Brick Wall Cleaning Methods

Cleaning can be carried out chemical or mechanical way.

In the first case, the brick is washed with aggressive solutions in several stages.

It is important to maintain the sequence and duration of the operations. Chemical cleaning does not cope with all types of contamination and often requires compliance with a certain temperature regime

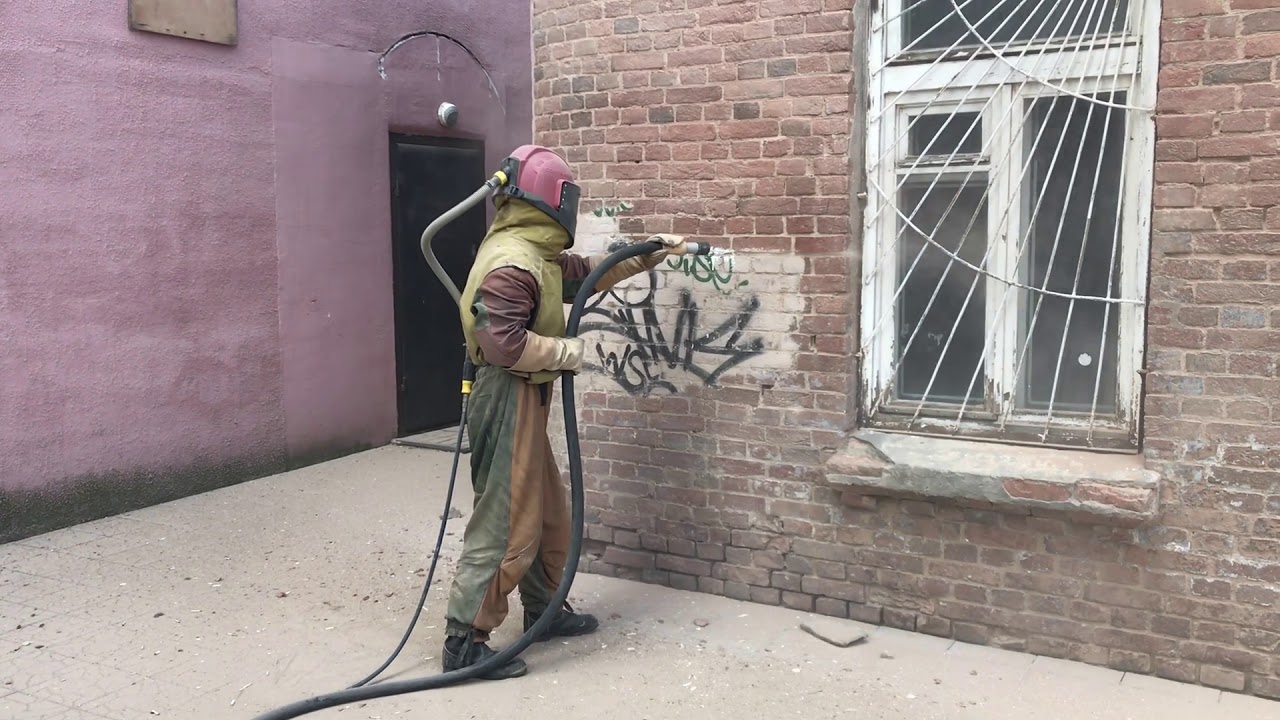

The principle of sandblasting a brick: abrasive particles are dispersed by an air stream and directed to the surface to be treated. Striking the surface, they clean the material from various contaminants, remnants of old plaster and paints and varnishes, after which the masonry takes on an updated look.

