2.4. Determination of the coefficient of relative compaction of sand, taking into account winter conditions

2.4.1. In winter, the shipped sand is

in a free-flowing state, therefore, the coefficient of relative compaction should

installed through the bulk density, determined in accordance with GOST 8735-88 at

natural state of the sand.

2.4.2. Standard tank temperature for

determination of bulk density should correspond to the ambient temperature

air.

2.4.3. Bulk determination procedure

density and the calculation of the coefficient of relative compaction are similar to those indicated

in p.p.

—

and adj. ...

SCROLL

regulatory documents and standards

1. SNiP 2.05.0.2-85 "Highways".

2. SNiP

4.02-91 and SNiP

4.05-91 “Collection of estimated norms and prices for construction work. Collection 1.

Excavation".

3. SNiP 3.02.01-87

"Earthen structures, foundations and foundations."

4. GOST 25100-95 “Soils. Classification".

5.GOST 11830-66

"Construction Materials. Weighing accuracy rate ".

6. GOST 8735-88 (STSEV5446-85) “Sand for construction work. Test methods ".

7.GOST 8736-93

“Sand for construction works. Technical conditions ".

8.GOST

12536-79 “Soils. Methods for laboratory determination of granulometric (grain)

and micro-aggregate composition ".

9.GOST

22733-77 “Soils. Method for laboratory determination of maximum density ”.

10.GOST

5180-84 “Soils. Method of laboratory determination of physical characteristics ".

11.GOST 30416-96

“Soils. Laboratory tests. General Provisions ".

12.GOST

12071-84 “Soils. Selection, packaging, transportation and storage of samples ”.

TERMS AND DEFINITIONS

Compaction factor (Kat) - the ratio of the density (skeleton) of dry soil in the structure

subgrade to the standard maximum density (skeleton) of dry soil,

determined by the device Soyuzdorniya (GOST

22733-77).

Required soil compaction factor (Ktr) - the compaction factor (fraction of the standard density) provided for

in the project of work or established in SNiP 2.05.02-85 for a specific horizon from

top cover.

Relative compaction coefficient (K1) - the ratio of the required density (skeleton) of dry soil in the embankment (), set taking into account the compaction coefficient according to table. 22

SNiP 2.05.02-85, to its

density adopted in calculating the volume of soil.

Roughly K1 it is allowed to take according to the table. 14 compulsory adj. 2 SNiP 2.05.02-85.

Required volume of earthworks () —

product of the design geometric volume of the soil in the embankment or otherwise

structural element of the road structure (V2) and the values of the coefficient of relative compaction (K1).

Design geometrical volume of soil (V2) - the volume of soil, determined by the calculation in the project for the corresponding

structural element of earthen road bed or bedding

clothing, taking into account the required compaction coefficient.

Average weighted density of dry soil in

career (reserve) - the ratio of the sum of the densities of dry soil

individual layers () multiplied by the layer thickness (hi), to the total thickness of the layers (еhi) presented in the quarry passport.

Bulk density of sand - the ratio of the mass of sand, dried to

constant weight, to the volume poured into a standard container with a capacity of 10 liters

at natural humidity (GOST 8735-88).

Application

3

TECHNICAL CHARACTERISTICS OF VEHICLES

|

Index |

The value of the indicator for a car brand |

||||||||

|

MMZ-585 |

MAZ-503, MAZ-503B |

KrAZ 256B |

KamAZ 5511 |

KamAZ with side loading |

MAZ 5516 |

MD 290, Magirus 380-30 |

Tatra 815, 815S1 |

Volvo FH 420 |

|

|

Carrying capacity |

4,5 |

7 |

11* |

10 |

7 |

16,1 |

14,5 |

15,3 |

27 |

|

Capacity, m3 |

3 |

3,8 |

6 |

7,2 |

7,9 |

11 |

14 |

9 |

17 |

|

Body dimensions, mm |

|||||||||

|

length |

2595 |

3280 |

4585 |

4525 |

5000 |

4450 |

5400 |

4300 |

6500 |

|

width |

2210 |

2284 |

2430 |

2310 |

2320 |

2300 |

2650 |

2290 |

2500 |

|

height |

650 |

676 |

650 |

816 |

635 |

1080 |

1200 |

970 |

1700 |

|

The same, dump truck, mm |

|||||||||

|

length |

5475 |

5970 |

8190 |

7140 |

7570 |

7530 |

8400 |

7190 |

9900 |

|

width |

2415 |

2600 |

2650 |

2500 |

2320 |

2500 |

2800 |

2500 |

2500 |

|

height |

2510 |

2700 |

2780 |

2700 |

2900 |

3160 |

3530 |

2900 |

3200 |

|

Weight, kg |

4570 |

6750 |

1140 |

9000 |

8480 |

12400 |

15500 |

11300 |

16000 |

*)

