Safety warnings

- Surfaces can only be painted with good air circulation in the room. To protect the respiratory system, eyes and skin, you will need a respirator, goggles and rubber gloves.

- Paints and varnishes contain flammable components, so do not store or spray paint near open flames.

- The can should not be overheated in direct sunlight or kept near fire. The container will explode if it warms up above 50 degrees. It is not recommended to leave aerosols in stuffy rooms (first of all, we are talking about metal garages).

- Spray paints are rarely adapted to cold temperatures. It should also be borne in mind that in frosty conditions, the paint will poorly fall on the surface and will flake off.

- Temperature paints have been developed especially for low and high temperatures. However, such compositions require special cleanliness: the surface must be especially thoroughly cleaned of dirt and dust. Otherwise, it will not be possible to ensure the proper level of adhesion (adhesion of dissimilar materials) and the paint will simply fall off.

- Do not open the can with scissors or other sharp objects. Even if the paint and varnish material has run out, but gas remains, the container may rupture.

- Shake the can for a few seconds before using it. This will help to evenly distribute the components of the composition throughout the container. If this is not done, the paint will come out unevenly or in lumps.

Paints and varnishes in aerosol cans have won well-deserved popularity among consumers, as this is the simplest and most versatile way to paint a surface. This paint is especially useful when you need to touch up small surface defects or paint small parts.

How is metal painting with powder paint

Metal surfaces, in most cases, are constantly exposed to environmental influences and therefore the paint and varnish composition wears out very quickly. Powder paints are an excellent solution to this problem.

They are relatively inexpensive, so the cost of a building made of metal structures will not change much, and many of the positive qualities of this material will protect the surface of the building for a long time.

The only drawback is the technology of applying powder paints, which requires certain knowledge.

How to paint metal with powder paint?

As stated earlier, the best metal fence paint is powder paint. The preparation of the surface, which is required by the technology of powder painting of metal, practically does not differ from the preparation of metal for other types of paints and varnishes.

The most commonly used degreasing, phosphating and etching of the metal surface.

Next comes the stage of direct metal painting with powder paint. If a large, uniform metal surface is required to be painted, electrostatic coating is more advantageous.

The bottom line is that with the help of a special device, paint particles are endowed with an electric charge and directed to the metal surface. This method ensures uniform application powder paint on metal.

The second technology for applying powder paints is to apply a paint and varnish product to a "fluidized bed".

To do this, the product that needs to be painted, most often a set or a metal product of an irregular shape, is heated to a temperature of 55-60 degrees Celsius, and for a short time it is lowered into a special container with powder paint, equipped with membranes from the lower side through which the compressed air, which brings the powder to the boiling point.

Dissolving, paint particles settle on the heated metal surface and form a smooth, uniform layer.

Powder Coating Equipment Price

In a domestic environment, manual electric sprayers are most often used, operating from a conventional 220-volt outlet.

The cost of such devices varies from 1,800 rubles to 12,000 rubles and depends mainly on the fame of the manufacturer.

Industrial equipment for painting metal with powder paint is very diverse and can cost from several tens of thousands of rubles to several million rubles.

How to apply powder coatings to metal surfaces?

Unfortunately, at home, it will not be possible to apply this type of paintwork to a metal surface with high quality. For this, special spray booths are used.

This is primarily due to the fact that about 30% of powder paint particles for metal do not settle on the surface the first time, and in the case of an open space, they will settle on everything that surrounds the object to be painted. In the spray booth, these particles are captured and sent back to work.

It is worth noting that such trapping of powder paint particles on metal not only protects the surrounding objects from damage, but also reduces the consumption of paint and varnish material.

As mentioned earlier, after applying powder paint to a metal surface, the product is sent to a special polymerization chamber. There are no specifics at this stage, you just need to follow the technology.

