Step-by-step instruction

When choosing a place in the garden for building a shed, it is necessary to take into account the presence of irregularities and slopes on the surface of the earth. It is recommended to carefully level the site before starting construction.

Also pay attention to wind speed and direction. An open arched alcove, which will be constantly blown by the wind, is unsuitable for its intended use

For this reason, try to cover the structure with a wall, fence, or even plants. It should be noted that the proximity of dense bushes and tall trees negatively affects the technical characteristics of polycarbonate. With strong gusts of wind, the branches of the plants scratch the roof of the building.

A garden gazebo that will be used as a summer kitchen should be close to the house. The close location of the summer cottage and the arbor will allow you to arrange family tea and dinners in the fresh air.

The frame of the structure can be made of wood or metal. Wooden beams and boards are prone to rotting, therefore, they require periodic treatment with antiseptics and fire retardants. Iron is strong, reliable and durable. It is possible to prevent the appearance of rust on the surface of a metal profile by treating it with special anti-corrosion agents.

In the process of erecting a canopy from a metal profile and a polycarbonate coating, you will need the following tools and materials:

- polycarbonate sheets;

- hermetic tape for processing the end face of polymer plastic;

- self-tapping screws and thermal washers;

- steel pipes with a diameter of 50 mm for the manufacture of supports;

- metal corner with a size of 40x40 mm for the manufacture of rafters, strapping and frame fencing;

- metal screws and brackets;

- electric jigsaw, hacksaw or polymer saw;

- building level, twine and wooden pegs;

- soil drill and hammer;

- container for mixing concrete, shovel;

- screwdriver, electric drill with attachments of various diameters;

- pliers;

- hacksaw for metal;

- welding machine, grinder.

To create a gazebo, you need a tool

Measurements and calculations

The preparatory stage for the construction of a summer cottage provides for the development of a drawing plan. A well-thought-out scheme will help you make the right calculations and avoid common mistakes during construction. You can draw up a drawing yourself. To do this, you need to draw a sketch of the future structure, calculate its dimensions and select the material.

In the absence of drawing skills, it is recommended to seek help from specialists who will help build a drawing and draw up a detailed plan for the construction of the project.

Foundation

The construction of a stationary gazebo in the courtyard of the personal plot begins with marking the site and pouring the foundation:

- Clear your garden area of plants and other debris. Level the pad.

- Determine the first corner of the wireframe. Place a wooden peg in this place.

- Use a spirit level to mark the other three corners of the canopy. Stretch the twine by connecting four points around the perimeter.

- Dig a pit 25–30 cm deep. Tamp the soil and check the horizontal and vertical lines are even. Fill the hole with sand and rubble.

- Using a soil drill, drill holes in the corners with a depth of 70–100 cm. Now you need to install, fix and concrete the metal support pipes. Strut the supports.

- Weld metal corners to the supports.

Frame

It is not difficult to assemble the metal frame of the garden alcove if you follow the step-by-step instructions:

- Weld the crossbars to the support posts.

- Make the top strapping of the frame. Test it for strength.

- Assemble the rafters and other floor slabs on the ground. Lift the welded structure up and weld the roof to the pillars.

- Treat the metal profile with anti-corrosion agents.

Glazing

At the last stage of assembling the garden gazebo, you need to cover the structure with polycarbonate.

Polycarbonate sheets are cut on a flat horizontal surface. Then you need to process the ends of the canvas with a sealed tape. When covering the frame, leave a small gap for thermal expansion of the canvas. You need to work with polycarbonate carefully and accurately.

Do not remove the protective film from the surface of the panels until the glazing of the structure frame is completed. Otherwise, scratches and cracks may remain on the polycarbonate.

How to work with the material?

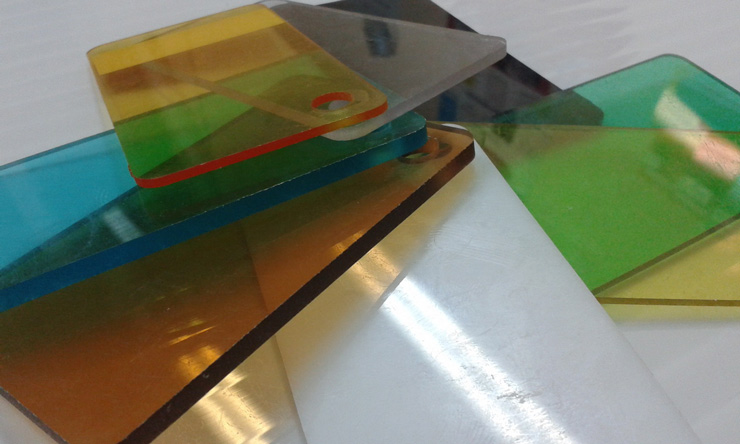

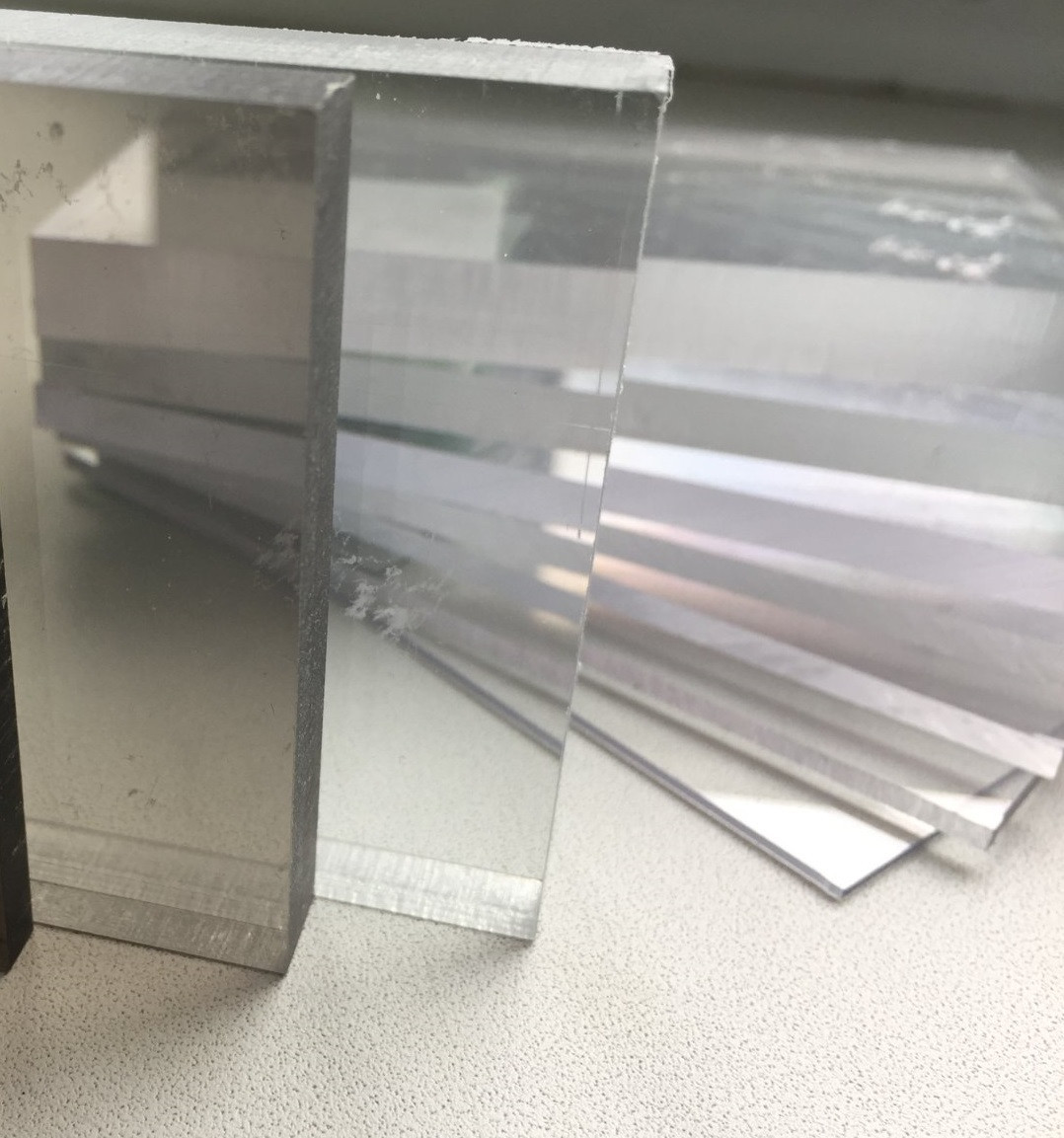

At home, a sheet of monolithic or molded polycarbonate can be subjected to different types of processing. Most often, bending, cutting, connection of individual layers to each other by gluing are carried out. This polymer does not create any particular difficulties in processing, it is well suited for cutting with hand or power tools.

