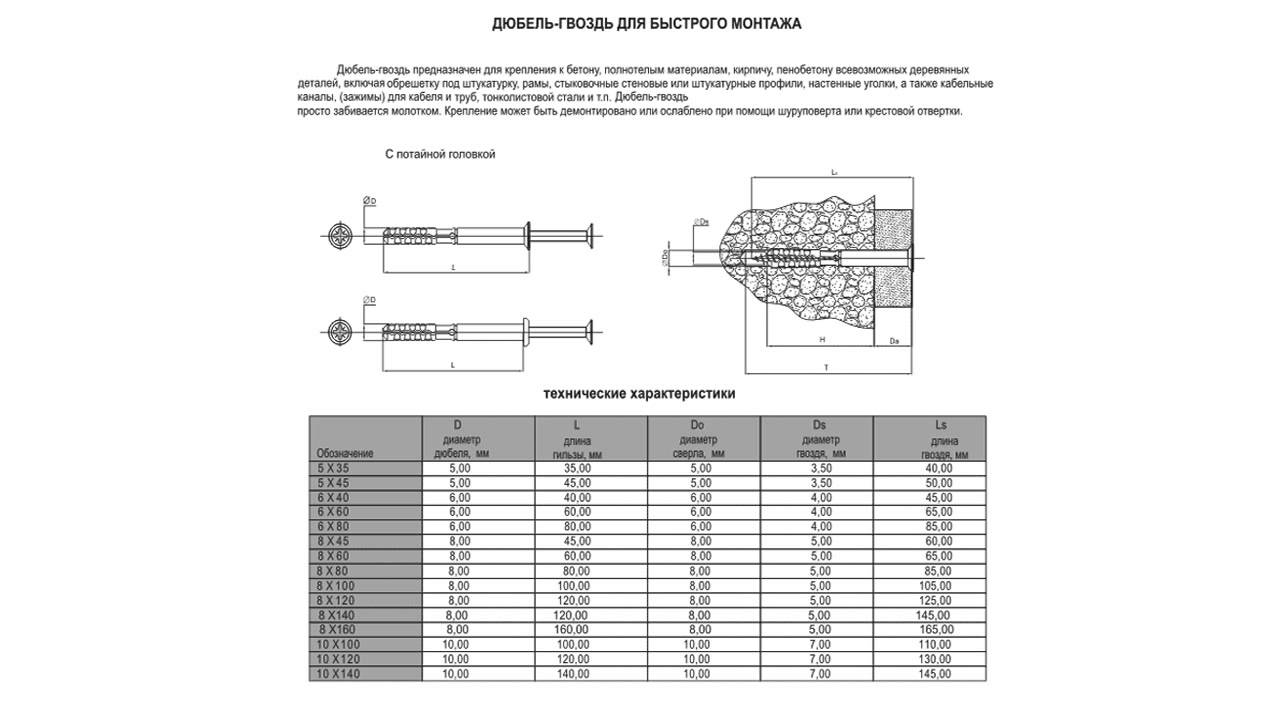

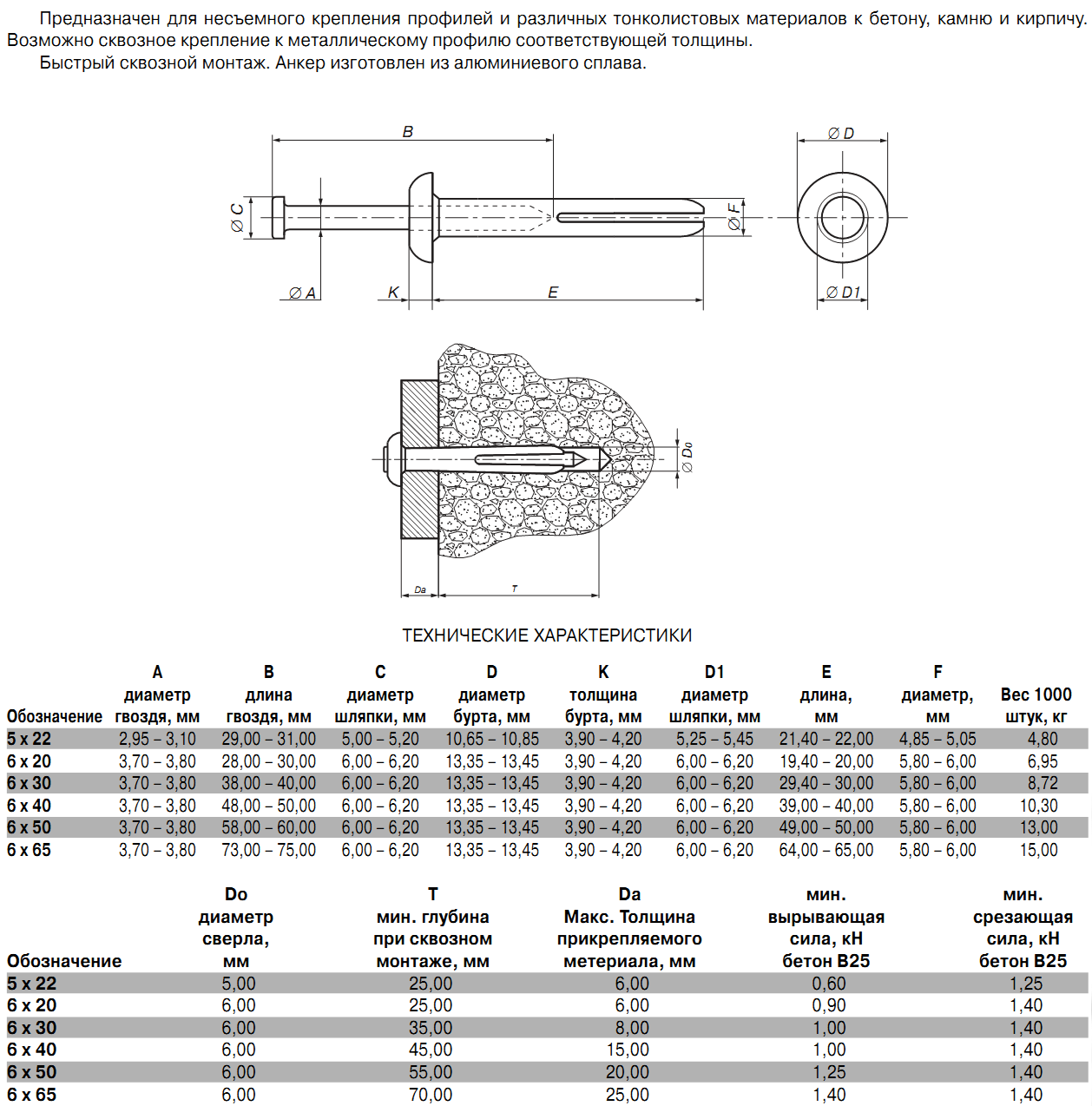

Dowel-nails for working with concrete, stone, brick - 6x30, 6x40, 6x50, 6x60, 6x65, 8x50.

