Hammer enamel painting technology

Before use, you need a solvent to give it a working consistency. Specific viscosity of the composition, with a nozzle with a diameter of 4 mm. is 24-25 seconds according to DIN3 viscometer.

Use the following solvents for dilution:

- For ML-165 composition - xylene;

- EP-1323ME - solvent # 667 and # 648;

- NTs-221 - solvent No. 646;

- Hammersmite formulations - Rustbeater # 1 Thinner or Brush Cleaner (recommended by the manufacturer).

The approximate dilution ratio is 2: 1 (solvent paint). Hammer paint is applied using a roller. When completely repainting a car, it is rational to use a spray gun, since it is impossible to apply a coating uniform in thickness on a large surface using a roller.

To properly adjust the supply pressure on the spray gun to a level of 2-2.5 atmospheres and set the widest spray pattern. If you do not have prior experience, practice painting third-party vertical surfaces, so you will determine the optimal distance for yourself between the spray gun and the body (the norm is 20-30 cm) and the speed of its movement.

Painting is carried out in a pre-prepared room - good lighting is required, a temperature of 20-25 degrees, no dust (when working in the garage, do wet cleaning, if possible - blow the floor and walls with compressed air).

Car preparation work consists of leveling the unevenness found on the body and their putty. Further, the surface is matted - the painted area is sanded to a rough state with sandpaper with a grain size of P80-100. After grouting, the body is cleaned of dust with a damp cloth and degreased with a solvent (use the compound used to dilute the enamel).

Hammer paint is applied in 3-4 layers, the interval between applications is 60 minutes (maximum pause time is 8 hours). Spraying is carried out in overlapping horizontal lines from a distance of 20-25 cm from the body. is 100 ml. by 1 m 2.

Types and manufacturers of hammer enamel

There are several types of such paint:

- ML 165 type is suitable for decorating a non-greasy surface. The advantages of this paint are durability and heat resistance (it can withstand heat up to 130 C). The disadvantage is the ability to emit toxic fumes when applied.

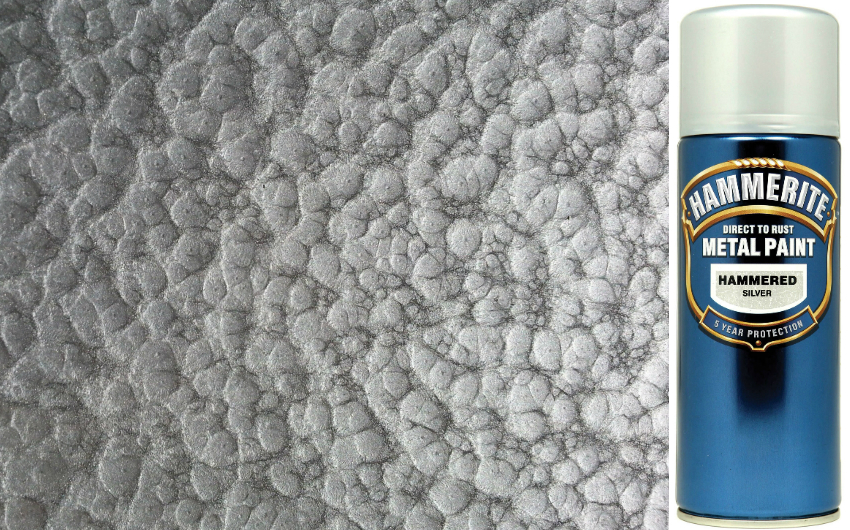

- Hammerite hammer enamel for rust is an expensive but very effective pleasure. This English-made paint will not only mask imperfections on the metal, but also protect the surface from oxidation. Thanks to a special technology with the addition of wax, Hammerite enamel will provide protection against moisture and corrosion for up to 8 years. In addition, this paint contains silicone, which prevents the penetration of external contaminants and household chemicals. Hammerite paints and varnishes are quick-drying and can be used on metal without prior preparation.

- EP-1323ME enamel is suitable as a paint-primer for metal. This type of paint is recommended for elements of cars, forklifts, as well as doors and all kinds of fences. You can also use this dye over rust.

- Enamel NTs-221 is inexpensive, but its protective properties are quite high. This "budget" type of paint can be used exclusively indoors, since it is not capable of performing a protective function and has purely decorative properties. Under no circumstances should this enamel be applied over rust, and the heat resistance index is not high here.