Home cutting

Cast or extruded polycarbonate without meshes cannot be simply sawed without prior preparation. Best of all, it lends itself to cutting with a grinder with a disc for metal No. 125 installed on it. In this case, the cut is obtained without burrs and chips. And you can also perform laser cutting of sheets, use a jigsaw with a fine file. The sharper the cutting element, the better the procedure will be.

In the course of cutting, it is worth adhering to certain recommendations.

- The sheet is cut only horizontally, placing it on a clean, flat surface. Any protrusions and other obstructions will lead to cracks or deformation.

- The cutting line must be applied in advance. The most convenient way to do this is with a marker.

- Panels less than 2 mm thick are cut in a stack, connected with clamps. This will avoid cracking the material.

- Cutting must be done from the side with UV protection. The protective film is not removed until the completion of the work.

Elements that are large in size are easiest to cut by placing them on a flat floor surface. A board is laid on top, on which the master can freely move.

How to bend a sheet at home?

Monolithic polycarbonate lends itself quite well to bending, but taking into account its characteristic radius. You can give the sheet the desired shape using a locksmith's workbench and a vice. Transparent or colored material is laid on a workbench, clamped and then manually adjusted to the desired bending level

It is important not to use excessive force to maintain the integrity of the slab.

Bonding technology

The need to glue polycarbonate most often arises when joining sheets in greenhouses or other structures. The connection of the elements is carried out using special chemical compositions that do not affect the main characteristics of the material. In light, unloaded products - greenhouses, sheds - you can use several options for adhesives.

- One-component adhesives. They are also suitable for mounting polycarbonate sheets on rubber, metal, glass or polymer surfaces. There are many products in this category, you can choose Vitralit 5634, Cosmofen, Silicone mastic. One-component adhesives are characterized by fast curing, they are not afraid of moisture and high temperatures.

- EVA. Adhesives based on ethylene vinyl acetate are suitable for connecting polymeric materials to each other in different planes. It is a good choice for creating multi-layer products.

- Hot curing adhesives. Provides maximum bond strength. The best formulations have a polyamide base.

In structures operated under loads, two-component adhesives should be used - Acrifix, Altuglas. Formulations on a polyurethane base that form a transparent elastic seam are suitable. Silicone adhesives are often used to seal joints. Polycarbonate can be attached to flat surfaces with a special double-sided tape on an acrylic foam base. It is recommended to apply adhesives of thermoplastic, silicone, polyurethane types, as well as fast curing with a mounting gun.

Specifications

Technical characteristics of cast or monolithic polycarbonate (MPK):

- lightness - it is two times lighter than glass;

- high optical properties - light transmission exceeds 86%, which is equal to the properties of ordinary glass, while being protected from ultraviolet radiation. For example, a transparent sheet with a thickness of 2 mm. has a light transmission level of about 86%, and a sheet of 12 mm. provides light transmission of about 82%;

- high impact strength - 240 times stronger than silicate glass and almost 10 times higher in impact resistance of organic (acrylic) glass, as evidenced by tests with firearms;

- ease of installation - due to its flexibility and plasticity, molded plastic is easily mounted without the involvement of special equipment;

- fire safety - unlike other types of plastic, IPC does not burn even in an open fire, it melts. At the same time, it has a unique self-extinguishing property. Ignition temperature +570 degrees Celsius.

- frost resistance - can be used at temperatures up to - 50 degrees Celsius without additional loads and with loads up to - 40 degrees. At the same time, it does not undergo significant changes in the form of cracks, etc .;

- heat resistance - the maximum temperature of use reaches + 120 degrees Celsius;

- chemical resistance - unaffected by many chemicals. Cast plastic is less resistant to ozone, nitropropane, liquid ammonia, amyl acetate, tetrahydrofuran, etc.

