Recommendations for the use of the repair mortar MAPEI MAPEFIL:

- Do not use Mapefill to repair structures by casting in formwork (use Mapegrout Hi-Flow).

- Do not use Mapefill on vertical substrates by gunning or with a spatula (use thixotropic materials)

- Do not add cement or other additives to Mapefill concrete repair mortar.

- Do not add water after the grout has started to set.

- Do not use Mapefill if the bag is damaged or has already been opened.

- Do not apply Mapefill at temperatures below + 5 ° C.

Instructions for the use of MAPEI MAPEFILL repair mortar:

PREPARATION OF THE FOUNDATION AND EQUIPMENT TO BE CEMENTED (CONCRETED):

1. Before installing equipment, remove loose concrete from the foundation surface with a light hammer drill, needle gun, or water jet.

Rough the surface to 5 mm.

Thoroughly clean the bolts and the supporting surface of the bed base (equipment base plate) from grease and oil stains, dust and other contaminants that may interfere with the hydration of the cement.

2. Check that air outlet holes are prepared on the base of the bed.

Make sure the equipment is on display and a grouting permit has been obtained.

Please note that it will not be possible to change the installation location of the equipment after the work has been completed.

3. Before starting work, thoroughly moisten the concrete surface of the foundation.

Remove excess water with compressed air or rags.

The substrate should be damp, but not wet.

4. The formwork must be made of durable waterproof material, securely fixed, be airtight, exclude the leakage of cement laitance, withstand the pressure of the mixture during pouring, leveling and finishing work.

On the pouring side of the Mapefill mixture, a clearance of 150 mm must be provided between the formwork and the base side of the equipment bed.

On the sides, a gap of at least 50 mm should be provided between the formwork and the sides of the bed.

Mapefill can be poured using mortar pumps, funnels, etc.

When pouring foundations for large bed bases and to ensure the free flow of Mapefill mix, use the maximum water value shown in Table 1.

Temperature effect:

Mapegrout Mapefill can be handled at temperatures between + 5 ° C and + 35 ° C.

At low ambient temperatures (from + 5 ° C to + 10 ° C), the strength grows more slowly.

If high early strength is required, it is recommended:

- a) store bags in places protected from the cold;

- b) use hot water to prepare the mixture (from + 30 ° С to + 40 ° С);

- c) after pouring, cover the surface with heat-insulating materials.

If the ambient temperature is very high (above + 30 ° C), then the only problem is the rapid loss of mobility of the mixture.

As a rule, at temperatures from + 15 ° C to + 23 ° C, the pot life of the mixture is 60 minutes, at higher temperatures it decreases noticeably.

At high temperatures, the following measures are recommended:

- a) store bags in a cool place;

- b) use cold water to prepare the mixture;

- c) prepare the composition at the coolest time of the day.

Useful Tips

During storage, bags with mixtures should not be exposed to low temperatures. The recommended water temperature for dilution is 25 to 42 degrees. At normal room temperature, the working qualities of the mixture and their technical characteristics remain for no more than an hour, therefore, this factor should be taken into account when preparing them.

To make the concrete mix correctly, you should follow the following recommendations that users give in reviews:

- open the required number of bags with the expectation that they are used in one cycle;

- gradually pour the mixture into water, while stirring thoroughly using an electric drill with a nozzle;

- the mixture must be homogeneous;

- if the composition is too thick, then it is permissible to add a little water.

In the next video, you will be installing carpet tiles using Mapei construction chemicals.

TECHNICAL CHARACTERISTICS OF MAPEI MAPEFILL CONCRETE REPAIR MIXTURE:

| Composition | powder based on high-strength cement, graded sand and a special additive with an expanding reagent |

| Coating color: | Gray |

| Maximum aggregate diameter (mm): | 3.0 |

|

Mixing ratio of components: Plastic consistency Flowing consistency Super fluid consistency |

3.5-3.7 l of water for 25 kg |

| Workability (cone spread) EN 13395-1 (mm): | 270-300 |

| Storage: | 12 months dry in original packaging |

| Warning according to Euronorm 1999/45 / EC: | contains cement, irritating to skin and mucous membranes. Avoid eye and skin contact |

| Consistency of the mixture (% of the fluidity of the solution without compaction): | Fluid |

| pH | >12 |

| Application temperature: | from +5 to +35 оС |

| Viability of the mixture (at a temperature of + 23 ° С): | 60 minutes |

| Maximum layer thickness (mm): | 60 mm |

|

Compressive strength, in MPa (N / mm2), in accordance with (EN 196-1): when mixed with water in an amount of 16% by weight in accordance with EN 196/1. - after 1 day: - after 28 days: |

> 32 |

|

Flexural strength, in MPa (N / mm2), in accordance with (EN 196-1): when mixed with water in an amount of 16% by weight in accordance with EN 196/1. - after 1 day: - after 28 days: |

