What are the disadvantages of brick houses?

Considering that modern people choose to build houses from bricks, it is also necessary to consider all the existing shortcomings of this material. Like any other building material, brick is not ideal, and there are certain points that must be considered before starting construction.

First of all, it should be borne in mind that brick houses require additional rather costly interior decoration. The thing is that the cement mortar, which serves as a fastening element when laying bricks, has a rather high thermal conductivity, so the house will be cold if the finishing was not carried out with high quality.

Among other things, it must be borne in mind that a brick house is an extremely heavy structure, under which it is necessary to equip a reliable powerful foundation, since otherwise the house will sink, and as a result significant cracks in the brickwork.

Among other things, it should be borne in mind that a professional should be engaged in the design of a brick house, since errors in the calculation of the foundation and load-bearing walls in this case can be simply fatal.

Considering the shortcomings of brick, there is another unpleasant moment of using this material for the construction of houses. It is the increased hygroscopicity of this material. The brick is saturated with water, therefore, much more time and energy resources have to be spent on etching the room.

At the same time, after the brick house is completely warmed up, it retains heat well. Often, to improve the thermal insulation properties of brick houses, special cakes are made of mineral wool, which prevent heat loss and reduce heating costs.

Main advantages

A professionally built ceramic brick house will delight its owners with high quality and durability. And all this thanks to the undoubted advantages of the building material.

The advantages of ceramic bricks.

The advantages of ceramic bricks:

- Long service life. According to manufacturers, a well-built brick house can last a very long time. Modern brick and monolithic buildings made of ceramic blocks have a service life of 125-150 years.

- Simplicity of masonry. The construction of walls and partitions from ceramic bricks does not require special skills that differ from the usual masonry of brick buildings.

- Variety of sizes. Allows to bring to life any conceived architectural solution.

- High strength. Internal and external brick walls are highly resistant to various external influences.

- Refractoriness. The ceramic block and brick does not burn, which means that it protects the home from the occurrence and spread of fire.

- Frost resistance. Ceramic brick houses show high performance values in harsh cold climates.

- The ability to efficiently store heat. A brick house has good heat capacity. The walls of such dwellings slowly give off heat in winter (they cool down for a long time and retain heat) and heat up weakly in summer. Ceramic walls smooth out fluctuations in air temperature and humidity, increasing the comfort of residents.

- Environmental friendliness of the material. All components of the mixtures from which ceramic bricks are made are natural, absolutely safe for humans and the environment.

- Good insulation. The thickness of the interior walls in the house, even in half a brick, muffles almost all sounds, allowing each family member to enjoy peace and relaxation.

- Wide range of colors and aesthetics.A brick house is beautiful. The modern variety of shades of facing ceramic bricks opens up ample opportunities for decorating a building, allowing you to bring to life the most original projects.

Ceramic bricks and blocks are unpretentious in maintenance, not prone to the formation of mold and fungal deposits on the surface (without additional processing).

The essence of the material

What is the basic principle of the Lego constructor? In it, elements are selected that are tightly joined together due to certain profiles, which allows you to assemble sufficiently strong, ideally even structures, simply by joining them together in a certain order.