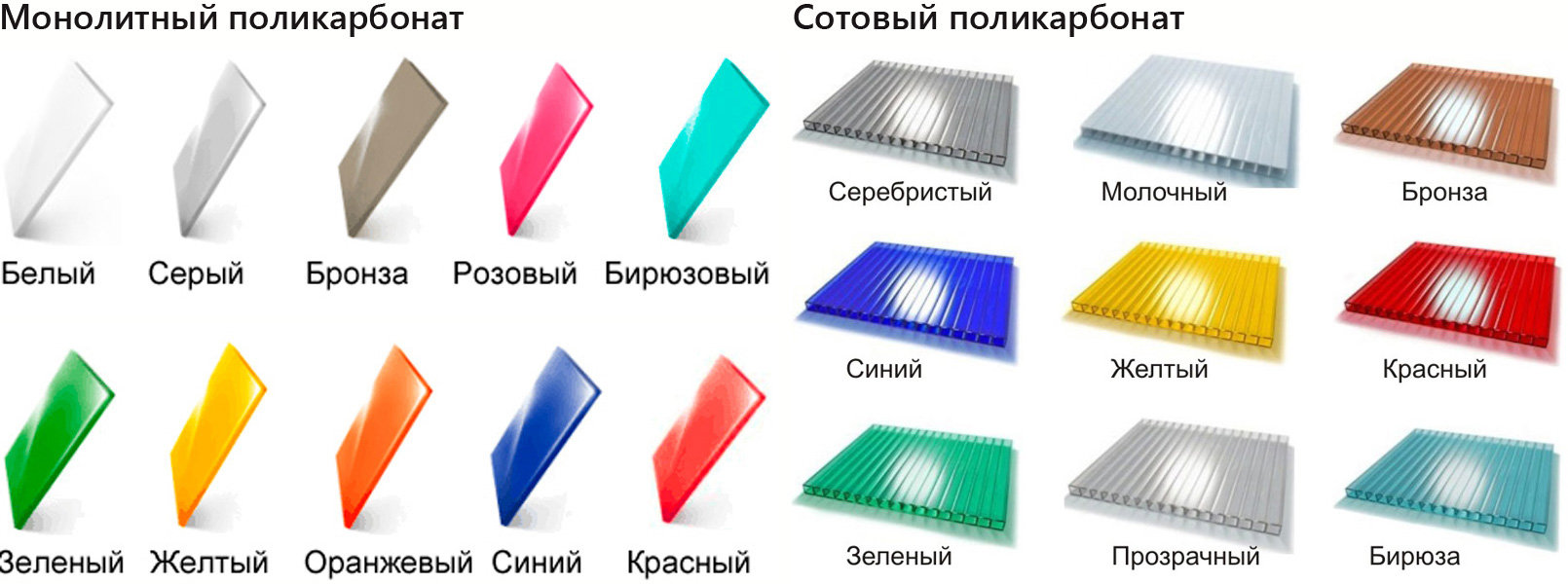

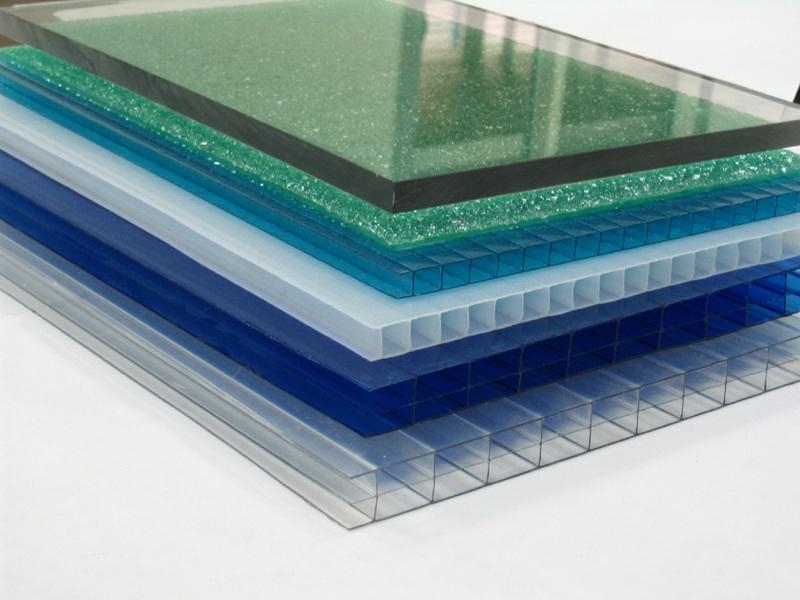

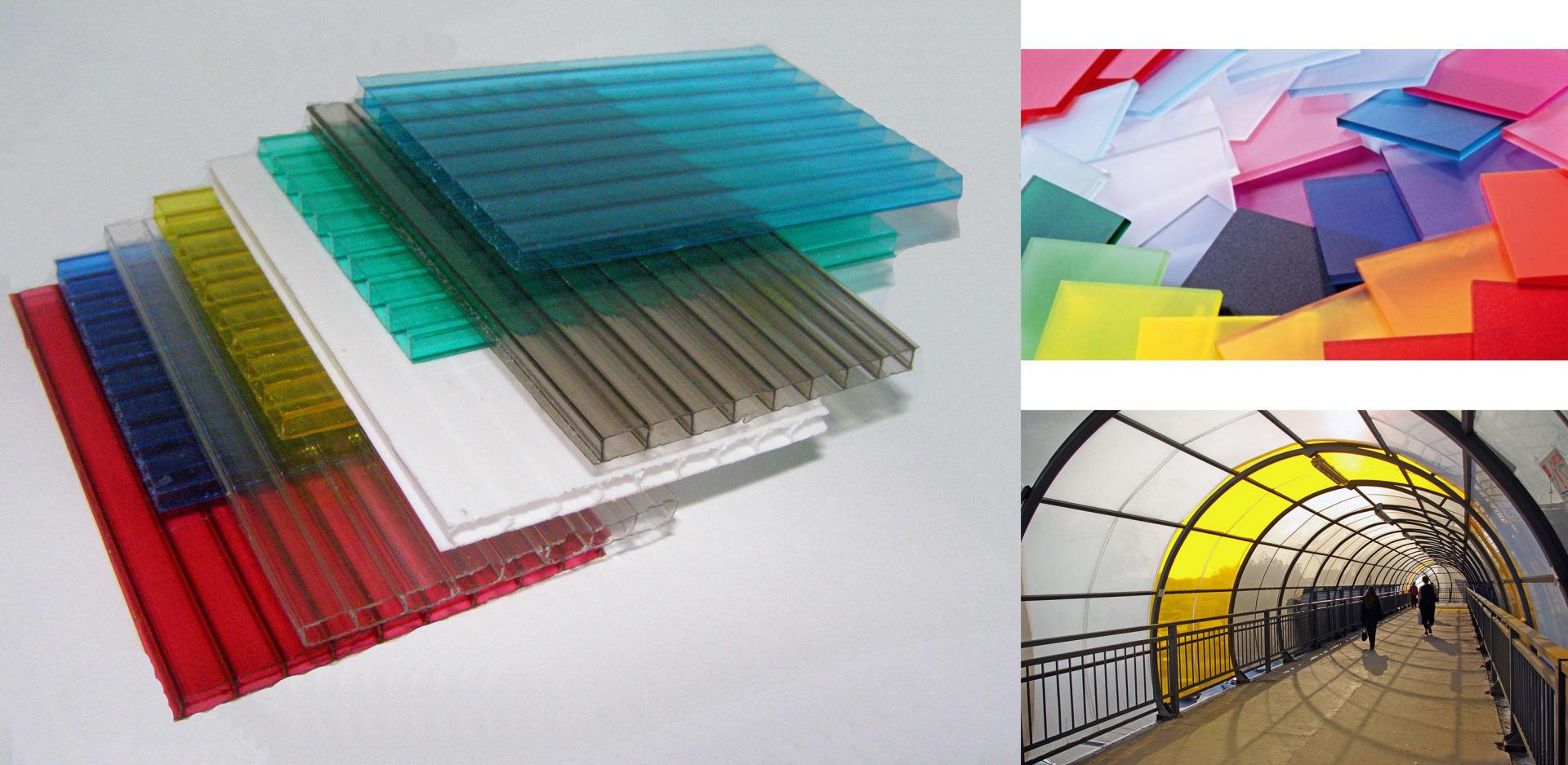

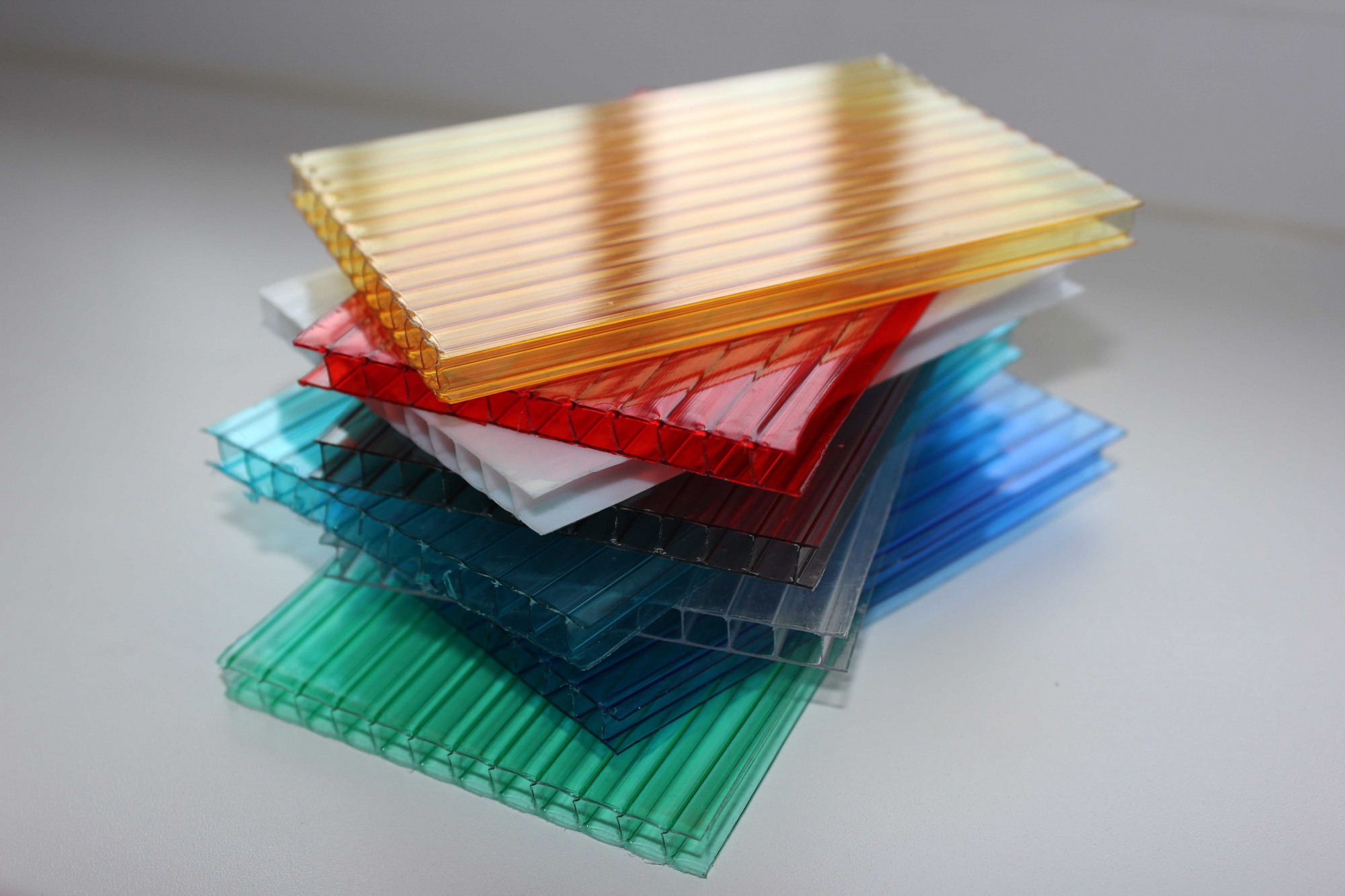

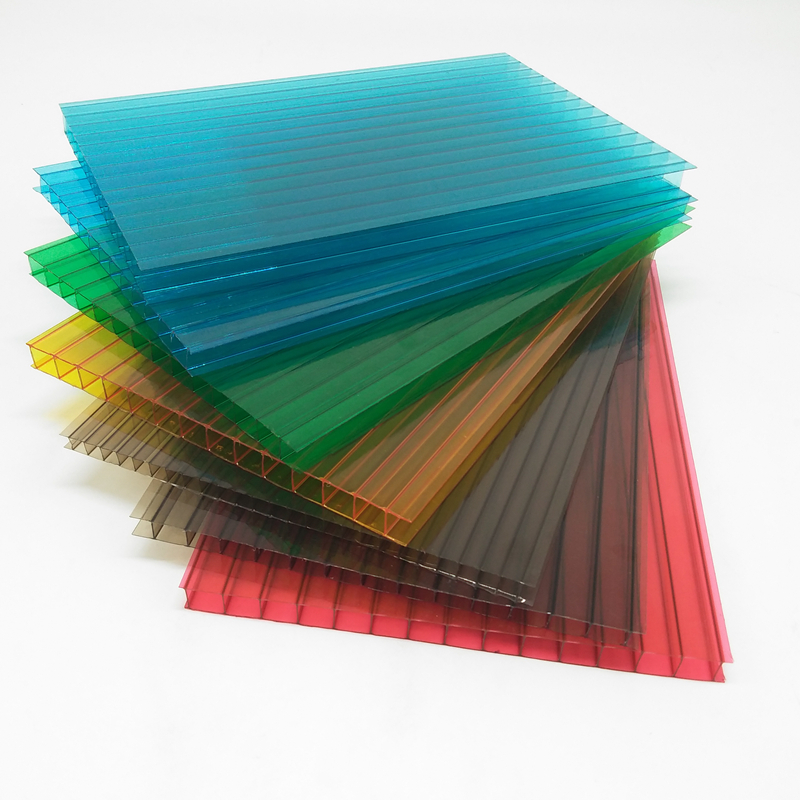

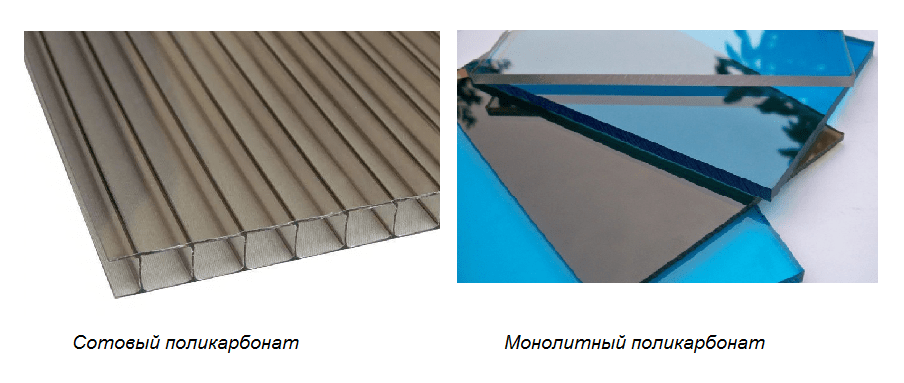

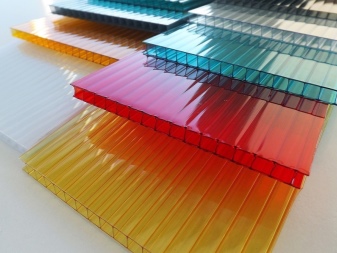

Comparison with cellular polycarbonate

What is the difference between the two types of polycarbonate? First of all - in the structure of the material. The main difference lies in the solidity of one type of sheet and in the presence of cells in the thickness of the other. Honeycombs make the structure less resistant to stress, but better insulate heat and sound.

There is also a difference in other aspects.

- In strength characteristics. They are higher in the sheet monolith. The visor from it will withstand the fall of frozen ice from the edge of the roof. With such contact, the honeycomb structure will simply crumble.

- In the ability to withstand constant stress. The same snow in winter or a strong wind from the gap between the houses will not damage monolithic polycarbonate. Cellular in such conditions will not last long.

- In transparency. The honeycomb structure reduces light transmission, the material does not look too much like glass, there are distortions.

- In aesthetics. It is believed that cellular materials are technical, it is not customary to display them.

- In the price. Here, the advantage will be behind the cellular analogue. It is significantly cheaper than even a flat sheet, not to mention corrugated sheet.

When deciding which option is better, it is worth understanding: each type of polycarbonate has its own purpose, their interchangeability is impossible without prejudice to the case.

Description

Polycarbonate is a fairly hard transparent synthetic polymer, which belongs to the varieties of polymer plastic. Due to its unique and inimitable chemical structure, it has a number of functional features: it is almost 100% optically transparent, frost-resistant, lightweight, plastic, lasts at least 10 years, has high dielectric properties, etc.

Canopy

From the point of view of environmental issues, this substance is environmentally friendly and in demand, since it can undergo numerous processing.Polycarbonate belongs to the class of thermoplastic polymers, which makes it possible to recycle raw materials many times, keeping the original characteristics and material properties of the resulting products unchanged.

