Tools and materials

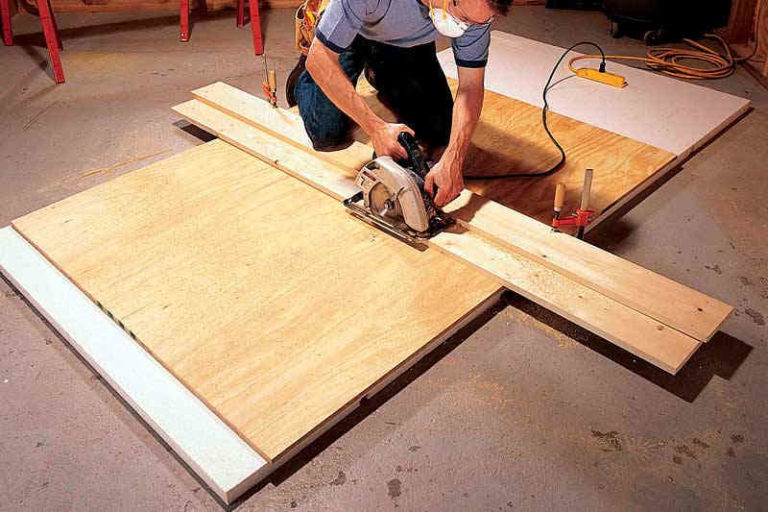

If possible, it is best to cut the chipboard with a hand mill, using homemade guides. This method is not very convenient when cutting large sheets, because when working with this tool, a table is required. In addition, with this method, the cutters have to be changed frequently. But as a result, you will get cleanly processed, "chamfered" edges.

