Selection Tips

When choosing a sealing wire, it is necessary to take into account several fundamental factors, selection criteria, among which the main ones are:

type of product, above we talked in detail about each of the types of sealing wire;

technical specifications;

what exactly the wire is needed for sealing;

the type of seal that will be installed on the wire, products for rotary and lead seals are different;

price;

manufacturer, it is important to consider which company is the manufacturer of the product, it is best to give preference to the most famous, popular and well-established companies.

For information on how to self-seal without a sealant, see the next video.

Characteristic

Sealing wire is a product that is widely used in various fields of activity, both in household and professional. Most often it is used by housing and communal services for sealing meters. Also, the product is used for sealing:

- doors that are both outdoors and indoors;

- cabinets and safes;

- counters, showcases, many other commercial areas;

- cars and trucks;

- fire extinguishers;

- terminals at train stations;

- collection bags;

- switchboards.

The sealing wire is designed to resist unauthorized opening and breaking of a sealed object or object, it also does not allow the seal to be forcibly removed and does not allow it to slip. That is why it must be very durable and not be afraid of various external influences - atmospheric, acid, etc.

Sealing wire is manufactured exclusively in accordance with the requirements of legislative normative acts, the main of which is GOST 3282 - 74 “Low-carbon steel wire for general use. Technical conditions ". This document clearly describes all the technical requirements, properties, which the product must fully comply with. Also, several requirements are indicated, according to which such a wire must:

- have high corrosion resistance;

- be characterized by high tensile strength;

- be resistant to various mechanical influences.

GOST 3282 - 74 also specifies the manufacturing technology of the product. According to this regulatory document, the product must go through the following stages, manufacturing processes.

- The stage of "etching". A stainless steel wire is soaked in a special solution with a high sulfuric acid content. This process removes the scale layer from the surface of the product.

- Next, the wire is washed in ordinary water to remove the remaining sulfuric acid.

- Cover the wire with a lubricating layer. This manipulation allows you to improve the properties of the product at the initial stage of its production.

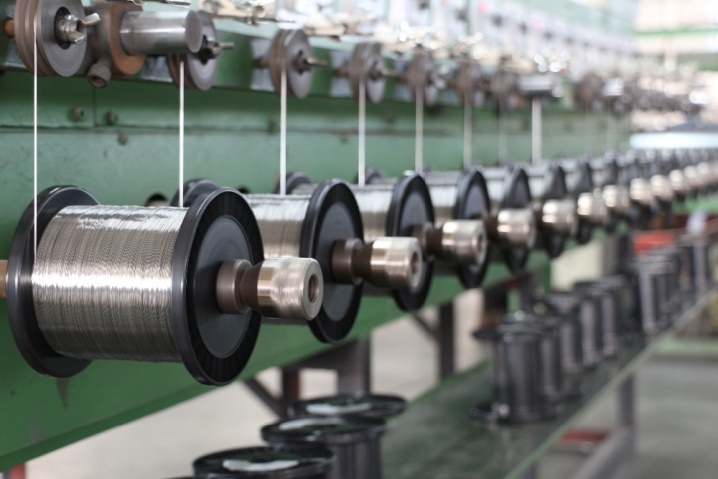

- At the last stage of manufacturing, special devices are used, with the help of which the process of single or multiple drawing of the wire and bringing it to the desired state takes place. The single drawing process involves the use of only one special apparatus. With repeated drawing, the number of fibers placed inside the unit can reach 15 pieces. With the use of multiple dragging, a small diameter sealing wire is produced.

After that, the wire is quenched at a temperature of more than 900 ° C and cooled in a solution of nitrate at a temperature of 500 ° C.For manufacturing, they use exclusively low-alloy steel or stainless steel, which is resistant to an aggressive environment and is able to withstand a very high load during operation.