A few words about the advantages of powder coatings for metal

This type of paints and varnishes has a number of advantages that distinguish it from other possible candidates for metal surfaces:

- With the help of this paint and varnish material, unique physical and chemical properties are achieved;

- It is enough to apply a coating of powder paints for metal in just one layer, which significantly reduces costs;

- The paintwork from this paintwork material has a higher level of impact-resistant and anti-corrosion properties, compared to other types of paintwork materials;

- The coating hardens very quickly - in just 30 minutes. This value is not achievable for any other type of paintwork;

- The powder coating process for metal is one of the most environmentally friendly.

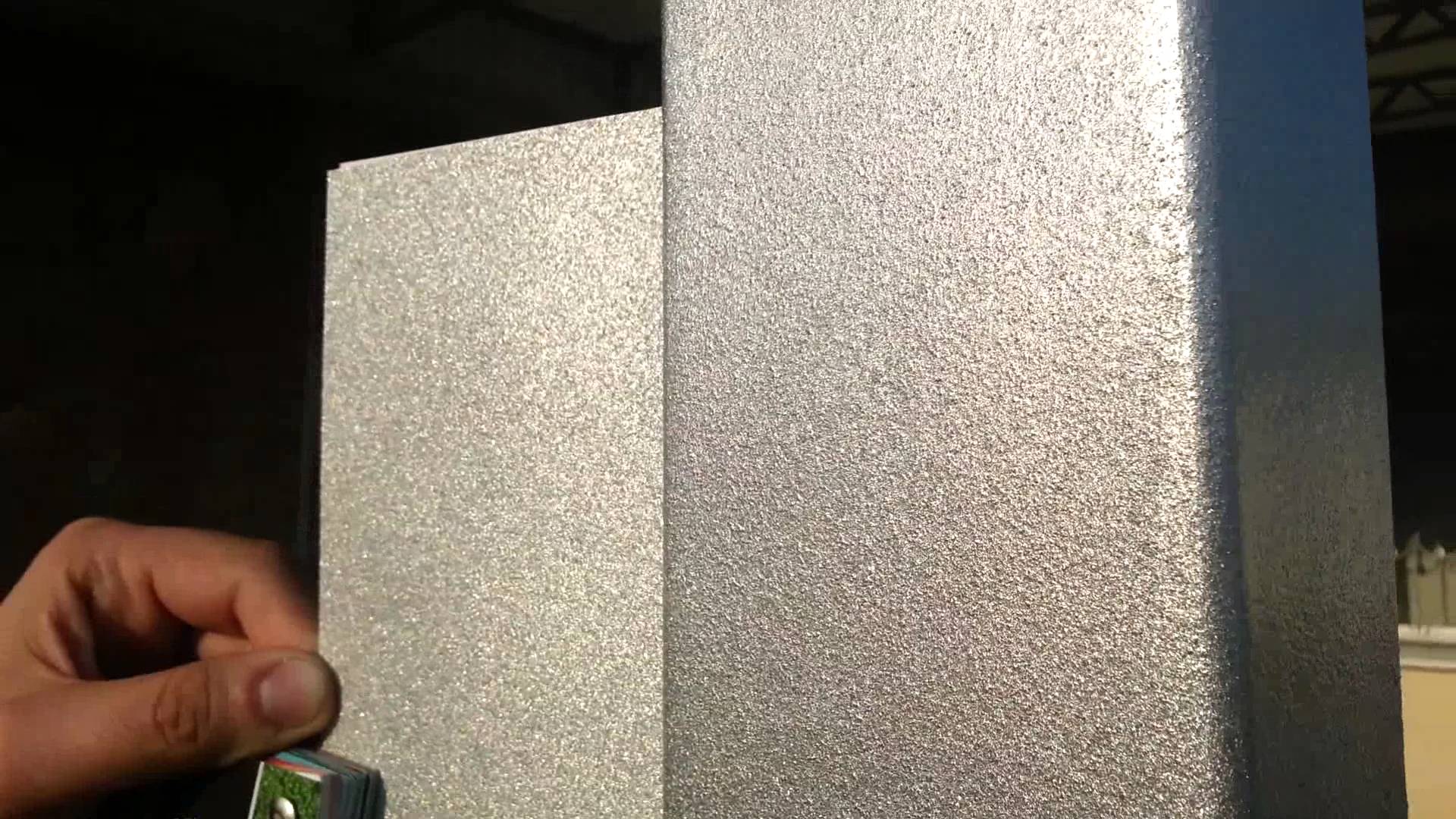

Serebryanka powder. Why is she so good

Its popularity is based on two main qualities. This is, first of all, its properties of a protective nature, as well as the decorativeness that it provides to any surfaces when painting. It is used to cover metal (it can be pipes, bridges, etc.), it holds well even on wood. Silver powder is an aluminum powder. When we dilute it, then varnishes and various pigments are also added to the composition. In fact, the composition of the silver is not particularly complicated, but it has its significant advantages:

- The layer, when applied, turns out to be uniform, thin and very smooth. In addition, it adheres well to the surface when properly prepared.

- Silverfish serves for a long time. If it is airspace, then about 7 years, and in water - up to 3 years.

- Serebryanka gives any surface a very attractive look.

- Good corrosion resistance.

But, she also has her own, rather serious drawback that you definitely need to know. The powder itself is very fire and explosive.

The presence of an open fire nearby is NOT ACCEPTABLE! Observing these conditions, you, first of all, ensure your own safety!

How to dissolve? Drying oil or varnish?

For dilution of silver powder, both of these components are suitable. But, if you do this you will be drying oil, then it should only be synthetic. There are some differences when mixing, but they only concern proportions.So, the powder marked PAP-1 is diluted with BT-577 varnish, while the ratio should be 2: 5 (that is, in other words, powder - 2 parts, and varnish - 5). So the silver that you get in the end will be able to withstand even +400 degrees Celsius during operation.

