Composition and characteristics of glue

The glue "Desmokol" contains polyurethane resins, organic solvent and various modifying components. This tool is widely used in the repair and manufacture of shoes. Due to its ability to reliably bond various types of surfaces, the glue is used to adhere the upper part made of leather or fabric to the sole of polyurethane, PVC, rubber or thermoplastic. When molding PVC soles, Desmokol glue is also added, which significantly increases the strength of the joining of materials.

The adhesive composition has many advantages over other similar substances.

- The glue is completely transparent, therefore, after the repair, the joint is invisible, which allows you to completely restore the original appearance of shoes or other products.

- Polyurethane adhesive is water resistant. With this tool, you can glue surfaces with a moisture content of up to 25%! Desmokol glue is often used to repair rubber boats, hunting and fishing equipment.

- The universal adhesive does not collapse in the cold and does not crack under the influence of heavy loads.

- It is convenient to work with glue, since it takes some time to completely dry it, which means that it is possible to adjust the gluing site if necessary.

- Durability and reliability of the connection. The two materials glued together by Desmokol make up a single whole.

- The seam turns out to be not only strong, but also elastic, without excessive rigidity.

On sale, glue can be found in different packages and conditions. For home repairs, small tubes of 50 ml or jars with a capacity of 1 liter are most convenient. On an industrial scale, drums of 20 or 200 liters are used.

There is glue in the form of granules that you need to dilute yourself with a solvent. The cleaner the solvent, the higher the quality of the adhesive.

How to apply

Before using Desmokol shoe glue, it is necessary to prepare the surfaces. Clean them from contamination, remove the remnants of the old composition, degrease and process with sandpaper.

Instructions for use:

- Apply a thin layer of Desmokol to both glued surfaces and leave for 5-10 minutes to dry. After this time, the glue should be covered with a glossy film that will not stick to your fingers.

- If the product is absorbed into the material, then apply another layer and wait again for five to ten minutes.

- Turn on the hair dryer and direct a stream of hot air onto the glue layer, heating it to 80 ° C, then press the surfaces together as hard as possible. There is no need to use a vice or load.

- The resulting connection will be very strong. You can use the glued product after 24 hours.

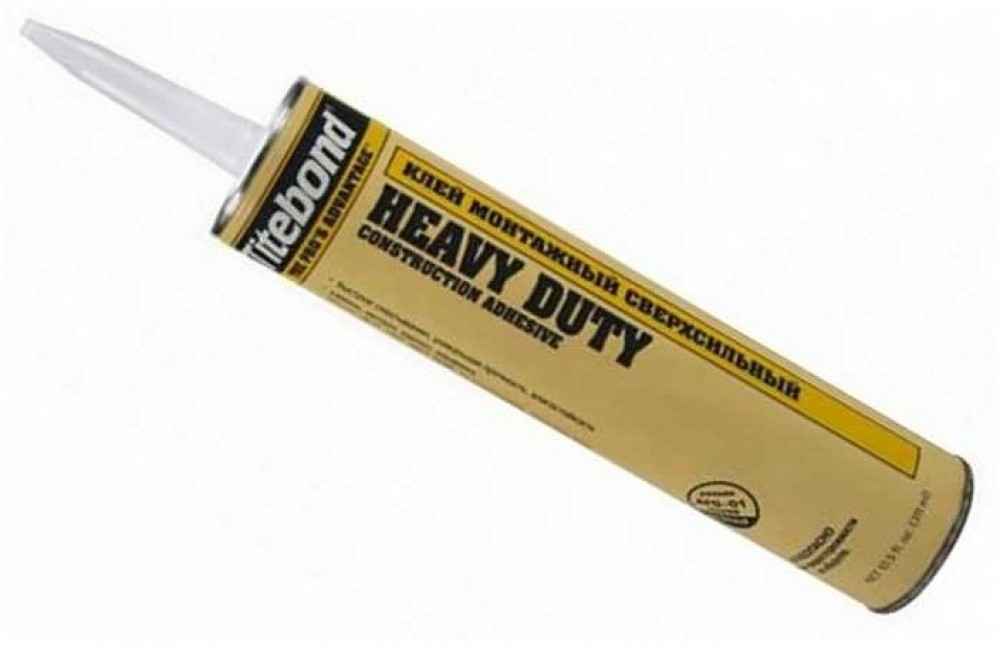

Titebond Original Wood Glue Industrial glue for wood

Titebond Original Wood Glue Industrial glue for wood

Water resistance class D2

Titebond Dark Wood Glue Adhesive for dark woods

Water resistance class D2

Titebond II Premium Wood Glue Adhesive industrial moisture resistant one-component

Water resistance class D3

Titebond II Transparent Premium Wood Glue Adhesive moisture resistant transparent for wood

Water resistance class D3

Titebond III Ultimate Wood Glue The ultimate wood glue (Breakthrough in adhesive technology!)