12 - for work in a career

Application

4

EXAMPLES options for determining the value of the coefficient of relative compaction and

calculating soil volumes

Determination of the degree of compaction

Its purpose depends on the density of the building material, for which structures and buildings it can be used. According to its indicator, the flow rate is calculated in order to find out how much of the mixture will turn out after mixing or how much it is required. It is often necessary to convert cubic meters to mass, and vice versa. In addition, some points of sale are sold in cubes, and somewhere by weight - in tons.

For conversion to other units of measurement, there is a special formula: P = M / V, where: P - degree of compaction, M - mass, V - volume. For example, in the body there are 3 cubes of bulk material with a total weight of 4.8 tons or 4800 kg. The density will then be equal to: 4800/3 = 1600 kg / m3. And vice versa, knowing the degree of compaction and the number of cubic meters in the container, it is possible to determine the weight of sand in a state of natural moisture or wet: M = P / V.

It is possible to carry out calculations with your own hands. Bulk material is poured into a 10 liter bucket from a height of 10 cm until a towering slide is formed. The surface is leveled with a ruler, without sealing it. The average density is calculated according to the following formula: P = (M2-M1) / V, where: M2 - total weight, M1 Is the weight of the container, V is the volume of the bucket, that is, 10 liters. The volume of the container must be converted to cubic meters - 0.01. For example, a container weighs 620 g or 0.62 kg, the sand together with it is 15.87 kg. Its density is: P = (15.87-0.62) / 0.01 = 1525 kg / m3.

Table with indicators of the bulk density of sand of different types:

| Variety | Bulk average density, kg / m3 |

| Quartz | 1400-1900 |

| River | 1500 |

| Wet | 1920 |

| River compacted | 1590 |

| Building | 1680 |

| Dry sand | 1200-1700 |

| Career | 1500 |

| Nautical | 1600 |

| Washed | 1400-1600 |

| Wet | 2100 |

| Water saturated | 3000-3200 |

Bulk material types

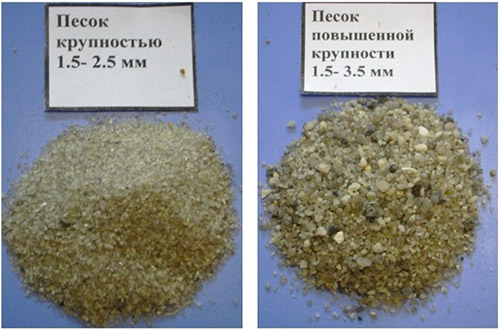

Most often, construction, river and quarry sands are used. The river is formed naturally as a result of crushing by water of rocks, has a rounded shape. Since it is constantly washed, there are almost no impurities in it, so it does not require additional cleaning before use. It is divided into several groups by size. Grains up to 2 mm are called small, 2-2.8 - medium, 2.9-5 - large.

Bulk average density is 1650 kg / m3. The main advantage is that it is an environmentally friendly and safe material both for the environment and for humans. It is used for mixing masonry and plaster mortars, making concrete products, dry mixes, as well as landscaping. River sand has a high cost, so if it can be replaced according to technical standards, then it is better to choose a quarry one.

It is used when laying highways, creating pillows for foundations, bedding. In the manufacture of concrete and various mortars, it is used as a filler. Consists of many different elements - spar, mica, quartz, and so on. Depending on which component makes up the largest part in it, it is assigned a name, for example, if it is limestone, it is called limestone.

When choosing, it should be borne in mind: the coarser the grains, the more binder powder will be required for mixing the solutions. The cement must close all the voids, otherwise the structure will turn out to be fragile. Because of this, the cost of the cement or concrete composition increases.