The electric jigsaw is the most popular tool for sawing chipboard

The electric jigsaw is the most popular tool for sawing chipboard

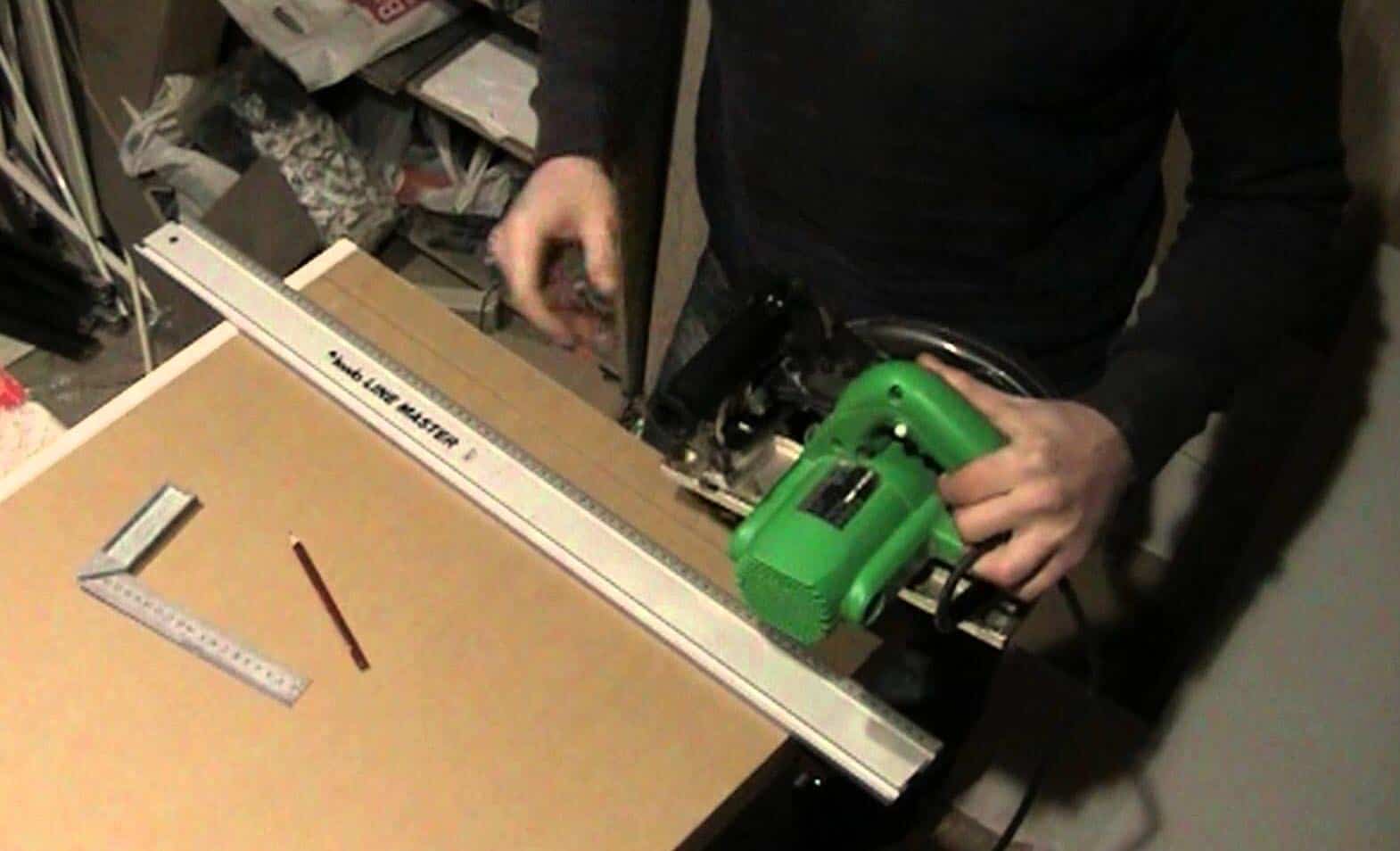

Some craftsmen use a jigsaw in their work, however, in the absence of skill, it is difficult to cut exactly, and chips can form.

You can try to install a bimetallic blade with teeth pointed inward, intended for a laminate, on a jigsaw. Cutting with a jigsaw should be increased by increasing the speed, with a small feed, so that breaks do not form.

If such methods do not suit you, then for cutting chipboard at home, we will prepare for work:

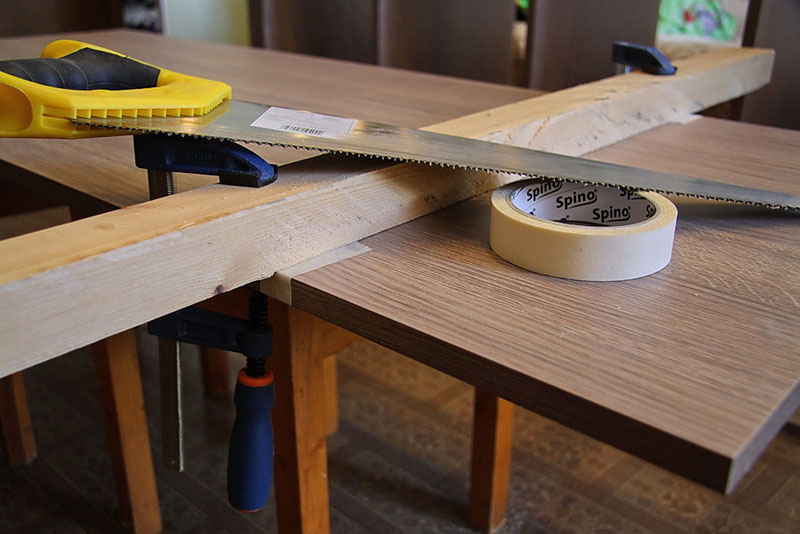

- a hacksaw with fine teeth (one that is best suited for metal work). In this case, the teeth must be divorced by 1/2 of the blade thickness and be hardened;

- paper adhesive tape;

- file for rough processing of the cut line;

- sandpaper for finishing the cut line.

Rough floor finish

Sub-floors are mounted from hardboard quite often, this material is especially suitable for leveling old plank floors, if work on their dismantling is not expected. In addition to obtaining a perfectly flat surface as a result, the fiberboard layer will serve as a good heat insulator, which is especially important for residents of private houses or ground floor apartments in old high-rise buildings.

For sub-flooring, non-refined fiberboard with increased hardness or soft fiberboard is used as a soundproofing pad. Despite the abundance of hydrophobic additives in the production of modern fiberboards, experts advise to further process them before laying. Good results are obtained by impregnation with hot drying oil in 2-3 layers. After complete drying, the sheets can be stacked.