Water resistance class D4

Titebond Liquid Hide Wood Glue Protein Wood Glue

Titebond Molding & Trim Wood Glue Molding Adhesive

Titebond Polyurethane Liquid Glue Polyurethane adhesive

Professional wood glue (standard for woodworking).

Strong initial tack and short pressing times.

Provides a higher bond strength than the wood itself.

Not abrasive. Does not damage cutting tools during finishing.

Bonding of hard and soft woods in the joinery industry (butt and surface joints such as tongue / groove, tongue, etc.).

Application of laminate, postforming, laminated plastics, paper films, natural veneer on any wooden surfaces, MDF, fiberboard, chipboard, plywood by the cold method.

Furniture assembly.

It is cleaned with water until it dries.

Physical properties

Base: emulsion of aliphatic resin

State: viscous liquid

Color: cream, translucent cream after drying

Dry residue: 46%

Viscosity: 3200 mPa * s

Acidity ph: 4.6

Freeze resistance: stable

Shelf life: 24 months in original packaging at 20 ° С

Moisture resistance class: D2

Directions for use

Application temperature: + 10 ° C

Consumption: 180 g / m2

Working time: 5-10 minutes depending on conditions Working surfaces must be dry, free of oil, grease, dirt, peeling old paint and any other materials that reduce adhesion

Cleaning: cleaned with water until dry

After drying, the excess is removed mechanically

Peculiarities

Freezing does not change the structure of the glue, but causes it to thicken.

After long-term storage, it is sufficient to stir it thoroughly before use to restore its properties. Meets the requirements of ASTM C557 (USA) and AFG-01 D3498 of the American Plywood Association.

Not recommended

Use outdoors, as well as in rooms with high humidity, where open water is possible.

Precautionary measures

Use only in well ventilated areas. May cause skin irritation

If dizziness or other unpleasant effects appear, you need to go out into the fresh air, consult a doctor. If any glue gets in your eyes, rinse them with running water for 15 minutes. If the glue comes in contact with your skin, wipe it off and wash the skin with soapy water. Keep the glue out of the reach of children!

Use only for its intended purpose.

Packaging

vendor code

package

box weight, kg

pcs / box

box / pallet

5063

237 ml

3,63

12

160

5064

473 ml

7,25

12

100

5066

3,785 l

9,07

2

63

5067

18.9 l

22,68

1

24

Store and transport at t> 5 ° C.

What types are there?

Adhesives for wood based on polyurethane, organic resins and PVA have gained great popularity and love of consumers.

Views

Products for gluing wood have a different composition and scope. Most of the materials are positioned as universal products, for which fastening wooden elements is only one of the areas of use. Other products are manufactured as ad hoc formulations, so they are not designed to come into contact with other types of materials.

There are several different compositions.

PVA glue is sometimes called a dispersed gluing agent.

The main characteristics of such products are:

- lack of toxicity, due to which the composition can be used indoors without additional safety measures;

- fast adhesion to the surface;

- static load of 60 kg / cm2;

- unlimited operational life of products;

- the ability to use with any surface.

BF is a type of glue that includes several options for the product. For wood materials, series 2 and 4 are recommended. This composition has such a feature as very fast solidification. On average, this requires 50-60 minutes, but provided that the humidity and temperature are within normal limits.

- Heat-resistant adhesives produced in the form of rods. To work with such products, you will need a special pistol. The scope of application of the products mainly concerns the fastening of small parts or the sealing of defects in a wooden surface.

- Joiner's adhesives. For work, the products need to be prepared. The basis of wood glue is organic protein, which is the main adhesive. It is necessary for joining various wood materials: hardboard, paper, cardboard, wood products. The natural composition ensures the safety of use.