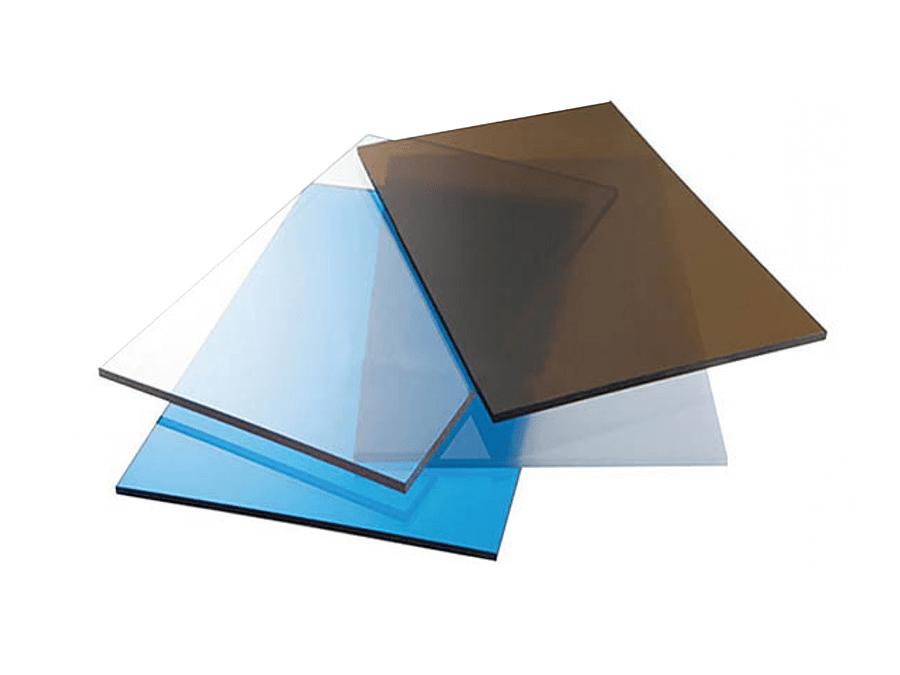

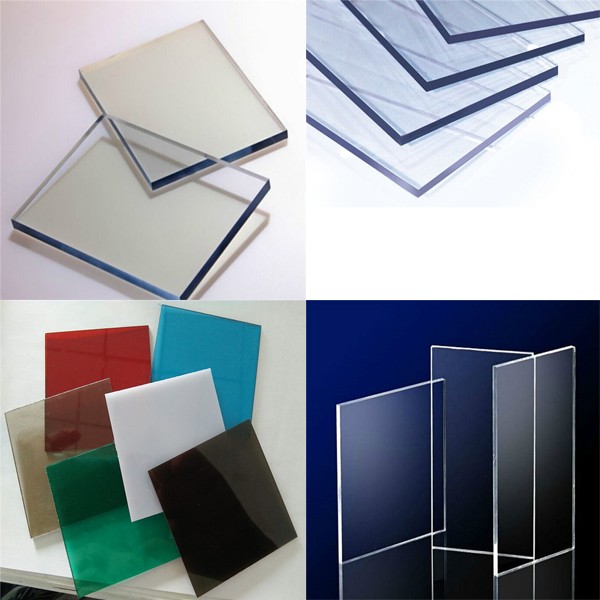

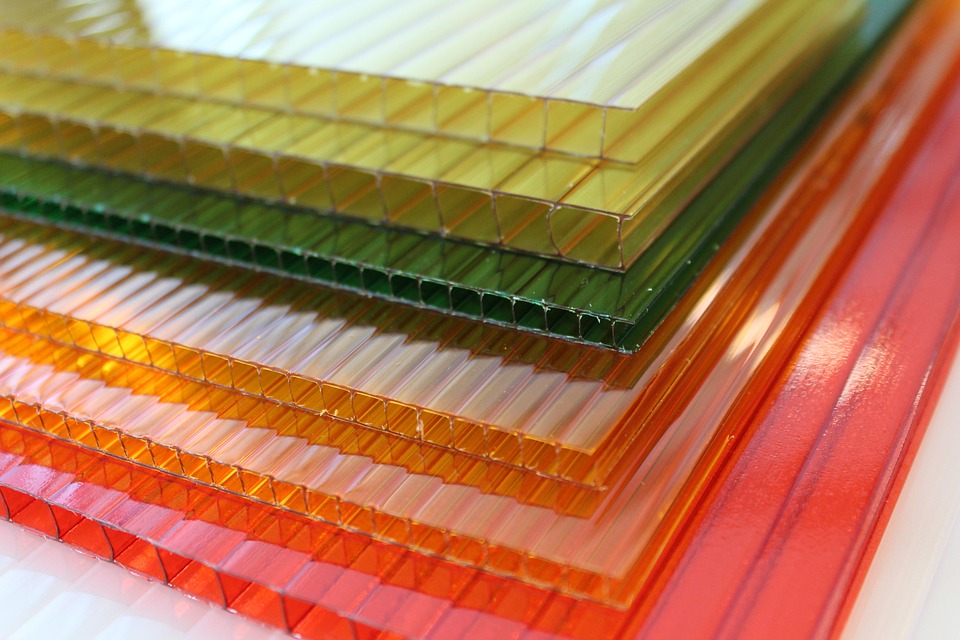

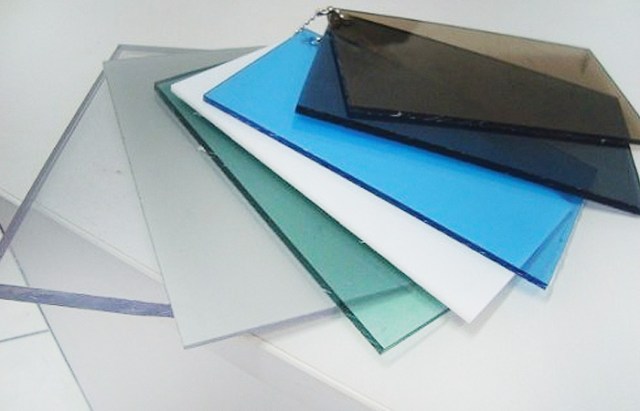

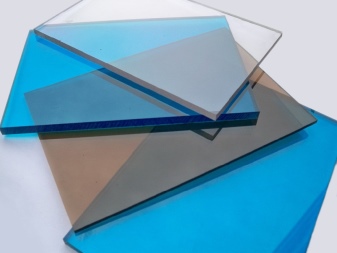

Currently, polycarbonate is usually divided into two categories: cellular (honeycomb) and cast (monolithic).

- honeycomb plastic is a polymer material made in the form of two-layer sheet panels with internal stiffening ribs forming a kind of “honeycomb”. This design provides polycarbonate panels with a combination of high strength and sufficient flexibility with a minimum panel weight. Main advantages: light weight, high impact resistance, noise and heat insulation, withstands sharp fluctuations in temperature indicators, low flammability, good light transmission, etc.

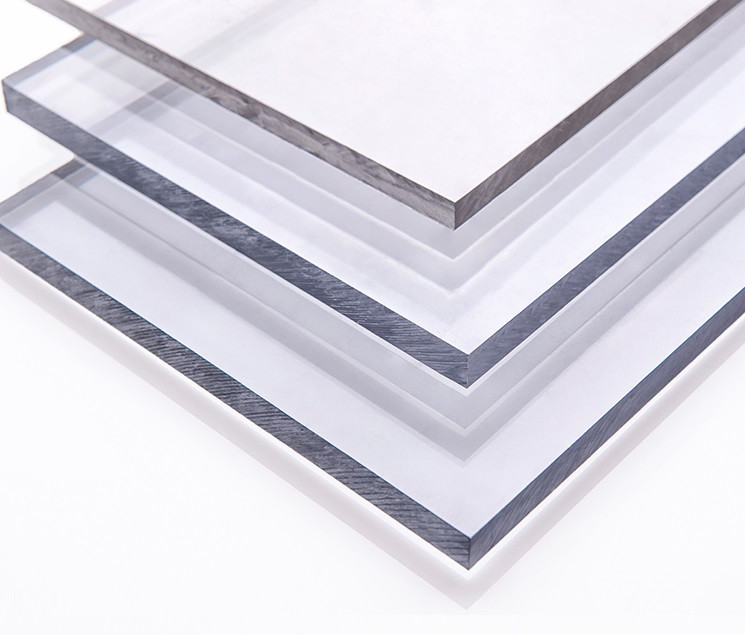

- molded plastic - a solid sheet of transparent material, without any openings. Mainly used when silicate glass needs to be replaced. By the way, transparent cast polycarbonate is used in addition to the construction services sector, as well as in law enforcement agencies. Protective helmets are made from it and used as glass armor on cars and aircraft.

Where can you buy

The most common option among consumers is the construction market. Here you can personally get acquainted with the quality of the product, and not just see the photo. But, more and more often, construction companies are purchasing polymer plastic through the Internet portals of manufacturing firms. The cost is significantly lower, but the color of the product can only be seen in the photo.