How to dilute correctly?

How this can be done, we have already decided, now we will decide on the intricacies of the process of making silver.

- Let's start again with the PAP-1 mixture. It is being bred gradually. At the same time, the varnish is used in small quantities, and these very small volumes are thoroughly mixed. It works well, for example, with a mixer.

- PAP-2 powder is diluted with any type of varnish. Here the proportions are slightly different - 1: 4, or, it can be 1: 3 (that is, the powder is 1 part, and the varnish is already 3 or 4). When you combine these components, the mixture will turn out to be quite thick, it is better not to use it right away.

- The choice of painting tool is the factor that determines the required consistency of the finished silver. And for this you can use an ordinary brush, or paint with a roller or spray. Working with these tools, you can dilute it with a solvent, turpentine or white spirit is also suitable. Under the spray gun, you need to prepare a more liquid consistency. In this case, the solvent and powder mix equally, that is, 1: 1. For painting with a brush or, for example, a roller, they do it already 1: 0.5, that is, they put less powder.

- If you dilute silver oil with linseed oil (remember that it is exclusively synthetic!), Then here the proportions are maintained by analogy with varnish.

All these methods of diluting silver powder end up giving approximately the following consumption: you can easily paint one square meter with 100 grams of ready-made paint.

How to paint with silver paint correctly?

If you want the paint to hold well, then you need to apply at least three layers. At the same time, be sure to wait until each of the previous layers is completely dry, and only then apply the next one.

You need to work with silverware only in personal protective equipment. At the same time, the space should not be closed, which means that windows and doors must be opened.

Any surface for silver plating should always be prepared. If it is metal, then there should be no remnants of old paint on it, as well as dust with dirt, or rust with greasy spots. The tree must be sanded.

If the surface is primed, then one single layer can be applied to it.

When applying silver on an unprepared surface (on which there is already something), do not apply it on nitro enamel, oil paints or NBH.

In this video, they will also tell you how you can dilute the silver. But, be sure to work in personal protective equipment!