> 5,0 |

|

Bond strength to concrete, MP (N / mm2), not less: - after 28 days |

> 3,0 |

| Frost resistance in salts (method 2), not less | F 300 |

| Water resistance, not less | W 16 |

Application

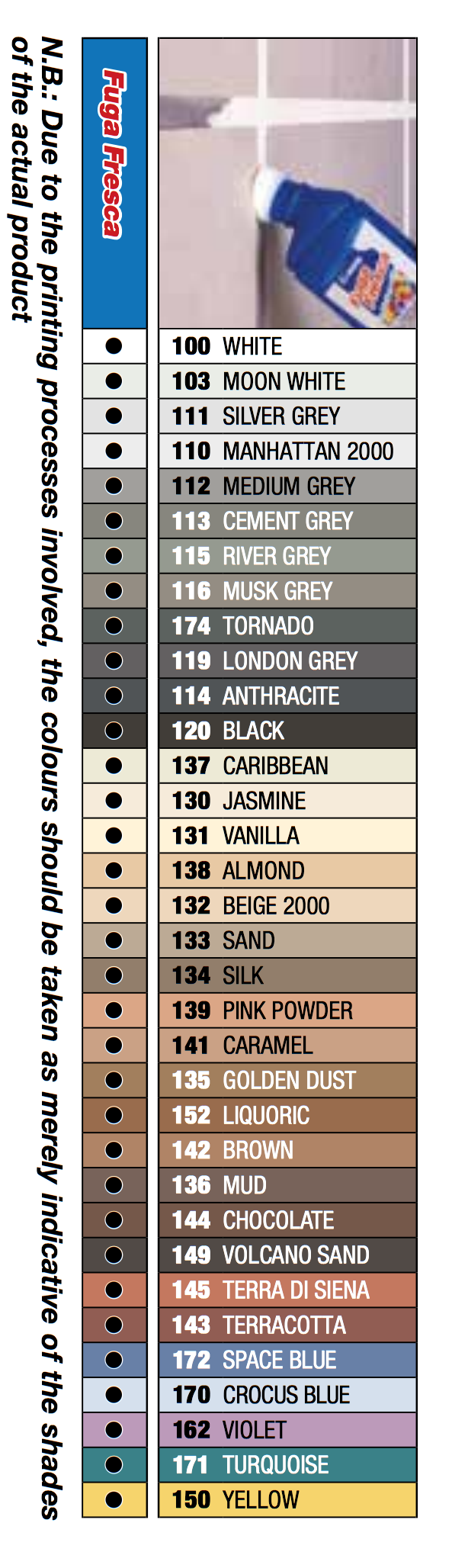

The use of Mapei formulations depends on the task to be performed. For example, mixtures that are made on the basis of epoxy resin with the addition of silicate sand and special additives increase the resistance of the treated material to moisture. Mapei epoxy grout is considered one of the best in the world.

When buying mortars produced by Mapei, it is recommended to look at the quality certificates, which must be present at all authorized dealers. It is also recommended to read the instruction sheet, which always reveals the purpose of this or that composition.

It is also important to prepare the area to be treated well before starting work. This postulate especially applies to concrete products - cracks in them are processed with a special tool with diamond nozzles or a perforator

All crumbs and microparticles are removed using the pressure of water, then the area is thoroughly dried. In addition to water, compressed air is used to clean the concrete.

The surface is treated with a solvent, then a primer. Solvents must be concentrated to be able to remove:

- paints;

- fat;

- cement and gypsum mixtures;

- sealants.

CARE AND FINAL OPERATIONS DURING AND AFTER APPLYING MAPEI MAPEFILL:

1. After pouring, all exposed surfaces of Mapefill must be immediately protected from moisture loss for a period of at least 24 hours.

Care can be carried out:

• spraying water onto the surface;

• covering the surface with foil or damp burlap.

2. After two days, the temporary leveling pads can be removed, provided they have been oiled. If such an operation is not recommended by the equipment manufacturer, then there is no need to remove the shims.

3. After putting the equipment into operation, it is necessary to tighten the screws and bolts. Use a torque wrench to evenly tighten the nuts to the recommended torque.

CLEANING TOOLS

Clean the tools from fresh Mapefill solution with water.

If the solution has hardened, cleaning is carried out mechanically.

Preparation of MAPEI MAPEFILL solution:

Before mixing Mapefill with water:

check the availability of Mapefill material, which will be required for the full scope of work, taking into account that the consumption of Mapefill dry mix for the preparation of 1 m3 of concrete is 1900 kg;

make sure that all the necessary equipment (mixers, carts, buckets, trowels, etc.) is at hand;

check the implementation of the preliminary work prescribed in the section "Preparation of the foundation and equipment to be cemented (concreted)". For the correct preparation of the concrete mix, you should:

For the correct preparation of the concrete mix, you should:

- a) immediately before mixing, open the required number of bags;

- b) depending on the required consistency of the mixture, pour into the mixer the minimum amount of water indicated in Table 2;

- c) switch on the mixer and pour in the dry Mapefill mixture continuously. Use the entire bag for mixing;

- d) stir for 1-2 minutes until the lumps disappear and the mixture becomes homogeneous;

- e) stop the mixer for 1 minute, clean the mixer walls from adhering dry mix residues;

- f) if necessary, add water (within the amount indicated in Table 2), turn on the mixer and mix again for 2-3 minutes, until a homogeneous consistency is obtained.

Stirring by hand is not allowed, as more water will be required, which will lead to a loss of the declared values and negatively affect the strength, shrinkage and water resistance of the material.

The pot life of the Mapefill mixture at + 23 ° C is 60 minutes.