- Hammer enamel "Molotex" is used in several areas at once - on rust, as decorative enamel or anticorrosive primer. The product contains persistent pigments and synthetic varnishes that perfectly hide the defects of the painted products and protect the surface from external influences. Available colors of this enamel: black, silver, dark green, brown, white and dark blue.

- Dali 3in1 rust enamel primer is used for processing metal affected by pitting or continuous corrosion. It is used for new or previously painted surfaces made of stainless steel, cast iron, non-ferrous and galvanized metals, as well as wooden surfaces with a moisture content of less than 20%.

What is hammer paint for metal?

Recently, hammer enamel has become popular in landscape design, interior and exterior design. They say a lot about this tool, but they do not specify what hammer paint is, which is why there are many misconceptions. The key difference between the paint is its special texture, it cannot be confused with any other type, since after the surface hardens, it takes on an appearance similar to numerous hammer blows. Due to the specific effect, the substance acquired its name, sometimes it is also called blacksmith.

Hammer paint is one of the most durable compounds for metal processing

Hammer effect paint is made from acrylic, styrene alkyd and epoxy base. To create a special appearance, aluminum powder, silicone oils and fine glass are added to the composition. Due to the presence of special silicone oils in the composition, it is possible to stabilize the texture and provide protection from water.

How Hammerayt paint is applied to a metal surface

Prior to application, surface treatment with a primer is optional. But if you want, you can do it. The effect of adhesion of paint to metal will only intensify. To do this, apply Hammerite No. 1 Anti-Rust.

If there are areas of well-adhered old paint on the surface, do the following. Apply Hameright to it in a test spot. Let dry for 30 minutes and inspect. If the coating is intact and even, then the composition of the previous paint allows you to apply a new one to it.

