Species overview

Depending on how the furniture structure will be used, there are also types of round head bolts. Furniture hardware is divided among themselves by design and size. In addition, the models may differ in color - it can be black or silver, yellowish or copper.

By design

In addition to bolts with a round head, furniture makers have other types of hardware that differ from each other in their design.

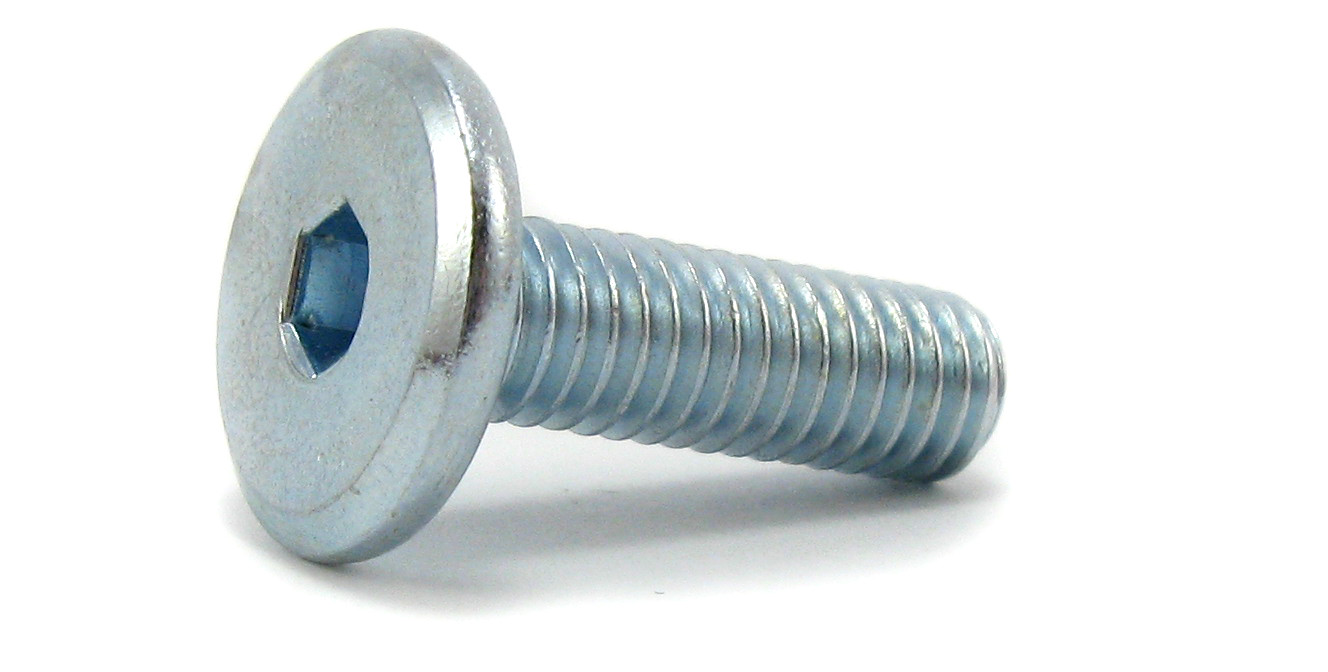

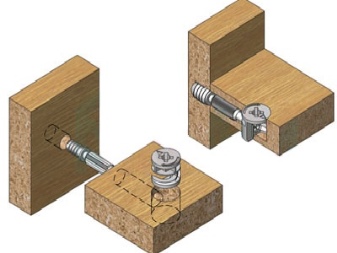

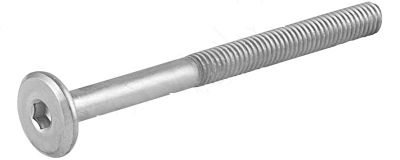

Confirmation (Euro screw) - this hardware has the shape of a working rod in the form of a long cylinder with a countersunk head located at one end. On the surface of the head there are slots designed for a Phillips screwdriver or a hexagon. The size of the working rod of a cylindrical structure depends on what the Euro screw will be used for. For example, to join a chipboard that is 16 mm thick by standards, a 16 mm long confirmation is required. Sometimes, longer hardware is used to connect two elements, the length of which can reach 50 or 60 mm.

The most common parameters of the Euro screw are 7x50 mm, and the configuration of their splines is most often demanded for an internal hexagon. You can wrap such a confirmation using a screwdriver or a screwdriver, into which a bit with six faces is inserted.