The origin of the main constituent of the joinery is different.

Products are classified based on the type of feedstock.

- Mezdrovy.The main component in such products is a substance that is formed during the processing of animal skin. The material can be produced in the form of flakes, tiles or powder.

- Bone. The bone remains of animals act as raw materials for it. The products have an average cost. It is better to use a transparent composition, instead of unrefined mixtures with impurities.

- Casein. It is widely used in aircraft modeling and shipbuilding. It is neutral to moisture and forms a strong bond. To prepare the composition, you must strictly observe the proportions and time interval.

- Fishy. It is prepared on the basis of the remnants of fins and scales. The composition is considered a professional product intended for bonding surfaces with varying degrees of rigidity. The glue has a rather high cost, therefore it is positioned as furniture glue and is used to repair or restore expensive furniture.

- Moisture resistant solution. You can cook it yourself using slaked lime and cottage cheese, which has recently been curdled.

There is a certain technology for making wood glue. For this, the dry mass is poured with water and left for 6-12 hours so that the composition completely absorbs moisture. Then the remaining water is poured off, and the mixture is heated in a water bath until the substance is completely dissolved. The cooking process requires periodic stirring.

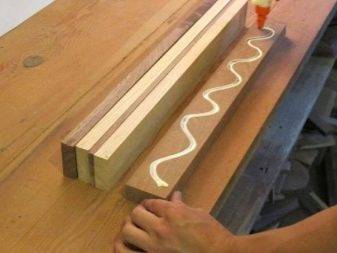

It is important to control the process so that the mixture does not boil. The glue is applied strictly in the direction of the location of the wood fibers, then the elements are pressed against each other and fixed

The main disadvantage of the product is a decrease in the gluing efficiency in the case of wood moisture content exceeding 10%.

- Syndeticone glue. It is prepared from a carpentry adhesive composition with the addition of lime and powdered sugar. The products are distinguished by a high level of strength of the connection of the elements. The glue is waterproof, resistant to chemicals. The disadvantage of the product is considered to be a rather long preparation process, since the mass for the solution must be kept in water for 24 hours.

- Glue paste. It is prepared on the basis of carpentry, wood ash and chalk. The material shows itself well when priming and puttying wood.

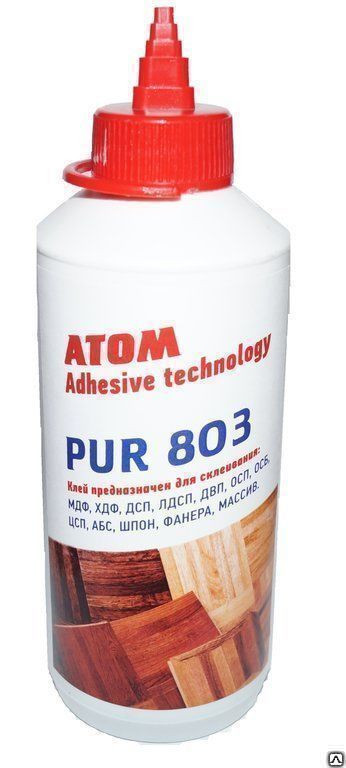

- Polyurethane products. It is the most expensive among the above assortment. The material has a number of positive features. The area where the composition is applied perfectly withstands high dynamic loads.

Polyurethane wood adhesive: hot melt adhesive, one-component Titebond

1.14 kg / l;

Volatile Organic Compounds (VOC): 0 g / l;

Freeze resistance: stable.

Applications

- Interior decoration and renovation

- Exterior decoration and renovation

- Gluing wood at home

- Manufacture of joinery and construction products for further use on the street

- Garden and park arrangement

- Furniture manufacture

Application examplesGazebos, benches, mailboxes, small architectural forms, etc. Directions for use

- Application temperature: above 10 ° С;

- Assembly time after glue application: 20-25 minutes (at 21 ° C and 50% relative humidity);

- Consumption: 165 ml / m 3 ;

- Compaction pressure: Sufficient to form a strong bond (typically 2.11-5.62 kg / cm 3 for HPL, 7.03-10.55 kg / cm 3 for softwood, 8.79-12.31 kg / cm 3 for medium wood, 12.3-17.58 kg / cm 3 for hardwood);

- Method of application: by roller, brush, spray;

- Work surfaces must be dry, free of oil, grease, dirt, peeling old paint and any other materials that reduce adhesion;

- Cleaning: excess non-dried glue is removed with mineral spirits, dried glue - mechanically.