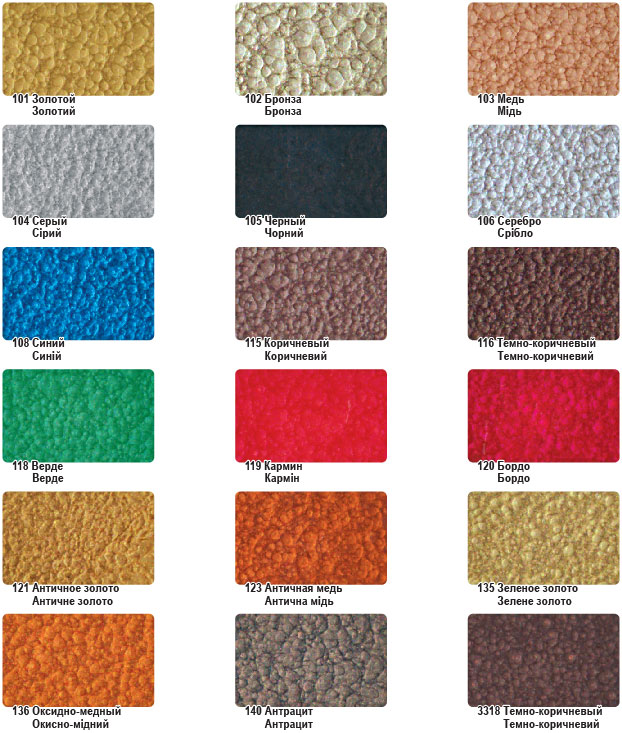

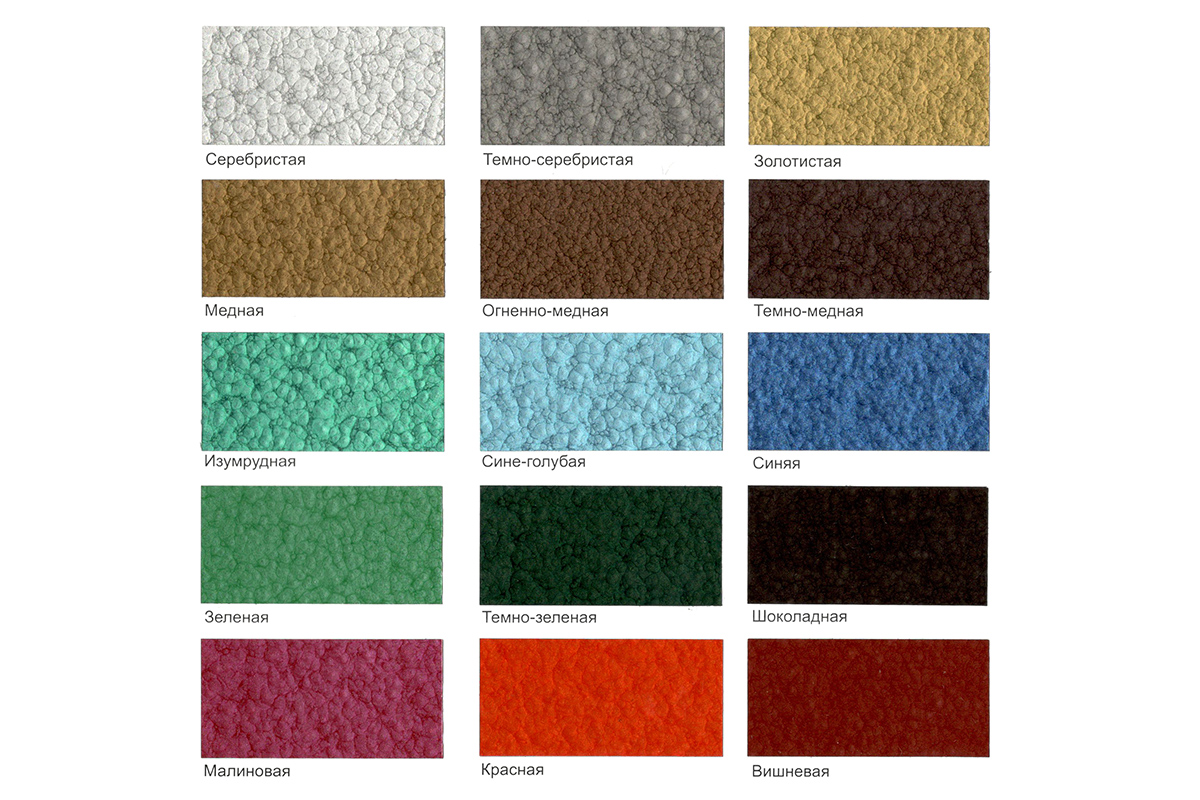

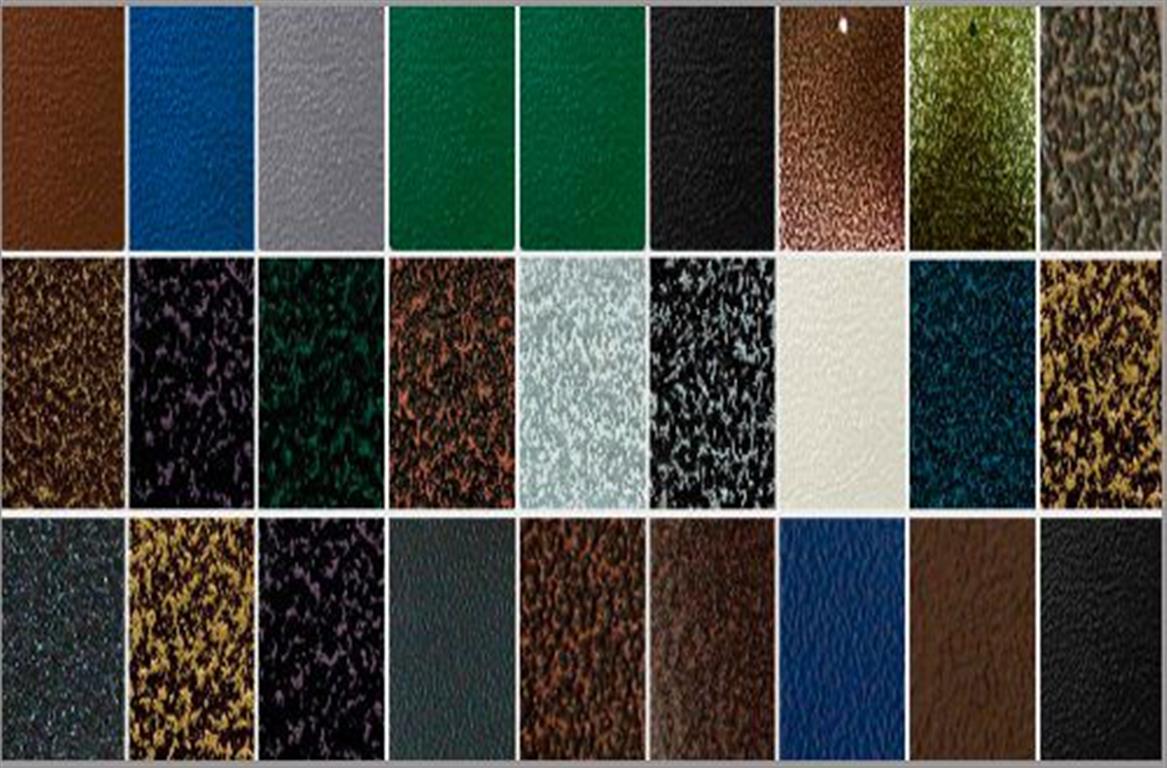

Hammerite coating colors

The composition is applied to the surface in the following main ways:

- paintbrush or roller;

- using paint spray in a special canister;

- using air spray (compressor with spray gun).

Consider the features of the application of each of the methods.

The first is with the use of a brush, when Hameright paint is applied on medium-sized surfaces and on objects with complex elements and shapes.

- Assess the viscosity of the paint before use. Generally no additional thinning is required. If it has thickened, it must be thinned. To do this, add 1 part Hammerite Brush Cleaner & Thinners to 9 parts of paint and mix thoroughly.

- Use good quality brushes made from natural bristles. This will ensure an even coating from the first pass. Do not use brushes, the fluff of which remains on the surface during the painting process.

- Dip your brush into Hammerite paint no more than half the size of your work surface. This will make it possible to use paint sparingly and without smudges.

Brushing Hammerite Paint

Move the brush preferably in one direction, overlapping each subsequent stroke by half with the previous one. This will ensure the uniformity of paint application. Be sure to carefully apply Hammerite to areas of the product to be painted, where access is inconvenient and difficult. This is your special focus area

Painting is done in at least 2 and no more than 3 layers. Coating in one layer will not provide the desired effect. Applying more than 3 coats will result in unnecessary consumption of paint material. Painting vertical metal surfaces requires special attention. This is due to the fact that, being at such an angle, the applied paint can drain and form smudges. Continuously monitor the condition of previously applied layers.If necessary, without letting them dry out, immediately correct this area of the surface with a brush. Before applying the next layer, it is necessary to withstand a time of at least 3 hours for the previous one to dry. You shouldn't be in a hurry. This will destroy the previously applied coating.