What determines the price of the service

The pricing policy for sandblasting is different in different regions of Russia. The cost of sandblasting services consists of a number of aspects:

The price of sandblasting depends on the brick cleaning method

The price of sandblasting depends on the brick cleaning method

- brick cleaning method;

- the type and degree of surface contamination;

- cleaning depth;

- the scope of the main work;

- room cleaning and garbage disposal;

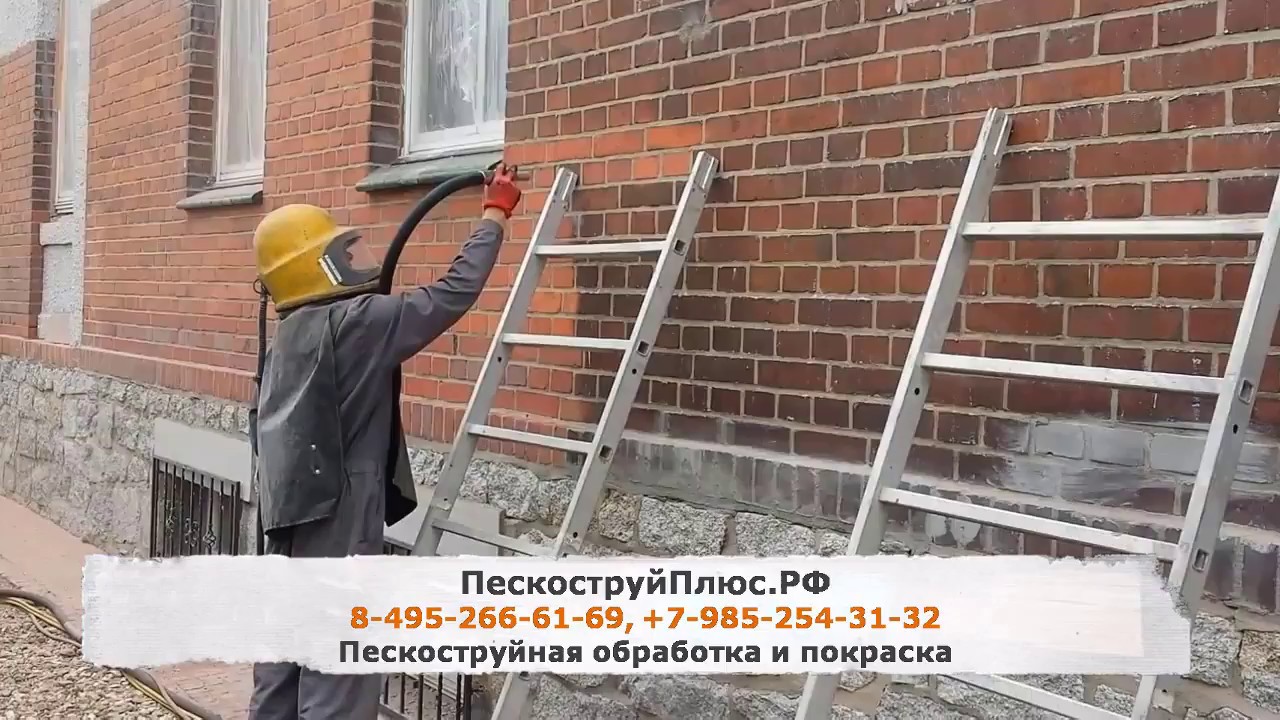

- the height at which the work will be carried out and the need for climbing equipment;

- the type of abrasive used;

- the presence of small architectural details;

- hard-to-reach areas;

- terms of work.

- level and price of equipment;

- popularity of the company in the market of construction services.

When removing complex contaminants, specialized devices with high pressure are used and the time spent on cleaning increases. Before calling the cost, a specialist must inspect the condition of the brick and the place of work.

Sandblasting is considered to be the most effective way to restore an attractive appearance to brickwork and increase its service life. High-quality work is within the power of qualified craftsmen with experience and knowledge. To achieve the desired result, an indispensable condition is also the use of professional equipment that meets quality standards and safety requirements.

Indications for use

Sandblasting brick walls is considered one of the most effective ways to bring buildings to a satisfactory condition and is carried out in a number of cases.

- Cleansing a freshly built wall from cement residues. The procedure is performed in a gentle mode using medium-grain sand.

