Peculiarities

The peculiarity of ceiling anchors is that their purpose is to withstand power loads after assembling structures on ceilings. For their manufacture use a special technology that is different from others used for the manufacture of anchors and dowels of a different type. The task of fasteners of this type includes not only a reliable connection of the structure with the main surface, but also a strong fixation of the mounted object.

In the technological process of manufacturing the ceiling anchor, high-precision equipment is used, the material is galvanized stainless steel, with the obligatory galvanization of all elements.

Metal profile PRIMET for plasterboard

LLC "U-Met" produces profiles of different types, each of which has a special shape, characteristics and purpose. Our overview of drywall profiles will help you make the right choice.

You can also purchase a full set of accessories required for the installation of profiles from us:

- profile hangers,

- profile connectors,

- profile extensions,

- fastening rods.

Advantages of the PRIMET metal profile:

- all plasterboard profiles and PPRIMET accessories are made of high quality steel,

- galvanized zinc coating provides anti-corrosion protection.

The profile manufacturer guarantees:

- consistent product quality;

- strict adherence to technology and compliance with standards;

- a wide range of types and thicknesses (from 0.35 to 0.6 mm);

- can be used for plasterboard and heavier gypsum fiber sheets.

Thanks to galvanic pair "steel-zinc", when metals come into contact with atmospheric oxygen, a strong oxide film is formed.

The company "U-Met" is ready not only to offer a profile for gypsum board / gypsum board of standard length (3m), but also to fulfill an individual order (from 2 to 6 meters).

Where is it used?

Fasteners in the form of ceiling anchors are used in the construction of houses, when interior decoration, during the connection of communications - electrical wiring, cables, air ducts and pipelines, plumbing structures. Installation of heating systems also requires ceiling anchors - anchor hook. Internal renovations are rarely complete without this type of fastener.

They are necessary for a false ceiling, for the installation of chandeliers and lamps, especially if these are devices that illuminate large spaces. Multi-storey mansions with a through atrium on all floors require special fasteners in the form of brackets for chandeliers weighing hundreds of kilograms. The same applies to high-profile institutions - in theater halls, halls, administrative and office buildings with high ceilings, heavy lamps weighing hundreds of kilograms are suspended.

In addition to the above, ceiling mounts are used to mount suspension systems of cassette, rack and pinion and plasterboard types. You cannot do without them when fixing rigging, chains and cables, if they are in a suspended state. Household hanging appliances are fixed with ceiling hardware. These are air conditioners, ovens and ovens, fire safety sprinkler systems. In sports halls, ceiling anchors of special reinforced structures are used for mounting pear and rope into the ceiling.

Varieties and overview of models

Ceiling anchors come in several varieties, differing in the type of application for different mounted items.

Ceiling wedge anchor. Used for the installation of structures on a solid base, such as concrete floors, brick and stone base.A feature of this type of anchors is a complete replacement of welding, since they are guaranteed to give a high-strength connection and visually look more attractive. It is in demand when installing metal sheet material, rails and iron corners. Consists of a metal wedge with a thickening at the end and a bushing with a groove for fixing.

Hammer-in anchors with a metal dowel are used when hanging chandeliers, lamps or other heavy structures weighing 30 kilograms or more to concrete floors. The anchoring surface has a diagonal cut and an internal metric thread up to half the length, the other half has four petals. The M8 drop-in anchor is capable of withstanding a maximum load of up to 1350 kilograms.

How to install?

To hang a lightweight chandelier weighing up to 10 kg from a wooden ceiling, it is enough to screw in a bolt with a hook and a thread at the end. The range of such hooks offers various diameters with the design weight of the structure - rod diameter 2 mm will hold a lamp weighing up to 3 kg, 3 mm - 5 kg, 4 mm - 8 kg, 5 mm - 10 kg, respectively. If the ceiling is a concrete floor, then first you need to prepare a hole, insert a dowel, then screw in the hook.

For the installation of suspended ceilings of the Armstrong system, direct and adjustable suspensions are used. To fix the entire suspension system to be strong, the master mounts the elements to the base in the central part on anchor dowels, using two or more elements on each suspension.

With particularly high main ceilings, the suspension system is lowered much lower than the possible length of straight suspensions. In this case, adjustable elements with rods and a clamping structure are used. Installation algorithm: the upper link is fixed on the main floor, and the lower one is connected to the supporting frame of the false ceiling system. Sometimes the center plate is compressed, and this gives the effect of free travel of the rods. In this way, the desired distance of the suspended ceiling from the main one is achieved. After the height is adjusted, the plate is unclamped, and a firm fixation occurs.

Ceiling brackets are used to mount and attach a sports equipment (bag, rope) or TV, hanging chair and other heavy structures. Such fasteners have several holes, usually four, but there may be more. The metal plate on which the mounted ring is located is bolted to the ceiling, securely fixed, then the suspended structure is hooked to the ring. To obtain a reliable fixation, you must follow the correct procedure.

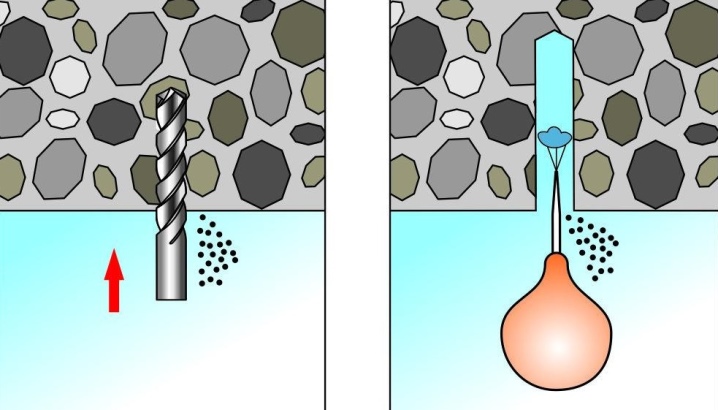

The place of installation of the bracket is outlined, marks are put in the places for the dowels. Then the marked places are drilled out and the anchor bolts are screwed in. The size of the socket must be exactly the same as the diameter and length of the ceiling anchor in order for it to sit firmly in the base. The finished hole is blown to remove dust and debris.

After that, the element is fixed in the way it is provided by its design - by screwing in, turning, additional hammering to open the petals. From the tools you will need a drill or screwdriver, a hammer and, possibly, a hammer drill if the ceiling is too strong for a drill.

This type of fastener is used on solid, solid materials: brick, stone, concrete; we are not talking about porous bases for ceiling anchors, since they will not withstand the weight of heavy structures. The load on the anchor is determined by the type of material that will serve as the basis for the fastener. The load on the popular size 6x60 anchor should not exceed 6 kN.

You can find out even more useful information about anchors in the next video.