- Bonding strength (on hard maple) according to ASTM D-905;

Restrictions:

- The adhesive is not intended for use in conditions of constant humidity and for joints below the water level.

- Does not apply when the temperature of the glue and material is below 12 ° C.

- Do not use for connections under significant static load.

- Freezing does not affect the properties of the product, but it can cause the product to thicken. Stirring brings the product to its original state.

- It is recommended to test on small samples of the parts to be bonded before gluing.

- Not recommended for direct food contact.

Storage

- Expiration date: 24 months in original packaging at 24 ° С

- Peculiarities

- Conforms to water resistance class D4

- Bonds almost any material

- The bond strength is the same as with epoxy adhesives, but the adhesive is ready to use

- Short pressing times - fast drying

- Excellent sanding ability

- Solids 100% - no harmful volatile components

- Solvent free

Security measures May cause irritation to eyes, skin, respiratory system. Contains isocyanate polymers. Titebond Polyurethane Liquid Glue may cause eye irritation. Prolonged or repeated exposure to the skin may cause irritation, sensitization or an allergic reaction. If eye contact occurs, rinse abundantly with running water for 15 minutes, consult a doctor. In case of contact with skin, wash with soap and water. Keep the glue out of the reach of children! Use only for its intended purpose.

Specifications

Compared to other similar products, polyurethane "Desmokol" is a glue that has higher reliability and ductility and is capable of repelling water.

The composition is available in the form of a gel or granules, the volume of the package may also differ:

- tubes (minimum volume - 50 ml);

- metal cans with a capacity of 1 liter;

- eurobucket (volume 20 l);

- barrels with a volume of 200 liters.

Granular glue will need to be self-thinned with a solvent before use. In this case, the quality of the resulting composition will directly depend on the purity of the solvent.

Features of polyurethane wood glue

Quite often you have to deal with a situation where you need to firmly glue wooden parts, surfaces or parts of objects. Such a need may arise during construction or renovation work. But also wooden items or furniture may need to be repaired due to a split or break. In any case, before carrying out gluing work, the question arises of choosing a high-quality and reliable adhesive composition. The article will focus on the properties and specifics of polyurethane glue for wood.

Description

Polyurethane adhesives have a very wide and varied range of applications. In our country, this type of glue appeared not very long ago. But in Europe it has been used for many decades.

Polyurethane glue for wood quickly gained popularity and began to be used for various types of glue work in everyday life, industry and the repair and restoration field.

The main advantages of these adhesives include a number of properties.

- The hardened glue line is very strong and can withstand serious dynamic loads.

- This type of glue is moisture resistant.

- The frozen composition does not collapse and does not change its properties during temperature extremes and under the influence of direct rays of the sun.

- This type of glue is very convenient for working with porous materials.

- Polyurethane adhesives with the addition of resins are resistant to aggressive solutions (acids and alkalis) and oil products. They can provide high-strength adhesion of wood to other types of materials.

Disadvantages:

- compositions for gluing wood materials on a polyurethane basis are the most expensive;

- during work it is necessary to use rubber gloves, since when the fingers of the hands come into contact with the glue-treated surface, dark, hard-to-remove marks remain on it and on the skin.

Varieties

The adhesive composition can be two-component and one-component. Their main difference is the gluing process.

Moisture is not required for two-component adhesive.The process of adhesion to the surface and hardening begins after mixing of its two components. In this regard, before use, it is necessary to knead the adhesive solution.

At the moment, the most popular and well-proven adhesives are several polyurethane-based adhesives.

Soudal 66A is a high quality Belgian adhesive. Possesses the highest adhesion and a wide range of operating temperatures (from -30 ° С to + 100 ° С). Suitable for gluing wood to each other and to other types of materials.

- Titebond is a professional adhesive. Based on several types of solid synthetic resins. The glue adheres perfectly to all types of wood, including oiled wood. The objects glued with it can be used in extreme conditions and under high dynamic loads.

- UR-600 - this adhesive is universal, can be used in everyday life and construction. This one-component adhesive is water resistant. The composition does not contain toxic solvents. The adhesive is sold ready-to-use.