Euro screw is used when manufacture of furniture for creating a rigid and durable fastening of parts to each other. Such a fastening would not have been possible if it were not for the metric thread on the working body of the Euro screw. The disadvantages of the confirmation are that it is rather difficult to perform fasteners using it, since this procedure requires great accuracy. In addition, the design of the fastener is visible on the furniture product, special decorative plugs help to hide it, but this cannot be done completely.

It is quite difficult to use a tapered coupler, therefore, a high degree of skill and experience is required to create such a fastener. An additional disadvantage is that the hardware has a small resource of repeated cycles of disassembly and assembly of a furniture product.

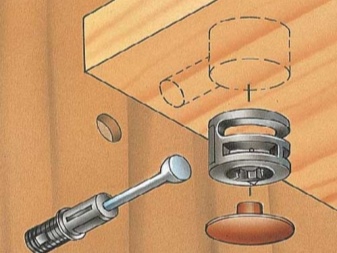

This type of hardware is also difficult to install and requires a highly skilled craftsman. In order to precisely fit the furniture elements, you will need not only to perform the correct markings, but also drill with milling. These manipulations are performed only with the use of special equipment.

This type of attachment is quite easy to use. This is a reliable hardware option for furniture assembly, it can be reused.

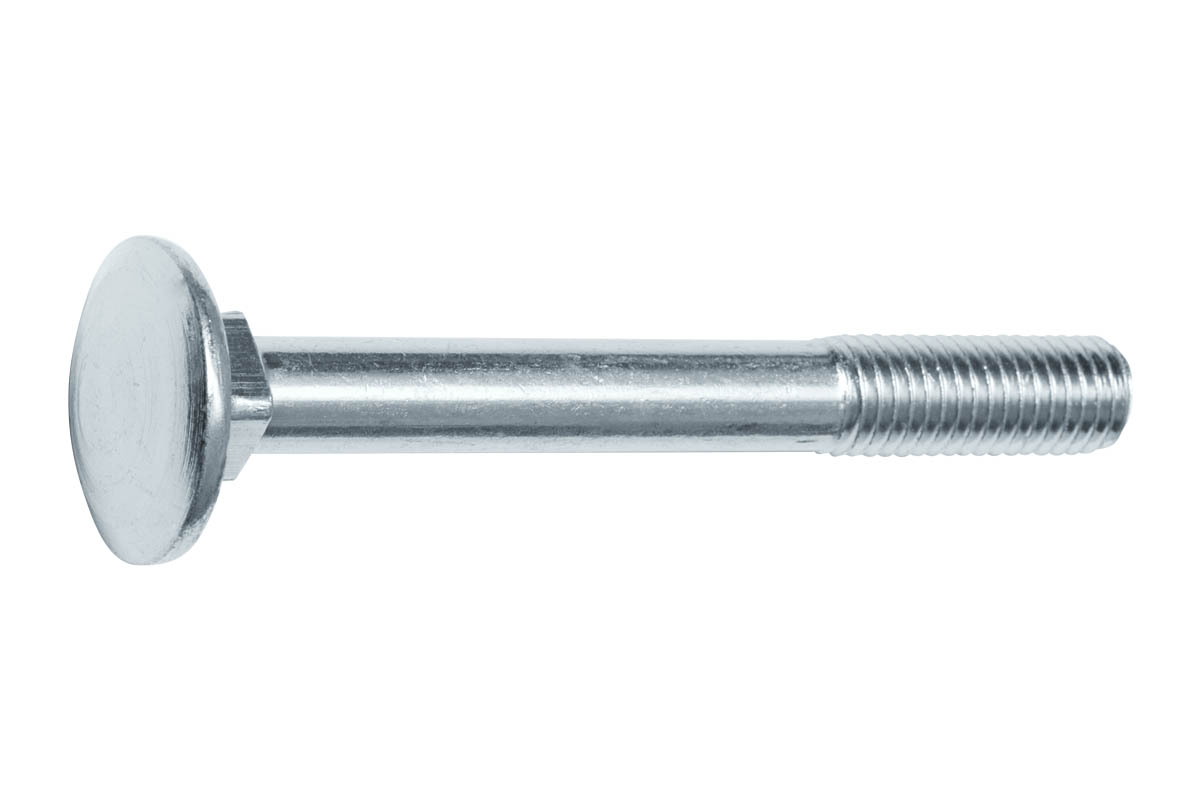

As for the semicircular head, such a smooth shape provides a comfortable and safe use for the consumer without the threat of injury from the projections of the hardware. This type of bolt is not only reliable and safe, but also does not spoil the overall appearance of the furniture. You can see similar hardware in almost every design of a bed, chair or sofa.

