Laminated chipboard assortment

Reading reviews and leafing through catalogs of laminated chipboard from Egger, I noticed that the choice is amazing, but at the same time, a large assortment does not compromise quality.

Egger laminated chipboards are combined into the Eurodekor line. These are chipboards that are faced with special decorative paper pre-impregnated with melamine resins. In addition to chipboard, MDF boards, OSB, lightweight boards, etc. act as the load-bearing material for lamination. At the same time, a certificate of conformity can be obtained for each offered product.

The main advantages of the offered laminated chipboard include:

- huge selection;

- variety of decor;

- special surface structure;

- optimal performance;

- abrasion resistance;

- coating durability;

- scratch protection;

- perfect layout and pattern;

- exact dimensions;

- elementary processing.

It is also important to note that each panel meets a high emission class, denoted as E1. The emulsion used in production, like hardeners, does not contain chlorine

This sets Egger apart from a number of competitors.

In fact, the material can be considered one of the most environmentally friendly among the entire range of our market. This allows you to independently assemble wardrobes or other furniture, and safely use it in children's rooms.

Another advantage is the lightness of the structure without loss of strength. Due to this advantage, it is possible to increase consumer qualities, improve the ease of use of furniture components and all furniture in general, and reduce wear and tear of used fittings and mechanisms. The load is reduced, and therefore the service life is extended.

Colors and textures

When planning to purchase material for a furniture body or decoration, it is necessary to take into account not only the technical characteristics, but also the color with the texture. In this regard, Egger has everything at the highest level, since there is a matte surface and gloss.

I cannot enumerate literally all the decor options for laminated chipboard. But I will choose the most popular and demanded ones. These include:

- bardolino oak;

- nut;

- oak cremona champagne;

- dusty gray (aka asphalt);

- concrete chicago;

- Cherry;

- French walnut;

- w1000 white premium;

- aluminum;

- ferro bronze;

- metallic copper;

- alpine lake;

- titanium;

- metallic gold;

- chicago light gray;

- flax anthracite;

- denver oak truffle, etc.

You can choose the decor by name or by article. Here it is already more convenient for someone. It all depends on your taste and individual preferences. Egger can satisfy literally any request, based on the range of decor for laminated chipboard.

Specifications

The final price largely depends on the technical characteristics and decor. For example, if chipboard has a thickness of 25 mm, the sheet will cost less than chipboard with a laminated coating of the same type, but with a thickness of 8 mm.

It is important to note that the choice of slabs largely depends on the thickness of the sheet, since they are all produced in the same size. Namely 2800x2070 mm

The thicknesses can be selected from a wide range of options, which include the following parameters:

Let's say you want to order a batch of laminated chipboard. You have already managed to decide on the color palette, but it is difficult to find the number of sheets.

Using several options as an example, I will now tell you how many sheets you will receive when ordering 1 pallet. Please note that all sheets have the same dimensions 2800x2070 mm. Their density is also the same and ranges from 660 to 670 kg / m3. All sheets have a single emission class E1.

Consider several sheets of varying thickness.

Then decide for yourself how much and what material you need to purchase in order to assemble furniture, make certain structures.

Egger is considered one of the leading manufacturers in the world. Moreover, consumers highly appreciate not only laminated chipboard, but also the rest of the offered range of products.

Thanks to everyone who is with us! Do not forget to subscribe, tell your friends about us and come to us again!

General characteristics

Egger laminated chipboards are made from standard chipboards. In their manufacture, up to 90% of flour from coniferous trees is used. The raw material has a fine structure, there are no foreign impurities in it, including small debris, sand, tree bark. Before production, it is thoroughly processed, dried, mixed with resins, hardener and supplied to the pressing equipment.

Chipboard slabs have a high density - 660 kg / m3 and more. These indicators are achieved due to the maximum compression of the feedstock. To improve the performance and aesthetics of the material, finished chipboard sheets are coated on both sides with paper impregnated with melamine resins. In the process of pressing and heat treatment, it is transformed into a strong protective shell.

Features of laminated chipboard Egger:

- lack of unpleasant odor due to the low content of formaldehyde and the absence of chlorine;

- excellent moisture resistance, which is ensured by a reliable and durable protective laminated coating;

- resistance to the effects of chemically aggressive compounds (it is allowed to use any non-abrasive agents to care for surfaces);

- increased resistance to mechanical abrasion, temperature effects;

- resistance to UV radiation;

- light weight (sheet 10 mm thick with dimensions 2800x2070 weighs 47 kg).

Egger produces 1 grade moisture resistant chipboard sheets. They have a perfectly smooth surface without chips and other externally noticeable mechanical defects. Their surface is carefully sanded, and the size corresponds to strictly established standards.

