Finishes: some features

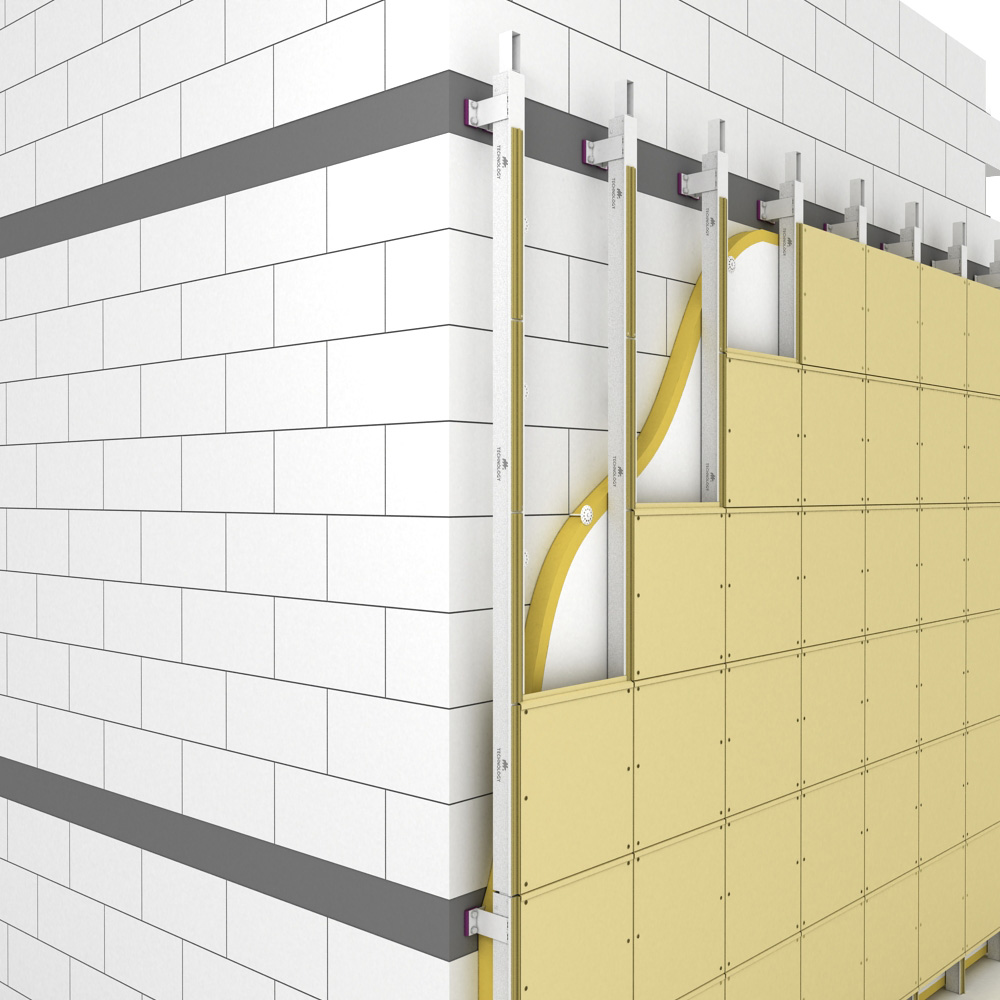

According to the method of application or fastening, finishes are performed using a frame and without using it. If you choose the frame method, then wall decoration from aerated concrete blocks can be done with plasterboard sheets, OSB plates, decorative panels. Before the frame work on the aerated concrete walls, the waterproofing and vapor barrier films are sequentially fixed. They will keep the wall material from moisture penetration and increase its service life. First, a frame is built. If drywall is adopted as the material for cladding, then aluminum profiles are used for the frame. They are attached with dowels to aerated concrete blocks. It is necessary to strictly monitor the observance of the vertical and horizontal, using the building level.

Drywall caps need to be slightly deepened. After the drywall is fixed, puttying work is performed. If the decoration is done with decorative panels, then bars with a section of 25x25 mm serve as the frame. Wooden lathing is performed on dowels, drilling holes or self-tapping screws. The first block is fixed at the ceiling, the second at the floor. Between them, after pulling the thread, the remaining lathing bars are mounted at a distance of 50-60 cm, depending on the size of the panels. Compliance with the horizontal is controlled by the level. This is necessary in order to prevent distortions of the decorative panels. A special profile is fixed at the corner, into the groove of which the panels will be inserted.

If you decide to use a frameless finish, for example, painting, wallpapering, then you must follow these steps:

- hardening and rough alignment;

- grinding.

The exterior walls of the house are the foundation of the entire structure, so they must be made from a solid foundation. Therefore, they are often erected from aerated concrete, because this material has high strength, wear resistance, only there is one significant drawback - an unpresentable appearance. In addition, it absorbs moisture like a sponge, so over time it begins to crumble, crack and collapse. It is for this reason that it needs to be protected. Usually, finishing the facade of a house made of aerated concrete blocks undergoes additional finishing, during which various materials are used. But initially it is worth considering the basic qualities of materials.

Often

at

construction

houses

, cottages

, residential

buildings

use

block

from

aerated concrete

basics

. Aerated concrete

- is an

variety

construction

material

, a

exactly

kind

artificial

stone

, which the

refers

To

honeycomb

type

concrete

.

His

make

from

concrete

, which the

is combined

with

lime

and

quartz

sand

... Everything

this is

diluted

aluminum

gasifier

... Components

diluted

water

after

what

observed

reaction

highlighting

hydrogen

and

foaming

cement

mass

... Ready

solution

flooded

v

special

shape

... After

Togo

, how

passes

all

reaction

and

solution

fully

grabbed

, his

share

on

blocks

and

dry

v

intended

for

of this

ovens

... V

the end result

it turns out

ready

aerated concrete

for

erecting

houses

.

