Material features

Tile adhesive Litokol Litoflex K80 is a dry cement mixture containing various improvers, artificial resins, chemical additives to increase adhesion. These substances are designed to optimize performance. This tile adhesive has excellent elasticity characteristics, due to which it compensates for the tension between the individual elements of the masonry, between the tile and the base, even with temperature changes.

Litokol glue is often chosen by professionals, builders, because it is very easy to use. Litoflex K80 is technologically advanced, economical in consumption, environmentally friendly, does not contain any harmful additives. Thanks to the quick setting with glue, all tile work can be completed without delay. Due to its heat resistance, the glue may well be used in the installation of a warm floor.

Additional Information:

Today in the construction industry there are many different types of tile adhesives, so the choice should be an easy task for everyone. However, the quality of many of them is poor. If we talk about a really worthwhile product, then one cannot fail to note the advantages of Litoplus tile adhesive. This mixture of glue contains white high quality cement. It is beneficial to use when laying ceramic tiles, both inside and outside. In addition to ceramic tiles, glue Litokol K 55 price perfectly interacts with the surfaces of glass mosaic, natural stone tiles, as well as with a number of other materials.

Why exactly Litokol k55?

First of all, its resistance to low temperatures and water can only be envied. I would also like to say that the technology for making such an adhesive is completely unique, and this, in turn, will serve as a guarantee that this tool will reliably perform all the required functions. The novelty inherent in this glue has a positive effect on its purity. You do not have to worry that Litokol K 55 white glue will negatively affect your health or your pets.

Where is Litoplus K55 usually used?

It is ideal for tiling shower stalls, bathrooms, kitchens and swimming pools with mosaic tiles. In order for the use of litoplus k55 glue to be more successful, it is recommended to apply it on concrete, plasterboard substrates, as well as on heated floors.

Please note that litoplus k55 tile adhesive must not be applied to surfaces with excessive dirt, dust and other contaminants. A clean surface will allow you to fully interact with the material of your chosen cladding.

How to prepare Litokol K55 white glue?

Pour the contents of the entire package of tile glue (25 kilograms) into a clean container, where you should add 6.5 liters of water purified from various impurities. Stir it right away, and then leave it on for about 5 minutes so that it can start a little. Then, the mixing procedures should be repeated. Do not allow lumps to appear in the solution.

So, what else can you say about the uniqueness of lithoplus tile adhesive?

Specifications

The composition of the glue includes white dry cement, as well as the necessary fillers. The general color of the dry matter is grayish. The main technical parameters of the tool:

- the consistency of the finished glue is pasty;

- mixture use temperature: + 5 ... + 40 degrees;

- operating temperature of the glue seam: -30 ... + 90 degrees;

- the time of application of the diluted mass - 8 hours;

- time for adjusting the position of the tiles - 60 minutes;

- specific gravity - 1.35 kg / l;

- adhesion - 1 N / sq.mm;

- frost resistance - at least 50 cycles;

- moisture resistance - high;

- aging resistance - high;

- thickness of the glue layer - 2-5 mm;

- glue consumption - 2.5-6 kg / sq. m depending on the size of the slabs and trowel notches.

After application, Litokol tile adhesive dries within 24 hours, but it is recommended to give it a serious load no earlier than 14 days, when the final hardening occurs. The glue does not allow the tiles to slide vertically, therefore it is used for wall decoration. Grouting on the walls after gluing the tiles can be done after 6-8 hours, on the floor - only after a day.

Glue preparation and application features

Craftsmen prefer to purchase large Litokol packs containing 25 kg of dry mass. To dilute the entire package, you need to take 6-6.5 liters of water. The temperature of the liquid should not exceed -20 degrees, but also not less than +15 degrees. The glue is prepared only by pouring dry powder into water. Changing the mixing order will result in lumps.

It is better to stir the glue not by hand, but with a construction mixer, a drill with a nozzle. Beat the glue until it acquires an even structure without lumps. For ripening, the mass is kept for 10 minutes, covering it from above. After that, Litokol is mixed well again. Further, it is considered ready for use.