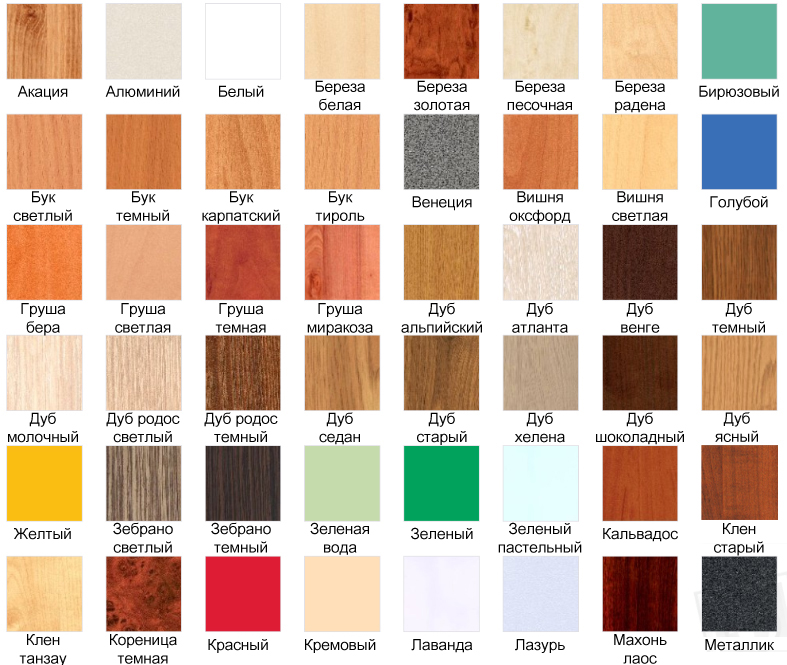

Palette of colors and textures

When choosing laminated chipboard panels, it is important to take into account not only their technical parameters, but also the color gamut and texture. Egger offers over 200 variations with different decors

Materials can be white, monochromatic, colored, wood-like, textured. The choice of one-color products is quite rich - these are "White Premium", gloss black, "Lime Green", gray, "Blue Lagoon", citrus and other colors. The assortment includes more than 70 shades of monochromatic color palettes. The panels can also be multi-colored. Photo printing presses are used to create them. The manufacturer offers more than 10 types of colored plates.

There are textured panels for marble, leather, stone, textiles - only about 60 of these options. The most popular ones are:

- "Concrete";

- "Black graphite";

- "Gray Stone";

- Light Chicago;

- Cashmere Gray;

- "Beige linen".

The most demanded materials are those with cladding imitating natural wood. The Austrian manufacturer offers more than 100 types of such solutions, including:

- sonoma oak;

- wenge;

- "Natural Halifax Oak";

- American Walnut;

- Bardolino Oak;

- "Halifax Oak Tobacco" and others.

The surface can be shiny, matte, semi-matt, fine-grained or textured.

A bit of history

The company dates back to 1961. It was then that the very first press was launched and put into operation, on which sheets of high-quality chipboard were produced. It happened in the city of St. Johann, in Austria.

Just 5 years later, the company bought a plant in Vegle, also located in Austria. Further, enterprises in Great Britain, Germany and other countries joined the production. Currently, Egger has representative offices, factories and factories in the following countries:

- Austria;

- Germany;

- United Kingdom;

- France;

- Russia;

- Romania;

- Turkey;

- Poland;

- Argentina.

The list is more than impressive.Therefore, it is not surprising that Egger's laminated chipboard is known in almost every corner of the world. At the same time, the products are in great deserved demand. Plates can be found not only in cities such as Moscow, St. Petersburg or Yekaterinburg, but also in small stores of building and finishing materials in much smaller settlements of our country.

Usage

Laminated chipboard panels from the Austrian manufacturer have found wide application in the construction and furniture industry. Various furniture is made from this material - individual structural elements, facades and cases. In furniture production, laminated chipboards have gained popularity due to their low cost in comparison with natural types of wood, an extensive color palette.

Plates are often used in the manufacture of kitchen furniture. Such furniture will serve for a long time, subject to the rules of operation. Laminated particle boards are also used in the production of:

- countertops and tables for the kitchen;

- kitchen chairs and stools;

- beds;

- writing tables;

- cabinets;

- dressers;

- frames of upholstered furniture.

Austrian panels are used in construction and renovation works. They are used in the production of interior partitions, various collapsible and non-collapsible structures. They act as a basis for floor cladding and sub-floors. They are also used as wall panels. Due to their good strength and low cost, the slabs are used to create commercial structures, for example, bar counters.