Part painted with Hammerite paint

The second is using a roller. The basic requirements for the preparation of the paint composition remain the same as when using a paint brush.

The peculiarities include the method of dipping the roller into a special container for applying paint to its working surface. Do this evenly over the entire fleecy area. Performing such an operation will ensure the application of the Hamerayt composition evenly and without gaps.

Painting with a roller

The third - at air spray aid... Paint the composition is applied from an aerosol can or a compressor with a spray gun.

Large areas are painted with a compressor and spray gun. In this case, it is imperative to meet the requirements for the viscosity of the paint. It is necessary to prepare the composition in a ratio of 2 parts paint and 1 part Hammerite Brush Cleaner & Thinners. If this ratio is violated, the spraying process will be difficult or impossible. The thick compound will not spray normally from the spray gun nozzle. Excessively thinned will cause smudges or an unacceptably thin coating.

Paint application by air spray

The paint is applied in 3-4 layers with intervals between applications in 30 minutes.

Advantages and disadvantages

In search of high-quality and attractive paint, each consumer seeks to find the ideal option that will delight him with its wear resistance and durability. The original hammer mix meets these requirements.

In addition, such coloring compositions have many other advantages that make them popular and in demand:

- Hammer paint is not afraid of temperature changes. Neither hot summer, nor frosty winter, nor rainy autumn will affect its appearance and performance.

- Hammer effect enamel can be applied to rusty surfaces. Moreover, for this it is not at all necessary to prepare the bases and treat them with a primer.

- Hammer mixes dry quickly enough.

- Such paints and varnishes are not afraid of dampness and moisture.

- Quality hammer paints protect metal substrates from rusting outdoors for up to 8 years. Not every enamel can boast of such a characteristic.