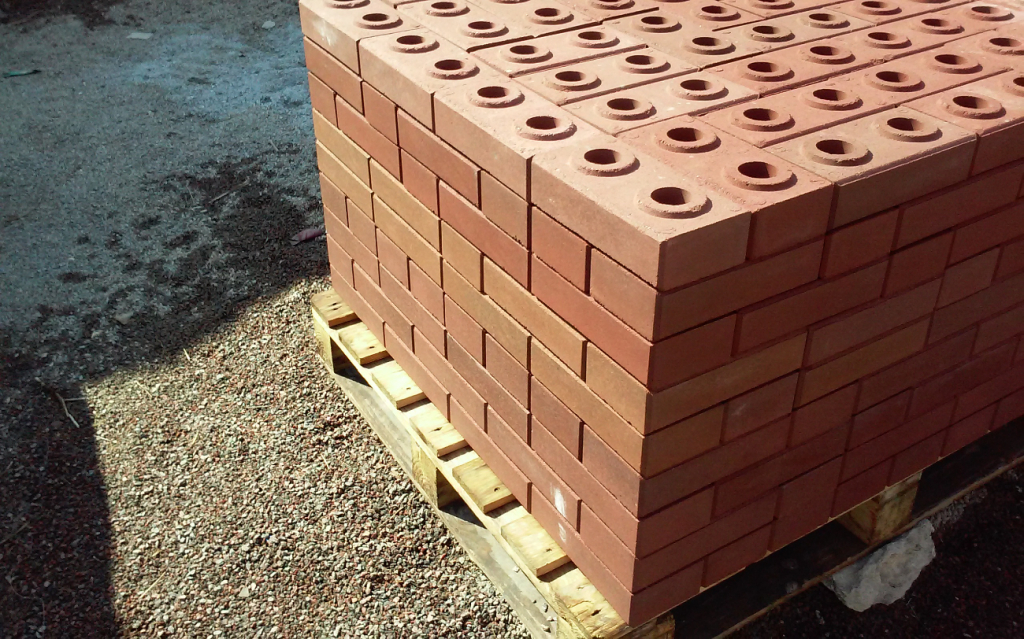

Lego bricks were developed less than 100 years ago and have the same principle as a children's toy. It is pressed from crushed rocks (usually of the calcareous type), volcanic dust and sand. A simpler option involves the use of raw materials based on crushed stone sieve.

However, the main difference is not the composition, but the geometry of the elements. They are formed by 2 through holes and profiles along their edges, providing a connection according to the "tongue-and-groove" system.

When laying such a brick, the holes are aligned, forming a channel through the entire structure, and the spike enters the groove, which allows the elements to be aligned evenly. Masonry, even without excessive control, is automatically carried out strictly vertically, and the bricks do not have the possibility of displacement relative to each other.