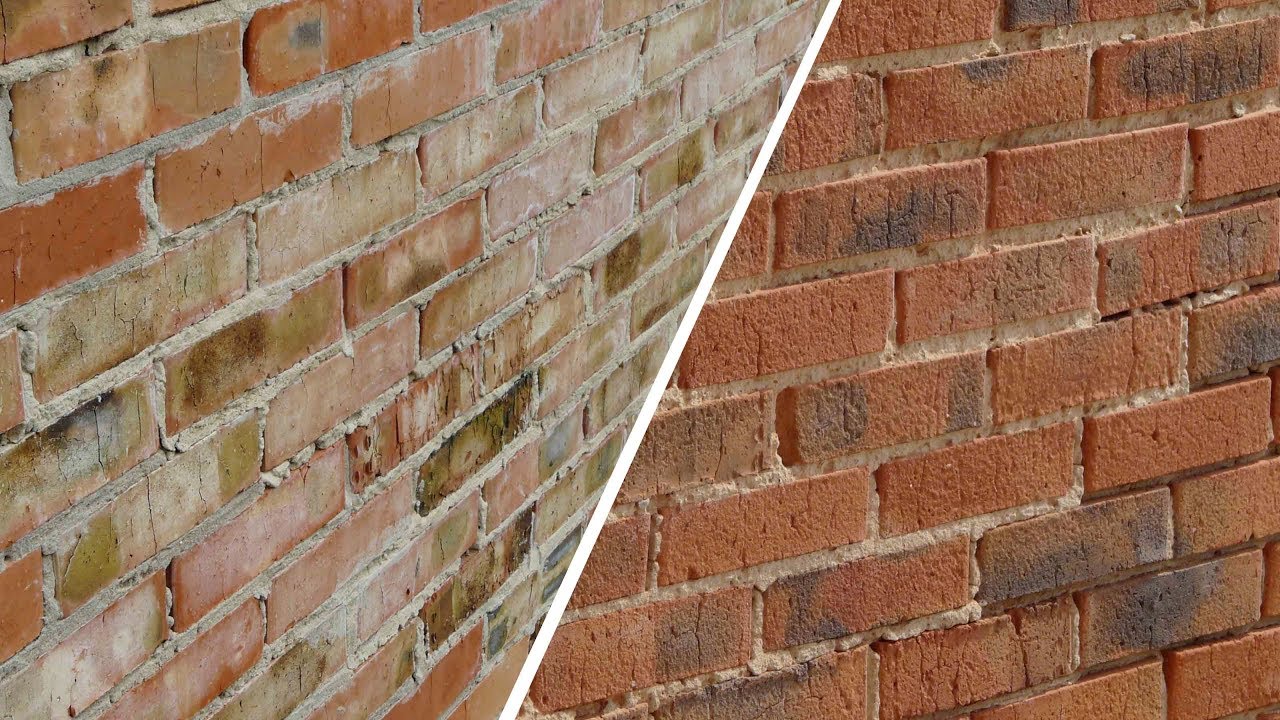

- Removal of efflorescence and traces of precipitation. This type of pollution is especially noticeable on facades made of red ceramic bricks. Such walls are prone to whitish streaks and stains, which has a very negative effect on the appearance of buildings.

- Removing corrosive stains. This type of pollution often affects buildings built of white sand-lime bricks. Facade metal elements such as balcony fittings, hooks for electrical wires and external fire ladders often do not have an anti-corrosion coating and begin to rust over time. When it rains, rust begins to run down the walls along with streams of water, leaving behind rusty red streaks. Such pollution greatly spoils the appearance of buildings, and is not removed by anything other than a sandblaster.

- Removal of mold and mildew. This type of pollution has a very negative effect not only on the overall appearance of the facade, but also causes a serious threat of material destruction. Sandblasting allows you to remove the pores of the fungus deeply embedded in the brick and for a long time rid the walls of gray-green ugly stains.

- Cleaning the interior brick walls from the remnants of old paint and plaster. When carrying out repairs, it often becomes necessary to remove the old decorative coating from the walls, and no unit can cope with the task better than a sandblasting unit. The abrasive material thoroughly leaches the surface, leaving behind a perfectly clean brick.

- Artificial aging of a ceramic brick wall. The brushing technique is often used by lovers of loft, Provence, country, techno, Gothic styles, as well as connoisseurs of traditional English interiors. As a result of the mechanical action of the working mixture, numerous cracks and depressions appear on the brick, and they look so natural and vital that it is almost impossible to distinguish the artificially aged material from the original century-old stone. To achieve the best effect, nickel slag, glass beads and ceramic beads are used along with sand.