- "Moment Kristall" is a universal adhesive composition of Russian production. It can be used for bonding wood, metals, plastic, leather, rubber, porcelain, glass and other materials. The cured composition is resistant to moisture, alkaline and acidic substances. Moment Crystal is sold as a ready-to-use transparent gel. It does not stain surfaces and does not leave noticeable marks.

- Purmelt QR 4663 is a very high strength polyurethane hot melt adhesive. The composition has high adhesion, quickly sets. Convenient for use in conditions where it is impossible to ensure long-term fixation of the parts to be glued. Differs in high heat resistance (up to +150? С), water resistance and resistance to aggressive solutions and substances. Forms a duroplastic seam.

- Desmokol is a high-quality fast-setting adhesive. It is a gel-like organic rubber solution. The hardened seam is resistant to temperature extremes and moisture.

Work tips

It is worth listening to the advice of professionals:

- excess adhesive should be removed from the surface with a sponge or rag as soon as possible;

- too thick layer of adhesive solution should not be applied;

- the adhesive must be distributed evenly over the surface;

- the surfaces to be glued must be thoroughly cleaned and degreased beforehand;

- for bonding porous surfaces, it is better to use a more liquid adhesive.

For an overview of Titebond Polyurethane Liquid polyurethane glue for wood, see the video presented.

How to choose the best wood glue for wood

The choice of a suitable adhesive material must take into account a number of requirements. Let's list the most important criteria.

1. Purpose

All funds are divided into universal and highly specialized. The latter cope with their task as efficiently as possible. However, buying them is not always justified. So, if you need to repair, for example, a small photo frame, it is impractical to buy an expensive super-strong and waterproof product. PVA or its analog is suitable

It is important to understand the features of the product and its operation. A quick-set mixture may be required for a vertical joint.

A part under load requires a particularly strong connection, etc.

2. Features of wood

The characteristics of the material, the features of its processing, depend on the type of wood. The adhesive mass must match them exactly. It is a little more difficult if different types of wood are combined. Each has its own characteristics. In this case, choose especially carefully.

ShutterStock

ShutterStock

3. Humidity and temperature

Application and operating conditions differ for different products. Even a slight deviation from the recommended standards deteriorates the viscosity of the substance, negatively affects the quality of the seam. At high humidity, the time of hardening and curing increases. This is especially true if you have to work outdoors or in the bathroom.

4. Environmental friendliness

It is important to know if the product emits toxic substances during the gluing and use process. What is the danger in contact with mucous membranes or skin, is contact with food or drinking water allowed

The best adhesives for wood in terms of environmental friendliness are natural. They are completely safe.

5. Water resistance

An indicator characterizing the degree of water resistance of the hardened seam. A scale has been developed based on laboratory tests. It is used to mark adhesives.

- D4. Maximum water resistance. Operation is permitted outdoors, in damp rooms.

- D3. Short-term exposure to liquid is allowed. Possibility of operation in street conditions.

- D2. Indoor use only. Possible short contact with condensate or liquid.

- D1. Minimum water resistance. Indoor operation. Contact with liquid is unacceptable.

ShutterStock

ShutterStock

Polyurethane glue for wood: selection and tips for use

When evaluating different types of adhesives, it can be difficult to choose the right one. This is especially true when working with wooden surfaces. When choosing the best option, the characteristics of the wood itself and the characteristics of the material to which it will be glued are taken into account. You also need to know about the loads that this seam must withstand.

In this case, the use of polyurethane glue will be quite justified. This type of composition has long been used in all European countries, and in Russia it is only gaining popularity.

Peculiarities

Polyurethane adhesive is an excellent product for working with wood, rubber, metal, stone, marble, PVC, MDF and mosaics. It stands out among its analogues for its excellent sealing properties. In a frozen form, such a composition is good heat and sound insulation. In addition, with its help, the gluing of different materials occurs quite quickly.

Polyurethane compounds are often used for interior decoration: in kitchens, bathrooms, restrooms and balconies. In external decoration - for cladding facades or roofs. In industrial premises, such glue is used less often.

The main advantages of polyurethane glue:

- high level of adhesion;

- able to withstand large temperature ranges;

- heat resistance;

- easy to use on porous surfaces;

- moisture resistance.