It is also necessary to pay attention to the degree of radioactivity, especially if it is quarry sand. Only first class material is used for the construction of the house

To keep costs down, you can buy unwashed sand and clean it yourself. But it is recommended to do this if a small volume is required, otherwise it will require too much time and large labor costs. You can purchase building materials both in bulk and in bags.

Bulk and specific

Bulk density is a special characteristic of any bulk materials, including dry cement. This indicator can be determined in various units of measurement, but most often builders and materials scientists represent it in kilograms per cubic meter (kg / m3).

An alternative name for this indicator is the specific gravity of a substance. This characteristic of cement can differ depending on many factors, but builders and materials scientists have determined approximate values for each type of material in a normal state.

In general, the bulk and specific gravity of cement is known for different groups of this material:

alumina class;

Aluminous

portland cement;

Portland cement

slag class;

Slag class

pozollan class.

Alumina cement is a fast acting hydraulic binders. A special mixture for this material is selected, since it must be rich in alumina. In addition to this component, this cement also contains a sufficient amount of various impurities.

They allow you to increase some indicators and performance properties of the material. At the moment there are several types of this cement: GC-40, GC-50 and GC-60. First of all, their difference is that they harden over a different amount of time.

Portland cement also belongs to hydraulic binders. It is made by grinding several components together. These include clinker, gypsum and various additives.

Among the chemical compounds in this material, calcium silicates predominate, the amount of which reaches 80 percent, depending on the manufacturer. It is this type of cement that is most often used in construction in different parts of the world.

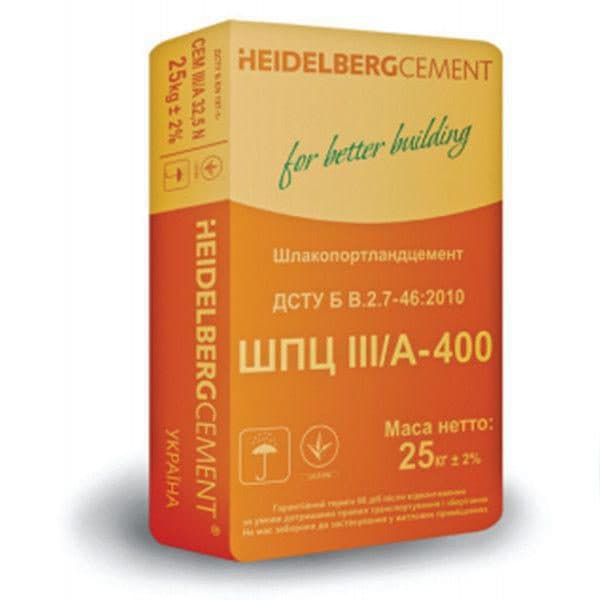

This is due to its excellent characteristics and performance. The bulk density of this cement of grades M400 and M500 ranges from 1100 to 1300 kg / m3.

M 500

As for the specific indicator, it is somewhat higher than that of aluminous materials: from 3100 to 3200 kg / m3.

The density of M200 cement is slightly lower than the provided data, since it has a smaller amount of various additives and impurities. Accordingly, the scope of application of such a material is more limited, since this indicator affects many properties and qualities of cement.

M 200

Slag cements are distinguished by the fact that their additives are active mineral substances in the form of granular blast-furnace slags. Due to the fact that these components of the material have the ability to harden on their own, a binder of this type is obtained of better quality than its puzollan counterparts.

In addition, the production of such cements is the correct disposal of blast furnace products, which are used in the smelting of pig iron from ores. There are three grades of these types of material: M300, M400 and M500. They have individual characteristics and application features.

Read the material about the technology of cement production.

The specific density of slag portland cement is 2900-3000 kilograms per cubic meter, while that of sulphate-slag substance is 2800-2900 kilograms per cubic meter.

Pozollan cements began to be produced a long time ago. These materials are among the most ancient binders, since for the first time the substance of volcanic rock - pozollana, was used in ancient Rome. This material is distinguished by increased anti-corrosion properties.

The specific gravity of pozollanic cement in a loose state is in the range from 800 to 1000 kilograms per cubic meter. If this material is compacted, then this indicator will slightly increase - up to 1200-1600 kilograms per cubic meter.