Let's sum up

Regardless of the type of polycarbonate, they are mainly used for glazing private or industrial buildings, because their lightness and flexibility allow them to be used without much effort. Moreover, this substance is the material of the future, because its functional and technical characteristics are favorably distinguished among analog building materials.

Optimum performance of polycarbonate

When designing a structure, it is important to select in advance a polycarbonate that is appropriate in terms of strength characteristics, and suitable for the rest of the objects with its external characteristics. If the building is being built with your own hands, it is better to consult a building materials specialist and designer

Thickness

The strength of the structure depends on this parameter. Often, wanting to save money, people buy cellular polycarbonate with a minimum thickness of 4 mm. This material is suitable for small greenhouses, but not for sheds. In this case, a minimum thickness of 6 mm is required. For greater reliability, you can choose a more multi-layer option.

Cellular polycarbonate thickness table for various loads

As for monolithic polycarbonate, the optimal thickness is from 4 to 6 mm. This is much less than in the previous case, and is due to the significantly higher strength of this type of plastic.

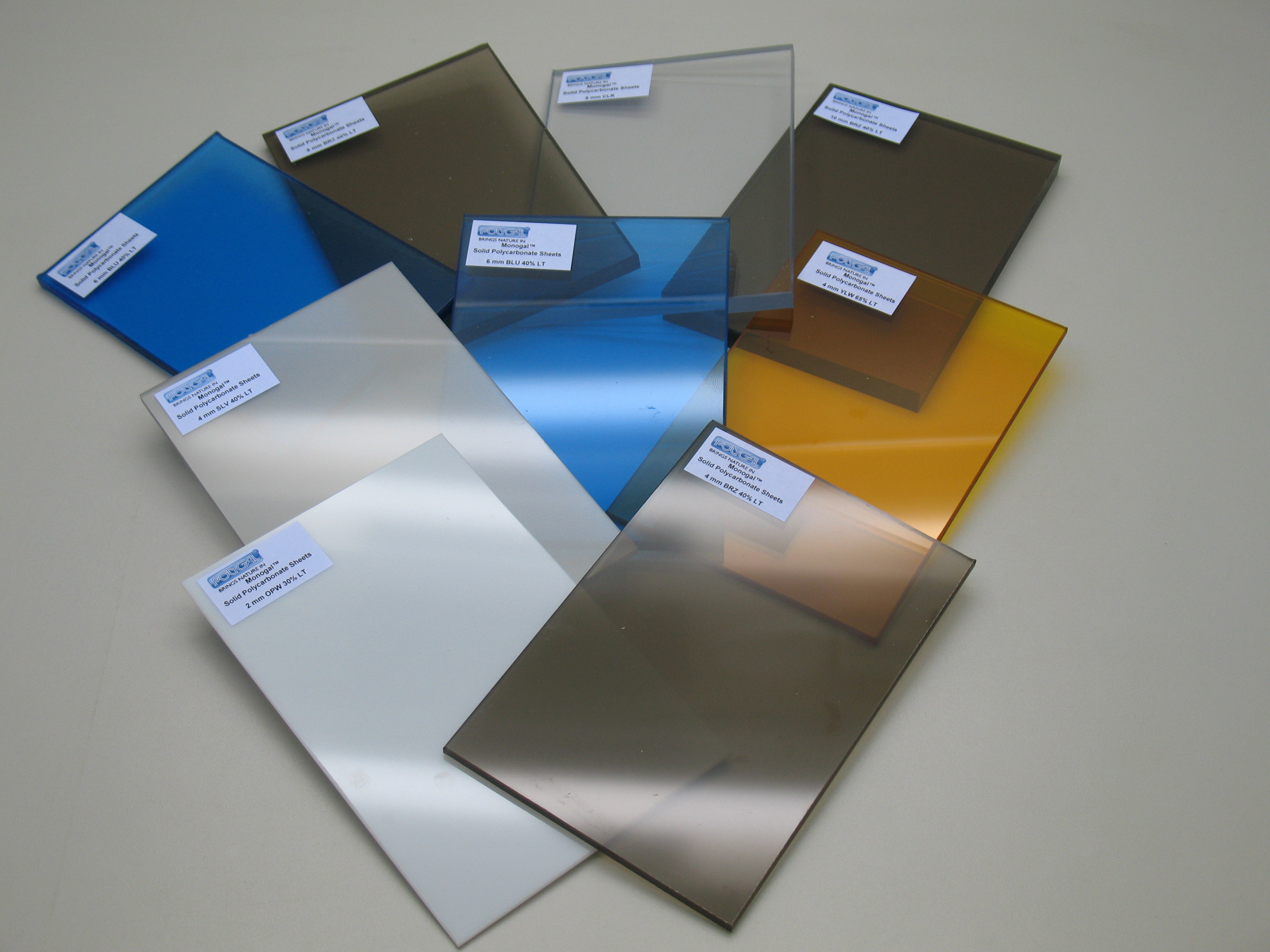