-

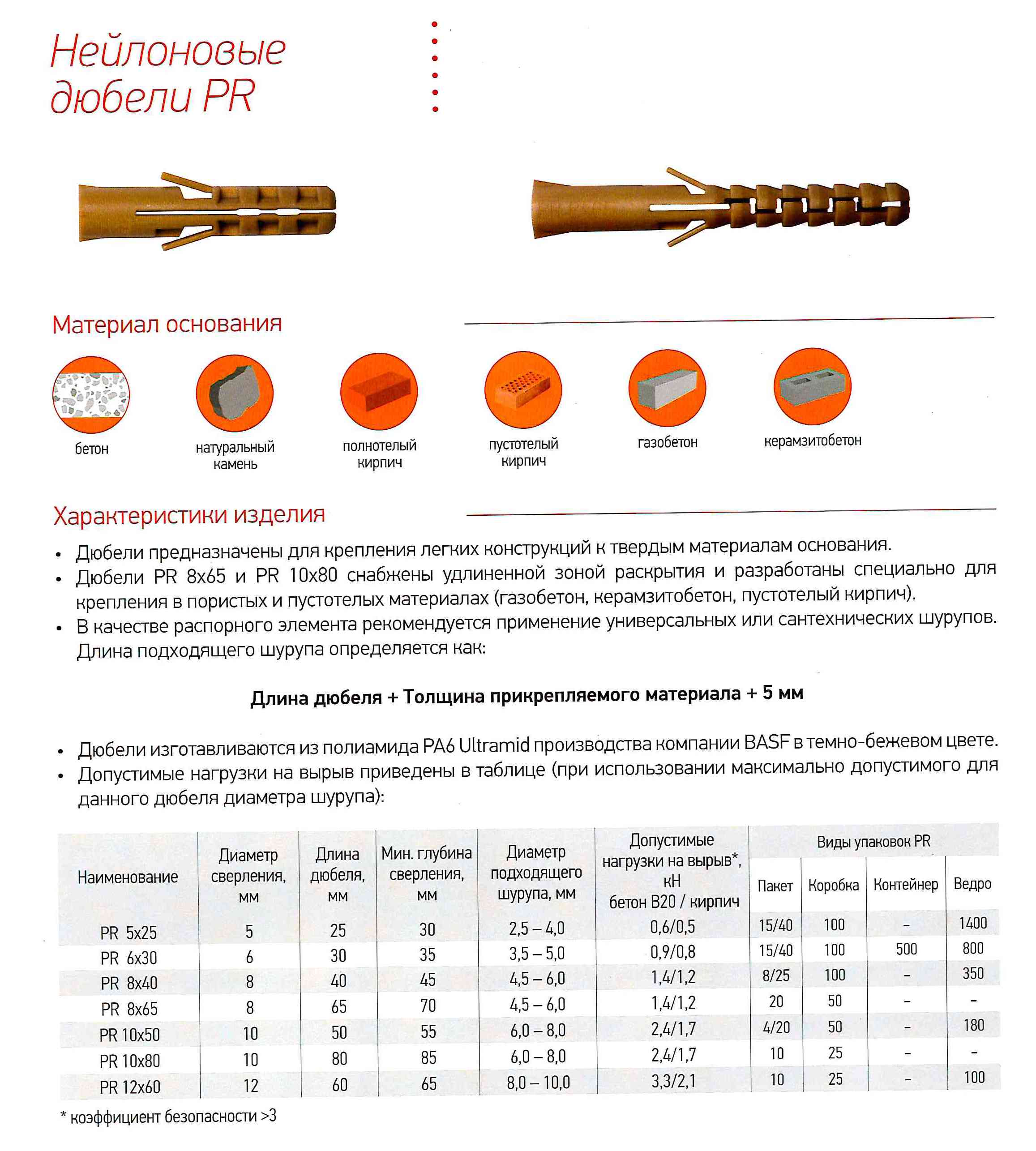

Nylon for facade work - from 8x100 to 10x100.

-

Dowel-stud, with the help of which lightweight structures are fastened, as well as all types of thermal insulation - 4x8x45, 10x50, 10x80, 10x90, 10x100 and up to 10x300.

-

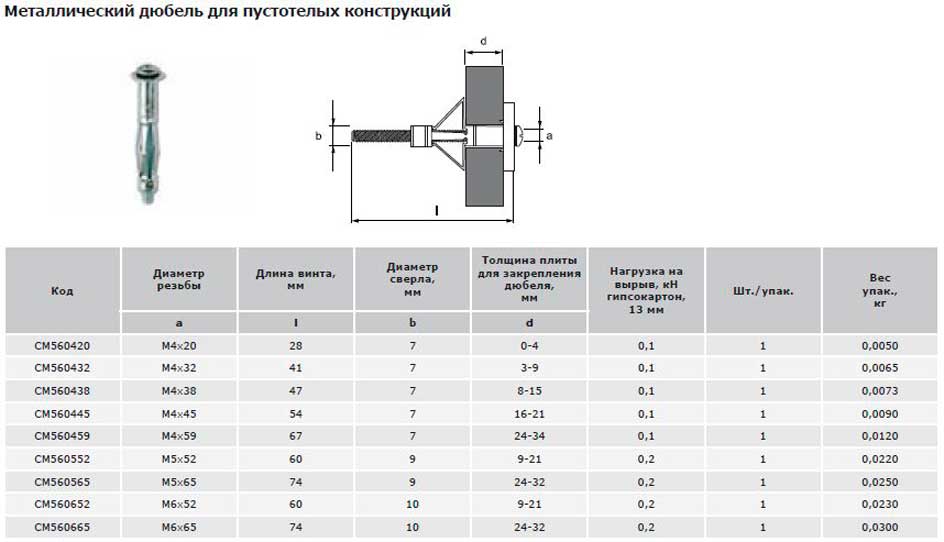

Metal dowel-crocodile, used in work with aerated concrete and other porous bases - from 8x30 to 10x60.

-

Screw drilled nylon or metal hardware offer sizes 4.8x45, 8x55, 14x80, 10x60.

-

The dowel-nail is produced in the following sizes: 4x40, 4.5x30, 4.5x40, 4.5x50, 4.5x60, 5x40.