As for the specific gravity of the pozollan binder, it does not exceed 2700 to 2900 kilograms per cubic meter.

For more information on how to determine the density of cement, see the video:

Other calculation methods

Calculations must necessarily be carried out during the preparation of a planning project for all work on the construction of real estate. If the soil is loose, this will allow the pit method to be applied.

For this, the soil is leveled and a small pit is made, the displaced sand is transferred to a special container, which will be weighed later. A cone is placed over the pit; it must be covered with dry sand. Then the volume of the pit is determined, from which the volume of suspended sand is calculated. You also need to know the soil compaction coefficient and the sand filtration coefficient.

This method is quite simple, but only preliminary calculations can be obtained with it, so always check the results mathematically.

This parameter is assessed based on how the material can absorb and scatter radiation.

Average additional indicators of sand that is mined from quarries:

- first class radioactivity;

- density in an unconsolidated state - 1.4 t / m3;

- mass of particles per unit of their volume - 2.6 g / cm3;

- crushed rock content - 1.9%;

- heat capacity.

Average additional features that are mined from the river bottom:

- the ability of atoms of some isotopes to spontaneously decay, emitting radiation A (47 BK / kg);

- density in an unconsolidated state - 1.4 ± 0.1 t / m3;

- the amount of chemical elements that have passed into the composition of the alloy in the process of its production as a technological additive is 0.1%.

The number of voids should be determined by the density of the material in the unconsolidated state. On their own, this value can be measured in this way: a little material for the sample is poured into a measuring liter container and weighed.

If the material has accumulated moisture very strongly, then the sample can be placed in a ten-liter container, then the values are converted to the required value.

From sand, which contains a high percentage of clay, it is forbidden to make plaster, high-quality building mixture, various mortars for construction.

With a high percentage of clay

All this is due to low frost resistance and strength.

How to calculate the amount of sand in kg using the density of GOST 8736 sand

To calculate the mass of sand GOST 8736, you can use the formula: m = V * p (m is the mass index, V is the volume, p is the density). For example, you need to find out the amount of material in question in 15 m3, then the numbers are substituted in this way:

m = 15 x 1.3 = 19.5 t.

In the example described above, the average density number p was used, which equals 1.3 t / m3. This is how the density of building sand is measured, t m3.

Why is it completely unprofitable for the construction of houses? Due to the increase in the volume of the binding material, the costs and the price of the concrete mix become much higher. As a result, the construction of real estate becomes unprofitable in terms of recoupment. This is extremely necessary for a construction company.

For private housing construction, such a difference in price will not greatly affect the costs, because here completely different scales are taken into account and taken into account. If the material has accumulated a lot of moisture, this will cause a decrease in density.

This can be explained by the fact that adhesion of fractions occurs.

If the material has accumulated a lot of moisture, this will cause a decrease in density. This can be explained by the adhesion of the fractions.

The density decreases until the moisture content is ten percent. Further changes increase the volumes of liquid, it actively fills the free space, which has a positive effect on the density, it begins to increase.

The fact that the cement slurry is constantly changing its parameters affects its quality. The main thing here is that certain standards are observed during delivery.

Concrete mix

You can also take measurements using improvised methods. Material of the same height is poured into a ten-liter container. The container should be completely filled, perhaps a slide will appear, which should be cut strictly horizontally. The result is a horizontally flat surface.

The remaining amount of material must be weighed, then the density is calculated.To do this, the mass is divided by the volume: the obtained indicators must be converted into tons, and the total number is divided by 0.01 m3

For a more accurate calculation, it is important to carry out all measurements several times, at least 2

Species overview

There are several types of quarry sand. According to the method of processing, each type has its own characteristics and differences. Each type has its own purpose. All types of material are mined by licensed enterprises, which, even before the start of work, submit estimates and plans for the development of quarries to government agencies. According to the type of processing, sand is washed, seeded and unpaved.

Alluvial

This type of sand is mined by means of hydromechanical devices. By using the water rinsing technique, it is possible to rid the sand of foreign suspensions. This species is distinguished by its purity, it is washed several times. It does not contain harmful components and various suspensions, they are removed immediately during extraction.