By form

Furniture hardware can differ from each other not only in design features, but also in appearance. For a certain type of assembly, different types of fasteners are used.

Flanged type - hardware with a flat round washer, which is located under a semicircular head.

Dimensions (edit)

Modern manufacturers produce furniture hardware in a wide range of sizes. The bolt parameters are indicated using a cipher, for example, M8x30, M4 6x40 or M5 6x50 A4, where:

- M5 is a metric thread and its pitch on the hardware rod, there are markings M4, M6, M8, M10, M12;

- number 6 - diameter of the bolt pin, excluding the thread, in mm;

- number 50 is the length of the hardware, in mm;

- A4 - stainless steel grade.

Minimum size the length of the furniture hardware is 40 mm, and the maximum can reach 120 and even 150 mm (in products with a square headrest). The diameter of the furniture bolt ranges from 5 to 7 mm.

Installation tips

When buying cabinet furniture, a set of hardware for assembly is included in its package. If you are assembling furniture yourself, you will need to stock up on a certain type of tool:

- hex and Phillips screwdriver;

- screwdriver;

- electric drill and drill;

- wrench.

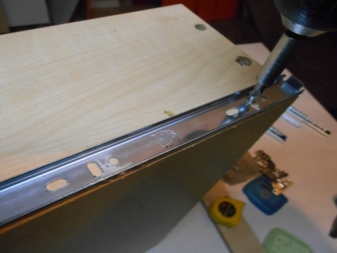

To assemble upholstered or cabinet furniture, you first need to make a marking of future holes - you need to approach this stage of work responsibly, since this moment is the key to a successful and accurate assembly. After completing the markup, you need to do holes along the markings with drills and drills. Sometimes such holes are already made in the furniture industry.

Following the instructions, you need to fasten all the elements of the furniture product using the hardware supplied in the kit. For the fasteners to be reliable, you need to tighten the hardware all the way, but excessive efforts are unnecessary here - you can rip off the thread at the bolt. It is necessary to tighten the furniture bolts and ties using a hexagon or a screwdriver.

Furniture connections are described in the next video.

Related products

for furniture bolt DIN 603 with square headrest

Screw with press washer Crepe-comp 5x25 DIN967 (5000 pcs.)

Countersunk screw Crepe-comp vp825f

Furniture bolt DIN 603 8x200

Galvanized screw Tech-Krep М6х30 DIN7985 50 pcs.

Bolt with a semicircular head furniture 10x20 DIN603

Furniture screw with internal hexagon, flat head

Internal furniture screw, hex., Flat Goal. М6х100 brass.

Screw with press washer Crepe-comp 5x35 DIN967 (4000 pcs.)

Galvanized screw Tech-Krep М4х20 DIN933 150 pcs.

Galvanized screw Tech-Krep М4х30 DIN965 120 pcs.

Zinc-plated screw semicircular head DIN 7985 M 6 x 12.

Furniture bolt DIN 603 8x50

Furniture screw DIN 603 10x80 2 pcs hort K27656-3

Furniture bolt DIN 603 6x20

Furniture bolt DIN 603 8x200

Furniture bolt DIN 603 10x60

Furniture bolt fastening technique 8x40 DIN603 (110 pcs.)

Screw M 24x60 DIN 912 class 10.9 REYHER 912-24x60-10.9-0

Galvanized screw Tech-Krep М4х30 DIN933 100 pcs.

Furniture bolt DIN 603 8x170

Round head square head bolt.

Furniture bolt m6x50

Furniture bolt fastening technique 8x100 DIN603 (40 pcs.)

Furniture bolt fastening technique 6x80 DIN603 (100 pcs.)

Furniture bolt DIN 603 8x100

Round head bolt M6x20mm 7380T G OBO 3164952

Furniture bolt fastening technique 6x35 DIN603 (220 pcs.)

Furniture bolt (stainless steel) М 8х 50 DIN 603

Hex bolt Partner 1062 73

Furniture bolt DIN 603 10x20

Galvanized screw Tech-Krep М4х30 DIN933 100 pcs.

Furniture bolt fastening technique 6x50 DIN603 (140 pcs.)

DKC Screw for mechanical connection of elements with plain

Furniture bolt DIN 603 8x100

Zinc-plated DIN965 screw M6x20 mm 1.