Aerated concrete blocks

Houses made from these blocks have the following qualities:

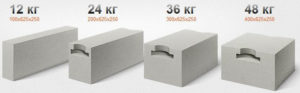

- block houses are lightweight, so there is no need to build a massive foundation;

- due to the fact that this material has an optimal ratio of light weight, dimensions during construction, there is no need to order additional equipment for lifting loads, which as a result saves money and reduces labor costs;

- block

easily

lends itself

cutting

sawing

, not

will arise

difficulties

at

gasket

subsystems

, communications

and

others

important

parts

at home

; - swift

construction

buildings

from

aerated concrete

... For

erecting

one

boxes

at home

from

this

basics

would need

about

1

months

; - no additional insulation finishing is required, because aerated concrete has excellent thermal insulation properties. For this reason, houses made from this base are always warm and cozy, especially in the cold season.

An overview of the comparative characteristics of various types of aerated concrete facade decoration

Decorating the exterior walls of a house made of aerated concrete is not an easy task. The list of materials suitable for this is extremely long. Here is a comparative table that will help you make a choice in favor of this or that material and answer the question: "how to wall a house from aerated concrete?"

Table 1. Finishing the facade of a house made of aerated concrete blocks: comparative characteristics:

| Finishing type | Positive sides | Negative sides | The cost of services for the performance of work (on a 10-point scale) | Material price category |

| Plastering with insulation and subsequent painting |

|

Seasonality of work Reduced strength and dependence on mechanical influences Requirement of strict adherence to the order of work, otherwise it is almost impossible to correct errors | 8 | average |

| Siding installation |

|

|

6 | Below the average |

| Laying porcelain stoneware |

|

High price | 9 | High |

| Painting with textured paints | Weather resistance Color retention

The ability to hide minor wall imperfections |

Costs due to the large volume of material required The service life is lower than for other types of finishes | 5 | Average |

| Facade decoration with block house material |

|

|

8 | Above the average |

| Decorative plaster |

|

|

9, some application technologies - 10 | Above average, some types are high |

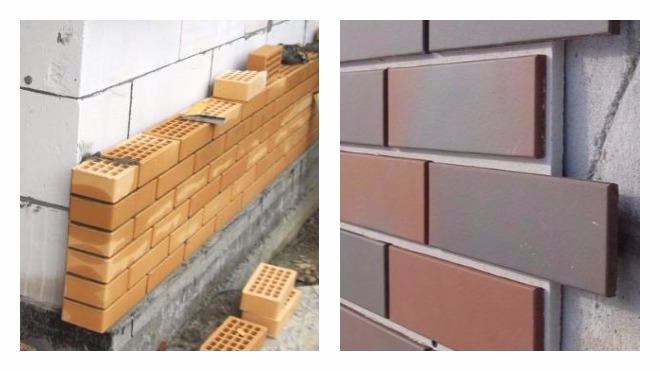

| Brick cladding |

|

|

9 | Above average and high for some types of bricks |

| Wet facade technology |

|

Very high level of sensitivity to temperature conditions Seasonality of work | 6 | Below the average |

How to sheathe a house from aerated concrete

Criterias of choice

As it is already clear, the external decoration of aerated concrete walls can be performed using a variety of technologies.

But the manufacturers of each coating are trying to attract the attention of consumers, telling that they have all the best and most reliable, that it is their solution that is ideal for gas blocks

It is categorically unacceptable to use in decoration:

- sand and concrete plaster;

- Styrofoam;

- expanded polystyrene;

- covering paint that forms a film.

Simple black self-tapping screws for fastening the battens under a ventilated facade should not be used. Dowel-nails proved to be much better in practice. They do not form cold bridges and are not subject to the harmful effects of condensing moisture. The assembly pitch is reduced to 0.4 m - this allows for the most even distribution of the wind shock load. If it is decided to finish the aerated concrete wall with bricks, you will have to provide for air vents in the lower part of the masonry, and also take care of closing them with gratings.

Even if the masonry is ½ brick, a significant mass is still created. You will also have to take care of flexible connections between the main and outer walls. Summing up, we can confidently conclude that the best results are obtained by using a ventilated facade. Only this technology guarantees both external beauty and resistance to weathering.

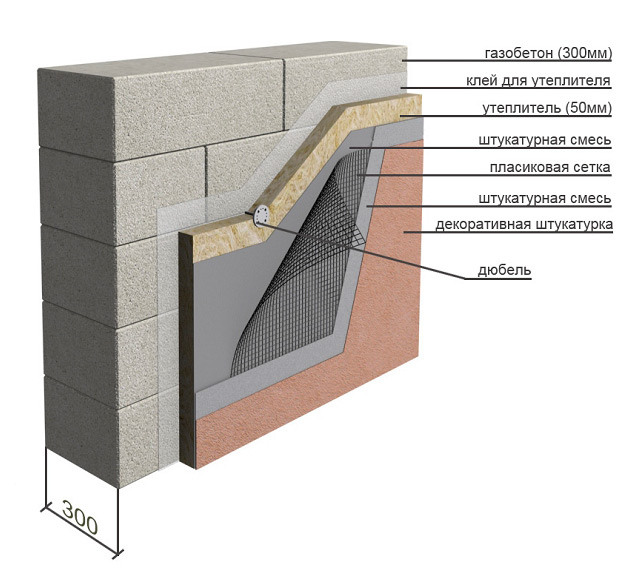

How to plaster aerated concrete facade

Plastering technology provides for several mandatory stages of work associated with the installation of a layer of insulation and surface reinforcement.