- Treatment of the working surface before applying plaster or paint mixtures. In this case, sandblasting contributes to the formation of a rough surface, which significantly increases adhesion and significantly increases the life of the decorative coating.

- Removing grease and oil stains. When cleaning the surface from this kind of contamination, sand or slag is used as an abrasive component.

Cleansing methods

Sandblasting bricks are cleaned by different methods:

- The most common is the classic way. It involves the use of an air-sand mixture, which is distributed over the wall under high pressure. The cleaning effect will be similar to using sandpaper.

- Another method is called wet and is suitable for heavily soiled facades with old dried stains and traces of mortars. In the wet method, water is used, with which the working abrasive mixture is mixed. The resulting composition is sprayed onto brickwork.

- The next method is highly effective, since natural or artificial fine fraction ice is used instead of sand. This mixture removes pollution from the most inaccessible places.

- There is also a thermal treatment, or fire. Together with sand, combustible materials are sprayed along the wall, which allows cleaning the treated surface from biodestructors, which include fungus, moss, mold and pathogenic microorganisms.

Precautionary measures

Sandblasting masonry requires utmost attention and adherence to safety regulations. You should use personal protective equipment - mask and goggles.

In addition to physical injuries, working with sandblasting without the use of personal protection can result in a serious disease of silicosis. This is a severe damage to the lungs, which occurs due to the penetration of sand dust into the respiratory organs. A well-cleaned respirator or a forced-air helmet should be worn. In addition, you need to protect your ears. The device produces a lot of noise, and industrial headphones will help preserve your hearing.

Sandblasting brick walls is a technically simple process that is widely used in construction. Thanks to compressed air and abrasive material, it is possible to significantly facilitate repair work associated with cleaning brickwork from dirt, get rid of traces of rust and atmospheric precipitation, sanitize mold, mildew and bacteria, and create a new interior style in the room.

Safety during work

Sandblasting is a complex technology that requires special training, knowledge and experience. It is associated with the risk of dust generated during processing.Failure to comply with safety precautions can cause serious harm to the health of the worker and the people around him.

Sandblasting is a complex technology that requires special training, knowledge and experience. It is associated with the risk of dust generated during processing.Failure to comply with safety precautions can cause serious harm to the health of the worker and the people around him.

The device accelerates microparticles to 650 km / h, and if the jet hits a person, it can cause serious injury and even death.

Dust causes silicosis, a serious lung disease. That is why, when sandblasting, it is necessary to protect the respiratory system, as well as the eyes, skin and hearing.

The working process is accompanied by a strong noise, which negatively affects the well-being: pressure rises, dizziness and pain in the head occur.

That is why the use of personal protective equipment is mandatory:

- industrial headphones;

- protective suit;

- mittens;

- helmet with air supply.

Cleaning bricks with sandblasting

Sandblasting removes mortar residues, oil stains, grime, dried paint and mold.

Sandblasting is an effective yet gentle way to combat material damage. In the process of surface treatment, the smallest particles of sand and air act on the surface of the brick, removing dirt and fungi.

Sandblasting allows you to remove from the brick surface:

- oily stains, dried varnishes and paints;

- remnants of concrete mortar;

- soot and fumes after a fire;

- mold, moss and other growths.

Sandblasting is carried out using a special compressor, which directs a special type of sand onto the brick wall with a strong flow of compressed air. The compressor is equipped with a sturdy hose and a sandblasting gun.

For brick cleaning, classic, wet, ice and fire methods of sandblasting can be used.

The most common is the classic method of sandblasting bricks. Its principle is that sand is mixed with compressed air in a sealed container. The sand is thrown at high speed onto the brickwork, acting like sandpaper.

Wet sandblasting involves using a jet of water with which the sand is mixed. Since the brick absorbs moisture, this method can be used on very dirty surfaces.

Sandblaster device diagram.

The sandblasting method with ice is the most environmentally friendly method and involves the use of small ice particles. At a high ejection rate, ice particles act similarly to broken glass when hitting a brick surface. They remove dirt from even the smallest cracks. After the completion of the work, there is almost no debris, only melt water.

