Plastic panel mounting technology

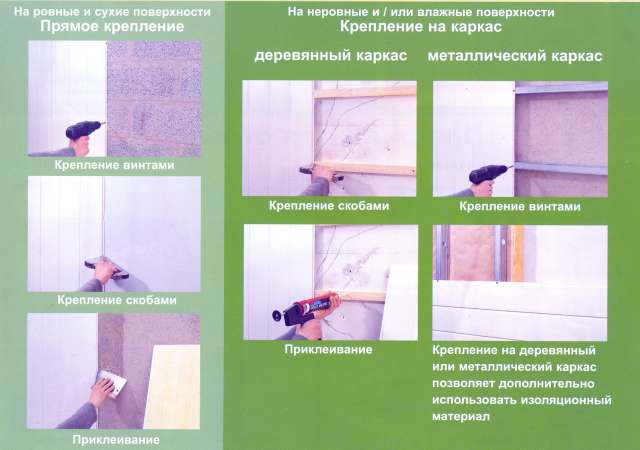

There are various options for wall cladding with PVC panels.

- Fastening to a pre-prepared crate;

- Fixing directly to the wall with liquid nails. In this case, the surface should be perfectly flat and smooth.

Tools and materials needed

Depending on the chosen technology for performing the work, it may be required:

- a drill with a perforator, multi-caliber drills and drills;

- screwdriver;

- set of screwdrivers;

- construction stapler;

- self-tapping screws, cleats and other consumables;

- level;

- gun for liquid nails and silicone sealant;

- construction knife;

- finishing material and accessories.

Materials used for lathing

Various materials are used to equip the lathing. The frame is made of wood, metal or plastic elements. Lathing options

- From wood - assembled from wooden slats. The bars must not be damaged. It is better to abandon the spoiled ones immediately, preventing the likelihood of destruction of the structure. Reiki should be treated with an antiseptic compound to avoid rotting and bark beetle infestation.

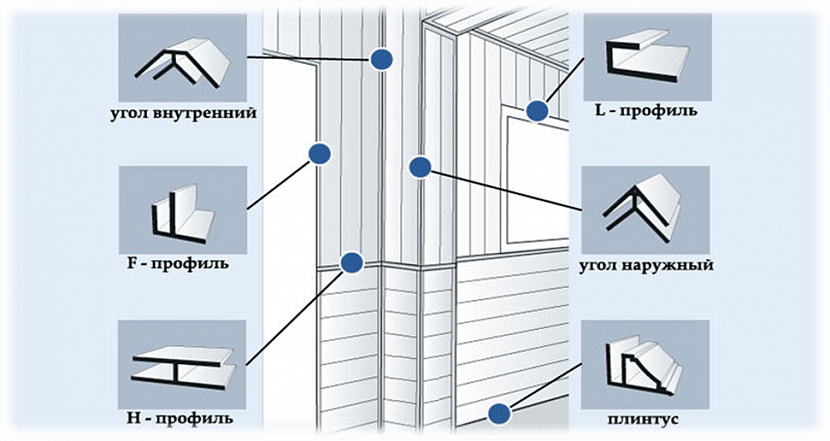

- The plastic profile is not afraid of dampness and fungus. There are several types of these fasteners. There are starting U-shaped, F-shaped, H-shaped profiles, as well as corner - for internal, external corners and universal. For the equipment of supporting structures, plastic slats are used.

- Metal profile - the frame is made according to the same principle as for drywall. Possesses the highest carrying capacity, durability.

Wall marking and installation of lathing

Before proceeding directly to the creation of the frame, it is necessary to mark the wall. First, its scheme is carried out on paper. This step allows you to accurately calculate the amount of material and fasteners. Then the drawing is transferred to the wall. Marking helps to erect a structure with high speed and maximum accuracy.

Step-by-step instructions for creating a wall frame

The process of installing a wooden lathing includes the following steps

- installation of vertical racks;

- fixation of transverse rails;

- installation of additional vertical stiffeners - if necessary;

- additional reinforcement of the structure with a sealant.

Wooden lathing is a great option for dry and often ventilated rooms. For wet rooms, a frame made of an aluminum or plastic profile is more appropriate.

The metal crate is suitable not only for fixing sheet materials - ordinary drywall, gvl, fiberboard, chipboard, mdf, but also for plastic lamellas. It allows you to hide the unevenness of the walls and ceilings as much as possible.