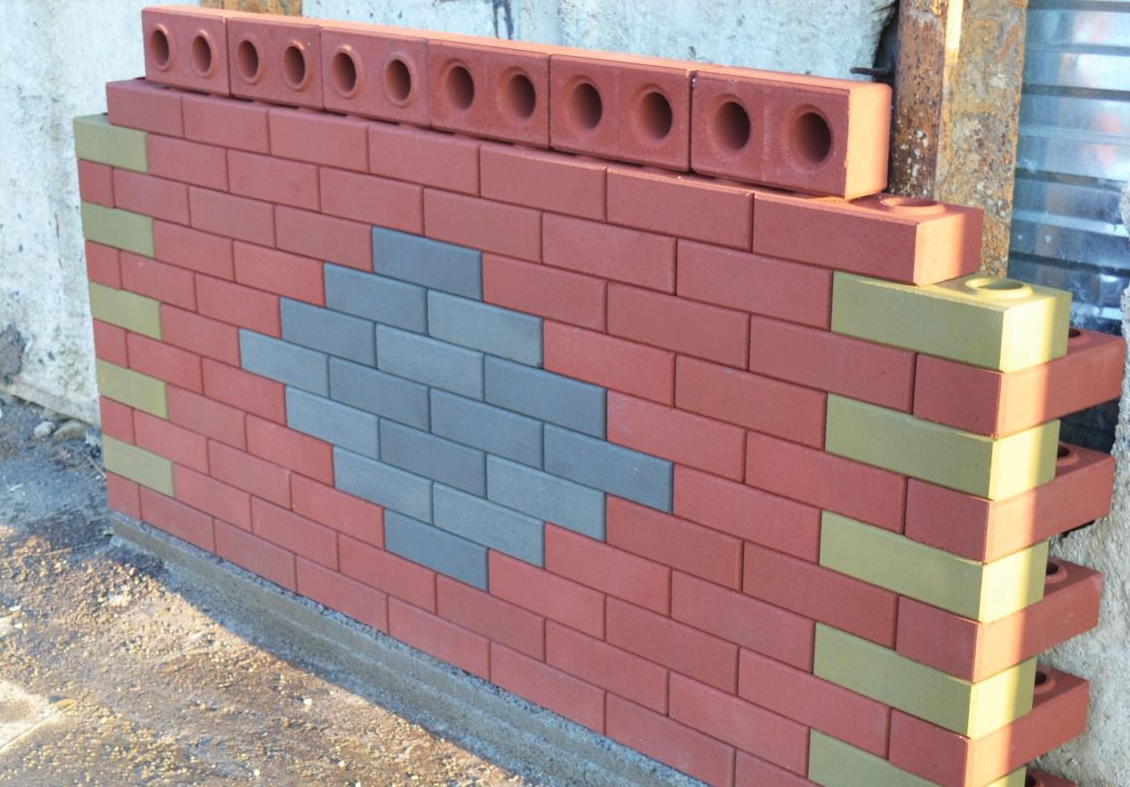

As a result of the use of Lego bricks, an almost perfect appearance of the building is provided, and taking into account the variety of colors, and with an exquisite design. This circumstance creates the main field of application - external facing of buildings, interior decoration of premises, construction of attractive fences (fences).

What is the difference between hollow sand-lime brick and hollow ceramic brick?

An important difference is that the voids in ceramics can take on various shapes and can be located anywhere throughout the product, which does not at all contribute to an increase in the strength of this building material. Hollow silicate has a regular cylindrical shape in the central part of the void. This feature significantly increases the strength of the product. Produced in individual molds, rather than using special extrusion presses, silicate can be produced even to specific dimensions specified by the customer. After all, individual shapes require certain sizes, and ceramic presses are difficult to customize, therefore ceramic bricks are produced only in standard sizes.

Advantages

The positive properties of the material are not its only advantage. The unique shape ensures simplicity of laying walls or partitions, high-quality connection of elements. The most important advantages of using a new type of brick include:

- Possibility of simple laying of communications inside voids.

- Low cost of products.

- Wide range of colors (from light gray to deep red, dark blue, pink or yellow).

- No need for subsequent finishing of walls and structures made of Lego bricks (has a smooth surface or has edges with a slight texture).

- The insignificant weight of the bricks does not require the preparation of a buried foundation (for buildings with 1-3 floors).

Attractive material and versatility. Suitable both for finishing buildings and for laying decorative indentations, stoves. It can be used for the construction of gazebos, fences.

Varieties of bricks

Listing the pros and cons of a brick house, one cannot ignore the characteristics of the material from which it is made

Listing the pros and cons of a brick house, one cannot ignore the characteristics of the material from which it is made

Listing the pros and cons of a brick house, one cannot ignore the characteristics of the material from which it is made, because there are several varieties of bricks that differ in technical and operational characteristics.And sometimes the owner of a brick house, dissatisfied with some of the qualities of the structure, does not understand that the reason is the wrong choice of the type of brick for making a tub of walls or cladding.

So, there are several types of bricks:

- Ceramic bricks are most often made from red clay. The product is fired in an oven at a temperature of up to 1000 ° C. This material is used for masonry of load-bearing walls and interior partitions. It is used in the arrangement of the foundation, in the cladding of the building, and interior decoration. Fireplaces and stoves are laid out of it, but not those parts that come into contact with fire. This material is quite resistant to the negative effects of weather factors. Ceramic products are divided into hollow, solid, smooth and textured elements for external and internal wall cladding. The shade of this material can be from red-brown to light beige. It depends on the type and color of the clay used.

- Silicate bricks are made from a mixture of lime and sand. Its shade is most often white, but sometimes other colors are obtained with the addition of pigments. The material is hollow, corpulent and porous. If we compare silicate brick, then its frost resistance index is lower than that of ceramic products, and its thermal conductivity is higher, so a house made of such a material will be quite cold. In addition, the material absorbs water more easily, but the sound insulation characteristics of silicate bricks are much higher than that of ceramic ones. This type is best used for laying load-bearing walls for cladding and internal partitions. It is categorically not recommended to be used for laying a foundation.

- Clinker bricks are made from refractory clays. The product is fired at a temperature of about 1200 ° C. Firing at this high temperature results in a homogeneous, void-free product that is highly durable. The brand of clinker bricks cannot be lower than 400. Among the advantages of this material, it is worth mentioning increased frost resistance, low water absorption, resistance to the effects of salts and alkalis. That is why clinker is successfully used for facing facades, paving paths and platforms, arranging gutters and landscape design items. The material is often used in the interior. Facade clinker bricks are rich in colors and textures.