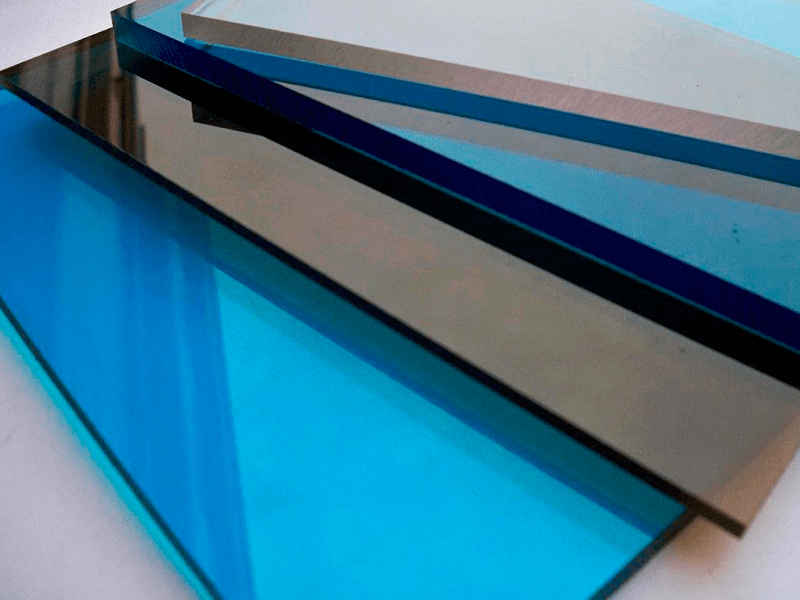

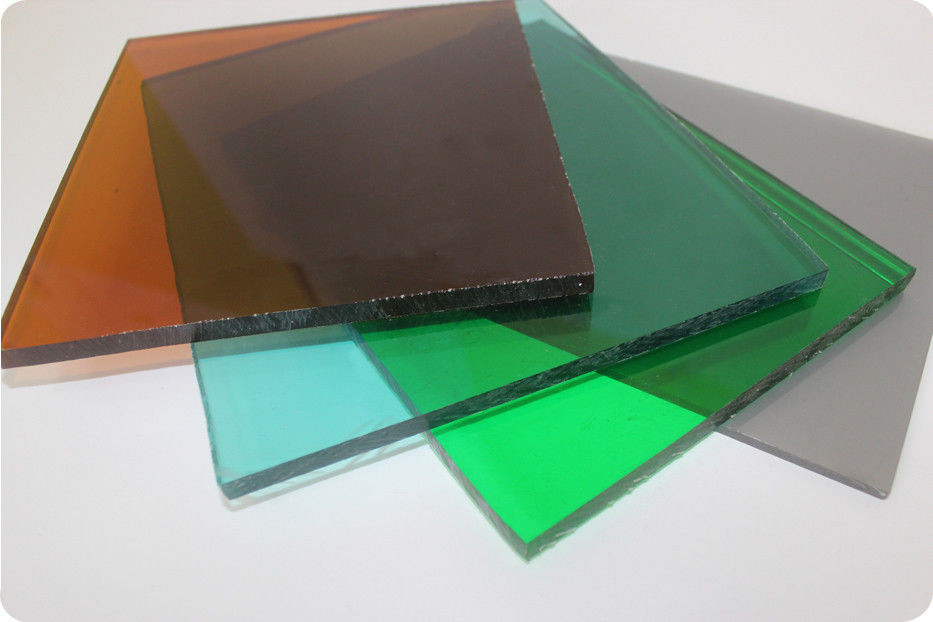

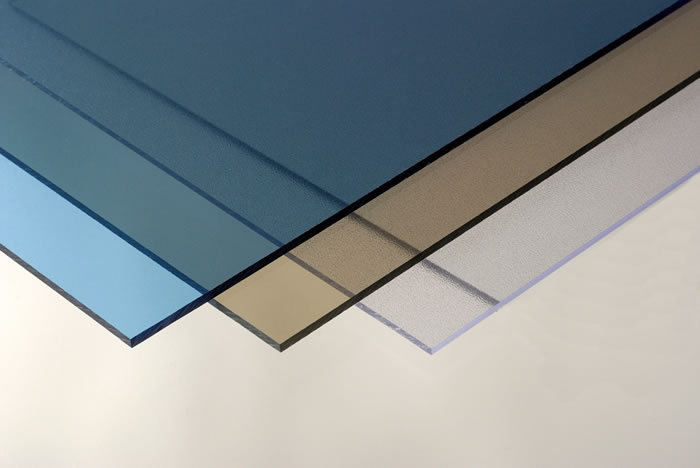

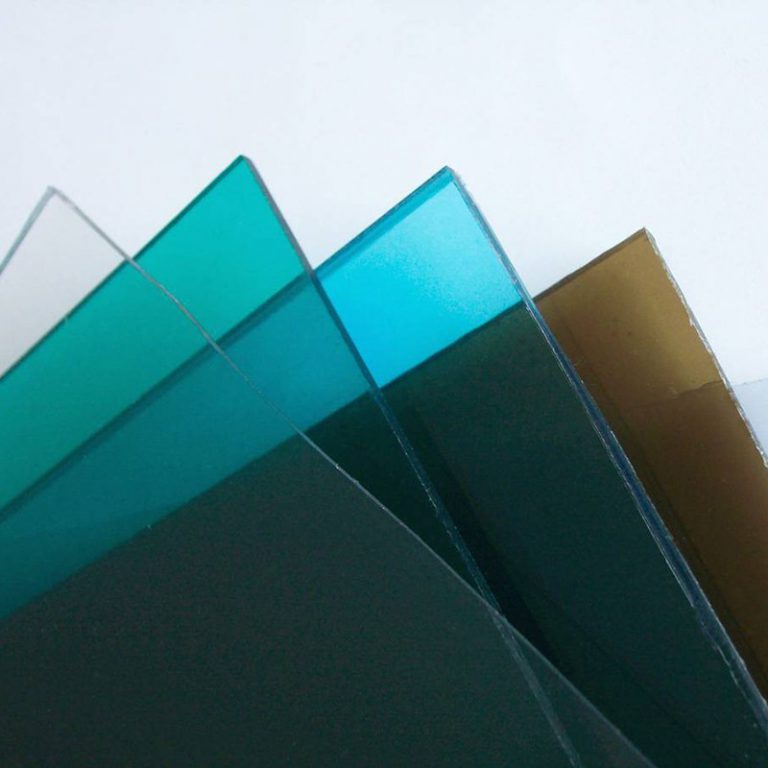

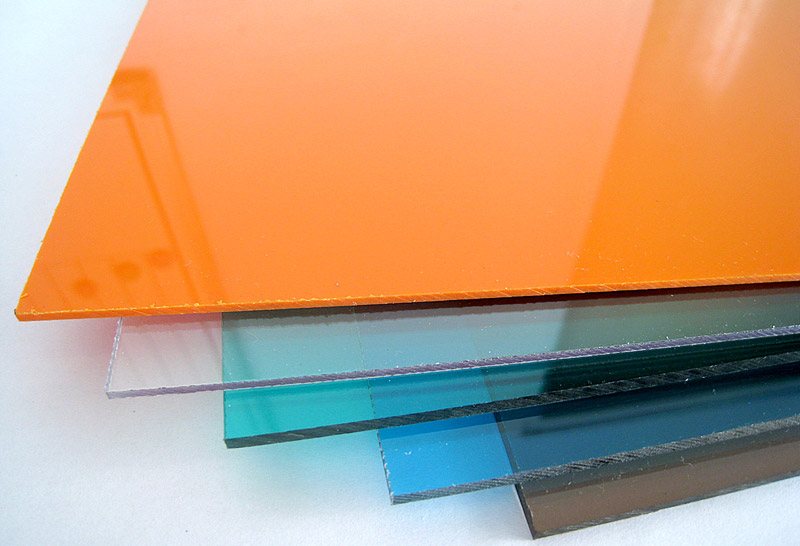

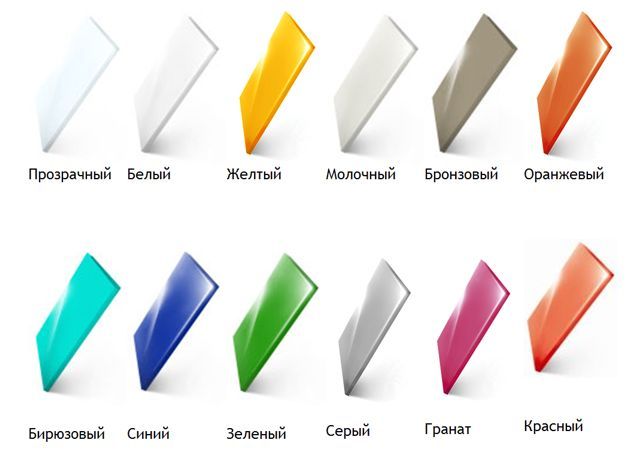

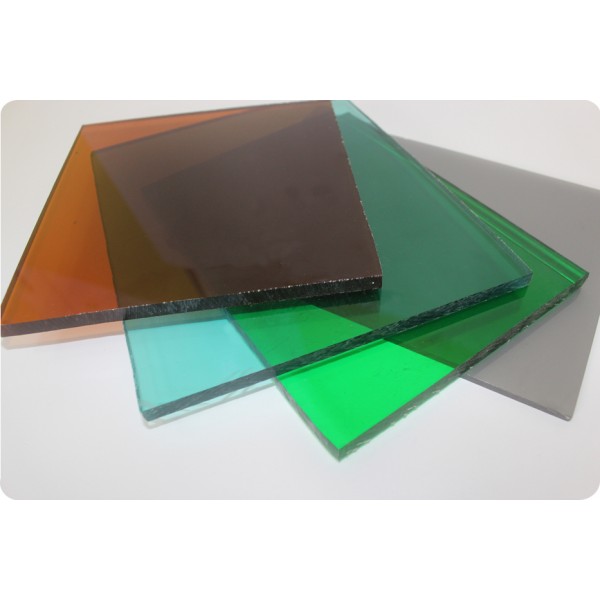

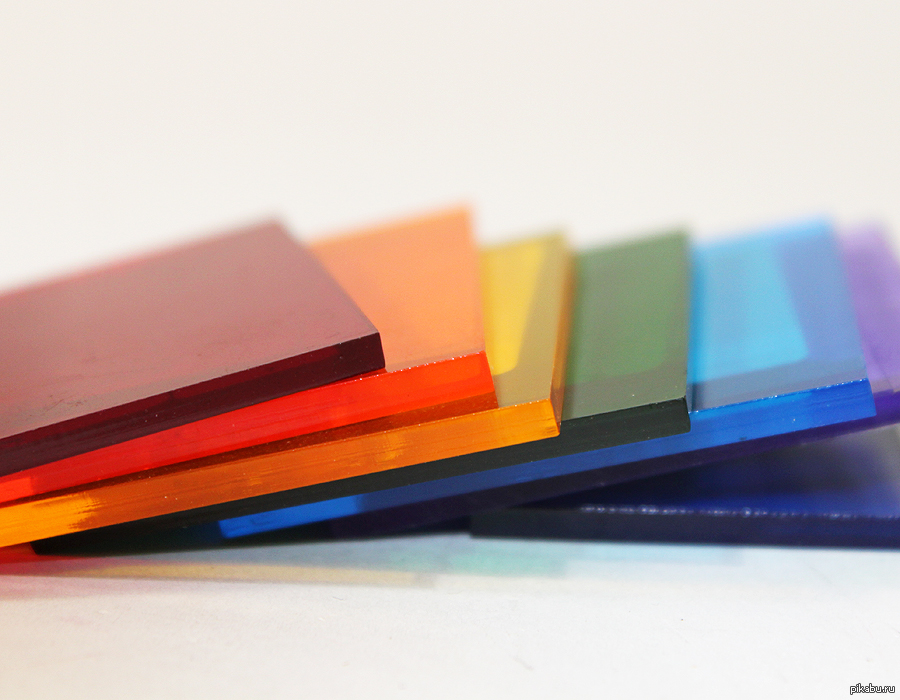

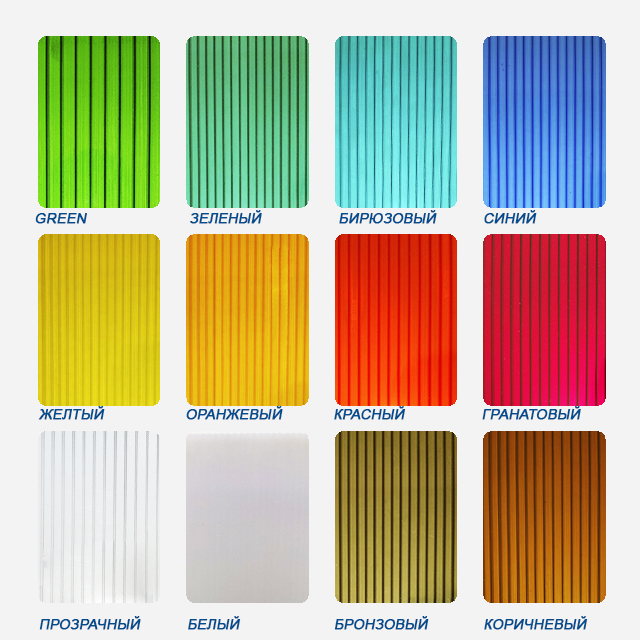

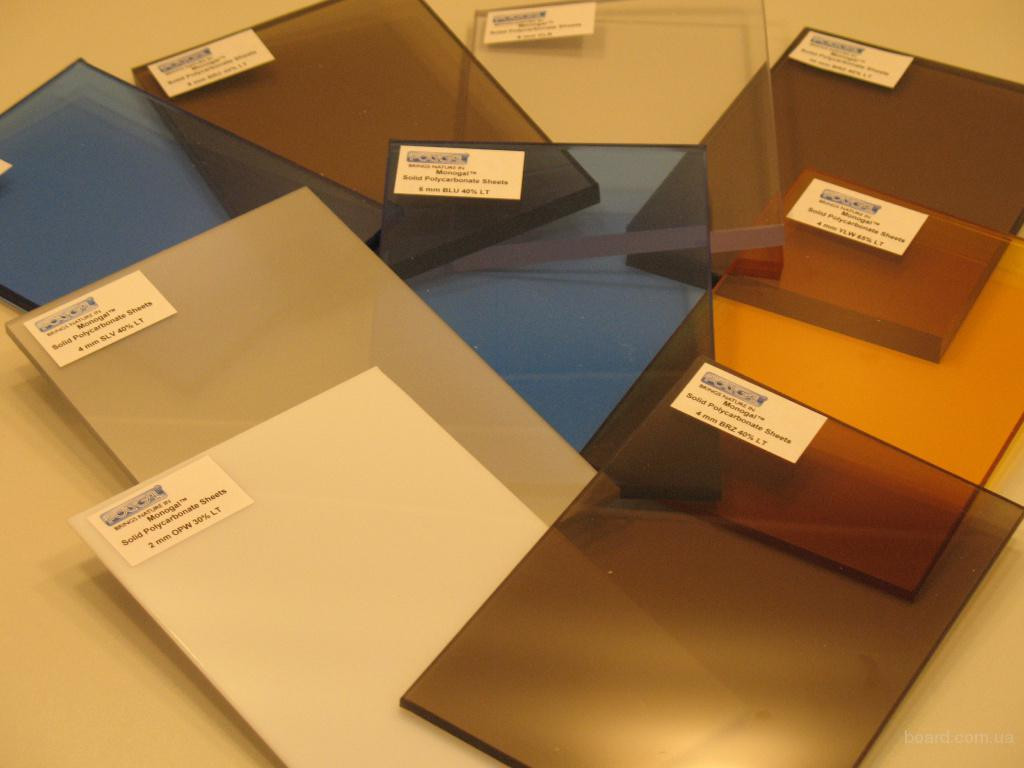

Colour

When choosing a material for this parameter, you need to be very careful, since the color of polycarbonate itself can be attractive, but at the same time it may not be fundamentally combined with the rest of the objects on the land. First of all, compatibility with the colors of the roofing materials of the house itself is important.

Polycarbonate color

However, there are colors that are versatile. Panels in milky, blue, bronze and green are compatible with most items.

In the case of using polycarbonate of such saturated colors as orange or red, the transparency of this material must be taken into account. Indeed, as a result, the atmosphere under the canopy will acquire the shade of the panels used in its construction.

Orange canopy

There are also options that do not miss the color.They are perfect when you need to make a canopy that protects as much as possible from the sun's rays.

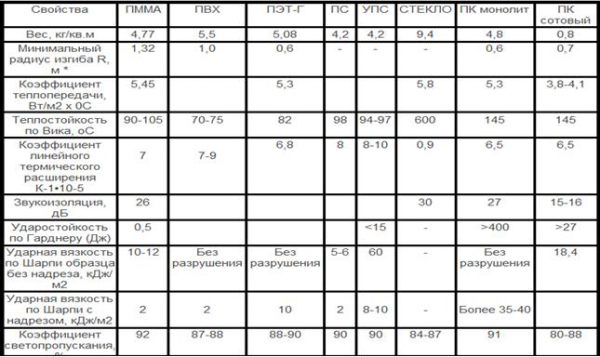

Performance comparison

Transparent polycarbonate cellular or monolithic type was created as an alternative to fragile, short-lived, expensive silicate glass. Therefore, when evaluating the possibility of using plastic in a structure, its qualities are compared with this material. Technical and operational characteristics differ:

- Transparency. Silicate glass is only 1% more transparent than monolithic polycarbonate. And honeycomb plastic is inferior in this indicator, having a light transmission coefficient of 84-86%, which is quite enough for the life of plants.

- Ease. Monolithic plastic is 2 times lighter than glass, and honeycomb is 6 times lighter, while both materials demonstrate high impact resistance.

- Impact resistance. The impact resistance of polycarbonate is more than 200 times higher than that of silicate glass. Moreover, it is 10 times stronger than acrylic glass, these data are confirmed by tests.

- Flexibility. Honeycomb polycarbonate sheets are easily bent without the use of heat treatment. In this performance, they bypassed silicate and acrylic glass.

- Thermal conductivity. Polycarbonate plastic retains heat better than silicate glass, which increases the value of this material for the construction of greenhouses or greenhouses.

Comparison with analogues

Comparison with analogues

Comparison of characteristics of glass, plastic and acrylic glass

Comparison of characteristics of glass, plastic and acrylic glass