To work with tiles and glue, you need to buy two spatulas (flat and comb) or one tool with two different sides. The size of the prong is selected according to the tile - the larger it is, the larger the prong size.

Recommendations for work are as follows:

- distribute the glue over the base with a smooth spatula;

- apply glue to the tile with a notched trowel;

- immediately cover the tile, which is planned to be glued within 15 minutes;

- in some cases (the need to increase adhesion, improve the quality of work), it is necessary to apply the agent both to the base and to the back of the elements, otherwise it is enough to apply only to the tile;

- within an hour, you can change the position of individual elements, this will not affect the quality of the masonry;

- we must not forget to make the seams between the elements, their dimensions are determined by the dimensions of the base material;

- between the tiles, you need to insert the appropriate crosses, then the seams will be even.

With a material size of less than 10 cm, 2-3 mm seams are sufficient, for 20 cm elements - up to 4 mm. Tiles up to 30 cm in size will require seams of 4-5 mm, more than 30 cm - up to 5-10 mm.

Types of adhesives

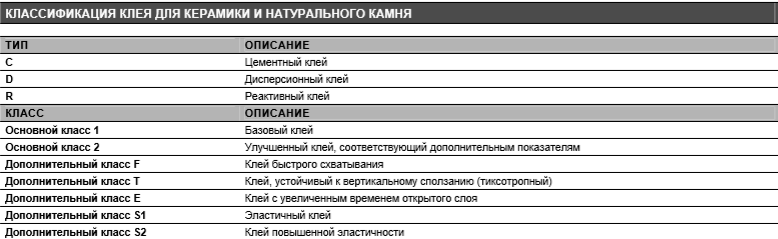

Tile adhesive is divided into 3 main types according to EN 12004 "Ceramic Tile Adhesive":

- Cement (type C, for example, Litoflex K 80) - sold as a dry mixture that is diluted with water. Suitable for laying tiles, natural stone, mosaics or glass.

- Dispersion (type D, for example, Litoacril Plus) - ready-made paste on an acrylic base. Used for laying tiles on a prepared substrate or drywall.

- Reactive (type R, e.g. Litoelastic) is a two-component mixture that must be mixed before use. When mixed, the components react and form a unique adhesive layer. Such glue is used on non-standard substrates: wood, metal, plastic, surfaces with increased operational load.

In addition, mixtures are divided into 7 more classes (according to EN 12004).

- Main class 1 - base adhesive;

- Main class 2 - improved glue, corresponding to additional indicators;

- Additional class F - fast setting adhesive;

- Additional class T - resistant to vertical creep (thixotropic);

- Additional class E - with increased open time;

- Additional class S1 - elastic;

- Additional class S2 - superelastic adhesive.

Classification of tile adhesives according to EN 12004.

Standards for each type of glue.

Preparation of the base

Before work, you need to make sure that the base is flat, without drops and waves. It is necessary to carefully check the surface with a level, the maximum allowable difference is 3 mm.If it is larger, you first need to plaster the walls with any suitable mixture (for example, Lithogypsum, Lithoplan Rapid). For the floor, pouring with a self-leveling compound from the Litoliv series is suitable. After such work, it is allowed to use the tiles only after 14-28 days when the humidity reaches no more than 3%. Concrete substrates are cured for at least 6 months.

Immediately before finishing you need:

- make sure that all areas are solid, securely fastened;

- warm up and thoroughly cool heated floors;

- to treat gypsum, anhydrite bases with primers with the function of reducing water absorption (for porous substrates, 2-3 priming is required);

- dry floors, walls after applying a primer;

- clean the surface from grease, dirt, paint, and other substances, otherwise the level of adhesion will decrease;

- sand, then dust the base.

Tips & Tricks

Finally, we have prepared a few tips to help you do your job efficiently.