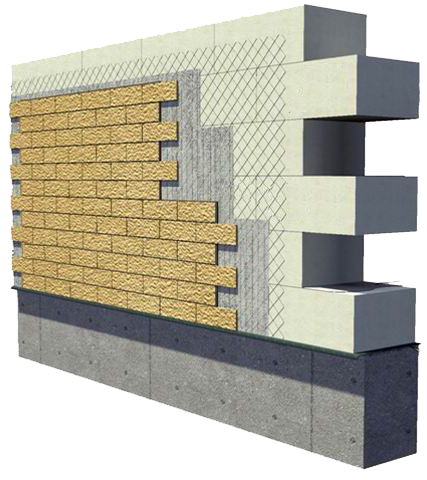

Figure 6. Plastering of external walls.

The technological map of plaster walls from aerated blocks can be represented as follows:

- Cleaning the wall from the remnants of adhesive mortar, sealing cracks and cracks;

- Primer;

- Installation of slab insulation, fixing it with plastic dowels;

- Strengthening the surface with a primer;

- Installation using an adhesive composition of the first layer of reinforcing mesh;

- Primer;

- Installation of the second layer of mesh and plastering;

- After drying, cleaning and painting with facade paint.

Plaster

The plaster layer can be created not only as a basis for a ventilated facade or clinker tiles. With the proper selection of the mixture and the correct execution of the work, it in itself will become an attractive design solution. It is recommended to use only specialized facade plasters. When working with acrylic compounds, you can count on the long-term preservation of useful qualities, but you should beware of open fire (the material can easily ignite).

The silicone plaster, which absorbs little water and is relatively inexpensive, demonstrates a wide variety of textures, but a meager color range. It should not be used where a significant amount of dust and dirt will get on the walls. The gypsum composition dries quickly and is not subject to shrinkage, and only one layer is enough for decoration. But one has to reckon with a low level of vapor permeability and with accelerated wetting under the influence of precipitation. In addition, the surface of the gypsum is often covered with spots, they will have to be painted over right away - there are simply no other ways to fight.

Features of houses made of aerated concrete

The porous material is produced on the basis of mineral binders and silica filler, it is considered one of the varieties of lightweight concrete. Not so long ago, cellular artificial material was used exclusively for arranging internal thermal insulation. As a rule, this is insulation on floor slabs, the creation of reliable thermal insulation of multilayer wall structures or thermal protection of pipelines in a cold period.

Characteristics of aerated concrete

Characteristics of aerated concrete

Recently, aerated concrete blocks have gained great popularity as a structural wall material. Buildings made of aerated concrete have the best thermal performance and have a number of positive qualities. Despite this, it is quite difficult to tile a house built of aerated concrete:

- during the construction of load-bearing structures, no violations and inaccuracies are allowed, all flaws in the work will be visible even after high-quality decoration;

- the external decoration of the walls should be carried out in compliance with all construction technologies, taking into account the high vapor permeability of the material;

- with a sufficient thickness of external walls, there is no need for additional insulation of the structure;

- facing with brick or stone requires preliminary calculations. The foundation may not support the additional weight of the finishing material.

Decorating must be carried out after the completion of all internal work. Most often, all finishing work takes place in the warm season.

Builder Tips

To increase the reliability of the connections, professional builders advise that in the case of using a threaded rod, cover with a special solution before use. This action promotes better mixing of the adhesive in the hole.

Fastenings to aerated concrete wall

In addition to the choice of fasteners, it is also worth considering the choice of filler for the holes, here are some of the resins:

- epoxy;

- epoxyacrylate;

- polyester;

- vinyl ester.

The dowel is one of the most commonly used for attaching finishes to blocks and is suitable for all types of blocks in the house. A mechanical anchor is used in cases where a sufficiently good fixation of the finishing element in the wall of a block house is required. Threaded rods are also one of the most frequently used block finishing elements, as a rule, they come with a chemical anchor. Chemical anchor is the best option for fastening to blocks if the element to be mounted is of large mass. Using this type, you get the best anchorage in the porous structure of aerated concrete wall blocks.

Types of wall decoration made of aerated concrete

Interior decoration is carried out with the following materials:

- plastic panels;

- plaster;

- wallpaper;

- drywall;

- ceramic tile;

- wood panels;

- dye.

When starting work with plaster, you need to prepare the work surface. Several layers of primer are applied to the walls to prevent the appearance of fungi and mold. It is necessary to monitor the evenness of the applied solution, this will ensure the accuracy of the subsequent stages. Further, if desired, use wallpaper or drywall. It is attached to special profiles using a hammer drill and screws. To attach the profile exactly, use a building level. The advantage of drywall is its heat and sound insulation.

A significant advantage of drywall is the absence of walls in the preliminary processing, which do not need to be putty and plaster. But at the same time, the surface will turn out to be ideally smooth and even, which means that you can immediately start the subsequent decoration. The only drawback in working with drywall will be the loss of the internal area of the house, for the fastening of the profiles and the thickness of the material used.

Another way of interior wall decoration is plastic and wood paneling. This is a very simple method, subject to even a novice builder, does not require preliminary leveling of the walls and is easy and short-lived to install. And most importantly, the end result looks attractive.