- Such enamel can be purchased for both interior and exterior finishing works.

- Hammer effect paint is not subject to mechanical damage. Due to this characteristic, it will be very difficult to leave a scratch or other damage on such a coating.

- Such a paint and varnish composition is safe for health. It does not emit hazardous substances either during application or after drying.

- It should be noted the decorative properties of such paint. It is presented in a very rich color palette. Over time, hammer mixes do not fade when exposed to sunlight.

- Hammer paint does not have an unpleasant odor.

- The dried hammer surface has an interesting ability - it repels water, dirt and dust. That is why the objects on which it is applied look well-groomed.

- Due to its characteristic texture, hammer paint is able to hide minor imperfections in the base. If there is a noticeable chip on it, then it can be painted over locally. In this case, the tinted area will not be noticeable.

As you can see, hammer paint has a considerable list of positive qualities.

However, it also has its weaknesses:

- Removing such paintwork from any surface is not an easy task.This requires the use of aggressive solvents and abrasive tools. However, even with such devices, it will be difficult to remove the paint layer.

- If you paint a metal base with hammer paint, then you need to make sure that no area remains unpainted. Otherwise, corrosion will quickly appear on the unfinished place, which will eventually spread to the coating itself.

- It is very difficult to apply such paint with a spray gun (or using a can, spray), since it is characterized by increased density and density.

- Many consumers consider the high cost of hammer paint as a disadvantage. Moreover, it is distinguished by high consumption, so there is no need to talk about its availability.

Hammer enamel: what is it, metal and rust product, Hammerite, material with hammer effect, packing 165 ml, Dali and Molotex enamel

I hereby freely, of my own free will and in my own interest give consent to RIFORN LLC (hereinafter referred to as the Site Administration) for the automated and non-automated processing of my personal data, including using third-party Internet web analytics services.

Personal data permitted for processing under this Privacy Policy is provided by the User by filling out the registration form on the Site and includes the following information:

In order to comply with the norms of the legislation of the Russian Federation, as well as for the purpose of concluding and fulfilling contracts and obligations, providing relevant advertising information and optimizing advertising.

I also give my consent to provide the Site Administration of my personal data as a Site visitor to third parties with whom the Site Administration cooperates (in particular, courier services, transport companies, postal organizations), solely for the purpose of collecting and processing statistical information, order fulfillment, including delivery of the Goods.

The site administration has the right to process my personal data in the following ways: collection, recording, systematization, accumulation, storage, updating, modification, use, transfer (distribution, provision, access).

This consent comes into force from the moment of my transition to the Site Administration of the site and is valid within the terms established by the current legislation of the Russian Federation.

In all other respects that are not provided for by this Agreement, the Site Administration and the User are guided by the User Agreement and the applicable norms of the current legislation of the Russian Federation. If the terms of this Agreement contradict the terms of the User Agreement, the terms of the User Agreement shall apply. "

I hereby freely, of my own free will and in my own interest give consent to RIFORN LLC (hereinafter referred to as the Site Administration) for the automated and non-automated processing of my personal data, including using third-party Internet web analytics services.

Personal data permitted for processing under this Privacy Policy is provided by the User by filling out the registration form on the Site and includes the following information:

In order to comply with the norms of the legislation of the Russian Federation, as well as for the purpose of concluding and fulfilling contracts and obligations, providing relevant advertising information and optimizing advertising.

I also give my consent to provide the Site Administration of my personal data as a Site visitor to third parties with whom the Site Administration cooperates (in particular, courier services, transport companies, postal organizations), solely for the purpose of collecting and processing statistical information, order fulfillment, including delivery of the Goods.

The site administration has the right to process my personal data in the following ways: collection, recording, systematization, accumulation, storage, updating, modification, use, transfer (distribution, provision, access).

This consent comes into force from the moment of my transition to the Site Administration of the site and is valid within the terms established by the current legislation of the Russian Federation.