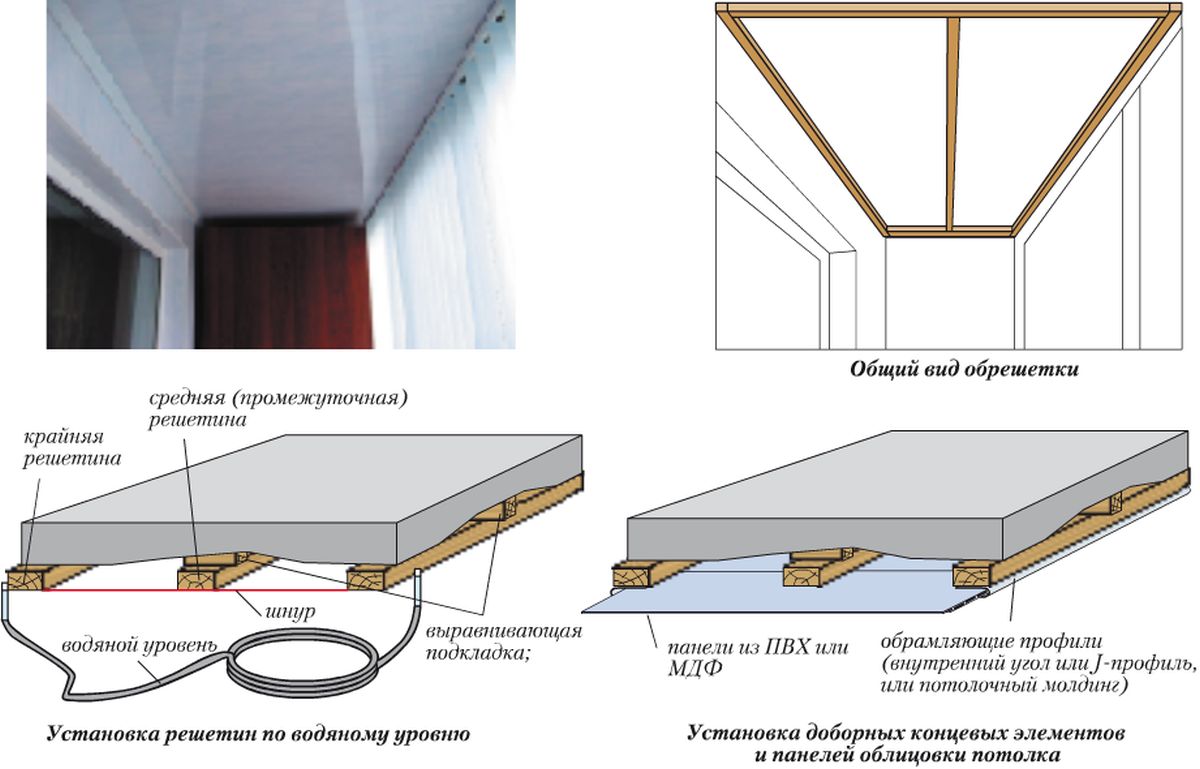

The first step is to attach the lower and upper, then the vertical guides. These elements are carefully aligned with each other. Install transverse horizontal parts. When trimming the ceiling, the rails are suspended using U-shaped brackets. The height of the suspensions is leveled using a level.