If you decide to build a house of bricks, the pros and cons of which we are considering, then you should know that a brick can be:

- corpulent;

- hollow;

- porous.

Solid products are distinguished by high compressive strength, therefore, the foundations and basements of buildings are often made from this material, and external load-bearing walls and columns are laid out. However, due to the dense homogeneous structure, the material has a sufficiently high thermal conductivity, therefore, walls made of solid bricks must be additionally insulated. Masonry without insulation will be able to keep the warmth of the house only if the thickness of the walls is significant - from 640 mm to 1000 mm.

Hollow bricks have through holes that reduce the thermal conductivity of the material. The more voids filled with air, the higher the thermal insulation qualities of the product. The elements are suitable for masonry exterior and interior walls of the house. At the same time, due to the voids, the thickness of the outer walls can be small, while the thermal conductivity of the outer structures will be low, so that additional wall insulation can be dispensed with. Also, thanks to the voids, the specific gravity of one element is less, which makes it possible to reduce the load on the foundation.

Porous products (gas block and foam block) have the highest thermal insulation qualities, while the strength of the material decreases, and its specific gravity will be less. For the manufacture of such elements, special additives to clay are used, which, after firing, burn out and leave behind isolated voids.Such products are oversized, which simplifies and speeds up the process of masonry work. The end parts of the elements have grooves and ridges, which increases the thermal insulation of the walls and allows you to save mortar on the execution of vertical seams.

Advantages of a brick house

Most of the advantages of ceramic brick houses are due to its technical characteristics. Read more about the technical characteristics of ceramic bricks.

Long service life. Brick is such a durable and time-tested building material that its service life far exceeds expectations. The minimum number of cycles of freezing and thawing a brick wall without any possible damage is 50 cycles. But in practice, this period is doubled or more. Of course, provided that you used high-quality brick for building a house and followed the construction technology. The average service life of a brick box is 100-150 years, depending on operation and climate.

Brick walls don't burn. Fire safety at home is one of the main tasks during construction. The brick is fire-resistant and refractory material. The very process of producing ceramic bricks takes place at high temperatures. Brick is fired clay and can withstand high temperatures. It definitely does not support combustion and does not burn. Even if other combustible parts of the structure are destroyed under the influence of fire, the box of the house and its structure will remain intact and retain their bearing capacity.

Resistant to physical and biological pests. Brick is a stone. For a single rodent or insect, a brick cannot become food and a place of residence. No fungus or mold grows in the brick wall. Unless the necessary ventilation has been made in the house according to the technical design. In this case, mold will start on the inner walls of any house. But unlike wooden houses, mold can only appear on the surface of the wall and is never able to destroy the solid structure of a brick wall.

High strength. Brick is such a strong building material that its structure allows multi-storey buildings to be erected without any risk. Not every artificial stone and wall material can boast of such a characteristic.

Resistance to external influences. A brick house is not afraid of sudden changes in temperature, rains, strong winds and other extreme environmental influences. The brick wall is not blown by strong winds.

Breathable house. Inside a brick house, a vacuum effect is not created, as in panel houses and using expanded polystyrene. Such a house does not need to be specially ventilated if there is normal ventilation.

Keeps warm and cool well. In the summer and winter seasons, a comfortable microclimate is maintained inside. When the heating is turned off, a brick house cools down for a long time and retains internal heat for a long time.

Aesthetic appearance. Currently, bricks are produced in any shape and color. Almost any surface texture for facing bricks is possible. Any design fantasy in terms of color and shape of the structure can be realized. This is evidenced by the brick monuments of architecture that have survived to our time. Brick can be safely called a creative building material. Columns, arches, specific indents and wall passages can be erected from it.

Good insulation. Residents of a house made of ceramic bricks, located in busy parts of the city or near highways, will not feel the discomfort of noise outside the walls of their home. Good noise insulation of a brick wall will protect you from external noise and allow you to take a break from the outside hustle and bustle

This is a very important property of a brick house, because one of the main purposes of your own home is the opportunity to relax comfortably.