About dowels

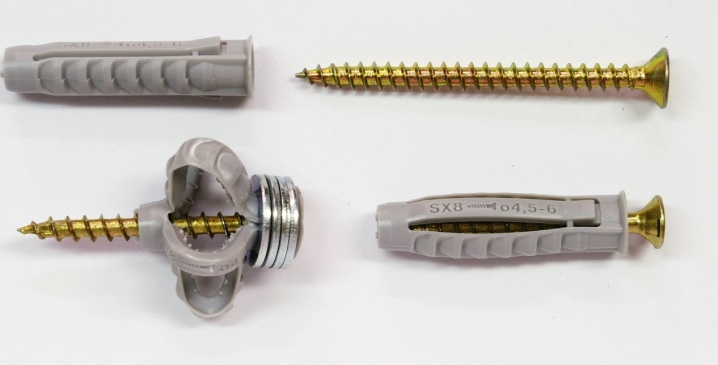

The dowel is a fastening element designed for fastening various building structures, insulation, cladding materials to the surface of various types of walls. Dowels are used when the free end of the rod (screw, anchor) is not accessible for the installation tool. The dowel is driven into the wall or the main part, a screw is screwed into it, while the dowel expands and it is impossible to remove it. Today the dowel is a versatile and popular fastener.

Dowels come in various designs and are made from different materials.

All dowels can be conditionally divided into two groups:

1. Dowels for monolithic (without voids) bases - have a spacer principle of operation.

2. Dowels for hollow bases - have an anchor principle of operation.

Dowel classification:

Standard nylon plugs: The plugs fit any wall and can be used with screws from 2 to 16 mm in diameter.

A hole is drilled in the wall, corresponding to the diameter of the dowel, in which it is held by the antennae directed backwards, and when wedged with a screw, it is "firmly" pressed into the walls of the hole with its large teeth.

Dowels for aerated concrete: A hole is drilled for such a dowel, corresponding to the diameter of its core. It is driven into the hole with hammer blows, and at the base it is held by spiral ribs and wedging under the action of a screw.

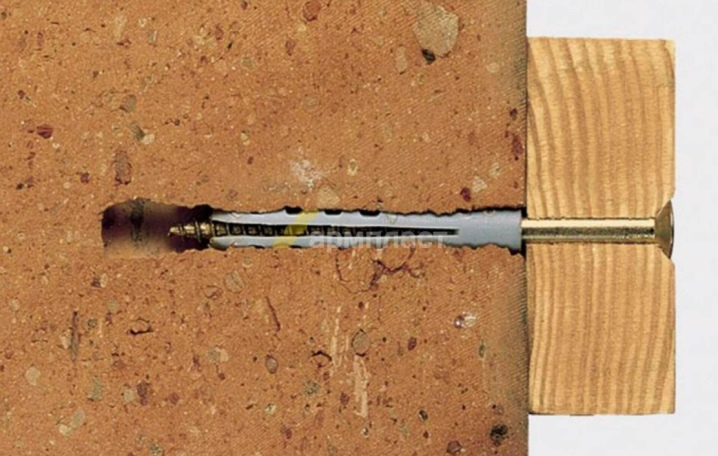

Frame dowels: 60 to 360 mm long. There are two main types - for solid solid substrates and for soft and hollow (slotted) materials. The elongated spacer part ensures that the dowel engages several lintels in the base with voids at once. They are used for fastening window and door frames, as well as cladding elements through a layer of plaster, thermal insulation.

Distance dowels (adjustment): fix the battens under the sheathing at some distance from the wall. They allow you to adjust the position of the battens of the lathing relative to the base in the range from 0 to 30 mm during their installation due to a dowel and a screw of a special design divided into two parts (one for the base, the other for the rail).

Universal: when fixing objects to a hollow base, they "determine" the presence of a hollow space. In the cavity, the dowel bulges out and is thus fixed in it. When attached to a solid brick or concrete base, it, unclenching, comes into close contact with the walls of the hole. Dowels with spring-loaded flap bars: for attaching objects to hollow partitions and false ceilings, for example, for hanging chandeliers. The dowel strips, passing through the hole into the cavity behind the casing, open under the action of the spring and abut against the inner surface of the casing.

Metal: for thin-walled hollow structures, they are able to withstand rather heavy loads.

When the screw is screwed in, the dowel plates bulge in all directions and press against the inner supporting surface.