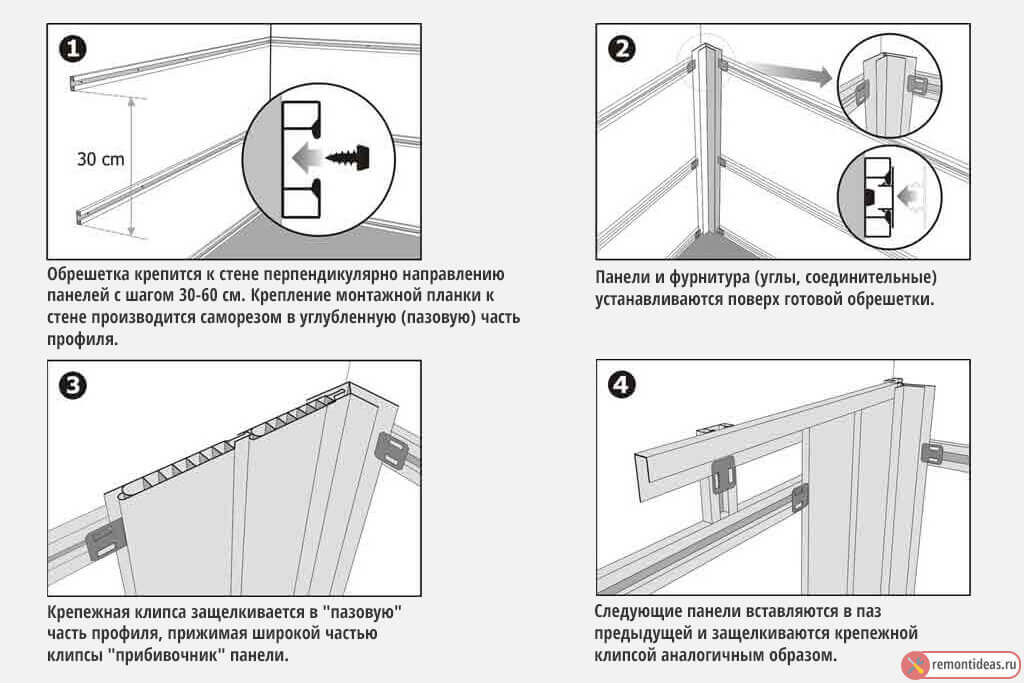

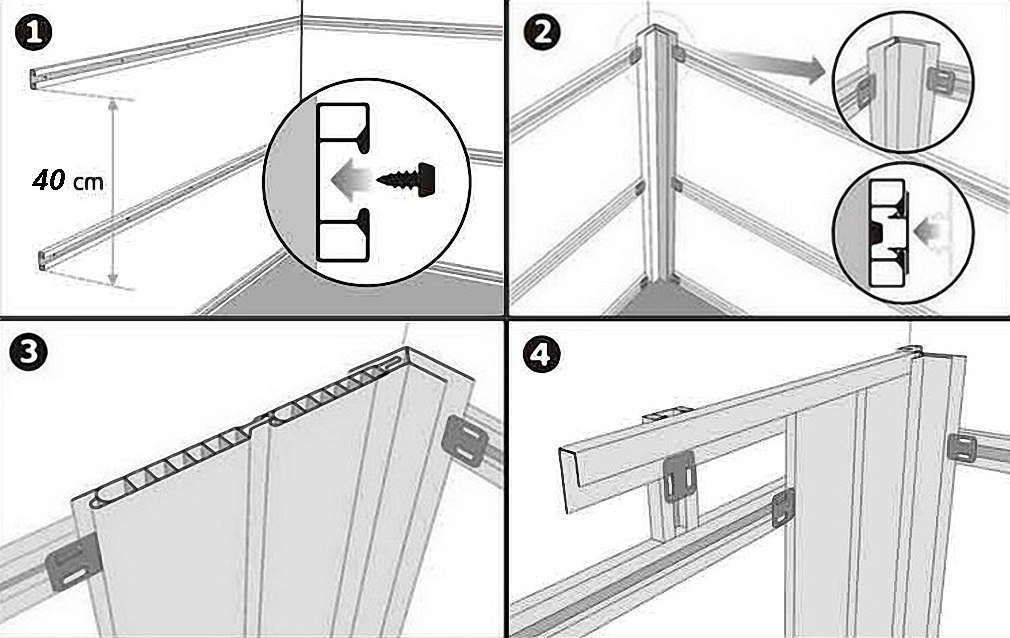

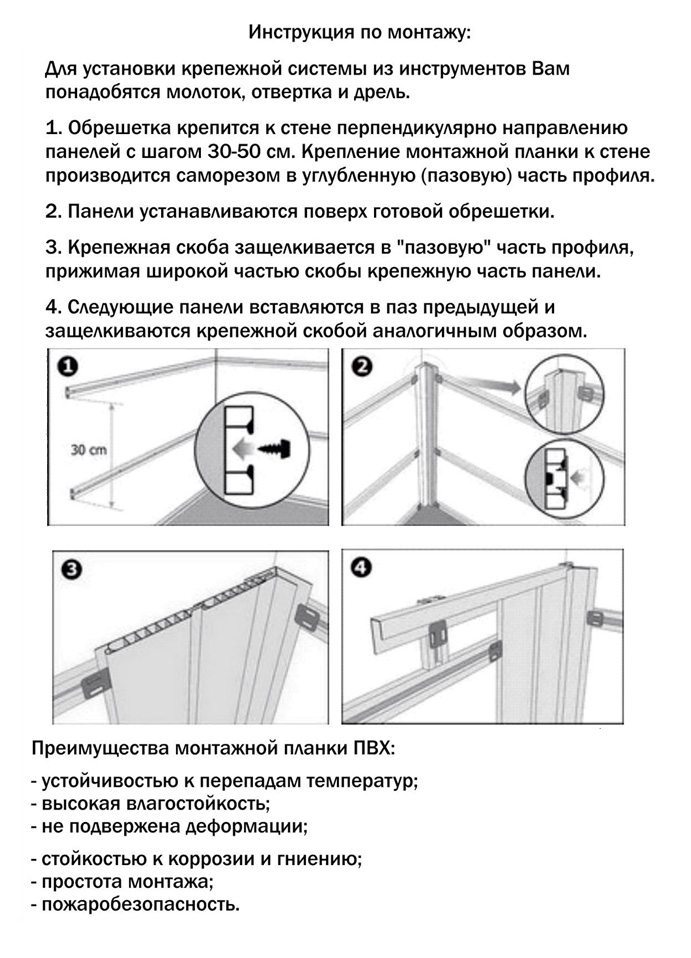

The guides of the plastic lathing are installed strictly perpendicularly towards the decorative lamellas. Otherwise, the fasteners - special clips, will not be able to snap into place and effectively hold the panels. The distance between the profiles is 30 cm.

Fastening lamellas and installing moldings

- Install the corner piece with panel grooves.

- Attach the floor and ceiling skirting boards.

- Measure the height of the first panel, taking into account the depth of the grooves of the baseboards and cut it off using a construction knife.

- Insert the first panel into the grooves of the corner with the narrow locking side.

- They are fixed with brackets or self-tapping screws from the side of the wide mounting shelf.

- Subsequent strips are inserted with a narrow shelf into the groove of the previous panel, aligning the parts as tightly as possible.

- The last lamella is forcefully installed between the previous strip and the final molding. If it does not fit, the excess is cut off.

Types of PVC products for walls

All products can be divided into two large groups, which differ in shape and texture on the surface. If we talk about the form, then there are such types of products:

- Tiled.

- Rack and pinion.

- Leafy.

As for textures, the following types of materials are distinguished:

- Under the stone;

- Under the tree;

- PVC panels 3D;

- Mosaic.

Tiled

The material is made in the form of small tiles. Fastening such plastic panels on the wall is a bit like working with ceramic tiles. It is this material that the products imitate. The main difference is weight. Thanks to this, during installation, adhesive for PVC panels is used. This is a common glue or sealant.

Dimensions are different, from large to small, starting from 50x50mm, ending with 500x500 mm. It becomes possible to create various visual effects, forming a pattern or a full-fledged drawing on the surface. The dimensions of PVC panels allow them to be used in rooms with uneven walls and problem areas.

The main disadvantage of this option is that fixing PVC panels to the wall in the form of tiles will take a lot of time. While the result is worth it, patience will be needed in the process.

Rack

This is a classic form of the product, reminiscent of an ordinary lining. These are narrow strips (up to 30–40 cm) of various lengths, allowing quick installation. With their help, it is easy to sheathe any vertical surface and ceiling. The whole process takes a little time. They are used for any premises. The fixation is performed using the tongue-and-groove method. Joints can be treated with sealant or putty.

The appearance of the products is very different, up to the imitation of natural materials. True, the drawings, if any, will need to be selected. Wall cladding with plastic panels involves the use of plastic moldings, including connecting elements, starting, finishing and coal. If there are beveled blades in the room, then the lamellas can be cut.

Leafy

These are large slabs, something in between slats and slabs. The size of flat sheet material is different, the assortment is also different. They are used both for curly cutting and for wall decoration in a classic form.

In this case, a frame made of metal or wood is required for installation. Glue for PVC panels will not help here, since the products have an impressive weight. If you really want to put the products on glue, you will have to cut the sheet into several parts.

Stone texture

The texture is responsible for the decorative appearance of products, their relief. Plastic panels are appreciated for their visual appeal, and thanks to new technologies, any surface can be imitated on the surface using laser engraving. Stone is one of the popular options. This material is expensive, since a lot of resources are spent on extraction. Moreover, it is heavy and difficult to work with.

All these disadvantages are solved by a beautiful PVC panel under the stone. The imitation is natural and beautiful. Sheet materials for interior decoration under a stone can be in the form of slate, wild stone, marble, etc. This also includes a popular option for creating a loft style - PVC panels under a brick.

Wood grain texture

Wood-like panels are no less popular, as wood always remains fashionable. The room looks noble and cozy. The stores have embossed products that are difficult to distinguish from natural wood, but there are lamellas with painting or decorative stickers. Usually, to create an imitation, you have to combine several plastic wall panels.

This option is easy to fit into any room interior.In addition, plastic lining is suitable for exterior decoration. This is true for small houses.

3d PVC panels

An option that is gaining popularity. There is a pattern on the surface. Its properties allow it to look voluminous. In design, 3d PVC panels are simply invaluable, as they create an unusual appearance of rooms.

On store shelves, 3d PVC panels are sold in a huge assortment. They are produced in the form of slabs or strips, since a large sheet is difficult to apply without disturbing the appearance.

However, when using it, it is important to take into account that this effect can be very provocative and annoying. For some rooms, this illusion is inappropriate.

Mosaic texture

This is a standard product that has a mosaic pattern applied to it. Relief elements that repeat the pattern and its features are often used. Mosaic is a frequent occurrence in rooms connected to water. These are: bathroom, toilet, kitchen.

How to glue PVC mosaic panel? Since this is a solid stove, it does not take a lot of time to work. For fixing, a sealant, special glue or liquid nails are used. The finished result will delight the consumer. The width of PVC panels for walls is different, it depends on the specific model.