Fiberboard floor, ready for further processing

If the old subfloor is fairly flat, the hardboard is laid directly on top of it. With significant level differences (more than 10 mm), you will have to level the old floor or lay logs. In any case, the surface for laying fiberboard is pre-treated with an antiseptic primer.

We cut hardboard

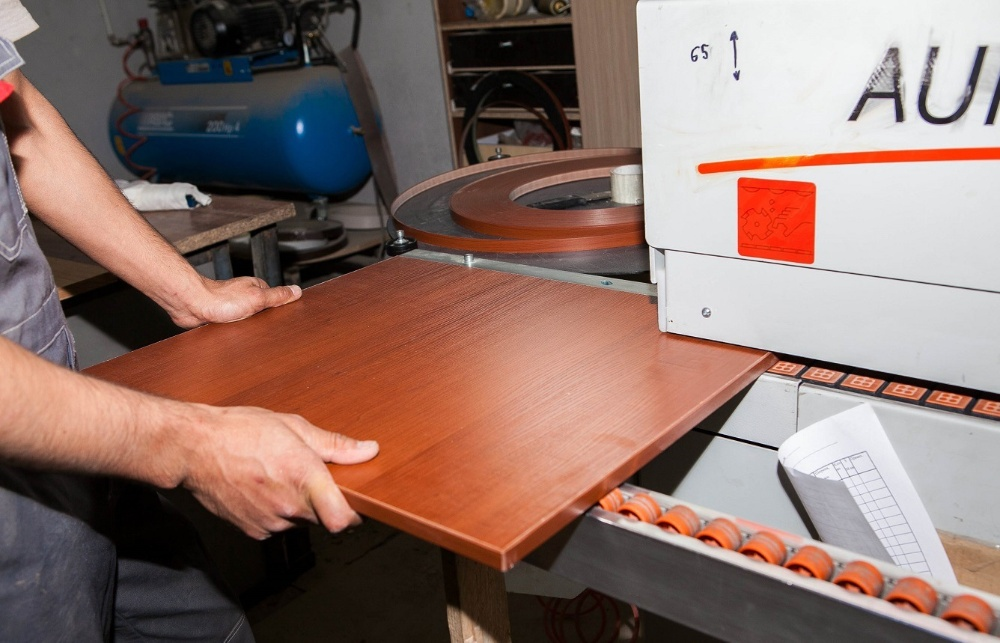

Many modern enterprises selling building materials offer their customers sawing fiberboard according to individual sizes upon purchase. Special high-precision equipment is a guarantee that the work on cutting the material and processing the edges will be done efficiently, without chips. In this case, your main task will be to accurately make all measurements. If you are so unlucky, you will have to cut the hardboard yourself at home.

In principle, a hand saw with a fine tooth is also suitable for this job. After all, the small irregularities formed at the cutting site do not matter for laying the material as a subfloor. With a significant amount of work, cutting fiberboard is much faster and easier using the following tools:

Jigsaw

- jigsaw or circular saw, preferably with a laser guide;

- saw blades of a special brand, suitable for cutting hardboard;

- trestles with a slope of 20-25% from the vertical, allowing you to fix a sheet of large-format fiberboard;

- metal ruler

- marker.

If you have to cut fiberboard for the first time, so as not to spoil the material, first practice on a small piece, setting the jigsaw file to the right of the marking line. Beforehand, be sure to familiarize yourself with the techniques of experienced craftsmen, for example, by watching thematic videos, one of which is presented below:

How to lay fiberboard?

If, after laying the fiberboard, it is planned to lay linoleum, the hardboard is laid with the wrong side down. In other cases, the corrugated surface will provide better adhesion of the fiberboard to the finishing materials, so it is turned up.

Installation usually begins from the corner opposite the front door. Fiberboard is fixed using special staples, nails or screws, or glued with mastics. Before nailing or gluing, they try to fit the sheets to each other with a minimum gap to make it easier to putty the seams.

By the way, sealing the cracks near the walls is not necessary, on the contrary, be sure to leave technological gaps that will allow the fibreboard to “play” without deformation when expanding with temperature fluctuations.

Cutting fiberboard when bypassing the heating pipe is easiest with an ordinary knife. More accurately, such work can be done according to a specially created template made of thick cardboard, using a jigsaw.