Compatible with any finishing materials.Brick is a versatile building material that works well when combined with any materials, without any unnecessary impact.

Environmental friendliness

Brick is an environmentally friendly building material that is completely made of natural clay, fired using a special technology. Does not represent any harm to human health.

Applications

Lego bricks are widely used in all areas of residential and industrial construction. Depending on the recipe for the mixture, it can be used for various purposes: laying, sidewalk or earthquake resistant. The high strength of the masonry allows residential, industrial buildings and special facilities to withstand earthquakes, landslides, blast waves, and other natural and man-made threats.

The strength, frost resistance and low permeability of Lego bricks practically does not limit its use in construction.

It can be used to build high-rise buildings, dry and wet rooms, fences, gazebos, utility blocks, and can also be used as a building or facing material. It is ideal for building or decorating walls, forming a basement and basement floors, laying columns, fences and fences. It will look spectacular when finishing near-window areas, doorways, fireplaces, corners and eaves of buildings.

Lego bricks are also widely used as a decorative element in landscape design when decorating flower beds and alleys.

How to decorate a brick house outside

Now let's deal with the issue of exterior decoration of a brick house. For decorating a brick wall, the most common plaster is suitable. The master will be able to achieve both an unusual relief and an absolutely smooth surface. This finish improves the fire resistance of the structure and has a positive effect on the soundproofing qualities. For finishing the basement, plaster is used less often.

The outer side of a brick wall is often decorated with natural or decorative stone. It looks very solid and respectable. This material is very strong and reliable, capable of retaining its original appearance for centuries. In this case, it is best to decorate the base with natural stone.

Another popular type of decorative brick wall decoration is modern thermal panels. The facade is particularly dense, looks aesthetically pleasing and elegant. A special advantage is that the thermal insulation properties of the house are improved several times.

Disadvantages of a brick house

- Long construction period. Compared to modern alternative building materials, the construction time for a house made of ceramic bricks will be longer than for houses made of blocks or frame materials. This is due to the relatively small size of the brick.

- Foundation costs. Brick is not an easy material in comparison with a foam block or aerated block. Therefore, for a brick box at home, it is necessary to build a solid and massive foundation, with a more than sufficient margin of safety. Additional costs are required for a reinforced foundation.

- House shrinkage. This is an inevitable process for every home. The shrinkage process occurs from the moment the box is erected at home and continues almost throughout the entire operation of the house.

The active process of shrinkage of a brick house lasts from 3 to 5 years after the end of construction. During this period, the foundation adapts to the heavy load of a brick house. If all the requirements for construction technology are almost perfectly met, according to a professional project, then the shrinkage process can take one year.

The duration of the shrinkage of a brick house depends on several factors:

- From the number of storeys and, accordingly, the load on the foundation

- From the type of soil, on stony soils, the shrinkage process is halved

- From the type of foundation

- Climatic conditions

-

Compliance with construction technology and other factors

- Cracks in the walls.If the shrinkage of a brick house began to occur unevenly, as a result of certain violations, then this will inevitably lead to cracks in the load-bearing walls and the house will become dangerous for living. Houses made of timber and wood materials are not subject to this property. Therefore, it is not recommended, at least in the first year after the construction of the house, to carry out high-quality external and internal decoration of a brick house. Brick houses are not suitable for areas with seismic activity.

- Brick cost. The cost of building a brick box at home is relatively more expensive compared to the cost of wall blocks and panel houses. The cost of brick laying work will also cost more, due to the laboriousness of the brickwork.

- Wall thickness. To make the house as warm as possible, it is recommended to lay bearing brick walls with a thickness of 51 cm to 64 cm, that is, one and a half to two bricks. For facing the facade, a wall thickness of 12 cm is enough - in one brick. Such a brick wall thickness takes up the usable area of the house and requires additional material costs.