Preparation

PVC is polyvinyl chloride, in a simple way, a kind of plastic. Panels made of this material are especially popular, since they are not afraid of moisture and do not rot, they are quickly mounted, they do not change under the influence of ultraviolet rays, they retain a decent appearance for a long time and, when using a frame, create additional sound insulation. Finally, they are relatively cheap.

Installation of PVC plastic panels always begins with a preparatory stage. First, the material is selected and bought in compliance with several important points. While in the store, you need to inspect the panel cut. If there are thick layers, both external and internal, and a thick lintel, then the finish will be reliable. The thickness of the panel can also be determined by weight - the heavier the panel, the thicker it is. The uniformity of the plastic is then examined. The entire sheet should have a uniform thickness without overly thick or overly narrow spaces - this is a guarantee of good quality.

When a brand and manufacturer is chosen (it is better to pay attention to European firms), then you also need to calculate how much material is needed. Otherwise, unused fragments will remain (and will be overpaid), or, on the contrary, the material will not be enough and you will have to urgently buy it in the store (unnecessary time will be spent)

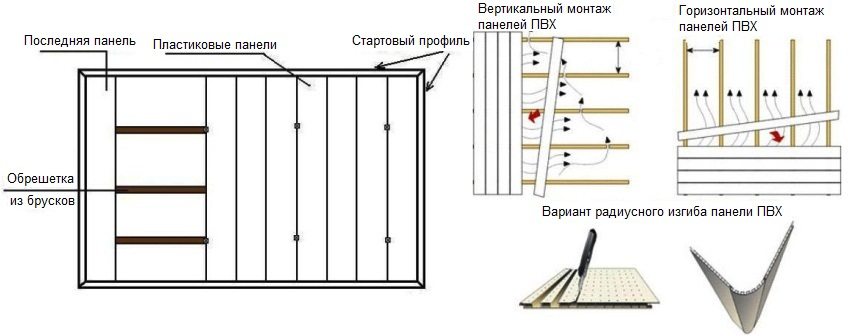

PVC panels are placed either vertically or horizontally. In the first case, you need to measure the length of the room around the perimeter, then subtract the width of doors and windows from this figure and divide the remainder by the width of one panel. You will get the number of elements needed to repair the premises. It is better to add a couple of units to this figure in case of unforeseen situations.

If the panels are placed horizontally, the first step is to calculate the area of the room. Next, the area of doors and window openings is subtracted from this figure. Finally, the resulting number is divided by the area of one panel (usually this figure is indicated on the packaging by the manufacturer). 10% is also added in case of unforeseen situations. If the sheets are mounted horizontally, then you should be prepared that the material will have to be cut, which means that there will be scraps.

Once you get rid of the packaging, you can get a good look at the edges and individual cells. The panels should not show any dents or damage. The more complex the image, the more important it is to study the quality of its application - blurred fragments and uneven coverage should cause vigilance. Also, if you have to purchase several packs of sheets that must match in color, it is reasonable to unpack and check if the shades converge.Finally, the material should be tested right in the store. One sheet is folded about 30% and then unbend. If there is no damage, then everything is in order with the purchase.

Having acquired the material, it is necessary to prepare the walls. The first step is to remove old paint, tiles, wallpaper and layers of old finishes. Then the surface is leveled with plaster. In addition, it would be a good idea to try to repair the existing grooves or to eliminate protruding elements. Having finished with the leveling of the wall, you can proceed to the primer. It is recommended to choose a composition with additives against mold and mildew. While the primer is drying, you can start assembling the crate, and also bring the panels into the room - they need to stay inside for about 12 hours to adapt to existing conditions.