The main advantages of spray paints

Spray paints are convenient to use not only for standard, but also for hard-to-reach surfaces that are difficult to process with a brush or roller. Also spray paints have a number of other indisputable advantages:

Readiness - spray paint does not require any preparatory manipulations, you just need to shake the can slightly, press the button and you can start working.

No need for additional attributes - using spray cans, you can skip buying brushes, pallets, etc. This not only simplifies the work, but also significantly saves the budget.

Versatility - you can choose paint for any materials (plastic, metal, wood, textiles, etc.).

Assortment - aerosols are widespread on the market of paints and varnishes, so if necessary, you do not have to rack your brains over where to buy a can of paint.

Convenience of storage and transportation - thanks to sealed packaging, you can not be afraid that the paint will leak out or exude a characteristic pungent odor. The cans are also very compact in themselves and do not take up much space, the paint in them practically does not dry out during storage.

Affordable cost - the price of quality paint in a spray can is quite acceptable for the average consumer.

Fast drying - after applying the composition until it dries completely, you will have to wait a maximum of five to six hours.

To the above features, it should be added that aerosols are in no way inferior to traditional canned paints in terms of their performance. They are also durable, resistant to moisture, temperature extremes and more. True, even such a versatile material has some drawbacks.

Dyeing process and physical features

Powder coating what is it? This is a popular question. After all, the process is strikingly different from the usual use of liquid paints. At the same time, we can say for sure that the result obtained is distinguished by a better quality property. There are several ways to carry out powder coating on the surface, select it based on the type of coloring matter of the product that will be painted.

The result obtained is distinguished by a better quality property.

The result obtained is distinguished by a better quality property.

Stages of work

Before painting, preparatory work should be carried out so that the object is as prepared as possible for processing. In general, the following steps are performed:

- Cleaning the product from all types of dirt and degreasing.

- Powder is applied with a special spray gun.

- Heating is carried out with further cooling.

On an industrial scale, painting is carried out in special chambers. In them, the powder fractions are distributed over the surface and charged with electricity, which allows them to securely fix on the surface of the object. A special spray gun can be used, which creates the necessary charge of a particle of powder for magnetic induction to occur.

After the distribution of the substance over the surface, polymerization is performed, which is done with the aim of getting particles into all the pores of the surface. After gradual heating, which can reach +250 degrees, cooling occurs naturally.

On an industrial scale, painting is carried out in special chambers.

On an industrial scale, painting is carried out in special chambers.