Furniture screw (DIN 603) 6x60 (packing 2 pcs) хort 2763.

furniture bolt din603 with nut m6x40 8 pieces

Furniture bolt DIN 603 6x20

Galvanized hexagon bolt Tech-Krep М6х20 DIN933 8.

Furniture bolt fastening technique 6x60 DIN603 (100 pcs.)

Hexagon head bolt DIN 933 M8x16 mm 200 pcs Kr.

Bolt Crepe-comp bp6150f

Screw with press washer Crepe-comp 5x35 DIN967 (4000 pcs.)

Bolt wxd fastening equipment 6x20 DIN933558 (300 pcs.)

Screw DIN7985 with a semicircular head, galvanized M5x10.

Furniture bolt stainless steel М 6х 40 S + P DIN 603

general description

Until metal fasteners appeared, furniture parts were assembled using wooden dowels or corners. A modern furniture bolt is made according to GOST standards, in the furniture industry it has one of the main positions. A bolt for assembling cabinets or chairs differs from construction hardware, also called a bolt. Furniture-type hardware provides not only strong fasteners, but also does not spoil the aesthetic appearance of the finished product.

The cylindrical shank has a metric thread that attaches the nut to the bolt shank. The most popular are the bolts, in which the head looks like a hemisphere.

The reliability of the hardware is explained by the fact that it is made of durable alloys. Most often, the bolts are galvanized to protect the mount from corrosion. Sometimes you can find furniture hardware made of aluminum alloy or polymer plastics.If we compare the strength of building bolts, then furniture hardware, of course, is inferior to them, since they do not need to hold excessively large weight loads. For this reason, furniture hardware is cheaper than construction bolts.

GOST 7802 regarding bolts

The protocol standardizes the diameter of furniture fasteners with square head heads and enlarged heads made in the form of semicircles. Nominal thread cross-sections should be 5-24 mm with cross-sections of the heads themselves 11-52 mm

Attention is also drawn to:

- head length;

- headrest height;

- side dimensions of the headrest;

- cross section of the head;

- thread length.

GOST 7802 contains a number of references to other important standards that regulate the production process. I remember, in particular:

- 24705 - thread description with detailed descriptions;

- 27148 - regulation of permissible thread undercuts and maximum runaways;

- 24670 - the dimensions of the radii under the heads;

- 1759.0 - a list of technical requirements for bolts;

- 12414 - sizes and shapes of ends.

The test procedure for elements with square head heads is set out in Gosstandart 1759.1.

The test procedure for elements with square head heads is set out in Gosstandart 1759.1.

It should be noted that furniture bolts are different from furniture screws. The second ones have a countersunk head (hexagon), produced according to DIN912. It is easy to tighten them, the screws themselves seem to "sink" in the objects made of wood. Thus, the fasteners have an additional decorative function, because the head will not rise on the surface. Screws with internal hexagons in our country are made in accordance with the requirements of Gosstandart 11738.

with an enlarged semicircular head and a square head; accuracy class C

3 DIN 603 requirements for bolts for furniture production

The German standard applies to products M6 – M20. According to DIN 603, M10 – M20 hardware is made from stainless steels of grades A4 and A2 or from galvanized (galvanized technology) steel alloys with strength 4.6, 3.6 and 5.8. It is allowed to use brass and other compositions for the manufacture of such hardware. And products M6 and M8 can be made from hard plastics.

Furniture bolts DIN 603

Furniture bolts DIN 603

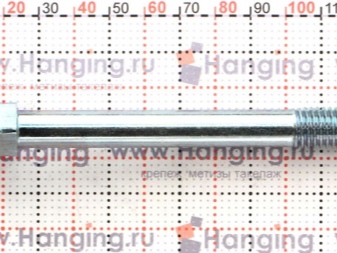

Key figures for bolts according to DIN 603 are shown below (values are given in millimeters):

- thread pitch - 08–2.5;

- head diameters - 12.45–45.2 (minimum) and 13.55–46.8 (maximum);

- headrest (height) - 2.9-14.1;

- head (height) - 2.7-9.95 (minimum possible values) and 3.3-11.05 (maximum possible);

- thread length - 16–65;

- the parameter of the side of the headrest is square - 4.52–19.16 and 5.48–20.84 (minimum and maximum, respectively).