In all other respects that are not provided for by this Agreement, the Site Administration and the User are guided by the User Agreement and the applicable norms of the current legislation of the Russian Federation. If the terms of this Agreement contradict the terms of the User Agreement, the terms of the User Agreement shall apply. "

"Pros" and "cons" of using paint

Like any product, this paint is endowed with positive properties, but also has negative aspects. The benefits include the following:

To paint the surface, you need to do a minimum of preparation;

For painting, a minimum of tools are needed, including the presence of only one stripper;

Any beginner can handle the processing process, you don't have to pay for the services of specialists;

It takes only three hours to dry the layers, which will significantly affect the repair work;

Getting a water-repellent and dirt-repellent coating is possible thanks to the silicone included in the composition;

Prevents the appearance of rusty areas;

Any surface structure that will be selected from the offered assortment - matte, semi-matte, glossy - will look attractive on the surface;

Lack of harmful and unpleasant odor, which is especially important when you have to work inside the building.

The negative side is the inadmissibility of coating a surface that has a layer of bitumen paint.

If it is not possible to determine which material was used earlier, then paint a small area with paint and wait for the reaction of the material. There should be no blisters or cracks on the surface.

It takes only three hours for the layers to dry, which will significantly affect the repair work.

It takes only three hours for the layers to dry, which will significantly affect the repair work.

How to paint a metal door with hammer paint

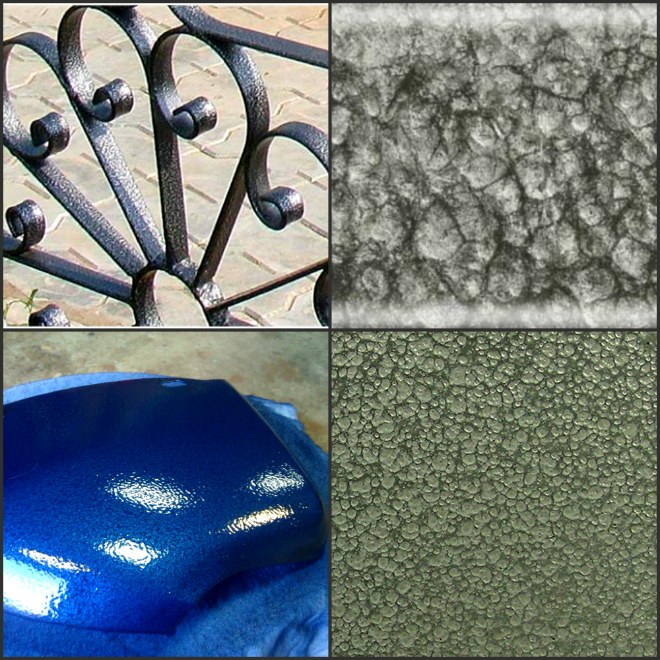

Hammer paint works well for painting metal doors and gates. This paint has a special texture when it dries - a surface with an interesting visual effect is obtained, as if it was beaten with a hammer. Hammer paint has stable anti-corrosion properties, it contains special silicone resins and metal pigments, which increase its density and increase resistance to external influences.

Benefits of hammer paint

- No preliminary preparation of the painted surface is required. The composition of the paint already contains primers, which facilitates and improves the painting process when there is no time or opportunity to thoroughly clean the door surface from old rust.

- Hammer paint is corrosion resistant and dries quickly.

- The color of the products does not change and does not lose its saturation for quite a long time.

- The dyeing technology is simple and convenient.

- Beautiful aesthetic appearance. Hammer effect paint comes in a wide variety of shades to help enhance the look of metal doors. Forged gates look very impressive and textured when hammer paint is used to paint elements of artistic forging.

- Hammer paint has a useful property of repelling dirt and dust - painted products always look neat and do not require special care.

How to paint a metal gate with hammer paint

To prevent the garage doors from rusting, their surface must be painted with a corrosion-resistant paint.The optimal solution for protecting metal surfaces from rust is painting with hammer paint.

The technology of painting metal doors with hammer effect paint is not at all complicated.

- The remnants of old paint are removed from the canvas using a metal brush or an electric drill with a special nozzle.

- The surface of the metal door is thoroughly cleaned with acetone.

- Hammer paint contains priming materials, but for a better staining effect, priming of the garage door surface is done.

- The gate is painted with a roller or spray. A paint brush for painting a wide surface will not work - with its help it is very difficult to achieve an even layer of paint and the absence of streaks or smudges.

How to paint a metal door with a roller correctly

Roller coating is effective on large, flat and flat surfaces.