One of the popular design options for vertical surfaces is wallpapering. To save money, you can also glue the wallpaper yourself, but before starting work, you need to take care of an even and clean base. For this, the walls are plastered, and then primed. For wallpapering, a special glue with high adhesive properties is used, which is resistant to moisture, mold or mildew. After you have decided on the choice of the adhesive base, you need to properly dilute it, relying on the instructions, and then let it stand for about half an hour. For better adhesion of the wallpaper to the wall, it is primed with a solution of glue, previously diluted with a little water.You can apply glue to the wallpaper with a roller or a wide brush on the back of the canvas, then let it stand for a while and start gluing it to the wall. To do this, by gluing the wallpaper, they are gradually smoothed out with a rag or hands. After the walls are glued, they take care of their drying. To do this, the appearance of drafts is excluded, the presence of which leads to uneven drying, and therefore, creeping, tearing or peeling of the wallpaper.

Many years ago it was fashionable to paint panels in different colors. Basically, water-based paint is used, which has a low price and is easy to use. Before painting, prepare the walls using sanding or sandpaper.

The surface is leveled to a perfectly even state. Next, the first layer of water-based paint is primed and applied, which is mixed with the desired color. The mixture must be thoroughly mixed until a homogeneous consistency. Painting starts from the far corner of the room. In order for the color to be saturated, several layers are applied, which must be alternated horizontally and vertically, then the surface will be beautiful and neat.

Ceramic tiles are also often used, which are vapor-tight and have found their application in the decor of the walls of bathrooms, kitchens and corridors. When working with tiles, a building level is used, and the surface is leveled before applying it and a layer of primer is applied.

Features of aerated concrete blocks

Aerated concrete production is a complex technological process. As a result of mixing cement, lime, quartz sand, a basis for obtaining this building material is formed. After the addition of aluminum chips, bubbles begin to form in the concrete. After pouring into forms and hardening of the resulting mixture, aerated concrete blocks are ready for use.

The advantages of aerated concrete blocks include the following properties:

- good thermal insulation;

- fire resistance;

- excellent sound insulation;

- frost resistance;

- the ability to maintain the indoor climate;

- duration of operation;

- ease of handling and weight;

- the lack of the possibility of penetration of fungi and mold into the material.

These advantages allow the use of aerated concrete blocks for the construction of internal and external walls of buildings for any purpose in various climatic conditions.

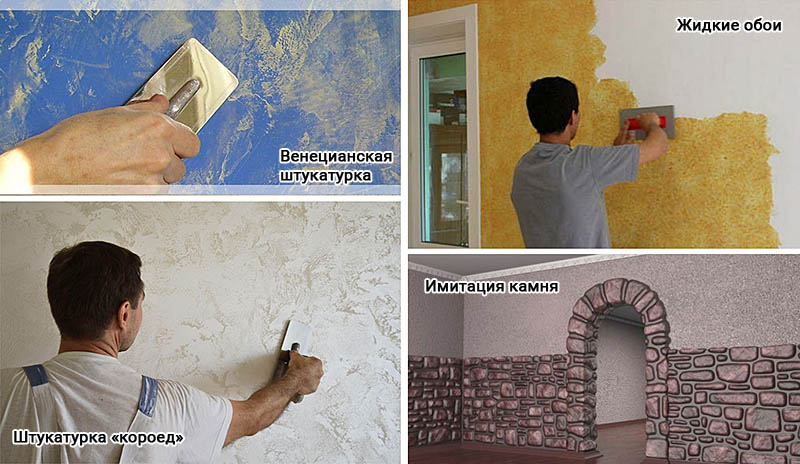

Dyeing

This method is even cheaper than plastering. Only for work is used textured paint, which has vapor-permeable properties and is applied in a thicker layer. Paint application requires care to avoid sagging.

Since aerated concrete absorbs moisture well, the paint consumption will be large. And although it is inexpensive, staining will be costly. To neutralize this, a tinted putty is first applied to the surface. The paint is applied as a finishing coat.

Although the staining process itself is simple, it should be borne in mind that the surface must be brought to the ideal. Such aerated concrete finish will not hide defects. Drops, defects, cracks, depressions - all of this is repaired.

Finishing aerated block inside the house

The interior decoration of the walls made of aerated concrete is somewhat simpler than the exterior, since climatic factors do not act. The following types are used:

- Plastering and painting

- Decorative plaster

- Drywall and wallpaper

- Decorative and ceramic tiles

- PVC panels, lining

Let's take a closer look at these types of indoor repairs.

Plastering walls

Plaster is used both for leveling walls before painting or wallpapering them, and as an independent decorative coating. Although the walls made of aerated concrete blocks are smoother than brick walls, plaster is carried out along the lighthouses for an ideal plane.

The installation of the beacons is controlled by a bubble level vertically and horizontally.The distance between them is chosen based on the number of problem areas on the wall and the length of the rule with which the mortar will be leveled.

Lighthouse plaster

The priming of the walls is an obligatory stage in the preparation for plastering. It eliminates fine dust and increases the adhesion of materials.

The use of mesh reinforcement is optional for interior decoration, but may be necessary when applying thick layers of plaster mix.

The sanding technology consists in throwing the mortar on the wall by machine or manually, followed by leveling with a rule. When plastering on the lighthouses, they start from the bottom of the wall and stretch the rule along the lighthouses up, leveling the layer of mortar.

How to properly prime and plaster aerated concrete so that cracks do not appear later is shown in the video.

After obtaining an even surface of the base layer, a thin-layer decorative plaster is applied. Of all its variety, Venetian plaster, textured type "bark beetle" or "lamb", liquid wallpaper is often chosen. Also, the prepared wall can be painted or pasted over with wallpaper.