- Dilute the mixture with clean water strictly according to the instructions on each package. It is best to mix the composition with a drill.

- After the first stirring, you need to leave the glue, then mix it again and proceed with the lining. During operation, the glue is mixed several times.

- Work with this mixture should be carried out in a room with low humidity, where there are no drafts.

- If the work will take place outside, the weather should be clear and warm.

- If during outdoor work the weather is too windy, the durability of the diluted composition will be halved. Therefore, it is recommended to dilute the mixture in portions.

- If you plan to lay the tiles for places with high humidity (baths, saunas, swimming pools), you should choose a mixture of Litokol K55, which is based on a latex additive.

- After finishing work with glue, it is better to immediately soak the tools in water and wash, otherwise it will be very difficult to do this later.

- It is not difficult to work with the material, however, it is the accuracy that will contribute to the best result.

For more information about Litokol K55 tile adhesive, see below.

Description

Tile adhesive Litokol K 55 \ LITOKOL K 55 is an adhesive mixture based on white cement. Designed for indoor and outdoor installation of ceramic tiles, glass mosaics, natural stone tiles and other facing materials. Possesses water and frost resistance, elasticity, manufacturability, environmentally friendly for human and animal health.

Recommended area of application of Litokol K 55 \ LITOKOL K 55 glue: pool cladding, mosaic cladding of walls and floors in showers, bathrooms, kitchens. For interior and exterior cladding. Recommended bases: concrete, including monolithic, cement-sand and gypsum plasters, gypsum plasterboard, drywall, "warm floors". The base must be thoroughly cleaned of various contaminants that impede good adhesion to the facing material.

The dry mixture is poured into a container with clean water at home temperature in the ratio of 0.26 liters of water per 1 kg of dry mix (or 6.5 liters of water per 25 kg bag). The solution is thoroughly mixed, then settled for about 5 minutes and mixed again. The finished solution should not contain foreign impurities and lumps.

Specifications

• Viability of the ready-made solution up to 6 hours

• Application temperature from +5 to + 35 ° С

• Frost resistance 50 cycles

• Possibility to walk on the laid tiles after 24 hours

• Average consumption for 1 mm thick adhesive layer is 1.35kg per 1m2

• The thickness of the adhesive layer is 2-5 mm

The material is packed in a 25 kg paper bag. Tile adhesive Litokol K 55 \ LITOKOL K 55 is stored in a closed manufacturer's container for 12 months from the date of manufacture.

How to use?

Before proceeding with the installation of any of the selected tiles, it is recommended to thoroughly clean the entire surface. The base should be free of dust, dirt, small debris and everything that will impede high-quality adhesion.Another important point is that the surface must be completely dry. Otherwise, the adhesion will be poor.

If the glue is to be applied to a gypsum surface, it must first be primed. The gypsum structure has the ability to absorb moisture. And if there is no primer on the surface, the glue mixture will simply be absorbed, the laying result will not be of high quality. In addition, the plaster surface must be sanded.

In the event that the installation must be carried out on a cement or other porous surface, the usual primer for preliminary preparation of the base will not work. It is recommended to choose a deep penetration mixture, and only then use Litokol K55.

If the glue is to be used for lining the pool, then waterproofing must be done carefully.

For those who will lay the tiles during the installation of the "warm floor", it is recommended to remember that it is possible to apply glue to such floors only after two weeks.

When laying conventional ceramic tiles, it is important to apply the adhesive directly to the surface. Try to apply the mixture only to the area of the working area that you can revet within the next 10-15 minutes.

An adhesive is applied to the reverse side if the work is carried out with:

- large format tiles;

- variety for lining the inside of the pool;

- material for "warm floor".

For the installation of mosaic tiles, almost all of the above recommendations apply. The surface must be clean and level. It is recommended to apply the composition with a toothed instrument. The reverse side of the tile itself must be thoroughly cleaned to obtain a high-quality result. When working with Litokol K55, it is recommended to remember that the mixture is made on the basis of cement.