Before painting a metal surface, for the first layer, hammer paint is diluted at a ratio of ten parts of paint to one part of solvent. The next layer can no longer be diluted. For work, it is better to use a medium-sized roller. First, paint is applied to the corners and edges of the doors with a small brush, and then the remaining surface area is painted with a roller. One layer will not be enough - the protective properties of a single-layer coating are not as effective as when painting in several layers. The decorative effect also deteriorates - if the paint layer is too thin, then bubbles may form on the dried painted surface. To avoid this, an additional layer of paint is applied. The next layer should be applied at least half an hour later, after waiting for the first layer to set a little on the surface. Apply another coat of hammer paint if necessary

Hammer paint dyeing technology with a paint brush

The hammer paint brush is used on complex shaped configurations where detailed and delicate painting is required. It is recommended to use natural bristle brushes. It is not necessary to thin the hammer paint when painting with a brush.

Peculiarities

Today hammer paint is very popular as it has anti-corrosion properties. In addition, she is not afraid of negative external factors. Hammer paint is not afraid of rains and snowfalls, therefore it is often used for finishing the facades of buildings.

Under the influence of temperature changes, such wear-resistant paint does not crack and does not lose color saturation. That is why it is used not only to decorate certain bases, but also to protect them from various external influences.

The secret of this wear resistance lies in the composition of the hammer paint. It contains special polymer resins that adhere especially well to metal surfaces. Moreover, they protect them from corrosion and extend their service life. In addition to polymer resins, such a wear-resistant dye mixture contains acrylic and alkyd components.

In addition, hammer paints are often mixed with silicone oil, epoxy resins and complex fillers such as aluminum powder or fine glass. The listed components make the coating not only of high quality and durable, but also provide it with increased adhesion, so hammer paint easily fits on almost any surface.

True, due to excessive density, it is unlikely that it will be possible to apply such paint with a spray gun. Initially, such dye mixtures were produced only in gray color. When they began to be used for decorating various substrates, manufacturers added pigments of different colors to their composition. Today in stores you can find reliable hammer paint of any shade.

Such paint looks very unusual on certain surfaces.It is not only distinguished by an interesting shine and unusual texture, but also forms small potholes, because of which it is very often confused with a powder mixture applied in special pressurized chambers. Real and high-quality hammer-effect paint is sold in ordinary cans and does not need to be diluted, since it is initially ready for finishing work. Working with hammer paint is pretty easy. Even an inexperienced home craftsman can handle this without any problems.

Unfortunately, there are a lot of fake hammer paints in stores today, which are not of high quality. They often have branded stickers that are trusted by many consumers.

Varieties

Hammer effect paint is divided into the following types:

- Nitroenamel "NTs-221" is considered the cheapest, as it plays the role of only a decorative coating. Therefore, it is used for interior work. She is afraid of high humidity and corrodes.

- Hammer enamel "ML-165" has an alkyd-styrene base. Withstands the highest temperatures, up to +130 degrees. Possesses a high degree of adhesion to any material. Used for outdoor and indoor use. It can even be painted over rust.

- Epoxy enamel "EP-1323" performs the function of a dye and a primer at the same time. Possesses thermal and anti-corrosion properties. Designed for cars, gates, art forging, etc.

- Enamel "Hammerite" is considered the most expensive. Manufacturer - Great Britain. When painting with it, a primer is additionally carried out. After drying, a film forms that protects the metal from oxidation. It is made from silicone additives, alkyd resins. Feature - it is undesirable to paint with a paint sprayer. Used everywhere, even on top of rust.

Advantages

Among the pluses of hammer paint:

- high degree of resistance to temperature extremes;

- anti-corrosion;

- the ability to apply directly to rust;

- quick drying, especially if spray paint;

- moisture resistance;

- reliable protection against rusting for 8 years;

- coating strength;

- no toxic fumes after drying;

- harmless to the body even when used indoors;

- a large selection of colors;

- unusual decorative effect;

- repelling dust and dirt;

- water-repellent properties;

- smoothing irregularities on the surface;

- in the presence of chips, it is not necessary to remove the entire layer of paint, it is enough to cover it with enamel at the site of the defect;

- immunity to vibration, therefore, hammer paint is used for cars;

- lack of unpleasant odors;

- the possibility of staining with different tools.

Main characteristics and features of the coating

The results and characteristics of the paint composition may differ from manufacturer to manufacturer, but for the most part hammer paints have similar characteristics:

- For the binder, an alkyd resin is used in the composition.