- Additional wall insulation. A brick house needs external insulation. External insulation of a brick house is also necessary in order to shift the dew point from the main brick wall beyond its outer boundaries. Otherwise, moisture will accumulate during temperature changes in the structure of the brick and, when freezing, in conditions of negative temperatures, destroy the structure of the wall.

-

Fast home cooling and heating costs. In the cold season, in the absence of sufficient insulation and in conditions of the building's heating turned off, the brick house cools down. In order to warm up a brick house again, it is necessary to spend more time than when heating a block house. Full warming up of a brick house can take one or two days. With frequent cooling and heating of the house, with incomplete external finishing, that is, in the absence of external insulation, moisture will accumulate inside the brick wall and the so-called Dew Point will form. The moisture accumulated inside the brick as a result of the temperature difference will destroy the wall. Therefore, a brick house must be heated throughout the cold season. Therefore, such a house is not suitable as a summer cottage, but only for permanent residence.

A brick house is truly a family hearth for several generations. However, you should take into account all its pros and cons, whether they are right for you. A good and optimal option is to use bricks in combination with other building materials. A combined approach to building a house made of ceramic bricks with other building materials will minimize the existing disadvantages and fully use the irreplaceable advantages of durable bricks.

Masonry features

Laying Lego bricks has its own specific nuances. The first row is fixed to the base using a cement-sand mixture, and all subsequent rows are laid on glue. For these purposes, an adhesive designed for ceramic tiles is usually used.

When laying, it should have the consistency of a fairly liquid sour cream. Consumption is 22-25 kg for 500 bricks. It is best to apply the mixture with a special glue gun.

Laying is carried out in the following order.

Laying the first row

The quality of the entire structure depends on the quality of laying the first row. For this, the surface line and the horizontal line are clearly controlled.

The first row is laid on the foundation, the surface of which is pre-covered with insulation and waterproofing, using cement mortar. Between the bricks at the ends, the adhesion is provided by a thin layer of glue.

All elements are joined so that the elements of the next row enter the locking engagement, taking into account the offset by half of the brick. The seal is provided with a mallet.

Subsequent laying

The glue is applied with a glue gun to the bottom of the brick with a zigzag roller 10-12 mm wide. First of all, the engagement spikes are covered with glue.

Glue is also applied to the end of the element. Each layer is laid with linkage, i.e. with an offset of exactly half the brick. The spike is aligned with the groove and with a little effort is tightly driven into it.

Formation of openings

Lego brick is capable of itself becoming a floor beam, which eliminates the need to install a reinforced concrete element that distorts the masonry. The opening is done as follows:

- formwork is installed;

- one row of Lego bricks is laid, in which longitudinal channels seep and steel reinforcement is laid;

- 2 more rows of bricks are placed on glue;

- concrete is poured into the holes.

After the solution has solidified, a sufficiently strong overlap is formed.

Making an armopoyas

To fix the roof on the wall, a reinforced belt is made from Lego bricks, which evenly redistributes the load.

For this, the last row of the wall is laid out of bricks with ready-made longitudinal grooves. Steel reinforcement is laid in parallel in them. Wooden plugs are inserted into the holes in the brick and a layer of concrete is poured around the entire perimeter of the structure.

We advise you to read: When is a monolithic belt used to strengthen walls?

Cons of silicate

Among the disadvantages of silicate bricks are the following:

- is a heavy construction material (30% heavier than ceramics and natural limestone). Therefore, as a rule, the masonry is erected on a solid foundation. It is more difficult to lay silicate, therefore, the prices for such works are of an increased size;

- does not tolerate the constant action of water (it is unacceptable for basement rooms, it absorbs water and contributes to an increase in humidity in the premises);

- cracks form at high temperatures (such a brick cannot be used in chimneys, furnaces, in the construction of fireplaces and stoves);

- there are no smooth shapes and decorative elements (performed only in the form of a rectangle);

- has good thermal conductivity (in order to avoid heat loss in the room, it is necessary to increase the thickness of the wall or insulate the room in another way);

- possible complete or partial destruction when heated to high temperatures, the passage of steam;

- is capable of absorbing water (up to 8%), therefore it is unsuitable for the construction of structures in conditions of high humidity.

