How to use?

In order for the plastic washers to be able to serve as reliable locks of the structure for a long time, to ensure even distribution of the mass, they must be correctly installed. The most difficult thing to install is thermal washers.

To do this, you first need to make the necessary measurements of the fastener legs. Then you need to choose a drill that is suitable for the resulting size. Its diameter should vary from 1 to 2 millimeters.

After that, in those places on the materials where the connections will be created, markings are applied. Holes of the required depth are made along the marked lines with a drill. The distance between them should be about 30 centimeters.

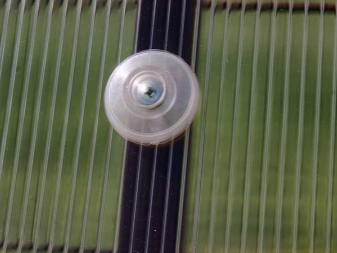

The legs of the washers are inserted into the grooves made. Do this until the latch rests against the base. At the final stage, insert a self-tapping screw and screw it tightly into the material. When the washer head is completely recessed, it is covered with a special cover.

When fixing the washers, it is worth adhering to some rules. Only well-sharpened drills may be used during installation. Otherwise, the holes will be uneven, the parts will not be able to firmly and securely fix in them.

For information on how to make plastic washers yourself, see the next video.

What are they?

Plastic washers may vary in size. In this case, we are talking about the diameter of such clamps. Standard values are M10, M8, M6, M4, but other sizes exist. In this case, such parts should be chosen, taking into account the material that will be fastened, its dimensions and weight.

In addition, they can vary depending on the design features.

Flat. This option is the most common and simplest. These washers can be used for almost any item of light weight. Often they are used together with nuts, studs and screws as part of various threaded fasteners. These elements allow you to evenly distribute the weight of the structure, they make the connections as reliable as possible.

It is worth highlighting the special washers that provide an anti-vibration effect. They are ordinary fasteners, but their surface is not flat, but slightly convex. These models are most often used when laying insulation, which during operation will be subjected to various influences, including vibrations.

A separate group contains plastic washers. They are produced in the form of convex round elements, in the central part of which there are holes that outwardly resemble a small cross. Models are made exclusively from impact-resistant types of plastic (high density polyethylene and nylon).

Washers-sealants provide special resistance to the effects of different chemical compositions, so they are widely used in industrial sectors. Models of this type have an internal ledge. This design prevents the element from flying off during fixation and after installation.

These washer sealants can also be used for structures that are subject to regular vibration or stress. Plastic products of this type will be the best option for joints in hard-to-reach places during finishing.

You can also see special insulating washers in stores. They look like thick fasteners. Their design is stepped, it consists of two round parts, one of which is smaller in diameter.

The smaller part is fixed into the hole of the larger circle, thus forming a stepped surface. Products are made from a special thermoplastic.Only such details can provide fairly good thermal insulation.

The surface of these clips is flat and has no protrusions. Their minimum thickness is about 4 mm, and the maximum reaches about 6 mm. The diameter of the fasteners can be different.