What are they?

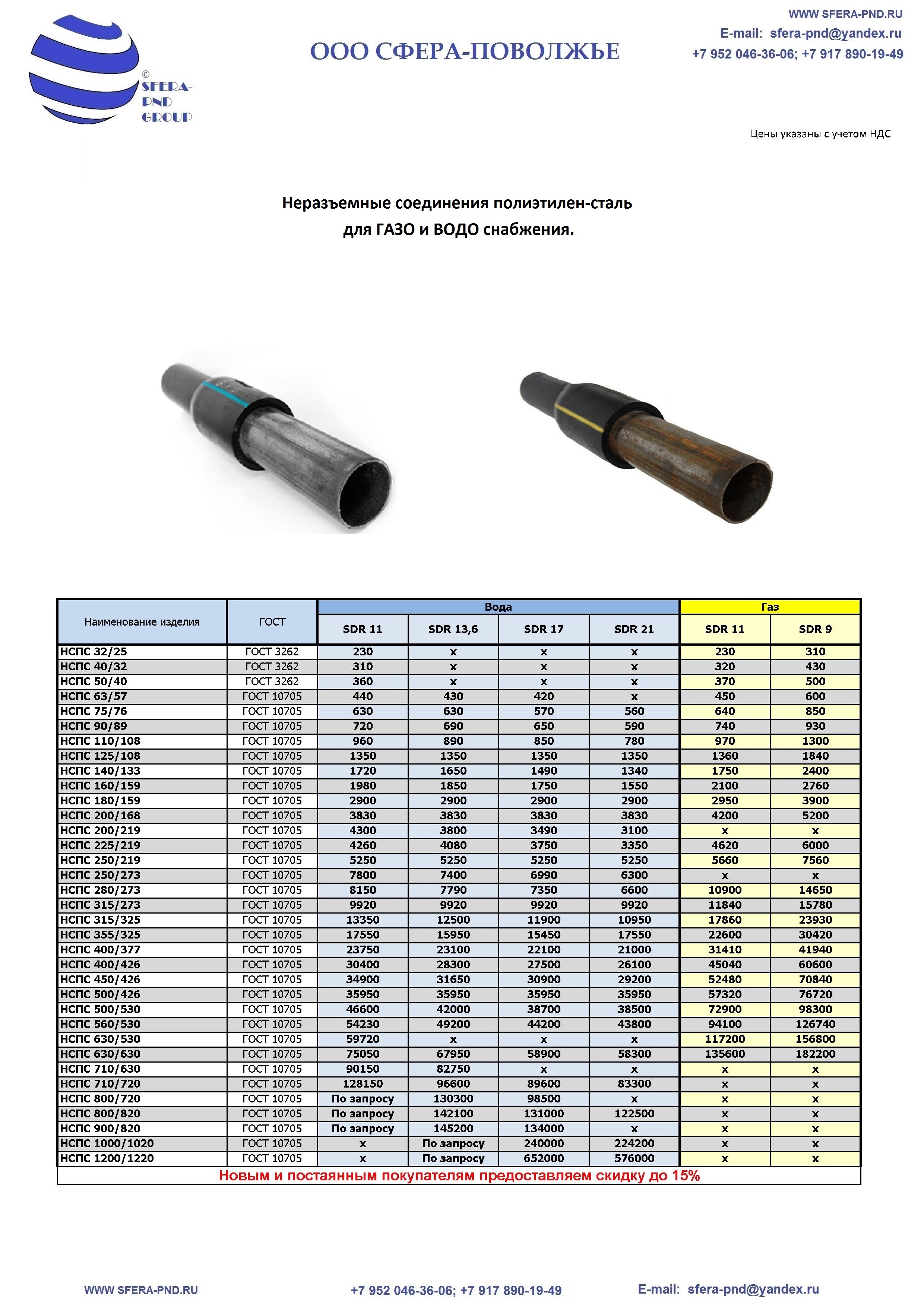

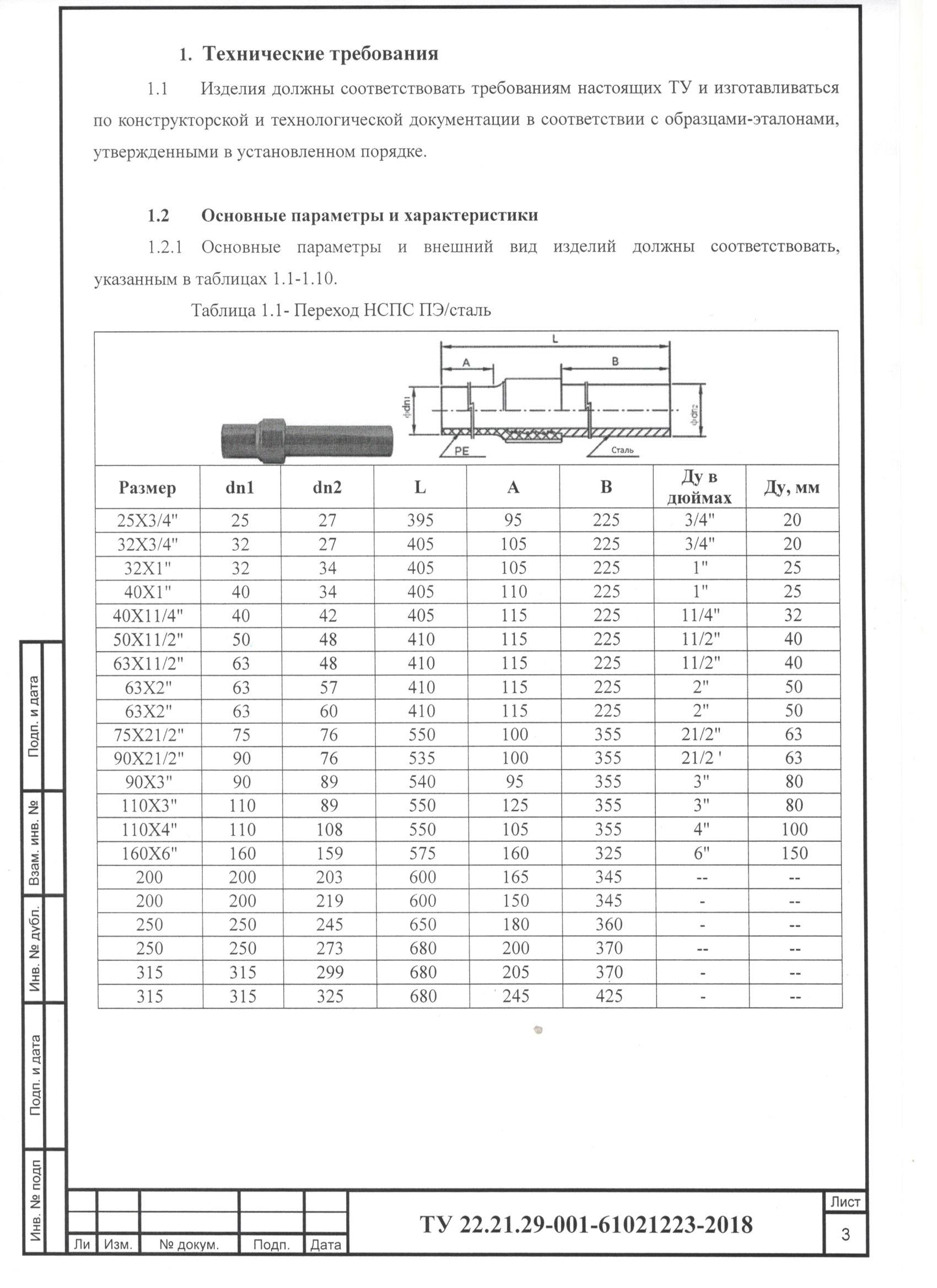

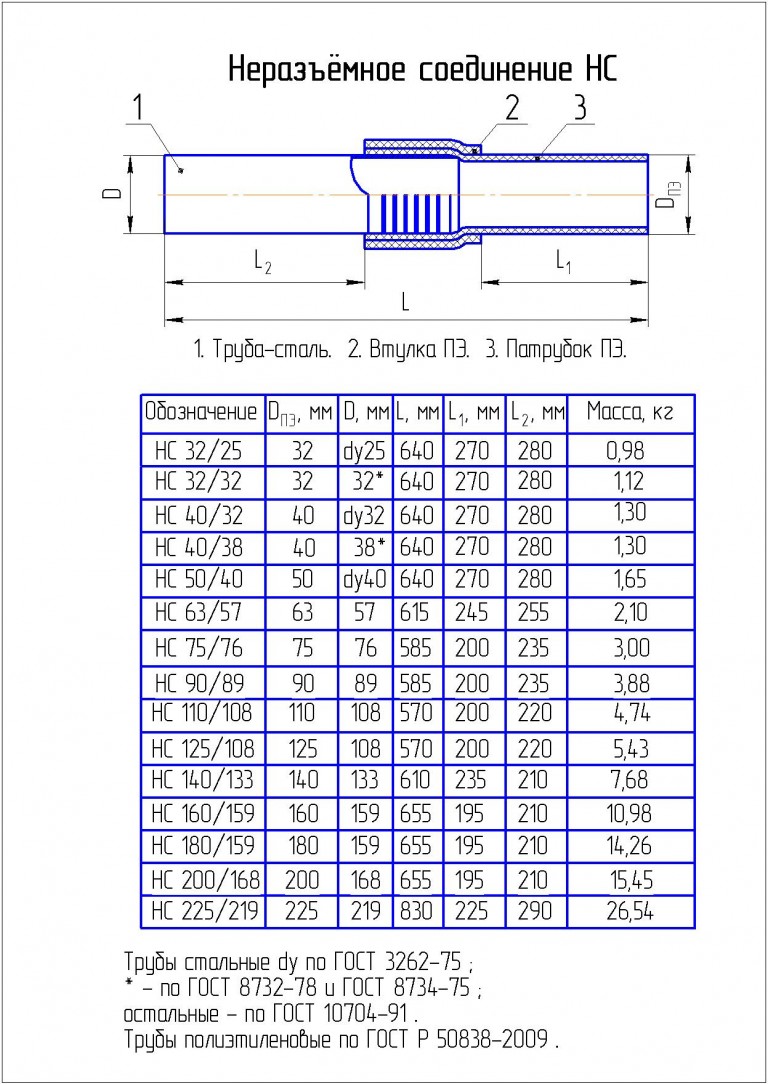

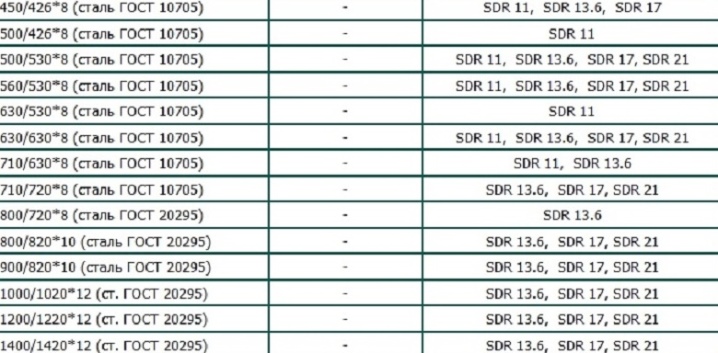

Typical dimensions of the NSPS can be 63/57, or rather, 63/67 / 3.5. Alternative dimensions are as follows:

-

32/25/3,2;

-

60/32/3,2;

-

50/60/3,5;

-

75/76/3,5;

-

90/89/3,5.

Along with these parameters, with a connection of 63x57 and 110x108, there are products:

-

125/108/6;

-

160/133/6;

-

160/159/5;

-

180/159/5;

-

200/168/5;

-

200/219/6;

-

225/219/6;

-

250/273/7;

-

400/377/8;

-

500/530/8;

-

800/820/10;

-

1200/1220/12;

-

1600/1420/12.