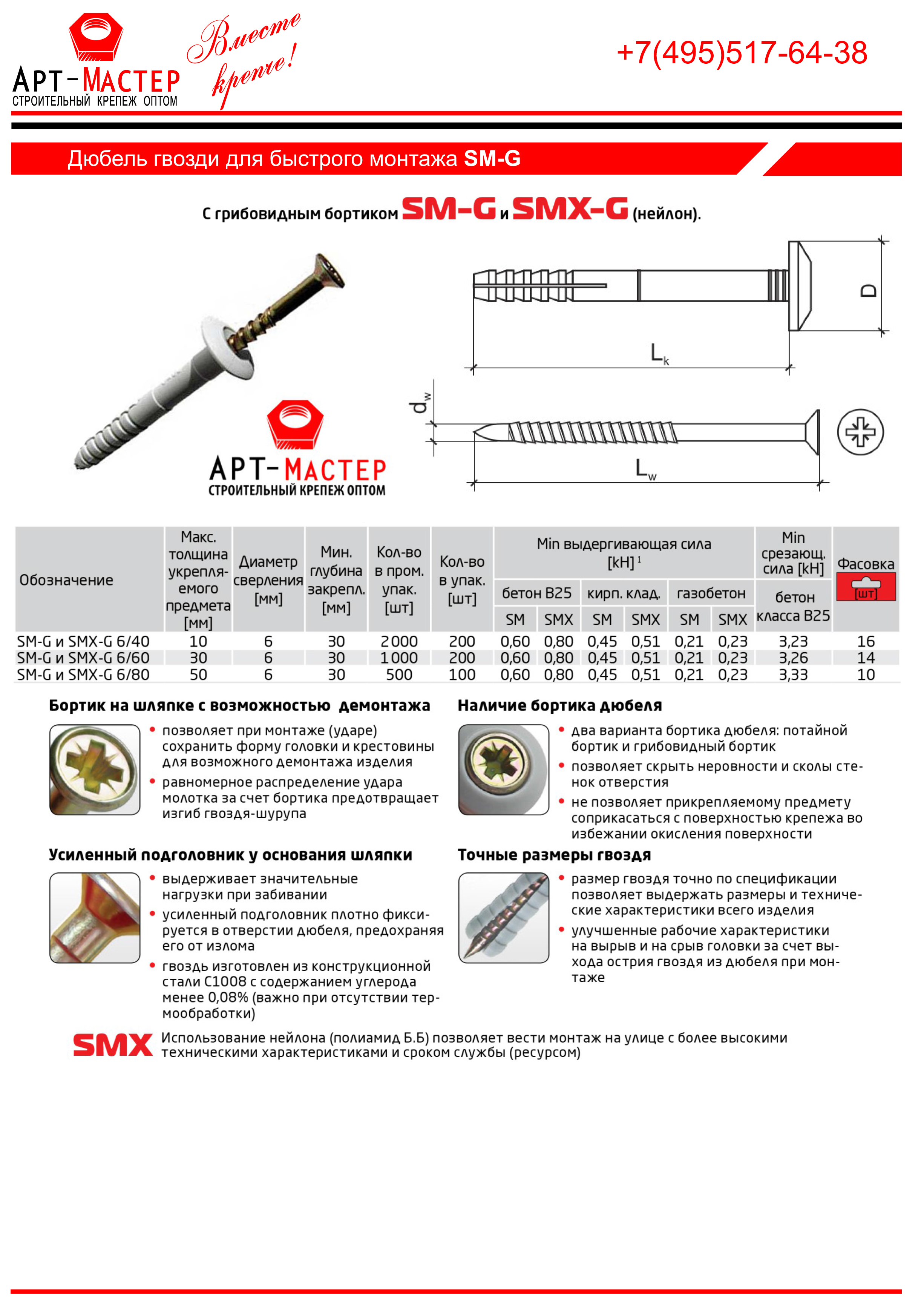

Nail dowels: designed for quick fixing of skirting boards, battens under the sheathing, when you need to install a large number of them. They are completed with a nail with a "finish" (knurling in the form of inverse cones). The dowel with a nail is inserted into the hole in the wall through the fastened rail. The nail is driven in with a hammer.

Insulation holders: for attaching mineral wool or hard foam insulation. A hole in a concrete or brick wall is hammered into a hole without a nail or screw.

Dowels for concrete and solid bricks: designed for large (up to several tons) loads, made of metal and completed with threaded rods or bolts. Suitable for attaching sunshades, garage doors or hoists. Plastic and metal: for soft materials (drywall and aerated concrete).