Ceramic tile

Interior decoration of aerated concrete with tiles is most often used in the bathroom, toilet and kitchen. The tiled wall is protected from moisture, easy to clean, does not require special maintenance and retains its strength for many years.

Walls for tiles are treated with a deep penetration primer. Then the walls are putty to level and close the pores of the aerated concrete. In the bathroom, it will not be superfluous to apply a layer of waterproofing at a height of 20 cm from the floor. After that, the tile is attached to the walls with tile moisture-resistant glue.

GKL, PVC panels and lining

If a wall made of aerated concrete is faced with plasterboard or PVC panels, then a crate is made of wood or metal profiles. For gypsum board, the guides are placed vertically, for panels or lining - horizontally. When creating a frame for drywall, mortgages from a wooden bar are mounted on the wall, so that later you can hang racks and cabinets. The crate is fastened with self-tapping screws and dowels for aerated concrete.

Installation of plasterboard on glue

The walls covered with plasterboard are covered with wallpaper.

Wall panels (PVC and MDF) are well suited for finishing a hallway, corridor or loggia. They are attached to the crate with self-tapping screws or metal plates - kleimers.

Kleimer

Next

Facade

Finishing of facades made of aerated concrete and gas silicate blocks with plastering compounds

On the market you can find many dry plaster mixes from domestic and foreign manufacturers. The simplest of these are lightweight cement-based building compounds. In more complex mixtures with increased viscosity, a lime additive is added. It is more convenient to work with astringent solutions, however, their cost is slightly higher.

Features of light plasters

To increase the vapor permeability of the plaster, manufacturers do not use quartz sand, which is familiar to everyone. Lightweight plaster mixes contain porous mineral fillers and marble granules. This helps to reduce the load on the prepared substrate and increases the diffusion capacity of the material.

Aerated concrete house decoration. Photo

The advantages of lightweight plasters include a rather high coefficient of thermal conductivity, which ranges from 0.250 to 0.321 W / mx? K. Thanks to this, even a thin layer applied to the wall allows a slight increase in thermal insulation.

The disadvantages of facade plasters include low strength, therefore, manufacturers do not recommend using such compositions for finishing the basement and basement walls of houses built of aerated concrete.

The use of mineral plaster compounds requires taking into account the features of these materials:

- increased resistance to shrinkage cracking;

- reduced mechanical strength compared to conventional plaster;

- improved heat-saving properties;

- increased vapor permeability.

The use of lightweight compounds reduces the load on the prepared base of the wall surface. This makes it possible to apply them in a thicker layer, which makes it possible to eliminate even significant irregularities.

Work order

When starting to decorate a house made of aerated concrete, keep in mind that in loaded areas with a high probability of shrinkage (building corners, openings, etc.), the plaster layer is best reinforced with a mesh. In addition, it is imperative to adhere to the recommendations of the mixture manufacturer regarding temperature, humidity, preparation and application conditions.

The work is performed in the following order:

First of all, all the shortcomings of the brickwork are eliminated: they fill in irregularities, eliminate chips, etc., for which they use the same solution as when erecting the building box.

Rough areas are rubbed with a coarse grater, after which dust and dirt are swept away using a brush.

The primary layer of plaster is applied with a metal trowel

It is important to achieve uniform thickness and uniformity of the composition.

Cut off the reinforcing mesh of the required size and press it into the lower layer of the plaster mixture with the same tool.

An additional primer layer is used to level the surface of the wall and allow it to dry.

All irregularities are removed with a thin topcoat, after which the plaster is structured with a float (if necessary, this type of decoration).

Often, polystyrene foam plates are glued to the walls of aerated concrete in order to increase thermal insulation. In this case, the plastering process does not differ from the method described above, and this technique is called a wet facade.