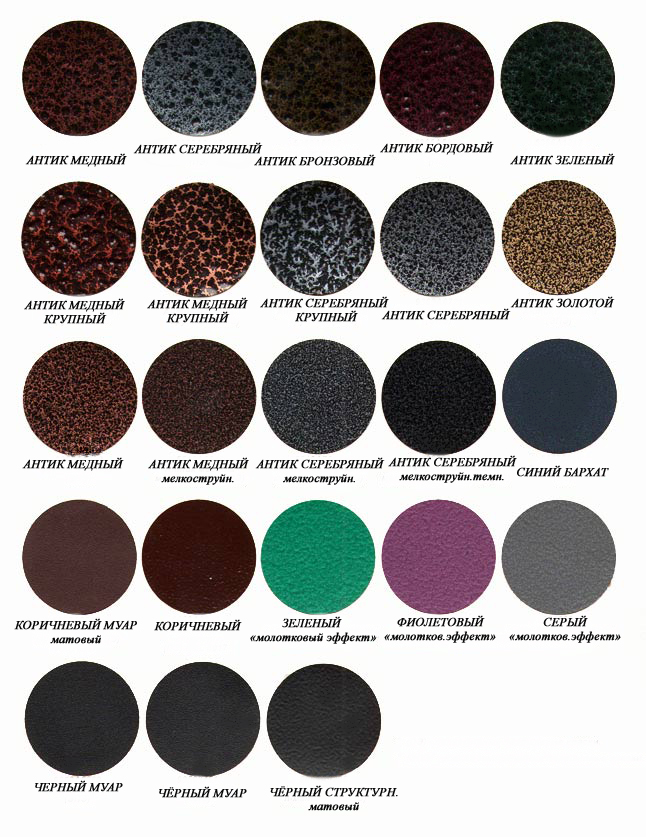

Palette

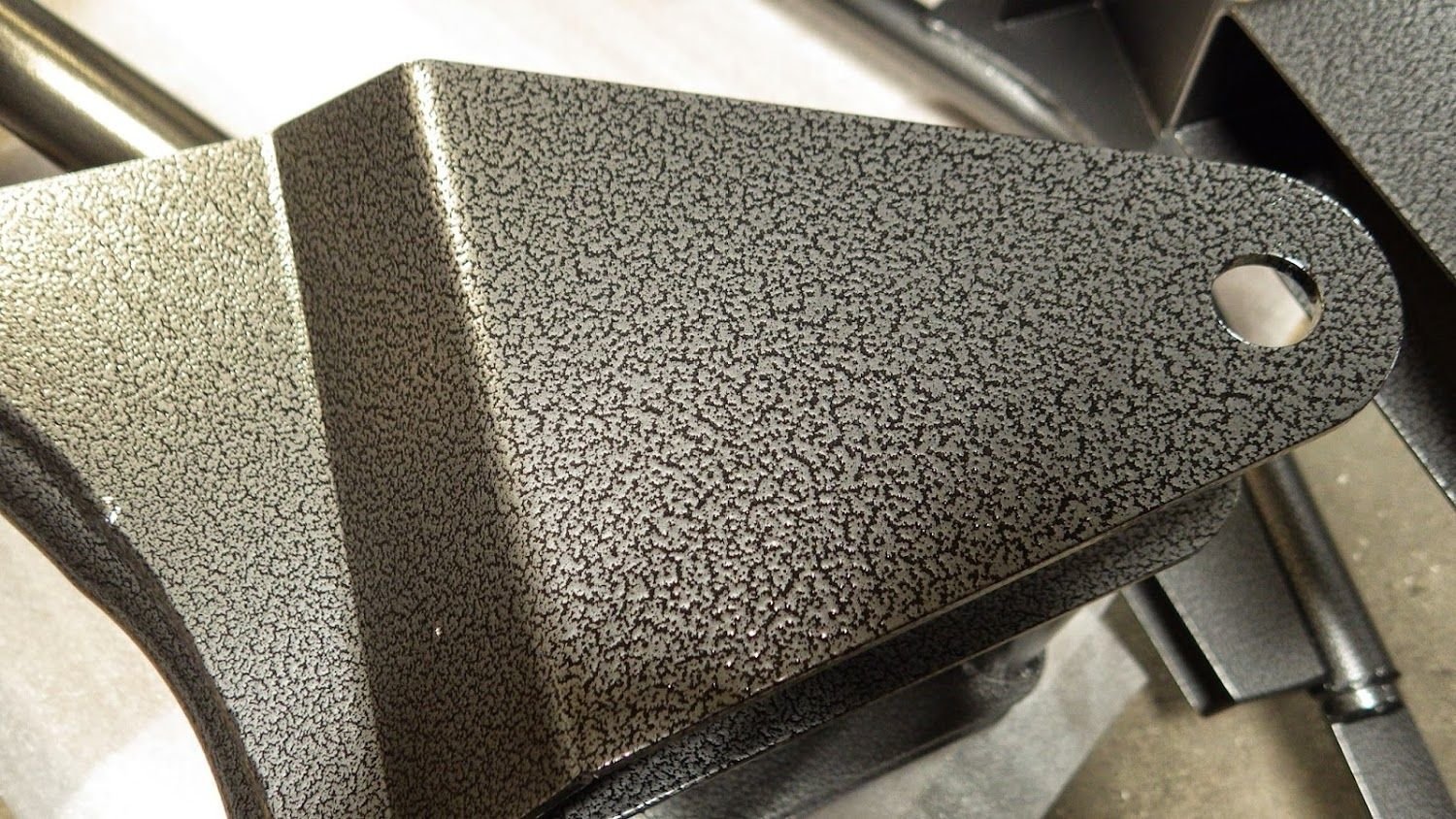

Powder paint can have any shade and shine, both glossy and matte varieties are available. The technology allows you to make a multi-color paint composition or metallic, to form a hammer surface and create reliable protection for the facade of the building.

