Peculiarities

The company has existed for almost 20 years and is one of the leaders in the production of technical aerosols. The company has its own research center with modern equipment. One of the center's departments specializes in the production of polyurethane foams. Product development is carried out by technologists with practical experience.

For customers, a selection of ready-made recipes is carried out. The recipe can also be developed and in accordance with the individual requirements of the client.

The production facility is equipped with two new automatic lines for filling aerosol cans with polyurethane foam. They make it possible to produce 12 million cylinders per year.

All stages of production are subject to technological control, and product quality is also monitored. In addition, the company is engaged in the delivery of finished products and the development of aerosol packaging design.

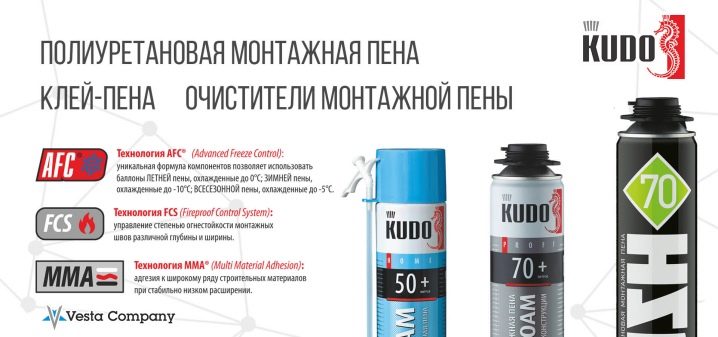

The company produces a wide range of polyurethane foams with different properties and characteristics. Kudo Foam is unique as it has an original formula of ingredients. For the production of fire-resistant foam, a special technology is used that allows you to control the degree of its fire resistance when filling joints with different depths and widths.

A special technology using a complex of structural converters contributes to the formation of a homogeneous spatial structure, which increases the thermal insulation properties of the foam in the cured state and allows to reduce the pressure on the structural elements. Kudo foams have low expansion and high adhesion to a wide range of building materials.

As an effective product of the latest generation, Kudo polyurethane foam is characterized by a short initial curing time, fast curing, and volumetric yield.

In addition to all the advantages, Kudo products have a very reasonable price, and not only professionals can use them, but also all people who need to make repairs. From the assortment presented by the company, you can easily choose the required type of product. The product will delight you with its durability, resistance to harmful environmental influences and a long service life.

A small disadvantage of this type of foam is that its polymerization is carried out only in the presence of moisture, therefore, the treated area should be moistened before installation.

Views

A wide range of manufactured products allows you to choose an option for various types of work and different environmental conditions, for professional and domestic use. Some foams come in two flavors: sprayed with a gun or with a plastic tube. The latter is suitable when there is a need to fill volumetric voids and cavities.

Proff 65+ has good qualities. This summer foam, which has an original formulation, can be used at temperatures from 0 to +35 degrees. The cylinders are equipped with a newly designed valve. It is guaranteed to work, not prone to sticking. A 1 liter can provides up to 65 liters of foam. The product output can be adjusted with the screw of the gun.

The surface film is already formed after 10 minutes. Complete polymerization occurs in 24 hours. When the foam hardens, it lends itself well to plastering and painting. However, it should not be used in areas where it will be exposed to strong ultraviolet radiation.

Proff 65 is used in the installation of windows and doors, when attaching wall panels, since deformations of structures are excluded with it.The foam has excellent heat and sound insulation properties, adheres well to most building materials.

For professional use, the Kudo Proff 70+ is suitable. It is used in a wide range of jobs. This one-component foam is wintry, so it can be used in sub-zero temperatures. Moreover, it is resistant to high humidity. A 1000 ml can gives up to 70 liters of foam.

Rush Firestop Flex is a specialized product designed for use with translucent structures. In addition, it will be an excellent sealant with excellent sound and heat insulating properties.

The substances included in the composition will ensure high-quality filling of the assembly seams and thereby exclude deformation in the structures. This is especially appreciated when installing windows, window sills, door blocks and other elements.

One of the features of Rush Firestop Flex foam is its fire resistance, so its use is advisable in rooms where fire safety must be observed. In addition, it is resistant to moisture and molds.

Kudo 65 ++ Arktika Nord also belongs to winter foams. It is used at temperatures from -23 to +30 degrees, has excellent insulating properties, suitable for use with almost all building materials. In this regard, it can be used for any finishing and installation work.

Its surface film is formed in 10 minutes, complete curing occurs in a day or two.

Glue-foam PROFF 14+ has proven itself excellently. This all-season one-component product is used for insulating work, fixing panels and plates, and sealing joints. It can be used to glue drywall, metal tiles, decorative elements. Bonding can be done on plastered surfaces, as well as on wood and metal substrates.

Foam glue is economically consumed, its amount in one 1 liter bottle is equivalent to 25 kg of dry glue. In addition, it is convenient to use: no special tools and devices are needed, and the composition is completely ready for use.