This type of sand is used in the production of concrete and bricks, reinforced concrete products. With its help, they build highways, they buy it for the construction of buildings for various purposes. This is a high quality type of material. It is mined from flooded deposits, washing out impurities and even dust.

Seeded

The method of extracting seeded sand is different. It is considered extremely simple. In this case, the technique of technical and mechanical sieving is used. In the course of cleaning, equipment with a mass of sieves and cells is used. As a result, large fractions and stones are removed from the total mass. A fine-grained product of this type is used in the manufacture of plaster mixes and mortars.

Sandy

Open pit sand is classified as a less pure variety. The content of foreign inclusions in it can reach 40%. Because of this, it is not suitable for finishing work, it is more often used as a trench filler and for leveling land plots. This is a low quality draft.

However, it is actively used in utilities and agriculture. It is he who is used in winter for sprinkling on ice. It is also used as a way to preserve vegetable crops. But it is not suitable for either concrete or cement mortars. Its impurities impair performance.

In the next video you will find interesting information about the extraction, delivery and application of quarry sand.

What affects the weight characteristics?

There is a whole list of factors to consider when calculating the weight of sand. Among them are grain size, size of fractions, amount of moisture and even density. The weight will also differ when there are impurities in the composition of the building material. They strongly affect the indicator in question.

It is also worth considering that there is always free space between the grains. It, in turn, is filled with air

The more air, the lighter the material and vice versa. The heaviest is compacted sand. Speaking specifically about the mass of natural material, then it can be real, bulk and technical. Indicators are determined taking into account the ratio of mass to volume.

For the derivation of the final index, not everyone takes into account the porosity. You need to understand that the real mass is lower than the same true value. And all because in real terms, the indicator is only conditional. Now let's talk about the bulk density. If this is dry material, not mined from a quarry, but from a river, then its indicator is 1.4-1.65 tons per m3. If we take the same type of sand only in a wet state, the indicator will already be 1.7-1.8 tons. In a compacted state, the same sand shows a figure of 1.6 tons per m3.

But there are other types as well. For example, material that is mined in a quarry. Sand with small grains, which is also called fine-grained, has a bulk density of 1.7-1.8 tons. If it is a material made of crystalline silica, then its bulk density is 1.5 tons per m3.If it is crushed sand, then the indicator will be 1.4. and if compacted, then 1.6-1.7 tons per m3. There is also material that is mined in a different way, in this case we are talking about the development of rock, which goes under the 500-1000 brand. Here the bulk density is 0.05-1.

Of great importance on the weight under consideration is the amount of foreign constituents, which are also called impurities, and the saturation with minerals. Sand can be made from an initially heavy mineral or from a light one. In the first case, the indicators will be more than 2.9, in the second less than this level.

Speaking specifically about volume, there are three types of sand. It is supplied for coarse, medium and even fine construction mixes. Why is faction size so important? Because this parameter affects the ability of the sand to absorb moisture. How much you have to spend to create a mixture will also differ. You can find on sale sand 1, 2 classes. If the grains are from 1.5 mm, then we are talking about the first class, in the second this indicator is not taken into account.

The specific gravity largely depends on the method of laying the building material. This can be either a classic bedding, or a compaction by workers, or just a loose surface. The more water is contained in the sand, the greater the mass of such building material. Also, if it was kept wet at a temperature with a minus sign, then its specific gravity increases.

How to calculate the quantity using density?

Mass is calculated by the formula: m = Vxp (m - mass, V - volume, p - density). Let's say you need to find out its amount in 10 m³, then the data is substituted in this way:

m = 10 x 1.3 = 13 t.

Here, an average density p of 1.3 t / m³ was used.

Always keep in mind that insufficient density means increased voidness. Then the preparation of the solution will require an increase in the amount of binders. Why is this disadvantageous for construction? The increase in the volume of binders increases the costs and cost of the concrete solution. As a result, the construction of facilities becomes unprofitable in terms of payback

This is important for construction firms. In private housing construction, the rise in price will not affect costs, because its scale is much smaller.