A specific color - white, black, gold - is given through the use of various pigments and changes in their concentration. It should be borne in mind that paint of a certain color can only be contained in one container, and during work you need to immediately decide what kind of tone you want to create.

For household purposes, paints with phosphors are applied to car wheel rims, concrete, clothing, various stickers, glass and many other things. In a big city, it is not so rare to see a car with wheels painted with glowing powder paint, passing by a billboard of the same design.

The advantage of such compositions is the ability to paint sharp edges and edges without sagging. Resistance to weather factors, light and mechanical stress is above average. But in terms of protection against caustic substances, paint based on TGIC is somewhat weaker than polyester-urethane.

Properties

In the description of the material, you can usually read that this coating is intended for metal; nevertheless, in modern production, polyester-based powder formulations are produced, which interact well with wood, plastic and other surfaces. Positive traits:

- Profitability.Coloring occurs with virtually no loss of material.

- The richness of the color palette and, as a result, the decorativeness of the resulting coating.

- Strong adhesion (the paint has a reliable adhesion to the base).

- High resistance to aggressive chemical attack.

- Good hiding power and the ability to obtain a sufficiently dense coating as a result of one staining.

- Lack of unevenness and sagging even on vertical surfaces.

- Short drying times.

- High anti-corrosion properties.

- Resistance to sudden changes in temperature and any atmospheric phenomena: hail, snow, rain (including acid).

- No reaction of the coating to ultraviolet light (color stability).

Polyester paints are used in the automotive industry, in the production of sports equipment, for painting parts of bicycles, power tools, garden and household appliances. First of all, these coatings are designed to protect surfaces from aggressive external influences.

Practice shows that they do an excellent job with the task. There are also disadvantages: the composition contains toxic components; it is very difficult to apply such paint yourself.

Powder paint composition

The composition of powder paints includes: oligomers (polymers), fillers, pigments, curing accelerators, hardeners, plasticizers, modifiers and various auxiliary substances.

Oligomers (polymers) are the basis of any powder paint, which determines the final properties of the product. Most often, for the production of powder paints, polymers (oligomers) are used in the form of a free-flowing powder, or substances that, upon grinding, form a dispersed powder. Sometimes liquid oligomers can be used (for example, as modifiers) or solid film-formers, which can, under certain conditions, become viscous.

For the manufacture of powder paints, it is necessary to use film formers with certain properties: rather low viscosity of melts, optimal surface tension; molecular weight should be in the range from 1500 to 3000; also requires a certain temperature of fluidity, melting, glass transition, degree of crystallinity; the optimal number of functional groups, etc.

Fillers and pigments in powder paints play the same role as in liquid compositions, for example, they give a certain color, shade, change the mechanical, plastic and other properties of the paint or the finished coating, improve the protective properties, etc.

Pigments have a great influence on the main parameters of paints: the ability to be applied to the surface, the tendency to electrify, flowability.

In the finished paint, the amount of all fillers and pigments can vary from 5 to 60%. The number strongly depends on the purpose of the paint, its color and the nature of the oligomer (polymer) used. Typically, powder paints use the same fillers and pigments as liquid paints. These substances can be of organic or inorganic origin. In order for the hiding power of the coating to be high, organic pigments are often used in combination with inorganic ones.

Often, in the manufacture of powder paints, the following fillers are used: kaolin, ground mica, blankfix (barite), quartz, silica, talc, etc.