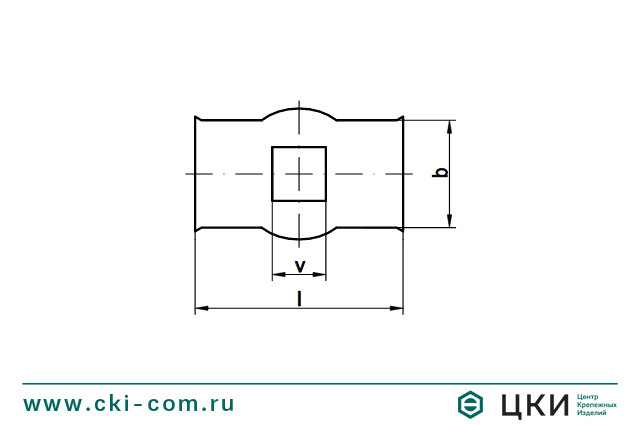

2 GOST 7801-81 - key provisions of the standard

This State Standard of 1981 gives a description of the geometric dimensions of hardware for furniture with a thread with a cross section of 6–20 mm (M6 – M20), with a mustache and a semicircular head. The most important of them are given below (all parameters are in millimeters):

- head height: bolt М6 - 3, М8 - 4, М10 - 5, М12 - 6, М14 - 8, М20 - 10;

- head section: from 14 (M6) to 44 (M20);

- product length: from 25 to 200;

- sphere radius: from 11 (M6) to 32 (M20);

- thread length: from 18 to 46 (popular M10 and M8 hardware have a length of 22 and 26, respectively);

- mustache height: from 3 to 5 (for bolts М6, М8 and М10) and from 6 to 9 (М12 – М20).

The weight of 1000 pieces of hardware with a mustache depends on the length of the bolt and the section of its thread. It varies from 6.501 kg (M6 fastener 25 mm long) to 484.3 kg (M20 200 mm long). M8 hardware is not produced in accordance with GOST 7801 with a length of 25 mm, M10 - with a length of 25 and 30 mm. And products with a mustache M20 are made according to this standard with a length of 55 mm.

Furniture hardware with a mustache

Furniture hardware with a mustache

State standard 7801–81 refers to the following GOSTs:

- 24670 (the value of the radius under the head);

- 12414 (ends of fasteners);

- 24705 (thread parameters);

- 1759.2 (inspection of surface defects);

- 27148 (permissible undercut and thread runaway);

- 1759.1 (product surface tolerances).

Strength classes

The steel grade from which the furniture hardware is made determines its strength class. In the furniture industry, fasteners are used whose strength ranges from 4.6 to 12.9. The decoding of these numbers is as follows:

5.6 is 5x100 = 500 N / mm2, while the material yield ratio is 60%.

The most in demand in the furniture industry are hardware, the class of which is from 4.6 to 6.6 and 6.8 including.If it is necessary to connect the heavy and most critical parts of the furniture structure, hardware is used whose strength is 8.8 - they are called high-strength. The higher the strength of the hardware, the more expensive its cost.

Related Posts via Categories

- Bolt strength class - how well do the hardware resist shattering?

- Anchor bolt with nut - proven fastening option

- Dowel-nail - which fasteners are of the highest quality?

- Anchor bolts - a special type of fasteners for complex structures

- Bolt designation in accordance with GOST - we are guided in the world of hardware

- How to rivet a rivet - automatic and manual methods for different materials

- Bolt manufacturing - straightforward workflow

- Spring Cotter Pin - Eared Fastener for Mechanical Engineering

- High Strength Bolts - Complete Fastener Information

- Blind rivet sizes - what should you think about when calculating?

Applications

The only and main purpose of hardware for furniture is to connect elements of a prefabricated structure. But hardware of smaller sizes is used to assemble decorative fittings for the purpose of fastening for the handle, and they also act as a tie for assembling and tightly connecting the body parts of furniture to each other.

Despite the fact that furniture screeds are inferior in metal strength to construction hardware, their fastening potential is quite high.

In modern furniture production, hardware is used for the following products:

- for the manufacture of sofas, kitchen cabinets, wardrobes and cupboards, countertops, dining tables, dressers and armchairs, beds and other items;

- to carry out restoration work in case of severe wear of furniture fittings and fasteners;

- for the construction of garden gazebos, awnings, as well as for the manufacture of wooden stairs located inside the house;

- in all other cases, when the assembly assumes the presence of a safe semicircular bolt head - in the manufacture of pointers, lightweight structures, in the manufacture of accessories, door locks, and so on.

When purchasing new furniture, few of us pay attention to what bolts the fasteners are made with.

But for those who are engaged in furniture production, it is very important to be able to understand what types of furniture fasteners exist, how to choose the right type and size