Varieties of wires for sealing

- The wire for sealing the combined type "D = 0.75 mm". This is the thinnest type of wire for sealing, used for devices made of lead. It is made of low-carbon steel that has undergone a special heat treatment. In addition, the wire is coated with a zinc coating in accordance with GOST 3282/74. Also, during its manufacture, a spiral twisting of two thin metal veins with a diameter of no more than 1/3 of the entire part as a whole is carried out.

- Wire for seals of the combined type "D = 1.0-1.1 mm". The composition of such a wire includes the same components as in such a wire of the previous classification, with the only difference that its diameter will be larger.

- Sealing monowire made of low-carbon steel alloy "D = 0.55 mm." It is made, respectively, of a low-carbon steel alloy.

- Rope for sealing "D = 0.52 mm". The rope for sealing is made by twisting seven thin metal veins, each of which is a thin wire made of stainless steel alloys.

- Copper monowire for sealing "D = 0.5 mm". This wire is intended for sealing objects in environments with a high level of humidity, since it is not subject to corrosion. for physical exertion of medium severity, be resistant to corrosion, temperature extremes, humidity. Stability is also necessary for such a wire, because it should in no way break from mechanical stress in the event of an accidental fall or sudden gusts of wind and other unforeseen situations.

Classic sealing wire for ZPU class "Sprut" and typical lead seals are made of high-quality steel with a low carbon composition so that they do not break when bent. As for the technical parameters of these filling components, their height is achieved thanks to a special production technology of spiral twisting of the thinnest metal veins.

Classic sealing wire for ZPU class "Sprut" and typical lead seals are made of high-quality steel with a low carbon composition so that they do not break when bent. As for the technical parameters of these filling components, their height is achieved thanks to a special production technology of spiral twisting of the thinnest metal veins.

All types of wires for sealing differ in diameter, while the diameter is based on the number of these same metal veins in the sealing rope. The number of cores can also vary, it all depends on the size of the seal for which such a wire will be used. Our company provides you with the widest range of wires for sealing meters.

Views

The assortment of sealing wire today is quite diverse. Products may differ in production technology, technical parameters, properties, color, area of application. It is classified according to these types.

Twisted (knitting)

For its production, stainless steel is used, which is able to resist high loads during operation and constant exposure to an aggressive environment. This type of product is very popular and is often used for sealing important objects. Twisted sealing wire is used for sealing lead, plastic and rotary seals.

She, in turn, also can be of several types. It depends on the material of the main and secondary veins of the product, namely:

- the product is completely made of stainless steel;

- galvanized steel was used for the manufacture of wire, its base and secondary core;

- the base is made of monofilament - fishing line, and the secondary conductor is made of stainless steel;

- elements of the product were made of galvanized monowire.

Stainless

Can be used with numbered, lead or polyethylene seals to seal any object. This type of wire consists of two cores - central and secondary. It is made of high quality materials using modern equipment. That is why the metal wire has high technical properties, excellent strength and high coefficient of stability.

Possesses the following technical parameters:

- product diameter - 0.5 mm, each of the cores with a diameter of 0.25 mm;

- consists of two cores;

- destructive force coefficient - 9 kg.

It goes on sale in the form of a coil on which the wire itself is wound.

Copper

Copper is the material most often used to make sealing wires. During the production of the product, reliable and modern materials and new equipment are used. As equipment for manufacturing, special machines are used - wire rods. The diameter of the copper sealing wire is from 038 mm to 0.2 mm.

Aluminum

Aluminum is also a fairly popular and frequently used material. The production process is similar to the production of copper wire, wire rods are also involved. But according to the requirements of GOST, the manufacturing process must necessarily consist of two stages.

- The first stage includes the process of drawing blanks without sliding. After this process, the diameter of the product ranges from 0.45 mm to 0.59 mm.

- The second stage involves drawing the product, only with sliding. After these manipulations, the final diameter of the product, ready for use, is established, it ranges from 2.0 to 0.3 mm.