Modifiers differ in type from the main film-forming additives. Modifiers are used in order to improve the properties of both the coloring compositions themselves and coatings based on them. Oligomers, monomers or polymers can act as modifiers in powder paints.

Plasticizers play a very important role in the production of powder paints, because without these substances, it is impossible to obtain a high-quality coating with high decorative and protective properties from the powdery mass.Plasticizers help to reduce the drying time of powder paints and varnishes, reduce the temperature of formation of coatings, and regulate the physical and mechanical properties of the cured layer.

Solid or liquid compounds can be used as plasticizers. Solid ones can be noted: diphenyl phthalate, salicylic acid, β-naphthol, triphenyl phosphate, etc. Liquid plasticizers used in the production of powder paints include: dioctyl phthalate, pentaerythritol ether (also glycolic) of synthetic fatty acids, dibutyl phthalate, etc.

Hardeners are used in the production of thermally convertible powder paints and varnishes based on polyurethane, epoxy, polyacrylate, polyester and some other oligomers.

Curing accelerators are used together with hardeners. In this case, it is necessary to take into account the type of used film former. Curing accelerators are complexes of amines with metals, salts of some metals (for example, Cd, Zn, Hg, etc.). If an epoxy base is used, aromatic amines, cyanamides, polybasic acids and their anhydrides, etc. are often used.

Varieties of aerosols

Spray paints for metal

- Eco-enamels based on water for facade and interior surfaces. They have a characteristic vanilla aroma. Such formulations dry quickly. If paint is applied to any surface by mistake, it must be washed off within 30 minutes, otherwise it will be much more difficult to do later. Eco-enamels reliably protect the coating from the effects of ultraviolet radiation.

- Metal paints are produced in three varieties: standard, double and triple. Standard is used only to give the surface a given shade. Double contains a primer. Triple spray paints in spray cans contain a rust converter.

Heat-resistant compounds

Thermally stable paints (containing oxygen and flint) are used primarily to protect materials from high temperatures. In addition, heat-resistant surfaces tolerate moisture and aggressive chemicals well.

Areas of application of heat-resistant aerosols:

- As a protective coating for metal, wood, ceramic, concrete substrates.

- For coloring products subject to increased thermal stress (stoves, boilers, fireplaces, etc.).

- The light-accumulating characteristics of the paint are used for road sign marking.

- For the treatment of surfaces that function not only at high temperatures, but also in high humidity (saunas, swimming pools, etc.).

Compositions for plastic

Spray paint in plastic cans is most commonly used in the automotive industry. Forms a moisture resistant coating that is resistant to abrasion and aggressive chemicals. As a result of staining, the surface takes on a velvety, rough or glossy appearance.

There are several types of aerosols for plastic:

- Polymer (acrylic). They are characterized by high adhesion. Includes a primer. Acrylic paint in spray cans is similar in technical characteristics to enamel.

- Abrasion-resistant mixtures are made on the basis of polyurethane resins. After painting, the surface becomes glossy.

- Structural paints and varnishes are used to smooth out small irregularities and are characterized by a high level of thixotropy. The processed plastic becomes smooth.

- Tactile paints based on acrylates and polyurethane resins give the material a velvety feel.

- PVC mixtures have significant adhesive properties and protect the coating from the negative effects of ultraviolet radiation.

Decorative compositions

A special type of paint is used to decorate surfaces - RAL-palette.There are many shades, each with a corresponding number. You can select the desired paint and varnish material according to the palette table.

Decorative spray paints are used to paint glass units, cans, flasks, as well as to create complex patterns using a stencil.

Do-it-yourself painting of a double-glazed window is carried out using the following technology:

- The glass is cleaned with household chemicals and wiped with a dry cloth.

- Masking tape creates an area for staining.

- The surface is degreased. During further work, you need to try not to leave fingerprints on the glass.

- The paint and varnish material is applied in a thin layer to the glass. The can is approximately 25 centimeters from the surface.

- After 20 minutes, another layer is applied.

- After 40 minutes, you can remove the tape.