When working with polyurethane glue, the surface must be free of dust and dirt. The applied layer should not be more than 5 mm. When hardening, it is best to lightly press the element against the surface.

Polyurethane adhesive mixtures are available in one- and two-component. You need to know the difference between these formulations. The action of the two-component glue begins immediately after mixing all the components. The disadvantage is that a special mixing container is required. The one-component composition is already ready to work. It does not begin to freeze immediately, but only half an hour after opening the package - this gives time for preparation, does not force the master to rush. Such glue begins to set under the influence of moisture or humidity in the air / surface.

Varieties

When choosing an adhesive, it must be borne in mind that there are many different types of adhesive mixtures on the market.

They have different properties and qualities, so you need to pay attention to the most popular

Sar 306

Sar 306 is a one-component compound for working with rubber or leather. Grips quickly, is able to withstand any temperature.

Ur-600

Ur-600 is a universal waterproof compound. It is used both in everyday life and at production facilities. Sold completely ready-to-use. It is used when working with almost all materials - its versatility explains its popularity. After curing, it forms an elastic seam that can withstand low temperatures or gasoline.

Soudal

Soudal is a glue designed for working with foam and drywall. Has a high drying rate, low consumption and high adhesion to wood or concrete.

The best brands of joinery adhesives

Manufacturers

On the market, wood glue is represented by a large variety of well-known brands. The leaders in this segment are Moment, Titebonde and Titan.

Titebond is manufactured by Franklin International. The product is recommended for plywood furniture, wooden floor surfaces, and other types of woodworking. The composition does not include solvents, and the main components are natural and synthetic polymers. This feature provides good adhesion of surfaces to each other.

There is a series of Titebond II Premium formulations that are in great demand for door and window applications. The composition has a high level of moisture resistance, therefore, it manifests itself perfectly during operation on the street. Quite often, a similar tool is used to decorate a wooden facade with various elements.

Henkel is popular for its "Moment Super PVA D3" products. It is used for industrial purposes, as well as in everyday life for gluing cardboard, paper or plywood. Waterproof PVA glue acts as an additive in concrete solutions, due to which the plasticity of the finished mass increases. D4 formulations indicate a high class in terms of product water resistance. Such funds are positioned as special-purpose goods, therefore, they are distinguished by a high price.

"Moment Stolyar" is the best Russian glue, which is a water dispersion that perfectly adheres any type of wood, as well as building materials. Professional carpenters note its quick drying, affordability and durability.

"Universal Titanium" is recommended for bonding plastic, glass and wood. Such a quick-drying glue quickly gains strength, becomes colorless, therefore it is considered an excellent option for working with wood and wood-containing materials.

Secunda wood glue firmly glues cardboard, leatherette, wood, chipboard and fabric. Can be used for fixing various combinations of materials and products. The adhesive is popular in furniture repairs and flooring installations. The composition is odorless, therefore it can be used in closed rooms.

Moment

The quality of the seam is slightly lower than that of the brands from the top, but still at a fairly high level. For the most part, PVA adhesives for wood from Moment are strong middle peasants, but they have no close competitors among domestic brands.

Kleiberit

A very high-quality German brand that produces only the most top-end products. Adhesive is a brand in different categories occupies the first positions due to the excellent characteristics and strength of the seam. The only drawback of this brand is the price, but for professionals who value the quality of the final products, this drawback is not so significant.

Akfix

Akfix is a Turkish brand that has been producing construction chemicals for a long time, including wood glue. Most professionals know this company, but ordinary people who need wood glue only for housework, it is little known. But this unknown should not scare you - Akfix produce sufficiently high-quality joiner's glue for wood, which for the most part is not inferior to many other, more well-known brands.

SOUDAL

For those who are wondering what a good wood glue is, SOUDAL is a great option. According to the reviews of professionals, they value this brand for its good quality, but the price is sometimes overpriced. In addition, adhesives of this brand tend to foam strongly, which may not always be beneficial.

This American brand also produces only top-end products in its categories. Many professionals consider Wood Glue Titebond to be the most convenient to work with. This is due not only to ease of use, but also to the high quality of the seam, which, moreover, is practically invisible after work. Another feature of Titebond glue is the ability to work with exotic wood species, but still it is most often used when gluing tenon and groove structures.