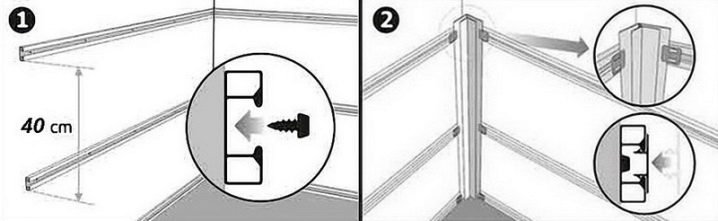

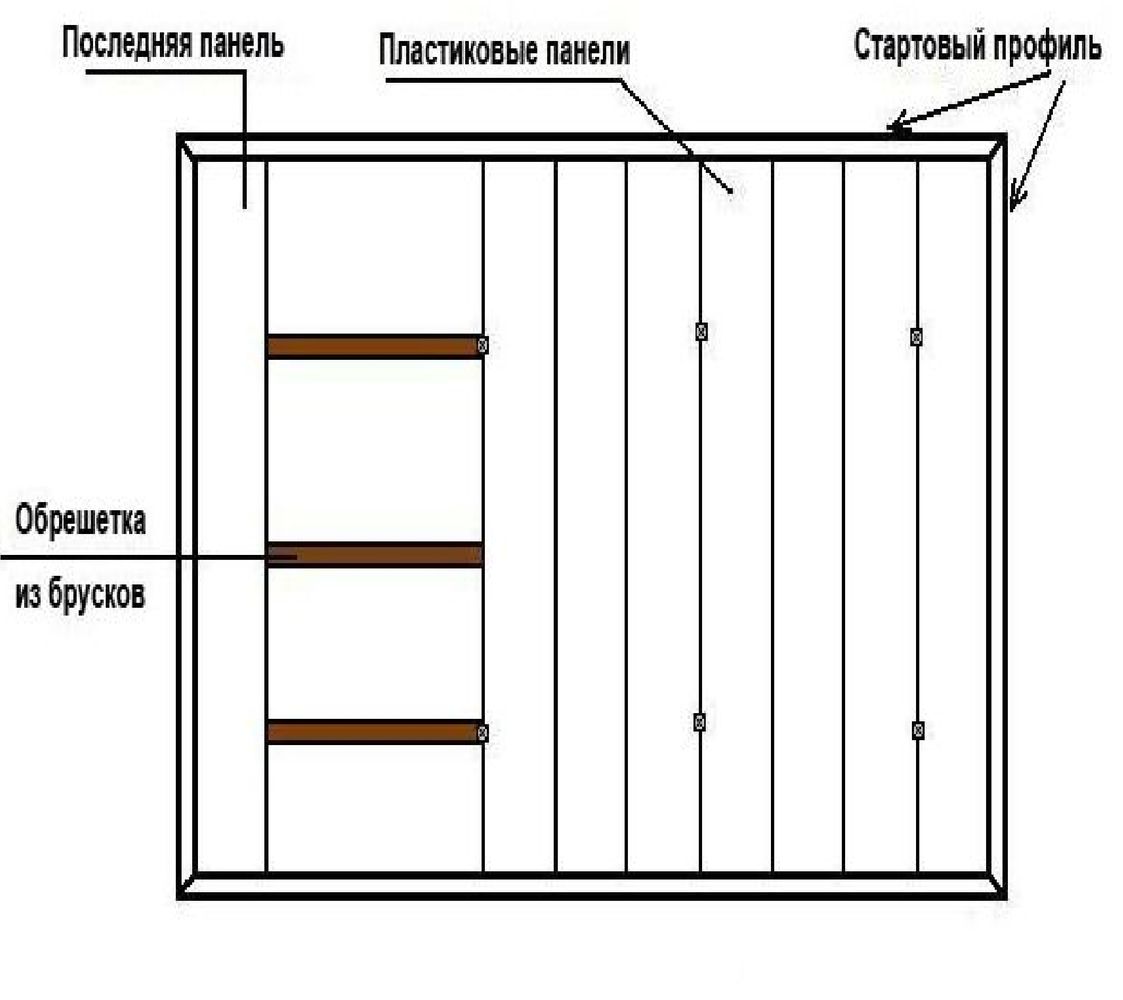

The elements of the lathing should be located perpendicular to the plastic sheets. This means that if the sheathing runs horizontally, the panels will run vertically and vice versa. The distance between the battens of the crate should be from 30 to 50 centimeters, the first figure is still optimal. The planks are to be fixed near window openings, near doorways, as well as at the beginning and end of the wall.

The lathing is most often attached to the dowels. The length for a concrete wall is 40 millimeters, and a brick wall is 60 millimeters. The distance between the dowels varies from 50 to 60 centimeters. In order for the PVC panels to be evenly laid as a result, the crate must also be in the same plane. To do this, you can use pieces of plywood or wooden spacers, pre-treated with an anti-fungal compound.