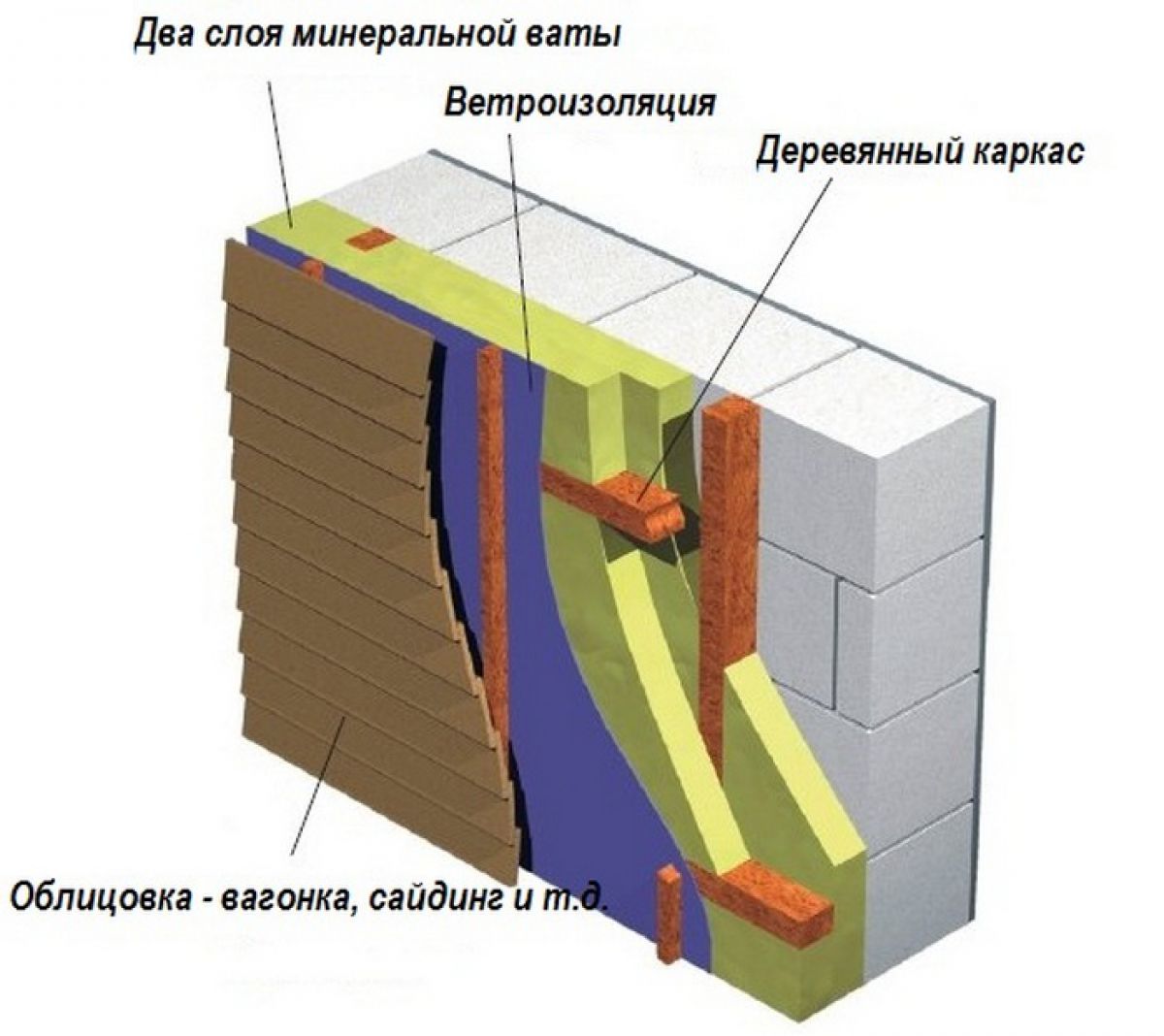

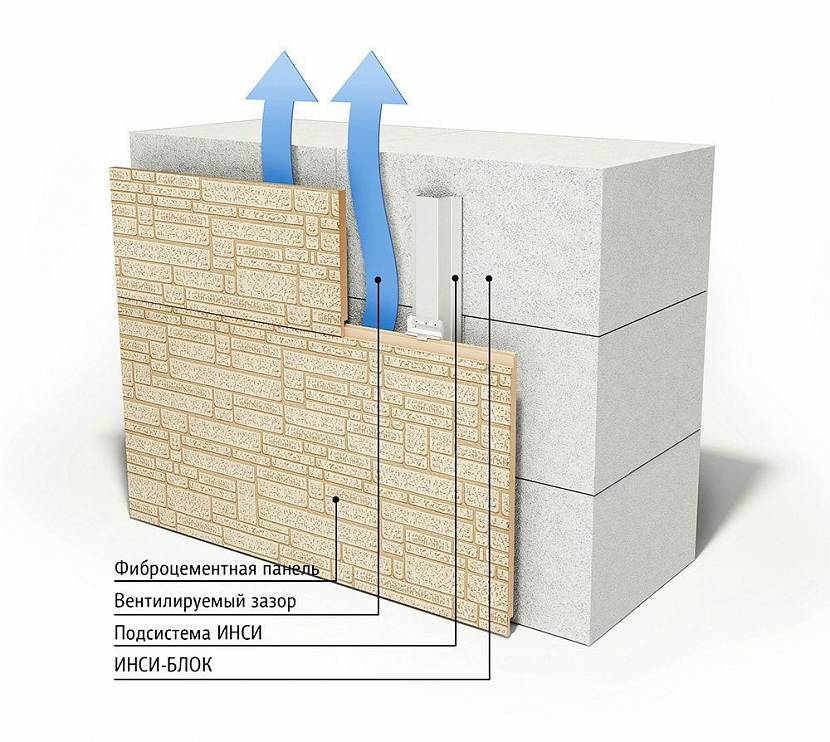

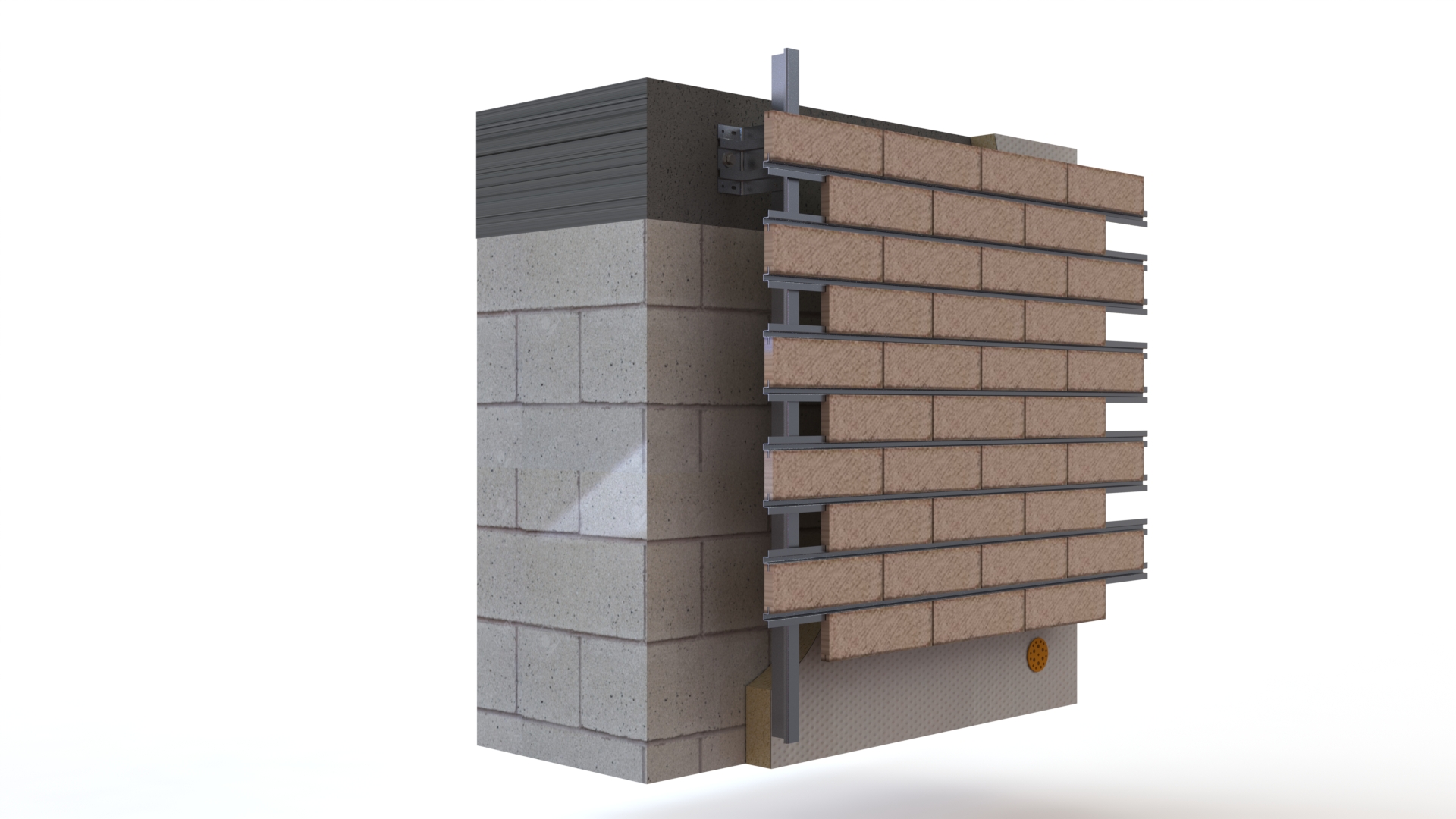

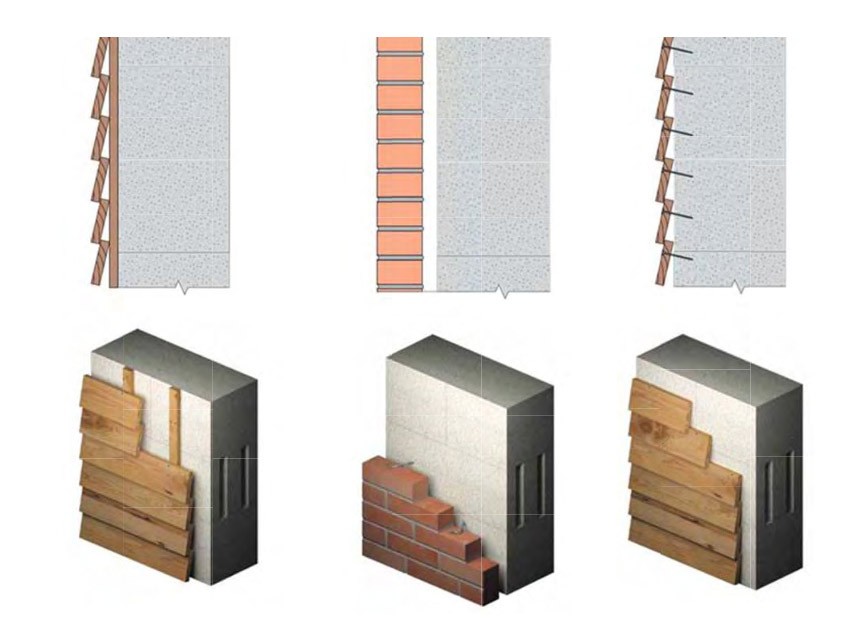

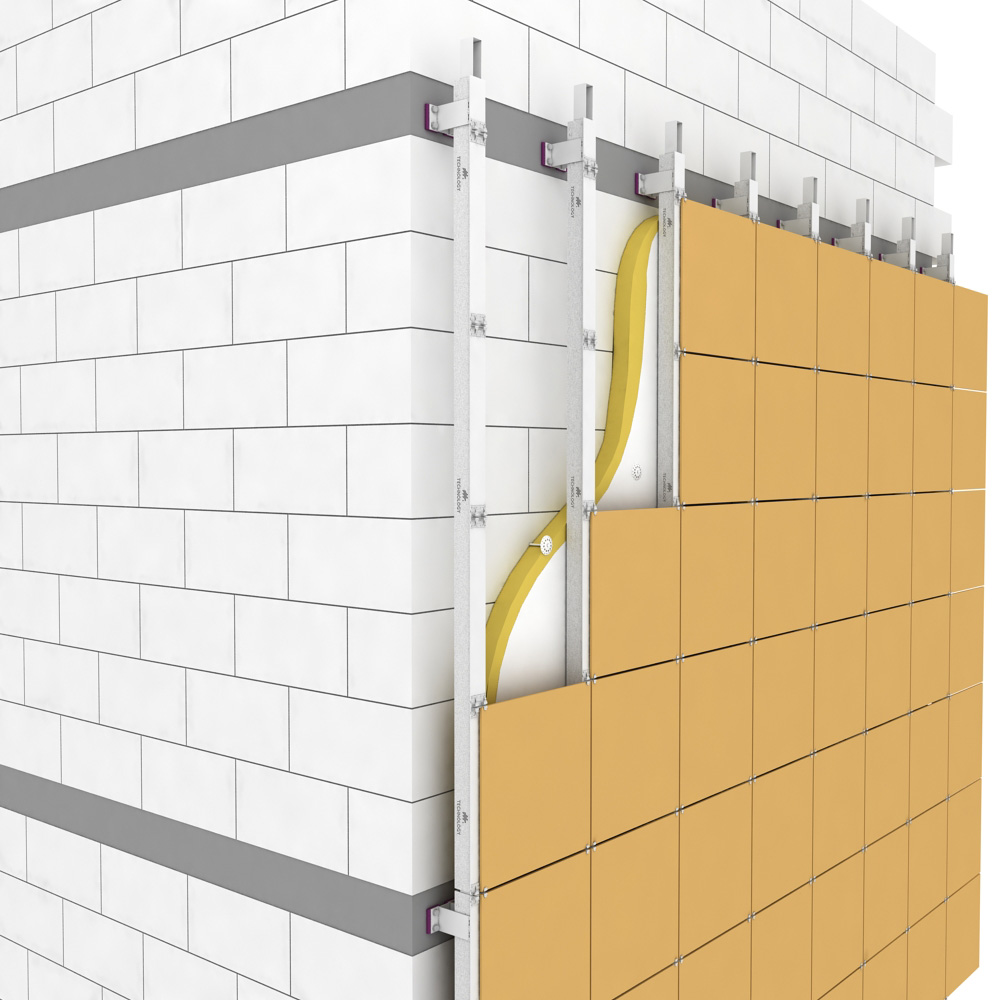

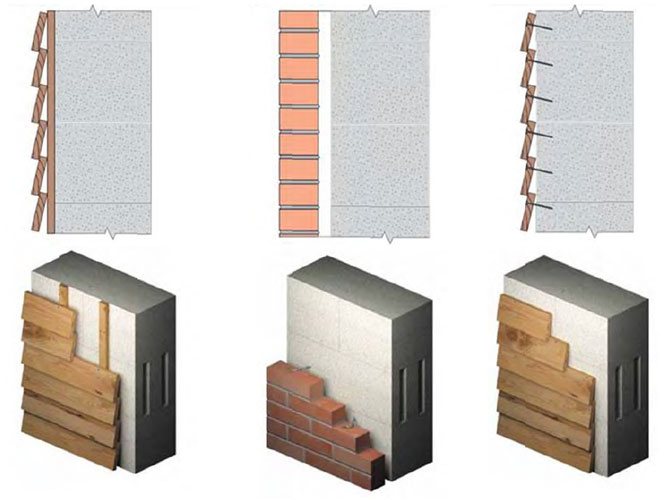

Ventilated facades

A feature of the installation of ventilated facades is the need to create a frame for the lathing and install a layer of slab or roll insulation. In this case, the role of a vapor barrier material can be played by both a special primer and a textile membrane.

During the installation of the lathing frame, the dimensions of the material, its weight and the method of fastening are taken into account. For siding and porcelain stoneware, it is preferable to install a lathing made of metal rails, and for wooden and plastic lining - lathing made of wooden slats.

Installation of the coating is carried out with the obligatory use of a metal protective mesh. Its installation in the lower part is necessary to prevent insects and rodents from entering the cavities.

However, the presented list of finishing options is far from complete, because in the design of a particular house there is always an opportunity to embody new non-standard ideas and options.