The fire method of sandblasting is the most effective. The sand mixture is supplied under the pressure of a jet of combustible material, removing not only dirt, but also plants with microorganisms. This method is used to clean brick walls abundantly overgrown with plants, moss and mold. After all, it is necessary to destroy parasites not only on the surface, but also to burn out their roots, which have grown into a brick wall.

However, the fire method must be used with caution, because with strong and prolonged exposure to fire, the brick can crack.

Sandblasting the brick will not only remove dirt, but also make the wall look unique. Today, the owners of many private houses deliberately beat the walls of the living room to brick, cleaning them with sandblasting. This cleaning gives the brick walls a unique appearance.

Procedure technology

The task of the sandblasting plant is to clean the brickwork from various types of contamination. Using this method, you can remove from the brick surface:

- a layer of soot and burning;

- white bloom;

- dirt;

- the remains of cement mortar;

- old drawings;

- paint.

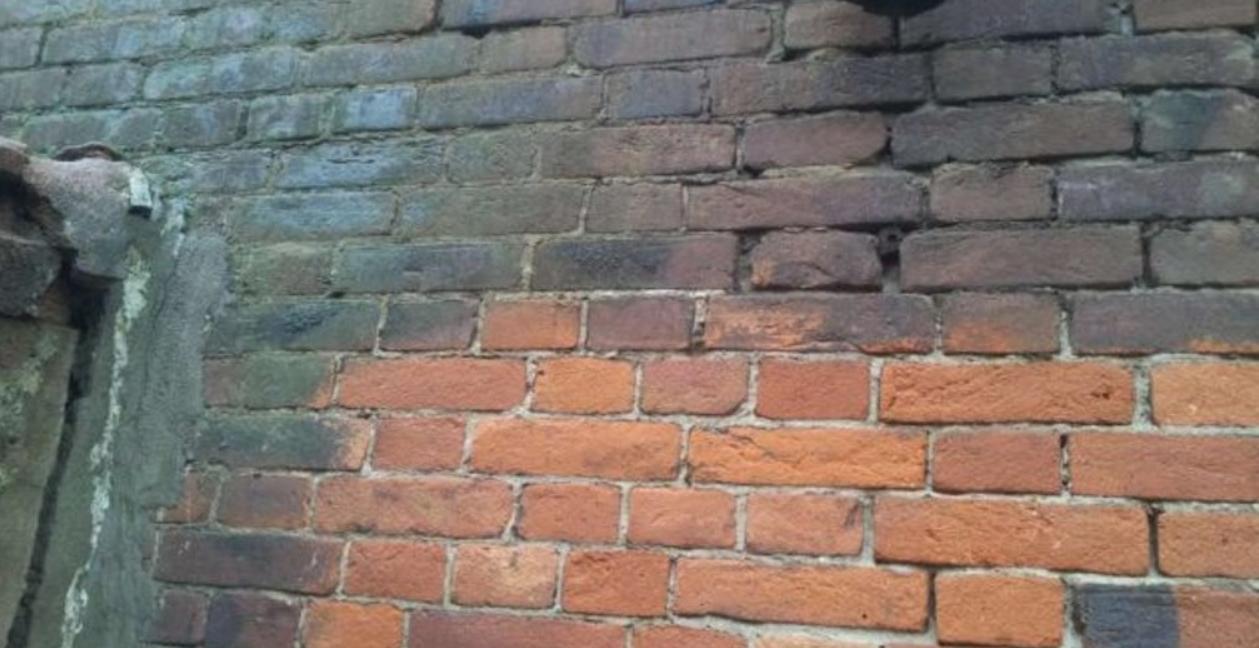

You need to sandblast a brick wall with a special tool called sandblasting.With the help of the device, the masonry can return to its original state and significantly slow down the destructive processes that eventually begin inside or outside the stone. Sandblasting has a powerful jet of abrasive particles that have a strong mechanical effect on the brick. But, despite this, the material retains its color and useful performance characteristics.

The work of a sandblaster looks like this: sand is mixed with highly compressed air. A pressurized compressor delivers the working mixture to the gun, which sprays the contents over the surface to be treated. In the process, the brickwork is easily cleaned of excess substances, and upon completion, the wall becomes updated and well-groomed. Also, using an air-abrasive mixture, you can get rid of the damage to the brick by bacteria and fungi.