Comparison of technical characteristics. Lego brick vs classic

On the net you can find many opponents of Lego technologies, leaving negative reviews. But take a closer look - basically all the disadvantages of Lego bricks are far-fetched and have nothing to do with practice. Most likely, these are the same professionals who are terribly frustrated by the reduction in prices and the arrival of new people in their business. Let's compare a Lego brick with an ordinary burnt brother in terms of basic technical indicators.

| Technical indicator | Lego Brick | Red ceramic brick |

| Strength | M150 | M150 |

| Density | 1550 kg / cubic meter | 1600-1900 kg / cubic meter |

| Frost resistance | 35-40 cycles | 35-40 cycles |

| The weight | 3 Kg | 3.7-4kg |

| Water absorption | 5,5% | 14% |

Data taken from open sources. We took the strength of the brick as a starting point. It can be different depending on the production technology. M150 is the recommended minimum strength for the erection of load-bearing structures.

What conclusion can be drawn from this blitz analysis?

- With the same strength, the weight of a Lego brick is less. This means that the cost of lifting the material to the place of work is reduced, and the structure itself will be lighter. This, in turn, reduces the requirements for the overall load-bearing capacity of the structure, which ultimately will affect the cost of the project as a whole.

- The water absorption of pressed Lego bricks is 2.5 times less than usual. This means that its service life in an unstable winter climate in the middle zone will be longer, and in a room with the same ventilation schemes, the humidity is lower.

Otherwise, everything is the same, which means that there are no special obstacles to using Lego bricks.

Now a few words about the price at which you can actually buy one and the other material. At the plant, it will be approximately the same and will range from 10 to 15 rubles per piece. But it would be incorrect to talk about the cost without taking into account transport costs and the costs of unloading and loading operations. These are inalienable accompanying expenses that need to be calculated based on the conditions in which the construction takes place.

Therefore, it is difficult to analyze here, but all other things being equal, the Lego brick has one indisputable advantage - it can be made directly at the facility, thereby significantly reducing all associated costs and time. Yes, this is not a reservation, during the season there is a queue for bricks in factories, but this is simple and a waste of time.

Specifications and requirements

Among the many types of bricks, the most demanded in low-rise construction is the ceramic type. To obtain this building material, not any clay is suitable, as it might seem. Technologists carefully select raw materials, achieving perfect properties and impeccable reliability. The main parameters depend to a large extent on the used production method. The so-called plastic technique consists in the formation of a clay fragment with a water concentration of no less than 17 and no more than 30%. A belt press is used in the work, after which drying and firing is performed.

Semi-dry pressing is much more demanding on the moisture content of the feedstock, its bar is reduced to 8-10%. In addition, the material must be subjected to very high pressures. The density of the finished product is expressed by a conditional numerical index from 0.8 to 2.4. It corresponds to a mass of 1 cubic meter. m of building material in tons.

It can be used both as a structural material and for external cladding. What the configuration of the products will be, how deep they will be, varies depending on the processing mode. It has been established that the mechanical strength, as well as the associated wall service life, is determined by how the cavities are oriented to the plane that carries the load. No experienced builder will lay bricks with horizontal passages in the masonry of a load-bearing wall.

An increase in the thermal qualities of blocks is sometimes achieved due to an increase in porosity by adding:

- finely cut straw;

- sawdust;

- peat.

Burnout components decrease in volume and after them small pores, saturated only with air, remain. But by enhancing protection from frost, the pores open a free path for moisture and water vapor. This significantly devalues the positive thermal performance of porous products. Therefore, a balance has to be carefully observed between these conflicting considerations. This is the only way to build a beautiful and warm house at the same time.

Steam permeability has another important aspect. All inhabited living rooms invariably serve as concentrators of water vapor. If they are not taken outside, the microclimate quickly becomes unfavorable for life. Ceramic brick perfectly removes water vapor to the outside, it confidently copes with this function both in private houses and in apartments - it is not for nothing that it is so appreciated. Construction is carried out in various climatic conditions, and a properly erected brick wall meets cold everywhere well, resists their destructive effect as effectively as possible.