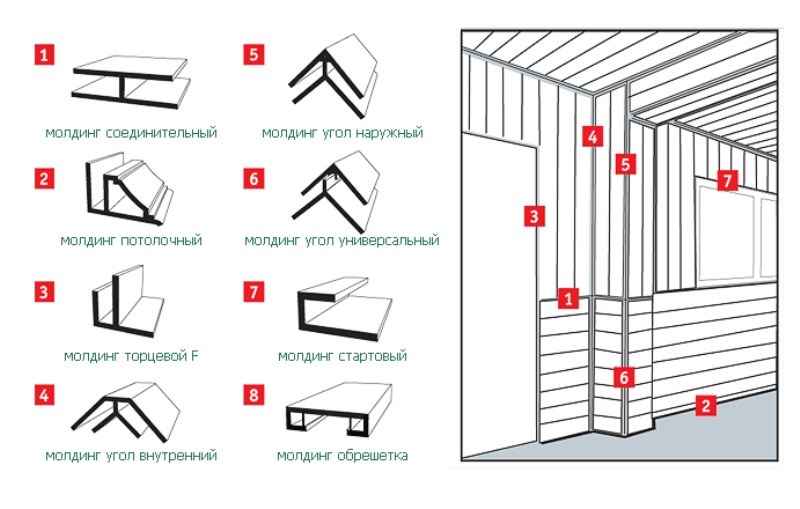

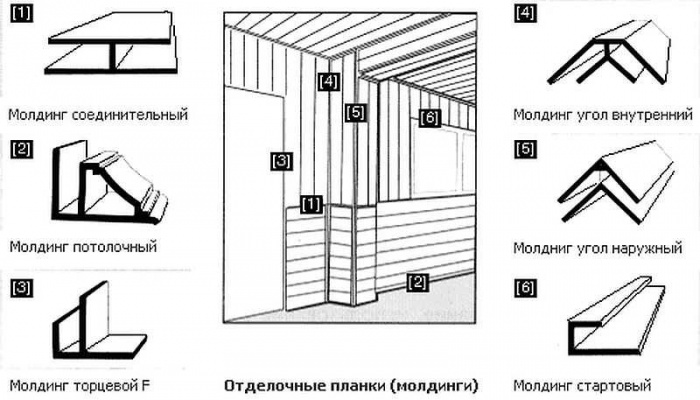

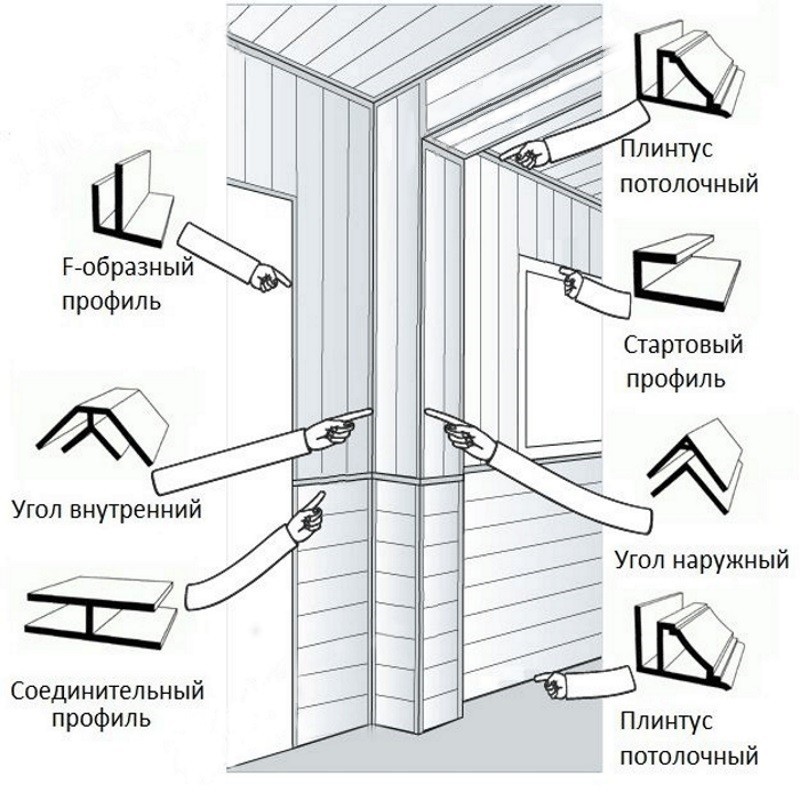

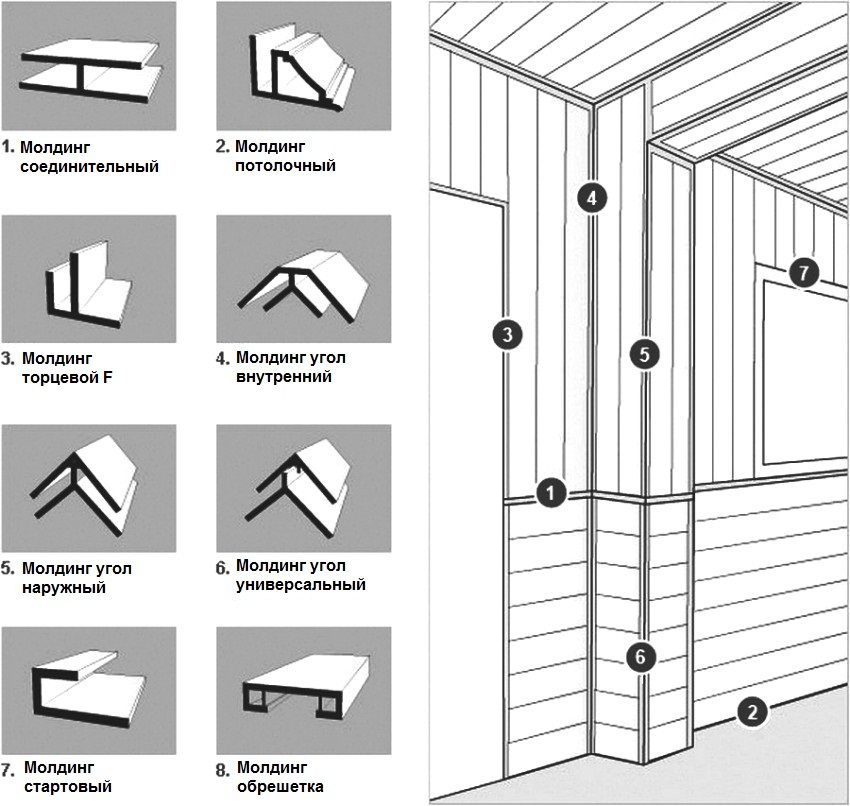

Completion and additional elements

We will talk below how to calculate the number of panels and additional elements, and now we will tell you what is included in the package of wall decoration with PVC panels. Select the appearance and specific dimensions taking into account the parameters of the panels.

| Name | Brief description and purpose |

|---|---|

Universal corner |

It looks like a plate bent at an angle of 90 °. Used for decoration inner and outer corners of the room. |

Ceiling and floor skirting boards |

A complex profile, part is installed under the panels, the outer side hides the unevenness of the cuts or surfaces. |

Outdoor corner |

Consists of a corner, the inside is wider than the outside. Conceals irregularities in the outer corner. |

Inner corner |

It differs from the outside in the width of the sides. The wide one is installed under the lamellas, the outer narrow one hides the unevenness of the inner corner. |

Connecting profile |

Allows you to connect lamellas without a lock, used if the length of the lamellas is insufficient for surface finishing |

Start / finish profile |

Installed first and last, sometimes it can be used instead of a universal or special corner. |

F-shaped profile |

Installed in the places of abutments, can be used as a platband. |

Purlin mounting plate |

The supporting element of the frame can be plastic or metal profile. |

|

Clammer |

Made of metal, presses the panel against the mounting plate. Allows to dismantle panels without loss of factory qualities. |

pvc panels for bathroom

The panels are fixed with self-tapping screws with a press washer, staples with a stapler, clamps or liquid nails. The choice of the method depends on the materials for the manufacture of the supporting frame and the quality of the walls and ceilings.

Methods for mounting PVC panels on walls

Required tools

Now you need to make a list of tools that will be needed to fix the PVC panels to the ceiling. You do not need something complicated or very expensive, all of the following can be found in any hardware store.

- Perforator - required to install the frame.

- Screwdriver. If you wish, you can attach plastic panels to a profile or timber using a puncher, but it is very heavy, and it is very inconvenient to use it for such tasks.Therefore, the presence of a screwdriver will greatly facilitate the work and increase the speed of installation of PVC panels. And if you attach them not to self-tapping screws, but with the help of staples, then instead of a screwdriver, take a construction stapler.

- To control the accuracy of the marking and the location of the plastic panels, you will need a square, a level and a paint thread.

- Pencil or marker for drawing lines and marking PVC panels in the order in which they are laid.

- Measuring tape.

- Electric jigsaw or circular saw - for cutting frame profiles and plastic panels.

- Stepladder. Of course, you can always get by with a table or stool, but this is unsafe and inconvenient.

- Rubber mallet, which can be useful for fitting PVC panels to each other during installation.

Tools for the installation of PVC panels

In addition to tools, you need to purchase material for the frame. It can be either a metal profile (UD-27 for the main and CD-60 for the guide), or a wooden bar. Also, do not forget to purchase fasteners (screws, staples or glue), drills for a hammer drill, screwdriver attachments, dowels and profile hangers.

Instructions for the installation of PVC panels on the walls over the lathing frame

Before sheathing the wall with PVC panels, the surface should be cleaned. There is no need for serious leveling, but if it is planned to finish a bathroom, kitchen or other wet room, it is recommended to waterproof the walls and cover with an antiseptic.

To form the lathing structure, 2x2 cm blocks of wood can be used.They are much cheaper than metal elements. However, it is not recommended to use wooden lathing for rooms with high levels of humidity. Before using wood, it must be thoroughly dried so that the moisture content of the material reaches the permissible norm - 12-15%. Remember to pre-treat the bars with an antiseptic.

To equip the metal frame, you will need a UD profile element (contour part) and CD (guides).