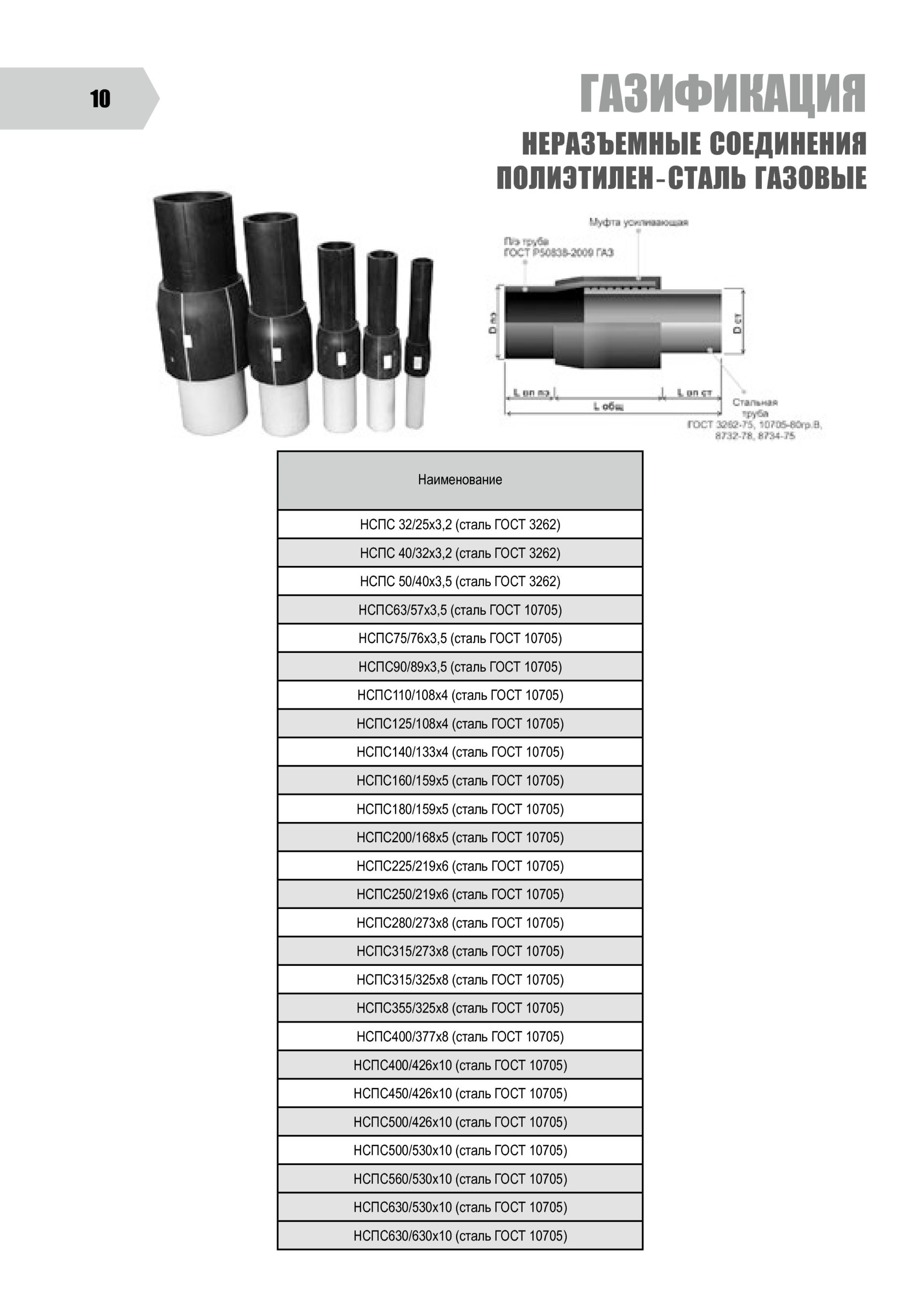

In addition to the difference in size, it is customary to distinguish:

-

conventional basement gas inlets;

-

basement gas inlets in the shape of the letter G;

-

the same inputs in the form of the letter I (straight lines);

-

insulating squeegees;

-

insulating welded connections.

How to connect a steel pipe to a polypropylene pipe, see below.