Sand is not the only working material. Corundum, copper slag, nickel slag, crushed plastic and ceramics, as well as glass beads are often used. These substances give good results in brick processing and cleaning. The material for sandblasting should be chosen depending on the type of stone, climate characteristics, age of the wall, nature and degree of facade contamination.

Due to these properties, the scope of the sandblasting installation is quite wide. You can take care of the appearance of not only brick walls, but also concrete and wooden ones.

Cleaning methods

Sandblasting is carried out in several ways, and the choice of the right one is made taking into account the nature of the pollution and the ultimate goal of the event.

- The most common is the classic method, in which sand, mixing with compressed air, is thrown onto the wall under high pressure, producing the effect of sandpaper.

- The next method is called wet and is used for particularly dirty surfaces containing old stains and dried residues of mortars. The essence of this method consists in mixing an abrasive substance with water and then spraying the resulting composition onto the masonry.

- A very effective technique is considered to be surface treatment with ice, which allows you to remove dirt from hard-to-reach places. In this case, the sand is replaced with small particles of natural or artificial ice and is fed to the wall under high pressure.

- The fourth method is thermal, or, as it is also called, fire treatment, which consists in the simultaneous spraying of sand and combustible material. The use of fire cleaning contributes to the complete destruction of biodestructors such as mosses, mold, fungus and pathogens.

Why you need to sandblast bricks

The most serious cause of brick surface damage is efflorescence. Brick is a very porous material, so it absorbs a lot of moisture. Salts penetrate the brick together with water. As a result, a white coating appears on the surface of the structure. It not only worsens the appearance of the structure, but also indicates negative destructive processes in the structure of the brick.

If the brickwork was not protected from efflorescence, then the fight against them becomes difficult. Then you will have to dry the walls, waterproofing, building a water drainage system. And these are only initial robots that do not always bring results. Sometimes, during restoration, the brick simply begins to crumble. These problems can be avoided by applying water repellents, inspecting brick luggage annually, and sandblasting it.

Sandblasting

During sandblasting, abrasive particles are accelerated from the sandblaster using the energy of compressed air.To achieve effective sandblasting by means of abrasive compressed air particles requires professional skill, high-end equipment and quality control. Each element affects the result of the entire system.

A sandblasting system consists of three main components: a compressor, a sandblaster and an abrasive.

The compressor must create sufficient pressure and volume of air to move the abrasive from the blast machine to the surface to be treated. Abrasive powder is poured into the apparatus and, by means of a metering valve, is fed into the air stream, in the path of which there should be no obstacles. The desired surface treatment result is achieved by controlling the compressed air acting on the abrasive.

Sandblasting directly depends on how efficiently the air moves from the compressor to the surface to be cleaned. Interference in at least one element reduces the productivity of the entire system. Contractors often do not consider the sandblaster as a possible source of restricting air and abrasive flow. High pressure air cannot pass through small bore fittings in the same volume as large bore fittings.

The role of the sandblaster is to evenly dose the abrasive into the air stream. Sometimes contractors install air restricting fittings and metering valves and end up wondering why performance has dropped. This problem could be avoided by choosing a sandblaster with large diameter pipes, fittings and valves and connecting it to the compressed air hose and nozzle of also larger diameter.

Another very important element in a sandblasting system is the abrasive. Ultimately, surface cleaning depends on the abrasive used. An abrasive should be chosen of the appropriate shape, size and hardness. If an inappropriate abrasive has been selected, cost overruns, paint layer damage and costly rework can be incurred.

When sandblasting surfaces, the abrasive should be carefully selected to ensure the best sandblasting speed and economic result.

The best compressor and sandblaster will not compensate for the wrong choice of abrasive. Most sandblasting elements are cylindrical in shape. Even a small change in the diameter of these elements entails an exponential decrease in the volume of air passing through them. Even when choosing a compressor and sandblaster of the required power and the appropriate abrasive, skill and professionalism of the operator is required for the system to work efficiently.

Sandblasting is divided into three components: surface preparation, surface cleaning and finishing, and shot peening.