After fiberboard flooring, if you plan to finish the floor with linoleum or paint, it is necessary to seal the joints. In addition to having high adhesion properties, the mass with which we will putty the fiberboard must certainly be plastic, since fiberboard floors are somewhat springy and are able to change their linear dimensions. If you putty the floors with a hard and monolithic putty, then it can either bend and deform the fiberboard sheet, or tear itself at the junction of the seams.

How to cut a chipboard without chips.

Before talking about the absence of chips when cutting chipboard and deciding what to cut, let's define what it means without chips? Each in his own way relates to their number after cutting, someone has a lot of one, and someone a dozen just right. Therefore, let's consider not one, but three types of chipboard cutting available at home, from which you yourself can choose the most suitable one. For obvious reasons, we will not consider the use of expensive equipment designed for sawing laminated chipboard, this is the lot of professionals. We are still lovers of furniture and therefore we will use the appropriate tool. There are three parts in the photo, the upper one was sawn with an electric jigsaw, the middle one was sawn with a hand circular saw (parquet flooring), and the bottom one was also sawed off with a hand circular saw, but then processed with a hand milling cutter. Of course, in each case, you can achieve different results, it's all about experience and skill. But in general, the capabilities of the equipment under consideration give approximately the same results for chips on laminated chipboard.

Chipboard without chips with a jigsaw.

In this case, three things allow you to get a more or less good cutting result.

- Guide. It's not worth it to be wise with a guide for an electric jigsaw. An ordinary building level and two clamps will do.

- Choosing a jigsaw file for laminated chipboard. The saw cuts the laminated layer and the chipboard itself with teeth, and, accordingly, the smaller the tooth, the smaller the chips. And the cutting speed is appropriate. The upward or downward direction of the tooth only indicates on which side of the workpiece there will be more chips, in the first from above, and in the second from the bottom.

- Control over the cutting speed. If you feed the jigsaw too hard, the saw will begin to bend and move the cut to the side, while the cut will not be perpendicular to the plane of the workpiece. After such a sawing, there is no need to dream of gluing an edge.

Now let's consider whether or not to “scratch” the laminate. Perhaps this can help, but only if the following conditions are met.Since the file forms chips not only on these layers, but also on the outermost layers of chipboard, it is necessary to “scratch” them, too. The width of the "scratched" line must exactly match the thickness of the file (if you make it narrower - it will prick, if you make it wider - there will be a mark on the workpiece). The lines should be strictly one above the other and sawing should be strictly along the line. Think about how realistic it is to do it at home with your own hands, and the answer about "scratching" will be obvious.

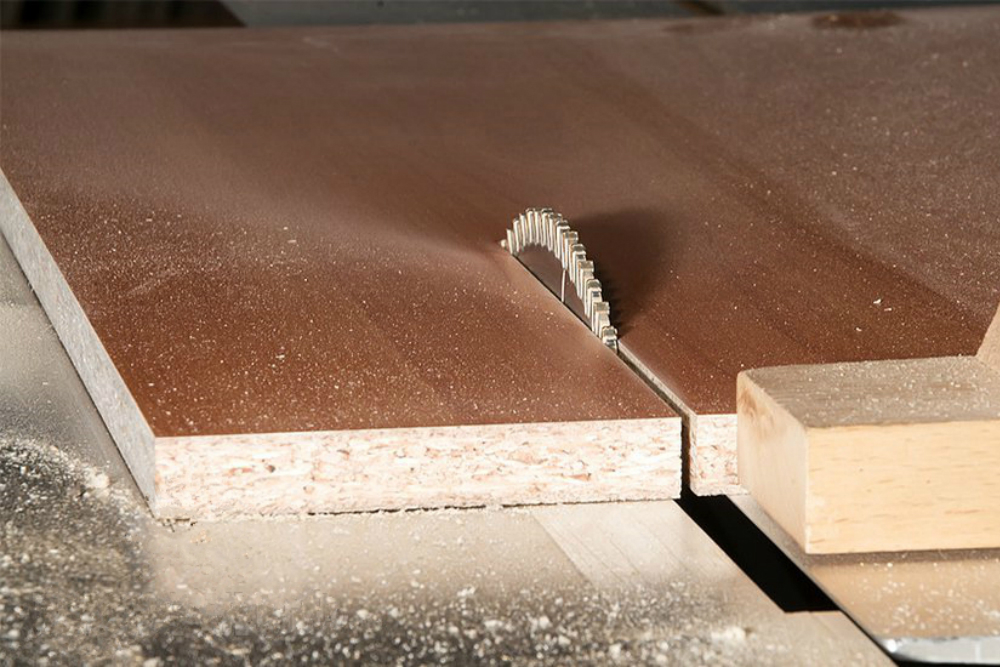

Sawing of laminated chipboard with parquet.