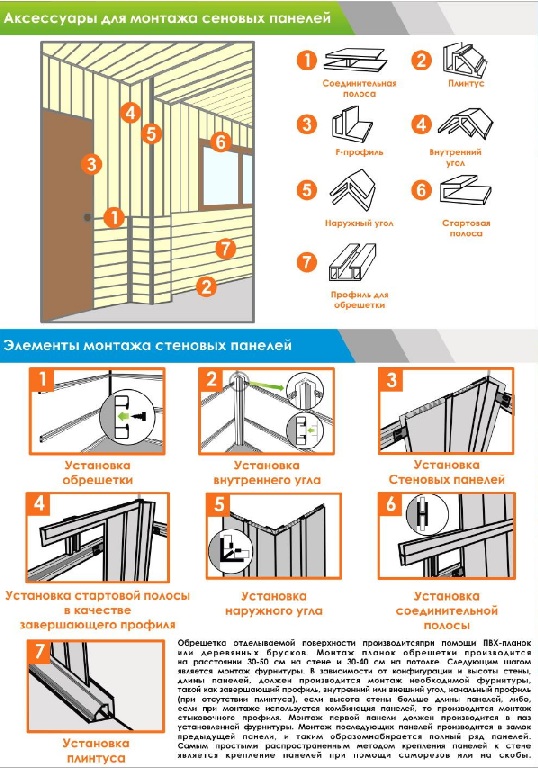

Installation diagram of panels and additional structural elements

Regardless of whether you make ceilings from PVC panels with your own hands or sheathe walls, the construction of a lathing structure should start with marking. If you are working with walls, you first need to determine the lower level, taking into account the further installation of the skirting board. As a guide, you need to take the most protruding point of the wall. It is she who will determine the indent of the crate.

After that, the line of the top level (with a reference to the ceiling) and side levels is determined. To control the upper and lower zones, it is recommended to use a building level, for side elements - a plumb line.

How to fix a PVC wall panel: working with the frame and cladding

The fixing of the lathing elements is carried out using straight hangers. The screws are positioned in increments of 20-25 cm (wooden frame) or 15-25 cm (metal frame). Installation of bars or metal profiles is carried out first along the edge, then inside the structure. This will ensure a secure hold of the trim around the edges.

Various Ways to Install PVC Panels

When installing internal profiles, it is worth considering the type of panel mounting you have chosen - horizontal or vertical. The lamellas will subsequently have to be fastened perpendicular to the guides, fixed with screws.

Panel mounting scheme on crate:

Installation of external and internal moldings.

Installation of the first panel and fixation with a cleamer (the spike of the lamella must enter the profile).

Mounting the second panel into the groove of the previously installed lamella and fixing in the same way.

Installation of material to the end of the wall.

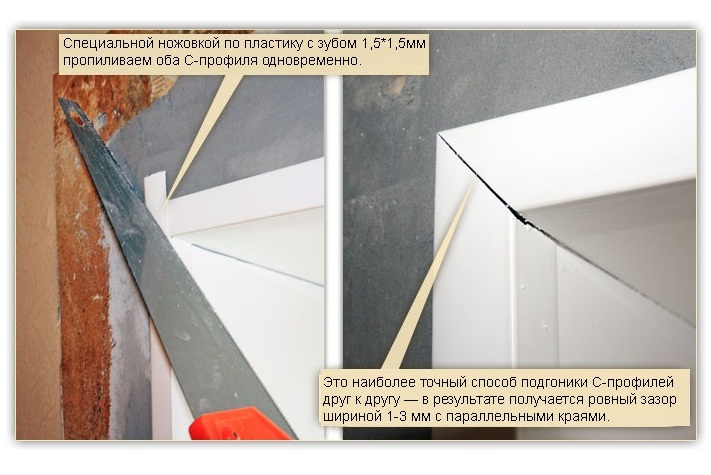

Cut the last panel, taking into account that the finishing material should be installed all the way to the corner area.In this case, a gap of 2-3 mm should form between the spike of the last element and the groove of the previous lamella. The cut side should be placed in the profile and the finishing piece inserted into place.

Use a video review of this procedure for a more detailed consideration of the installation of PVC wall panels with your own hands.

Installation of panels on a crate

This method involves the installation of a frame for PVC panels. It simultaneously serves as a supporting structure and a product for leveling walls. Before fixing PVC panels, you should prepare all the necessary tools, fittings and materials, as well as carry out some preparatory work.

What you need to carry out preparatory work

Fastening PVC panels to the wall implies the following things:

- wooden or metal profiles, from which the frame will be made;

- building level and plumb line - to determine the angle of inclination and location of the main elements of the crate;

- dowels - for attaching the rails to the wall;

- screws - for connecting structural fragments;

- tape measures - to measure the distance;

- material for the substrate under the guides - wooden beams or thick plywood;

- screwdriver and drills.

Tools and materials required to create PVC panel sheathing

Tools and materials required to create PVC panel sheathing

As additional tools, you may need metal scissors (in the case of aluminum profiles) or a saw, chisel and mallet if you plan to create a wooden base.

Wireframe creation

To answer the question - how to properly attach plastic panels to the wall by means of a crate, you must first consider the principles of creating a frame.

The installation of the lathing begins with the marking of the working surfaces. To do this, find the most protruding point of the wall in its lower part, after which they draw a strictly horizontal line, which is constantly checked by the building level. The first profile is screwed strictly along the line. Then they move on to marking the upper part. To do this, two vertical profiles are installed in the cavity of the lower profile at both ends, after which their verticality is checked with a plumb line. The upper points are connected in one line, along which it will be necessary to attach the upper profile.

Screwing the profile to the wall

Screwing the profile to the wall

Using a drill, the profile is drilled through, partially drilling into the wall, after which the slats are screwed to the surface with dowels or screws and a screwdriver. Fasteners must be fixed every 25 cm for timber frames and every 20 cm for metal slats.

After that, you need to set the internal jumpers.

It is important to remember how the PVC panels will be fastened: horizontally or vertically. The fact is that plastic products should be fixed perpendicular to the frame rails.

After installing the frame and checking the correctness of its installation, you can start screwing the panels.

Creation of a frame for vertical installation of plastic panels

Creation of a frame for vertical installation of plastic panels

What is required for basic work

To carry out work on the installation of plastic panels, it is recommended to prepare the following:

- PVC panels - they need to be given time to acclimatize. To do this, they must lie down in the room where the finishing will take place for at least 24 hours;

- moldings - special angle profiles that provide tight and reliable contact;

- clamps - metal staples used to fasten panels to the crate;

- building level - with its help it will be possible to accurately determine the location of the first plastic panel on the crate, which is a reference point for subsequent installation;

- a special knife for metal - required for cutting PVC panels.