Features of production

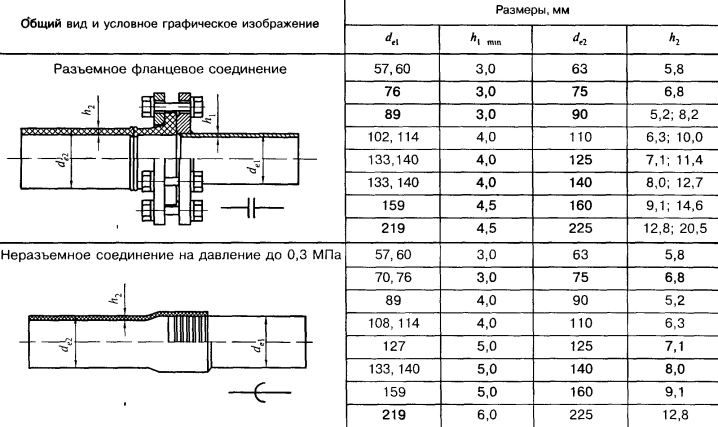

Getting "transitions" is done using polyethylene and steel pipes. If polyethylene is used and a gas pipeline needs to be prepared, the norms of the GOST R 50838-95 standard apply. For water pipelines made of polyethylene, the standard GOST R 18599-2001 is used. If the transition is made to a steel pipe, you will have to focus on the standards of GOST 10704-91, 8731-74, 8732-78. Non-collapsible joints are created using a socket.

Preparation of gas distribution lines with pressures up to 600 kPa has its own characteristics. They are created using a reinforced transition. A crimping sleeve is strung onto such a transition - it goes over the bell.

The procedure is different when working with pipes of DN category and with a diameter of 20 to 40 mm. They are collected in a cold way, heating is not used. The prepared transition is thoroughly tested for tightness. The axial load test is also important. Last of all, they find out how resistant the product will be with a stable internal pressure.

The production of permanent polyethylene-steel joints is currently very developed. Modern technologists have mastered the diameters of such products ranging from 35x25 mm and ending with 1400x1420 mm. Therefore, the industry can satisfy the request of the builders or owners of any pipeline. Sufficient quality is guaranteed only by large suppliers who are able to check the shipped goods in special laboratories. Of course, they use only impeccable modern equipment, which is operated by qualified employees.