The cause of the chips in this case is the impact of the cutting teeth, but not only in the direction of the cut, but also from the opposite side. (Vibration from the power tool does not allow the parquet to be perfectly level, as a result of which there is a skew of the blade relative to the cut). The guide in this case not only allows you to cut the chipboard evenly, but also prevents the appearance of chips from the side opposite to the direction of sawing.

When choosing a blade for sawing laminated chipboard, you should pay attention to the number of teeth, the more teeth, the cleaner the cut

Chipboard without chips with a hand router.

Before processing furniture parts with a milling cutter, it is necessary to cut them out with a margin of 3-5 millimeters on each side to be processed. Unlike previous sawing methods, the hand router leaves behind a perfect surface. Chipping after such processing is rare and at the same time, it turns out, maintain the perpendicularity of the cut. Until now, we have considered only straight sawing, but when it comes to sawing various kinds of circles and rounds, then there is no alternative to a jigsaw and a router. The disadvantages of using a router include the need for skills in working with it. We will talk about them in other articles.

How to bend a chipboard - a practical aspect

Sometimes it is necessary to make a bent part from a chipboard - the end of a table, cabinet, shelf.

To do this, you first need to cut the required piece of material to size, and then make numerous parallel cuts on its inner surface (see Fig. 1 and 2)

:

Required snippet

Making cuts

To give a curved shape, the resulting part should be glued to the template with PVA glue and fixed with self-tapping screws. After keeping the time required for the glue to harden, the part can be removed and used for its intended purpose.

Before screwing the screws into the chipboard, it is advisable to drill out the material in advance. For this, drills are used that have a diameter of 1-2 mm smaller than the self-tapping screw. Chipboard drills are used the same as for wood drilling, and standard self-tapping screws are purchased.

Due to the lower cost of chipboard than other assembly and building materials, a small amount of rejects when working with your own hands is not critical. Damaged sheets can be used to make smaller products without incurring the cost of professional equipment and specialists.

We recently bought a coffee table, the price is inexpensive, but there is a "but". The height of the table for our interior is too big. It would be nice to reduce the height by 10 centimeters. As they say, we are not looking for easy ways, I decided that

I can do it myself.

I remembered that on our site there is an asoleg specialist who did it, of course, I'm far from him, but some recommendations can help. I contacted him, explained the problem and he kindly shared his secret. With his permission, I publish his technology for cutting furniture chipboard without chips.

Everything turned out to be corny and simple. We mark the cutting line. Then with a clerical knife, along a ruler, cut through the top layer of chipboard. Just run the knife several times with little effort along the cutting line. (I recommend practicing on the unnecessary part of the chipboard) If you press very hard, then the decorative layer will begin to swell and it will not turn out very nicely.

Further, retreating 1-2 millimeters from the marked line towards the rough part, we cut it with a jigsaw or a suitable file with teeth directed to the saw handle. We make a wash on the opposite side of the cut, so that there is no chipping at the end of the cut. And we saw through to the end. You need to cut carefully, slowly. Then, with a medium grain sandpaper, fixed on a bar, we clean the end of the part. If necessary, remove the millimeter that we retreated. My cut turned out to be almost perfect, after processing with sandpaper there were no scuffs at all. The photo shows the difference between the left and right side of the cut. Well, and, accordingly, if both parts of the chipboard are needed, we cut it with a knife on both sides of the cut. We measure the thickness of the cut of a jigsaw or file, add 2 millimeters. The result is the distance that should be between the cuts made with a clerical knife. Cut exactly between these lines. Then there will be no scuffs on the other side. Naturally, you need to use a sharp instrument, I use an instrument.

Everything worked out great. On the finished table, my wife did not find the place where I cut.