Step-by-step instruction

Installation of PVC panels on the walls

Installation of PVC panels on the walls

You need to fix wall panels using the following technology:

- Step one is the installation of moldings. Further editing takes place from them.

- Step two - installation of the first PVC panel.The spike of the product is inserted into the profile cavity, and fixed on the crate with clamps. Subsequent panels are placed in the groin of the previous ones and so they are gaining the entire wall.

- Step three - completion of the work. The last planks are trimmed so that they fit neatly into the inner corner.

If it is necessary to hide the moldings, then do-it-yourself installation of the panels occurs in the reverse order, with the first plank fastened to the corner, and then cut it off so as to remove the spike, after which the entire surface is recruited.

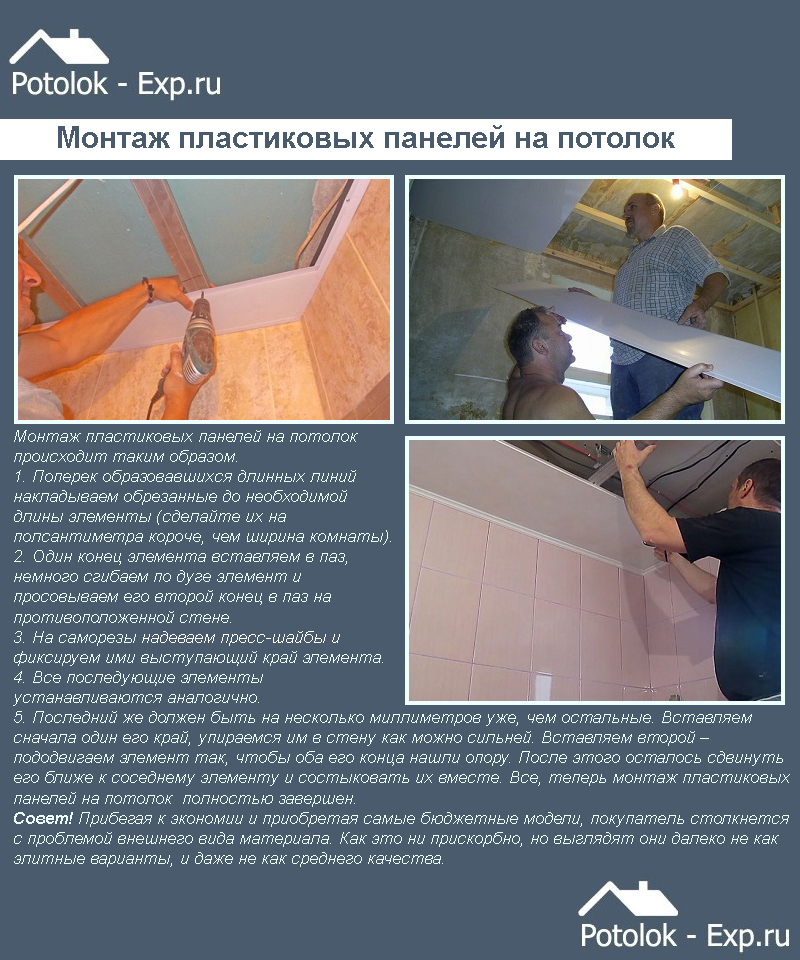

Installation of panels to the ceiling on a metal frame

This method is recommended for uneven ceilings, the ceiling can be reinforced concrete or wood.

Step 1. Beat off the line for the installation of the bearing profiles along the perimeter of the room, make sure that the ceiling is horizontal. Fix the rest of the profiles at a distance of about 50-60 cm. If the ceiling is very uneven, then use suspensions. They can be fixed and adjusted in the same way as on a wall. The difference is that the ceiling frame is more difficult to check with the level: it is more difficult to work, the arms are raised up and get tired quickly.

Frame for PVC panels

Frame

Step 2. Glue three plinths with liquid nails, file them at 45 ° in the corners. If the plane of the ceiling does not have right angles, then each gash will have to be adjusted. Glue the skirting board both to the wall and to the metal profile. Observe the technology when gluing. After the skirting board is attached, remove it and wait 2-3 minutes, then press the element again. Check its position by rule or level. The rule is applied to the bottom edge of the skirting board

If there are gaps, then with your hand carefully move the plinth down until it stops with an even edge of the rule. Give time to solidify

The slots in the corners are sealed with a liquid sealant, but for professionals, the fit should immediately be tight. It is very hot and humid under the bathroom ceiling. You can be sure that the sealant will peel off in 4–5 years, it will have to be removed and the cracks repaired.

Attach the skirting board to the guide profile

Step 3. Insert one end of the lamella into the skirting board, bend it slightly and push the other end into the opposite skirting board. Straighten the panel and slide into the third skirting board. We have already mentioned that the dimensions of the ceiling should be checked exactly before installation. If one side is longer than the other, then the difference must be gradually leveled by adjusting the gap between the lamellas. The method, of course, is not ideal, but there is no better way. Always install the panels along the long side of the ceiling. Due to this, it will be possible to reduce the number of cuts and facilitate bending of the lamellas during installation.

Installation of a plastic ceiling

Step 4. Each panel is fixed with self-tapping screws with press washers to the profiles. This is quite difficult, hardware often falls out of a drill or screwdriver.

PVC panels are attached to the metal frame with a self-tapping screw with a press washer

Panel fixing

Check the position of the lamellas at all times. In order for a screwdriver that has jumped off not to damage the end of the panel, place a clean, wide metal spatula between them while tightening, it serves as reliable protection. It is not necessary to twist the press washers into the tail of the panel, it is difficult and increases the risk of damage, the main thing is that it presses it against the profile with a hat.

Installation of panels on the ceiling

Step 5. The last panel needs to be cut to fit the remaining gap. To facilitate installation, make a gap of about 1–1.5 cm, it will then hide in the skirting boards.

Step 6. Cut off the back plate of the skirting board, cover the remaining surfaces with glue and glue in the wall. Do not forget that gluing must be done in two stages. If the skirting board creeps down under its own weight, then hold it for a few minutes or come up with any temporary stop.

This completes the work, you can proceed to the installation of lighting devices. Before you start finishing, you should know the type of devices and the place of their installation, cut holes of the corresponding diameters in the panels in advance.

How to arrange and connect fixtures

The hole for the light can be cut with a knife

Drilling a hole with a crown

Fixture for luminaire

Plastic ceiling