Description

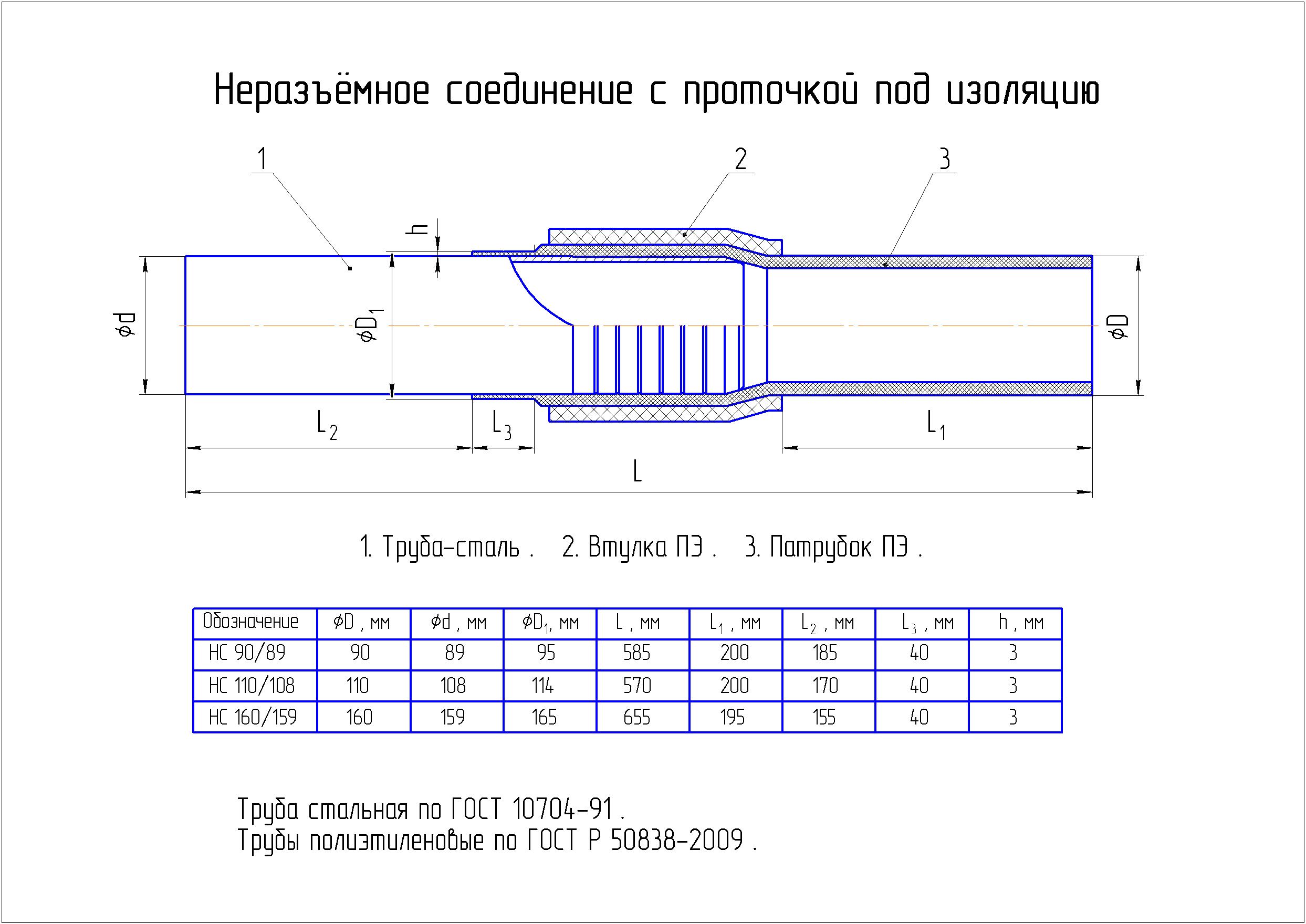

The permanent joint polyethylene-steel is a specialized product for pressure pipelines. The essence is very simple: a steel pipe section and a polyethylene pipe segment are hermetically connected. A coupling device of this type is much more promising than traditional side bushings. It has long been established that polyethylene pipelines laid underground experience significant compensatory loads of various types. Both elongation and compression of these products are accompanied by their mechanical deformation and significant wear.

But the polyethylene-steel flange adapter is much more reliable, and it is even openly recommended by many regions of Russia in their territorial technical standards. The rigid attachment of the flange to the steel block of the one-piece bundle is very reliable - this solution eliminates the need for further maintenance and repair work.

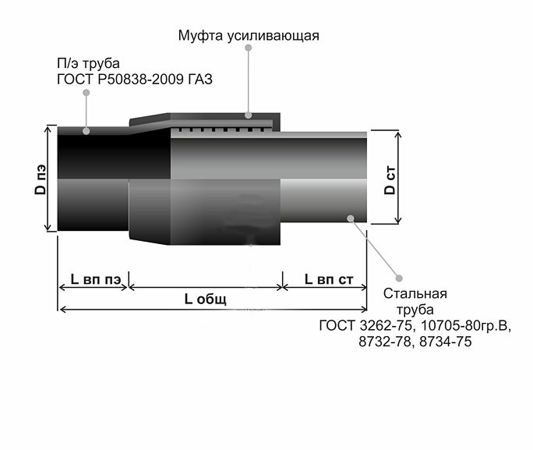

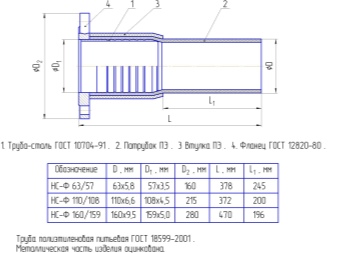

Products for the transition from steel to polyethylene and vice versa may be subject to the requirements of GOST 3262, 10705, 20295. For gas pipeline systems, technical conditions 4859-026-03321549-98 apply. The creation of water supply lines is possible subject to technical conditions 2248-001-86324344-2009. The highest pressure, depending on the specific category, can be 1 or 1.6 MPa. A typical layout includes:

-

polyethylene and steel billets;

-

clutch;

-

the length of the release of polyethylene and steel sections;

-

total length;

-

diameters of both blanks;

-

thickness of materials;

-

the length of the overlap.