Thanks for the assistance and help asoleg.

Tags: How to cut chipboard without chips

, how to cut chipboard without chips

.

This article is found by the words:

- how to saw off chipboard without chips

- how to cut chipboard without chips

- how to cut chipboard without

- how to cut chipboard without chips with a jigsaw

- how to cut wood chipboard without chips at home

- how to cut wood chipboard without chips at home

- how to cut chipboard without chips

- how to cut chipboard without chips

- how to cut the chipboard

- how to cut chipboard without chips

If you love doing something with your own hands, read the article.

Any home craftsman sooner or later is faced with the need to cut chipboard. This can be the manufacture of furniture with your own hands or wall cladding with MDF or chipboard panels. As you know, it is not difficult to cut a chipboard, but making a cut even and without chips is not an easy task.

Reception 2. "Reverse cut".

The first pass is performed in an unusual manner - in reverse. That is, the circular saw rotates in the direction of feeding the workpiece. We set the minimum cutting depth, turn on the saw and move not forward, but backward.

If you have a regular saw, then simply fix the saw with a minimum overhang. The point of the first pass is that the blade, moving along the guide, only clings to our workpiece. We need a small groove in the chipboard.

Having made the first undercut cut, you will make sure that there are no chips at such a feed (back). The surface is perfect!

Now we will set the saw to full depth and cut the workpiece along this groove with a normal cut - forward feed. We will have two cuts per piece. No gouging waves, arson, nothing - perfect quality!

Sawing panels from chipboard and other materials

This is especially important when sawing slabs with a double-sided finish. Cutting fiberboard can be done at home using an electric or manual jigsaw

Of course, the file must be sharp, with a fine tooth; the maximum speed must be set on the jigsaw. Install the fiberboard horizontally on a support that should not interfere with sawing (between two tables or chairs, for example), secure, if necessary, with clamps

Sawing fiberboard can be done at home using an electric or manual jigsaw. Of course, the file must be sharp, with a fine tooth; the maximum speed must be set on the jigsaw. Install the fiberboard horizontally on a support that should not interfere with sawing (between two tables or chairs, for example), secure, if necessary, with clamps.

The electric jigsaw should be held with both hands, pressing firmly to the surface, moving smoothly, strictly along the line of the marking, without jerking or pressing.

The same applies to working with a hand jigsaw.

In the case when it is necessary to cut a lot of sheets of material, it is more convenient to contact a specialized company. This will save you time and effort.

Reception 1. Cut along the guide

We install a guide (tire) on the workpiece, set the cutting depth and perform the cut. As you can see for yourself, even on the outside of our chipboard blank there are no chips, no explosions. The cut itself is even without signs of scoring or side waves. Why such difference?

What is the merit of the guide?

When we saw with a disc, we inevitably wiggle the saw, the so-called "iron movement" is obtained. That is, when we move our hand, we all the time move the saw to the right, to the left. The guide, which has a rigid edging, avoids this.

Accordingly, when we guide the saw along the guide, it does not move and the saw blade itself works smoothly, without changing its position. It turns out a perfect line parallel to the guide.

What if there is no hand-held circular saw and guide?

You need to make the guide yourself. We find an ordinary profile, you can take the rule, any even rail, the main thing is that its geometry is even.

We measure the distance from the saw blade to the edge of your chipboard workpiece. We attach the guide to the workpiece with any clamp and start cutting.

The main thing in the process is to constantly press the saw against the guide. That is, your hand should always guide the saw towards the homemade tire.

After cutting, you will get an almost perfect cut, the cutting line is barely visible. We made a very high quality cut, the cut itself is clean, no side marks are visible on it. Except for a small pile on the back of the workpiece.

Where did this pile come from, because we worked with a guide (tire)?

There is a special plastic protective tape on the purchased cutting bar. This tape prevents the pile from rising and the saw cuts it. In this case, we did not have this tape, so we got this pile on the surface.

What to do with the pile in this case?

There are two options:

1. Take ordinary masking tape. It is glued to the place where it was cut, marking is made on it and sawn together with masking tape. The scotch tape keeps the root in place and when we cut it, we get everything clean.

2. Just drive the saw blade more slowly. That is, if you do the same with a slower feed, then there will be much less chips.