- The density of the substance is 1 kg / l.

- Indicators of the remainder of the coating on the surface - 47%.

- Drying time parameters - at least two hours.

- If it is required to apply several layers, then each subsequent one is applied 5 hours after the previous one.

- Shelf life in a container is 2 years, subject to all storage rules.

- Gloss level indicators - 66.

- Withstands the influence of temperature up to + 80 ° С.

- For one coat, use a liter of hammer paint per 10 m2.

Among the main advantages of the paints in question, there are several of the most attractive:

- it is not required to clean the entire surface from rust before use;

- the coating tolerates vibration and many atmospheric phenomena;

- paint helps to protect metal from rust;

- re-painting of the metal structure may not be required for 10 years;

- the paint does not contain toxic elements that adversely affect human health;

- the coating does not have a strong and pungent unpleasant odor, which contributes to the use of the substance even in poorly ventilated rooms;

- the coating has a wide variety of shades, which makes a very rich choice;

- paint does not fade for a long time;

- dirt and dust do not adhere to such a coating.

The only drawback is that old paint is very difficult to remove from the painted surface. In some cases, even a strong solvent does not help.

Application area

Hammer effect coating is a widely used material for painting a wide variety of metal surfaces. It looks especially gorgeous on forged products. In addition, paint with a hammer effect is used:

- For painting machinery, as well as various equipment.

- Metal pipes.

- Coloring of the main units in structures of different types.

- Glass surfaces.

- Fences and fences made of appropriate material.

On the street, this coating is very often used specifically for painting fences and other metal structures. They will be able to stand for a huge amount of time and not change their appearance.

Surface preparation

In order for the surface to last as long as possible with a new coating, it must be properly prepared. First of all, the surface is preliminarily wiped with acetone. It is easy to use a thin sheet of plain paper to test readiness. If you run it over the surface and there are no traces left, the product is ready for painting.

In order to better prepare the surface for painting, it is advisable to process it with an iron brush. After such stripping, the adhesion of the surfaces is improved.

The next step is to treat the surface to be painted with a primer. She will create a special film on which the paint will adhere to an even and durable layer.

Advantages and disadvantages

Hammer effect enamel is in demand in various areas related to repair and production. Its popularity is due to a number of functional advantages over classic paints.

- Resistant to weathering. Hammer paint forms a waterproof layer that is immune to the effects of ultraviolet radiation and temperature extremes.

- Durability and long service life. The composition confidently withstands mechanical force - scuffs and scratches do not appear on the painted surface, and its appearance remains in perfect condition for several years. This is especially true for metals subject to intensive use. For example, from which gates or doors are made.

- Resistant to high temperatures. Ordinary enamel with a hammer effect retains its properties even when heated to 80 C. Also, there are special modifications that are resistant to fires and can withstand higher temperatures. This ensures increased durability of the painted structures in extreme situations.

- Tightness. The use of hammer enamel for metal prevents corrosion by isolating the painted surface from oxygen. This factor is important for high-quality rust work - it localizes the damaged areas, preventing their enlargement.

- High polymerization rate. Compared to how long regular enamel dries, hammer paint is a true sprinter. Within three hours after application, it loses its tack, which significantly speeds up the processing of large structures.

In addition to the functional advantages, you can also highlight the visual effect. Hammer paint combines gloss and relief that are pleasing both visually and tactilely.

Speaking about the shortcomings, we can rather note a number of features associated with the use of hammer enamel

It is important to take them into account in advance in order to avoid possible difficulties.

Difficult to remove. The composition of the enamel acquires special strength when it dries, which can become a problem if you need to clean the surface.Both scraping and the use of solvents do not give quick results and will require a lot of effort.

The need for a solid surface paint to protect against corrosion

It is important to apply hammer paint to the entire area of the structure, otherwise rust from unpainted areas can penetrate under the enamel layer, leading to its gradual destruction.

The complexity of painting work. Smooth painting with hammer paint with a spray gun will require a stable pressure in the region of 4-6 atmospheres, otherwise the formation of drips, unpainted areas and "spitting"

For a high-quality result, it is recommended to use a professional technique.

Price. The peculiarities of the paint determine its price - the spread in the market ranges from 500 to 1200 rubles, depending on the manufacturer's brand.