Sandblasting bricks - benefits

Sandblasting bricks has a number of advantages over other methods of surface preparation for further finishing:

- suitable for cleaning facades of any complexity (including those with various decorative elements);

- removes various contaminants (graffiti, traces of oils, soot and soot, mold, stains from efflorescence) and copes with the preparation of surfaces for the application of protective and decorative coatings;

- it is possible to impart increased roughness to improve adhesion with water repellents or finishing mixtures;

- after cleaning the brick with sandblasting, all defects are exposed, therefore, during subsequent finishing work, it is easier to notice and eliminate them;

- sandblasting of brickwork allows you to quickly clean surfaces on an industrial scale and provides a high degree of cleaning.

Sandblasting surface preparation

Sandblasting removes unnecessary materials and makes the surface ready for coating.

Sandblasting removes old paint, rust and other contaminants from metal structures. In addition, sandblasting removes the secondary scale that forms on the new steel.

Angular abrasive particles roughen the surface and create a profile, or notch. Most paint manufacturers specify what the profile should be in order to ensure effective application of their products. Contractors sandblast the brickwork before applying putty or paint. Sandblasting exterior plaster and sandblasting bricks removes old paint, mildew, grime, stains and even graffiti while leaving an ideal surface for coating.

Contractors sandblast prestressed concrete panels, monolithic concrete walls, columns and other concrete structures to remove residual cement, formwork marks, discolored areas and expose concrete.

In addition to sandblasting metal and sandblasting masonry, sandblasting can remove the top layers of paint from wooden houses and boats. The top layer of helium coating is usually removed from fiberglass by sandblasting to expose air bubbles. When sandblasting aluminum, titanium, magnesium and other metals, corrosion is removed and, depending on the selected abrasive and pressure, a profile is applied.

Newer, softer abrasives (including plastic and wheat starch) and special low pressure sandblasting equipment are used to remove coatings from composites, allowing aircraft, helicopters, cars and boats to be sandblasted without damaging the structure of the materials. In addition, the transition to a dry method of sandblasting the upper layers excludes the possibility of exposure of workers to toxic chemicals.

The list of sandblasting options seems endless. Every day hundreds of companies resort to sandblasting to solve long-term cleaning and surface preparation problems.

Sandblasting and sandblasting finishing

Sandblasting the surface and sandblasting the finishing process are significantly different from the surface preparation process. The difference is that the expected result is to improve the appearance of the product and its usefulness, and not simply to prepare it for coating or assembly. Sandblasting the surface includes removing contaminants and scale. Finishing sandblasting includes removing burrs from cast products as well as enhancing the appearance of products.

Sandblasting using glass or ceramic beads as an abrasive creates a matte finish and relief on soft metals. In many foundries, sandblasting is used to remove burrs.

In most cases, sandblasting reveals microcracks and defects in metals. Soft materials such as rubber and plastic are usually made using special molds that leave bumps. Sandblasting easily removes such irregularities.

Sandblasting is widely used in industries that use elevated temperatures to quench metals. High temperatures can discolor the metal. Sandblasting removes discoloration and scale from items exposed to high temperatures.In addition, sandblasting can improve the appearance of products by removing various stains, corrosion and tool marks.

At high temperatures, carbon deposits and used oil deposits form on many automotive parts. Electric motors are often clogged by overheated insulating materials and molten stator parts. In most cases, maintaining the original dimensions of these products is critical. Sandblasting with plastic abrasives, glass beads removes contaminants and provides the desired result.

Back to the list

Safety precautions during sandblasting

Sandblasting works are carried out with the help of special equipment by people who have experience in such work. If it so happens that you borrowed a sandblasting compressor to clean the wall, for example, under plaster, then you should know the safety rules.

Sand blasting is a huge health hazard. The dust generated by cleaning is very dangerous.

It consists of very small particles, which, getting into the lungs, severely injure them. Therefore, the use of a respiratory protection mask is mandatory.

In order to protect the skin from injuries from chipped bricks, you need to wear pants and a long-sleeved T-shirt. The compressor emits a strong hum during operation, therefore, industrial headphones must be worn to protect your hearing. Noise greatly affects a person: blood pressure rises, headaches, dizziness appear.