But much depends on the specific characteristics of a particular batch of blocks. Correct laying in a building that is constantly heated in winter will surely work for 50 - 100 years without visible external changes. Ceramic brick protects the residents of the house well from such a scourge of modern cities as the incessant noise that penetrates everywhere. From this material, you can always build not only a capital wall, but also a screen on the street or a sound-dampening partition in the house.

Equipment

The construction equipment market offers a wide range of equipment for making lego bricks... Here you will find both large lines and mini plants for organizing a workshop in a small room.

The price of equipment for the production of Lego bricks depends on the power, output and pressure that is applied to the raw materials during the formation of the block.

From technology, you will need a crusher, a vibrating sieve, a mixer, a hopper, a dispenser, a hyper press, a mold for the production of Lego bricks and a steaming chamber.

The best equipment for making Lego bricks

We will look at the best installations that are suitable for organizing mini Lego brick production.

Below are both cheaper mechanical (manual) and hydraulic (semi-automatic) machines, the price of which is an order of magnitude higher. These installations are produced in many cities of Russia. You can buy a machine for the production of Lego bricks in Saratov, Krasnodar, Kirov, Blagoveshchensk, etc.

1. Hydraulic machine "Lego 180" - $ 2,540, manufactured by LLC "TechTron", Kirov; Allows to make bricks in the following sizes: length - 250 mm, width - 125 mm, height - 65-90 mm. The weight of the block depends on the raw materials used - 3.5 - 4 kg.

Specifications:

- Dimensions: 150 by 65 by 120 centimeters;

- Weight: 202 kilograms;

- Motor: 3 phase, 380V;

- Productivity: 180 pieces per hour, 1440 pieces per shift (3.8 m3);

- Product pressure: 8-10 tons (adjustable).

2. Mechanical machine "Lego 120" - the cost of 680 dollars was produced by LLC "TechTron", Kirov. Allows to make bricks with the following parameters: length - 250 mm, width - 125 mm, height - 65-90 mm. The weight of the block depends on the raw materials used from 3.5 kg.

Specifications:

- Dimensions: 160 x 50 x 110 cm;

- Weight: 89 kg;

- Productivity: 120 pieces per hour, 960 pieces / shift (2.5 m3);

- Product pressure: About 2 tons.

3. Mechanical machine cost - $ 630, manufactured by LLC "Stanki-Saratov", Saratov. Allows to make bricks with dimensions: length - 250 mm, width - 125 mm, height - 65 mm.

Specifications:

- Dimensions: 20 x 50 x 14 cm;

- Weight: 99 kilograms;

- Hopper volume: 40 liters;

- Productivity: up to 1000 pcs / shift;

- Pressure: 2 tons.

4. Hydraulic machine for Lego bricks SGU-2000 - $ 2,370, manufactured by Ferrum LLC, Kirov. Allows to make bricks with dimensions: length - 250 mm, width - 125 mm, height - 65 mm.

Specifications:

- Occupied area - 3 sq. m .;

- Productivity: up to 130 pcs / hour;

- Product pressure: 20 tons;

- Power consumption - 7.5 kW;

- 12 months warranty

5. Hydraulic machine for making Lego bricks - $ 6,360, manufactured by "ImportTechKom-invest" LLC, Blagoveshchensk. Allows to make bricks with dimensions: length - 300 mm, width - 150 mm, height - 100 mm. / Length - 250 mm, width - 125 mm, height - 75 mm.

Specifications:

- Machine type: hydraulic;

- Productivity: up to 1900 pcs. per shift;

- Size: 350 * 500 * 1000 millimeters;

- Pressure: 80 - 100 kN;

- Weight: 450 kg.

6. Hydraulic machine 5BRICKS40S - $ 4,650, manufactured by GlobImport LLC, Krasnodar. Allows to make bricks with the following parameters: length - 250 mm, width - 125 mm, height - 75 mm.

Machine parameters:

- The machine is hydraulic;

- Productivity: 200 bricks in 1 hour;

- The kit includes tooling for the manufacture of 3 types of products;

- Dimensions - 0.94 x 0.65 x 1.45 m;

- Hopper volume - 95 liters;

- Weight: 198 kg.