Finishing materials made of wood: a variety of types

The specific variety of modern finishing building materials made of wood, intended for horizontal or vertical wall cladding made of foam blocks, is quite large:

- Lining is narrow and thin well-finished boards. Due to its small thickness (up to 14 mm), it is used for finishing interior walls and partitions.

- Planken - wider wooden elements (18 and 20 mm thick), planed on four sides, with a smooth edge that can be beveled at an acute angle. This is an ideal option in terms of price / quality ratio for the decoration of the facade made of gas silicate blocks.

- Imitation of a bar - a cladding board with an even greater thickness (up to 45 mm), and its relief is profiled in such a way as to give the appearance of a beveled bar.

- House block is a wide plank with a thickness of up to 45 mm, which has a rounded shape, reminiscent of a rounded log.

Most of these decorative overhead elements: planken, imitation timber, block house - are used to decorate a house from wood concrete, foam blocks, aerated concrete outside or inside. Smaller lining is suitable for cladding interior walls and partitions.

Tile

Facing aerated blocks with clinker tiles is no worse than other finishing options. She gradually pushes brickwork into the background.

It is important to consider that simply applying clinker (gluing to the wall) will do nothing. Aerated concrete will dry out the glue mixture in a matter of weeks, whatever it is, and after that the tile will begin to crumble to the ground

This should not be allowed.

The initial layer is applied with metal or fiberglass mesh reinforcement. Then you need to put an additional final layer of plaster and level it. Only after all the plaster has completely dried can the tiles be installed. To do this, use resistant to cold and moisture varieties of glue, create a large seam between the tiles. The minimum gap dimension is ¼ of the area of the cladding element.

Intermediate reinforcement with steel or plastic dowels will help to improve the bond between aerated concrete and ceramic plates. They can be replaced by ordinary nails or stainless screws. In all four cases, it is required to drive the fasteners into the masonry and mask it in the seams between the parts of the clinker array. Experts believe that you need to do 4 or 5 attachment points per 1 sq. m. Then the cladding will hold securely and will not collapse prematurely.