An increase in moisture will lead to a decrease in density. This is due to the adhesion of fractions. In this case, the decrease continues until the humidity reaches 10%. Further growth increases the volume of the liquid, it fills the free space, and the density begins to increase. A constant change in the parameter changes the quality of the concrete mix

It is important here that the norms are respected for deliveries

How to measure it in an improvised way? Sand is poured into a 10-liter bucket from a height of 10 cm. The bucket should be completely filled to form a slide. It is cut strictly horizontally to obtain a guaranteed flat surface of the filled bucket. This amount of sand is weighed, then the density is calculated. To do this, divide the mass by volume: the resulting kilograms are converted into tons, divided by 0.01 m3. An even more accurate calculation is obtained if measurements are taken twice. Then they are summed up, divided by 2.

Specifications

The document strictly regulates the partial proportion of dusty lumps in the sand. The percentage of clay is also determined.

| Classification | Amount of acceptable components in natural sand | In the sand from the screenings | Content in natural sand clots | Clay in the screening sand |

| Class I | ||||

| Very big | – | 3 | – | 0,35 |

| Large - Medium | 2 | 3 | 0,25 | 0,35 |

| Small | 3 | 5 | 0,35 | 0,50 |

| Class II | ||||

| Very big | – | 10 | – | 2 |

| Large - Medium | 3 | 10 | 0,5 | 2 |

| Small and very small | 5 | 10 | 0,5 | 2 |

| Slim - very thin | 10 | There are no regulations | 1,0 | 0,1 |

Strength grade

Deviation in fine-grained material of the second class is allowed, but by prior agreement with the manufacturer and within 7%. The grade of sand depends, especially in the screening type, on the resistance of the material.

Standard characteristics are presented in the table:

| Strength grade | Resistance limit of the rock when it is saturated with water, MPa | Crushed gravel grade |

| M1400 | 140 | |

| M1200 | 120 | |

| M1000 | 100 | Dr8 |

| M800 | 80 | Dr12 |

| M600 | 60 | Dr16 |

| M400 | 40 | Dr24 |

With preliminary agreement of both parties to the contract, it is possible that GOST 8736 sand will have differences (screening out when breaking) strength. Instead of a minimum threshold of 40 MPa, a decrease in this indicator is allowed, but still not lower than 20 MPa.

Sand, which is intended for filling concrete, among other characteristics, must be resistant to the effects of a chemical reaction on alkali. This is influenced by the composition of the sifting sand.

Filtration coefficient

The necessary indicator is the coefficient of filtration and compaction of sand, which allows you to assess the penetrating ability of the material.

Filtration coefficient

The higher the value, the more qualitative characteristics it has. The lowest throughput brings the value closer to 0. A low indicator indicates a clay component, which may narrow the scope of use of sand.

In position A, sand GOST 8736 contains instructions on the types and possible components, impurities that are considered harmful. Bulk and true density, filtration coefficient, grain components - sand made according to GOST 8736 93 must be kept individually by the manufacturer and indicated in the documents.

True and bulk density

Natural quarry or mining

Quarry and screened sand, which has a grain density of more than 2.8 g / cm3 or contains rocks, impurities with a negative impact may have a limited number of applications.

Career

When there are any deviations from the standards, then such sand has a narrow focus on undemanding areas of production. This is preliminarily regulated with specialized research centers.

Coarse for construction work

Building sand that has passed GOST 8736 93 is allowed to mix between natural type and screening sand. Mass fraction of the second type is not more than 20%.

Building

The manufacturer is obliged to provide the buyer with full information on geological exploration, which indicates: petrographic and mineral structure of the rock, the amount and type of organic matter, the density of grains, and voidness.

Medium-grained river

Natural river sand should have a reference color even when the material is treated with sodium. Radiation-hygienic assessment is carried out in special laboratories, where the level of natural radionuclides is determined.

River

Based on the estimated data, a conclusion is drawn about the scope of use of sand:

- content less than 370 Bq / kg - the material is applicable for the construction of new buildings;

- the amount from 370 to 740 Bq / kg allows the use of sand as filling for highways that are located within populated areas. Also allowed for use in the construction of enterprises;

- if the assessment showed 740-1500 Bq / kg - this is the least valuable type, it is used only for laying highways outside cities.

Road laying

Sand GOST 8736 93 is cleaned of garbage, if possible, otherwise it is excluded from production.

For more information on the use of sand, see the video: