Peculiarities

Today's laser machines with numerical software successfully process workpieces from any material (glass, polymer, paper, plastic, stone, wood, steel, rubber, and so on). However, despite the impressive versatility, any modification (or line of models) has its own direction.

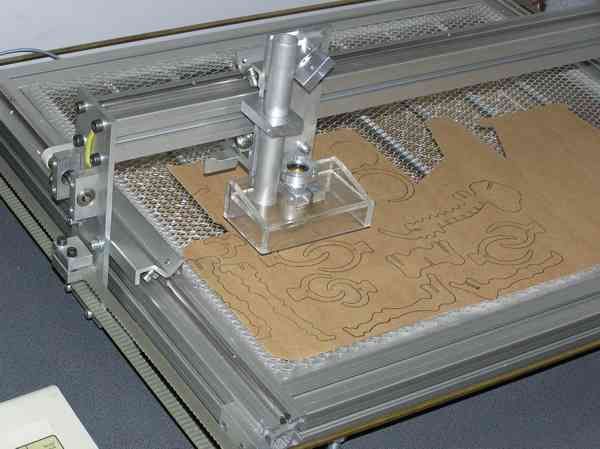

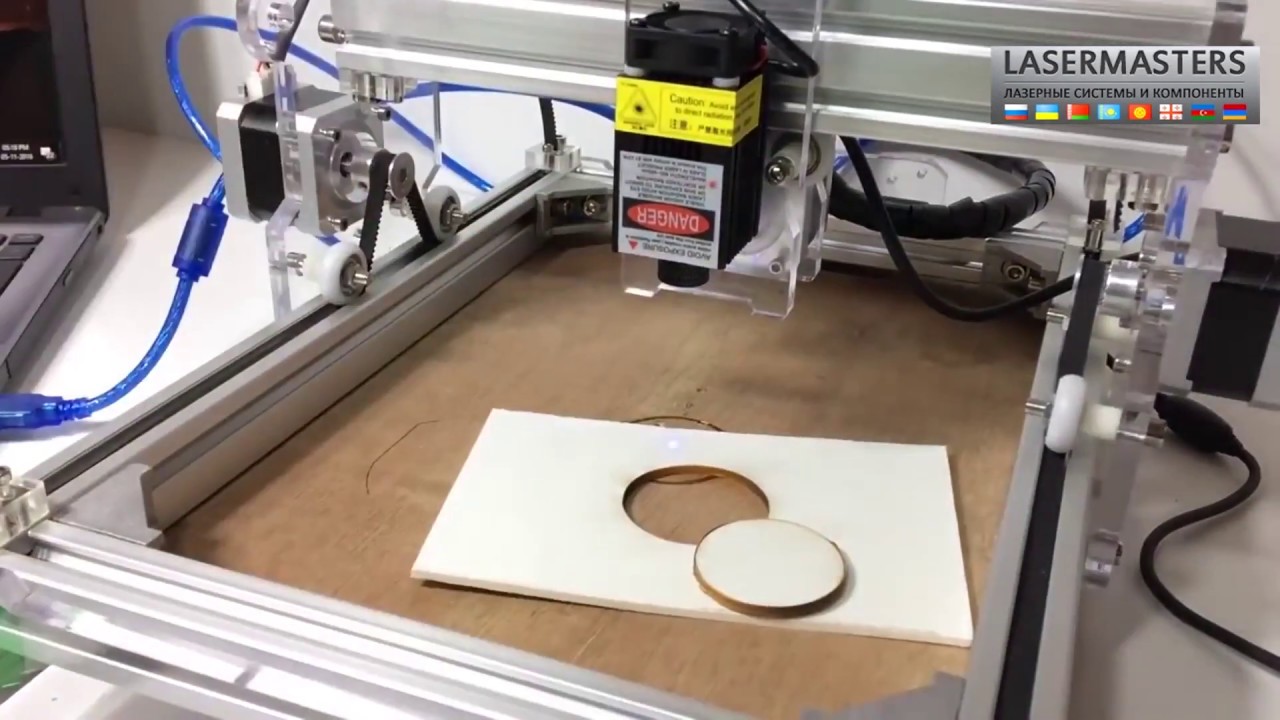

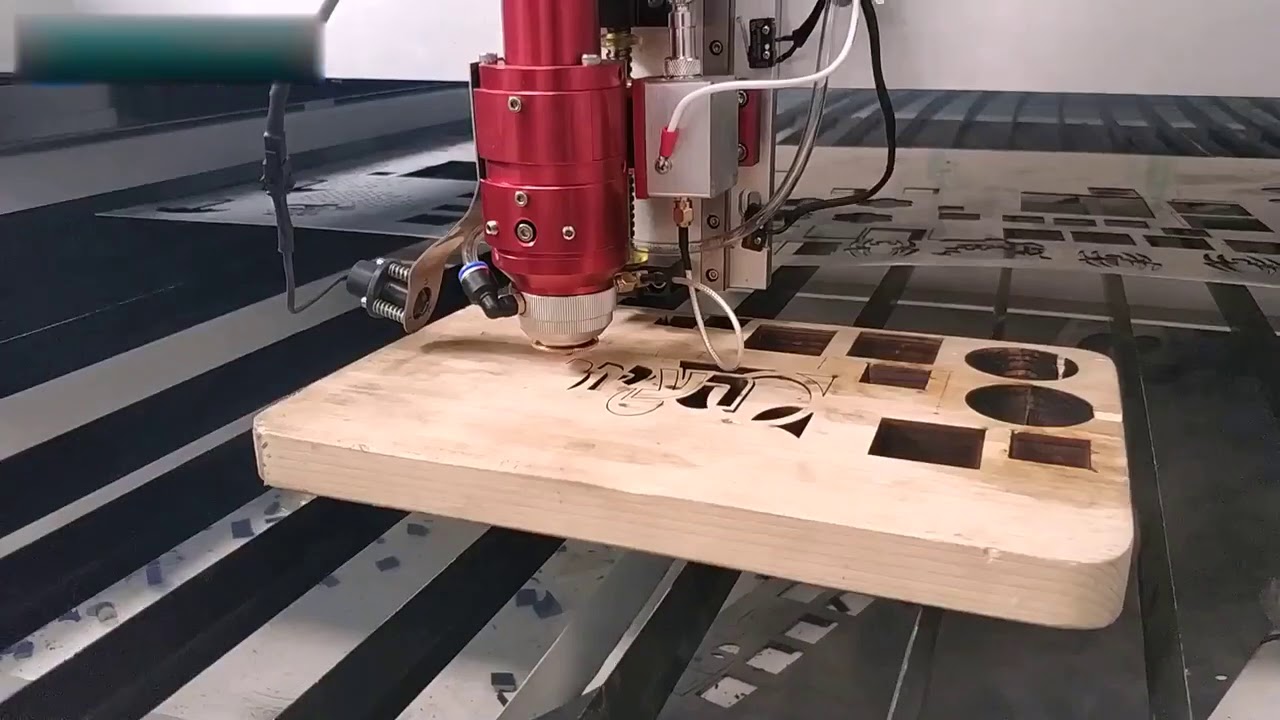

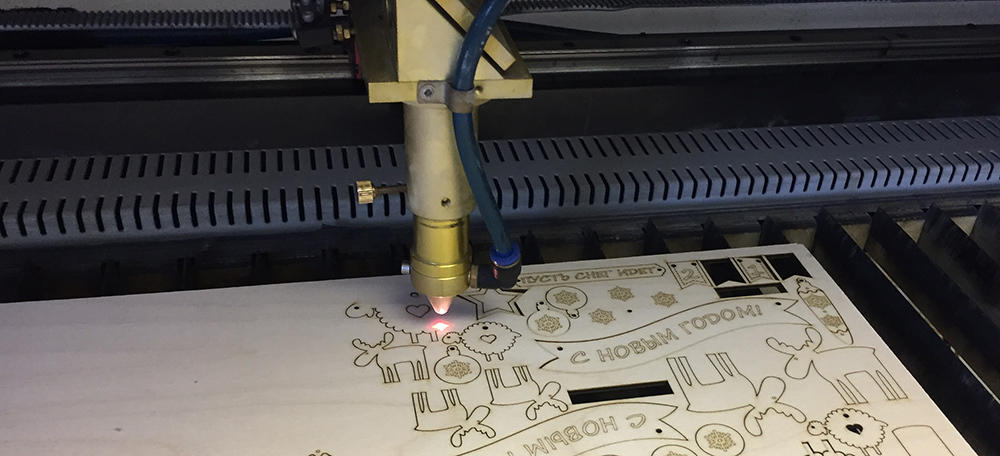

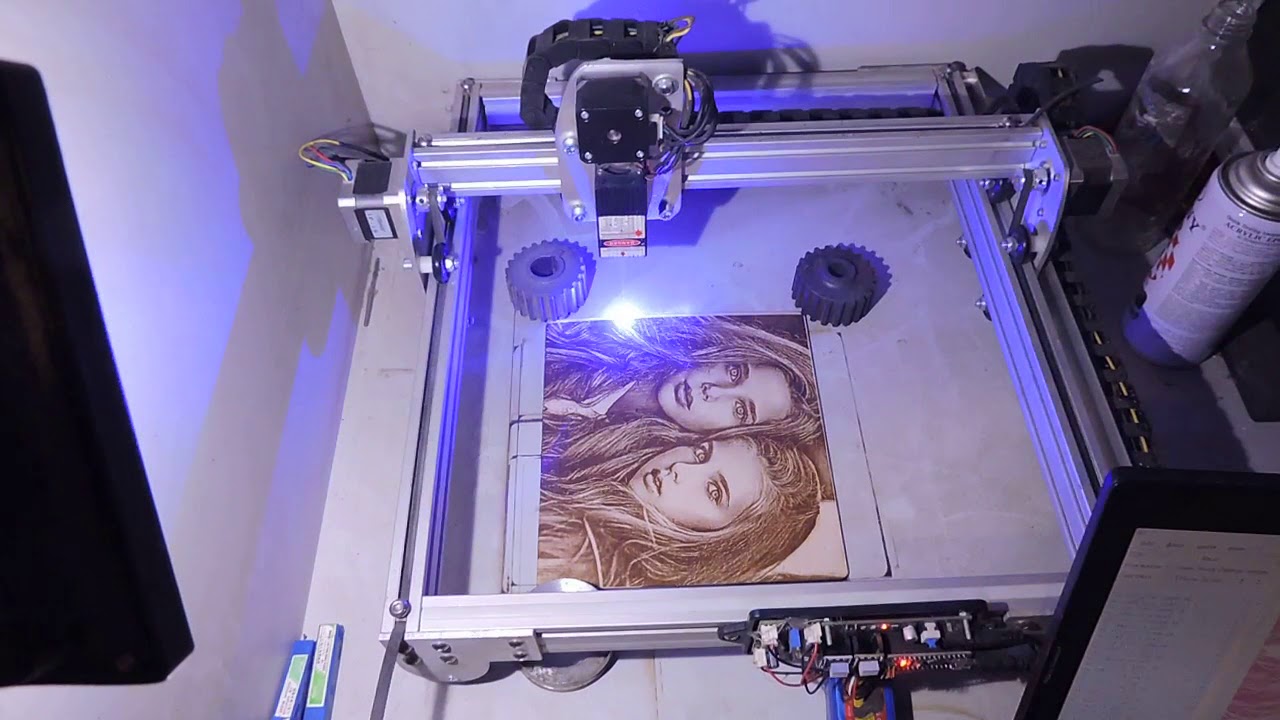

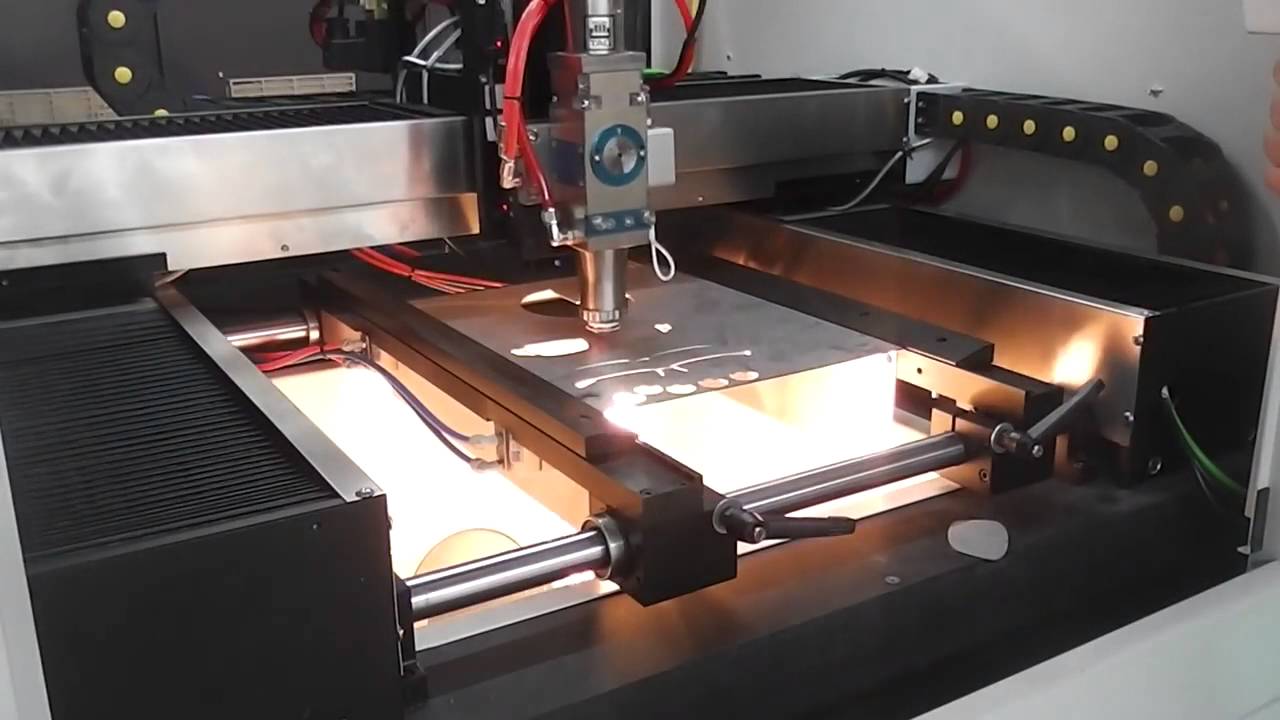

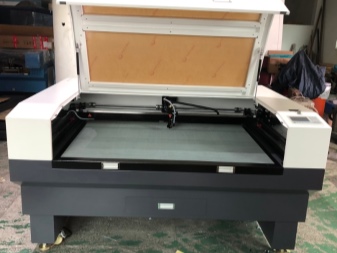

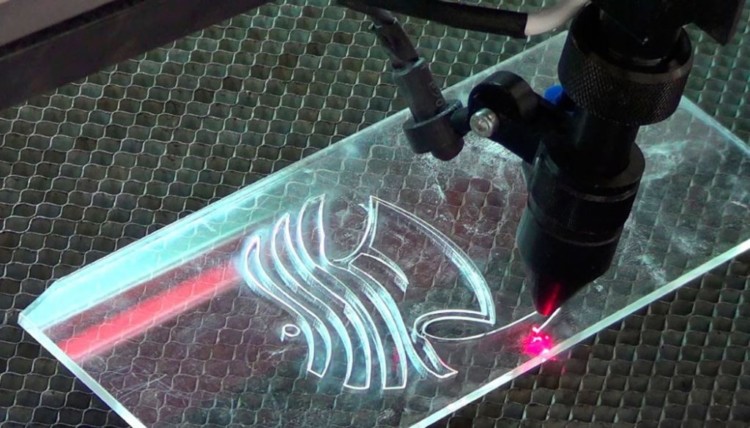

Desktop laser engraving machines. In the majority of small dimensions, they do not need installation in a specialized room (suitable for office and even for home - when there is such a need). The engravers are equipped with a good optical system, only its power is relatively low. And yet the engraver can carry out engraving of good quality (drawing three-dimensional and planar patterns on a plane) and, of course, a through cut of workpieces of insignificant thickness from most materials (except for steel), only slightly yielding in the productivity of cutting and cutting to other modifications of laser machines.

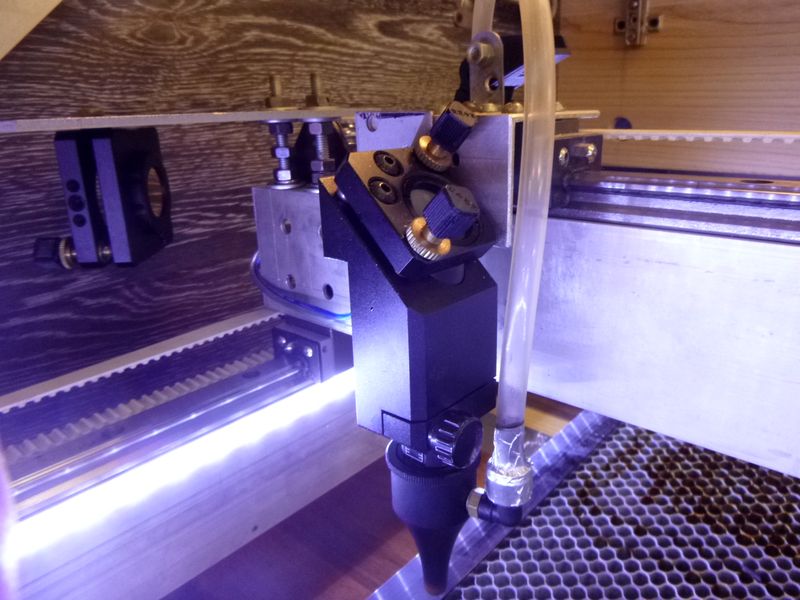

This is achieved due to the special structure of the optical system of the coder. Some lenses can move mutually, as a result of which the laser beam formed by the CO2 tube appears in a 2-dimensional plane and is sent to any point on the workpiece at the required angle. At the same time, the head of the tube directs the beam not with a flat lens, but with a specialized lens that maintains the stability of the laser under various operating conditions.

Laser Cutting Tools Capabilities

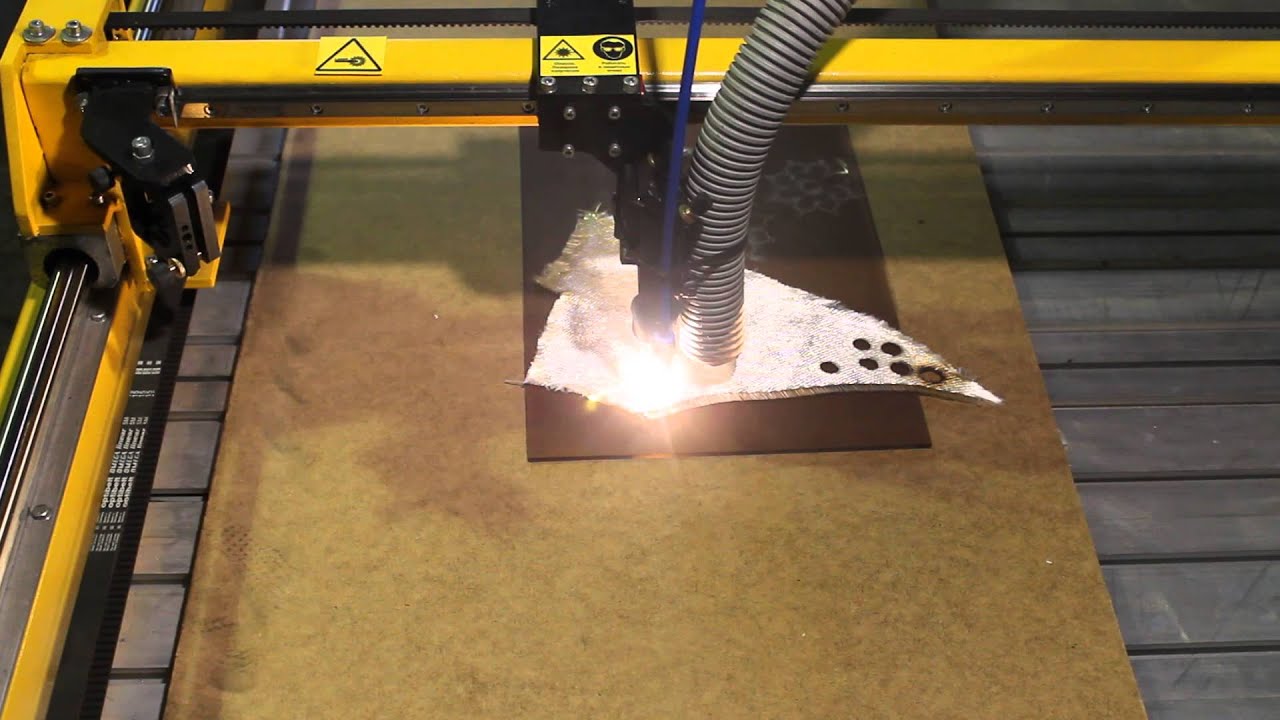

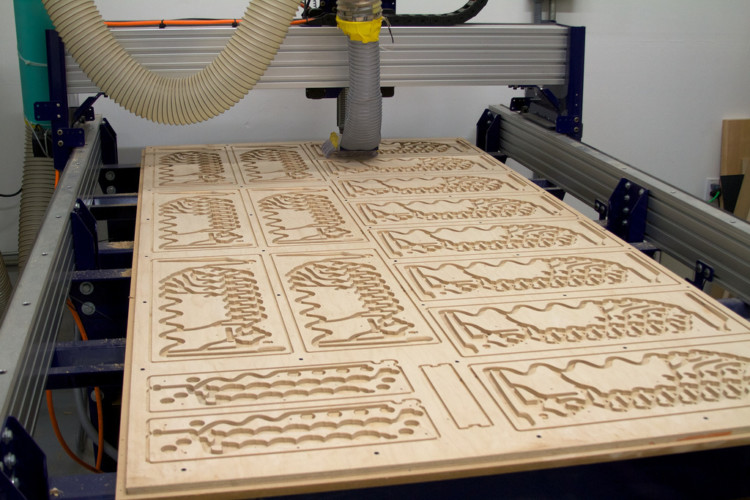

According to their intended purpose, all existing models of laser cutting machines for wood are divided into the following classes. Firstly, these are devices with a small margin of power, which are mainly intended for woodworking operations. And, secondly, these are units with a fairly powerful emitter used for cutting solid materials (including non-ferrous metals and similar substances).

Small-power laser machines designed for processing wood materials (plywood in particular) are in demand among craftsmen for home and household use. They are installed in small private workshops for personal needs or permanent production work.

Regardless of the features of a particular laser unit, they are all capable of performing the following unique operations:

- cut free-form blanks or stencils from solid sheets of plywood and veneer;

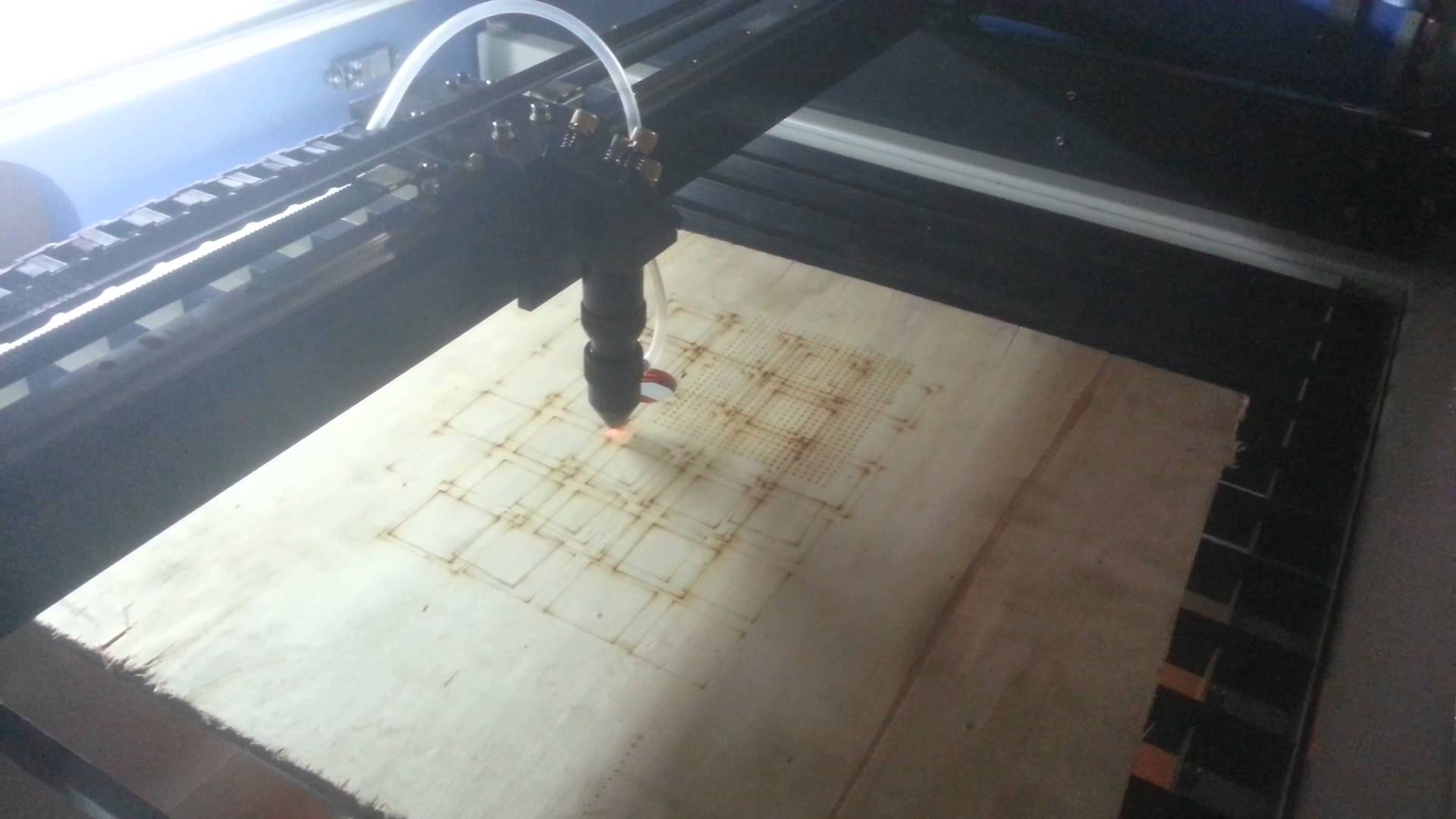

- engrave various markings and inscriptions on the surface of wood blanks;

- to apply the simplest drawings on the working planes;

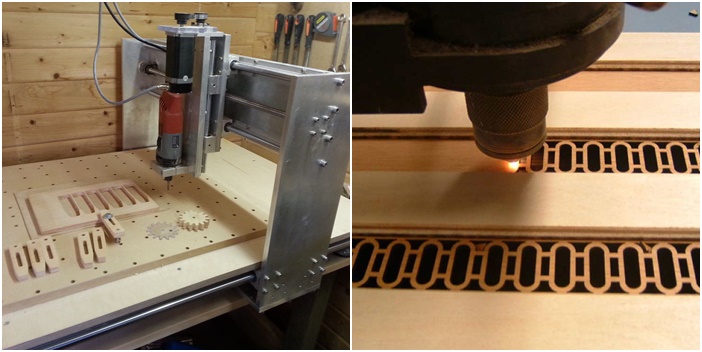

- milling wooden parts of varying degrees of complexity, accompanied by the selection of grooves, grooves and chamfers in their body.

Certain models of particularly advanced devices may have a 3D cutting function. Depending on the configuration of a particular sample, all of the listed functions can be present in various combinations, determining the final cost of the processing equipment.

Review of the best brands

Many companies are engaged in the production of such machines and parts for them. They can all be subdivided into 3 broad categories.

Luxury and premium equipment companies

This includes factories located in Japan, America, Taiwan and European countries. The list of especially recognizable brands includes: Farley Laserlab (America), Trotec (Austria), GCC (Taiwan), Schuler (Germany), EuroLaser (Germany), LaserStar Technologies (Iceland-America).

The products of these companies are characterized by ideal parts and assembly quality, good productivity and durability. Tubes with active gas, as a rule, are made of ceramics or are enclosed in an iron shell, and the period of their operation can reach 100 thousand hours. Not every enterprise can afford this equipment, since the price is quite high.

Brand firms in China

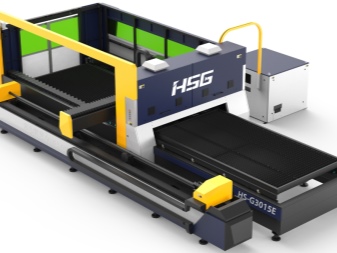

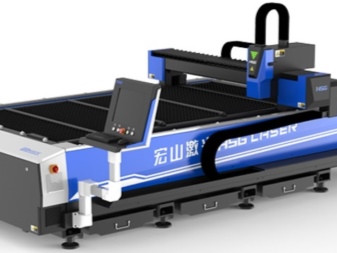

The reputation of products made in China is not the best, only such views are not completely impartial.Large manufacturers are trying to enter the world market and take a strong place in it, in this regard, they invest all their efforts and resources in the development of laser technologies, their practical application in their own products and strict quality control at every stage of production. Laser machines of such brands as HSG LASER, WATTSAN, Raylogic, KING Rabbit, HGLASER are distinguished by very high performance parameters, a small volume of product returns under warranty and are quite lively competitors to expensive brands. Actually, luxury equipment from China takes first place in the ranking of the most purchased machine tools, since the price and quality have an acceptable ratio.

Laser copy machines

Produced by those factories from the Middle Kingdom, because of which the products of this country have become a model of poor quality. As a rule, the assembly of such machines is done in a hurry, and the parts may be inoperative a priori. The names of the models are either not given at all, or they are selected as much as possible in tune with the promoted brands, counting on the carelessness of consumers or their poor awareness of this issue. Most of them are highly inexpensive machines with low beam quality and unreliable laser emitters.

Criterias of choice

In fact, it is almost impossible to choose the best model specifically, since the purposes of using the equipment can be different, as well as the budget allocated for the acquisition, the planned volumes of manufactured products, or the main materials for the work. But a general classification based on manufacturers, sizes and a number of other characteristics can be put together.

So, when choosing a cutting equipment, there are important factors to consider.

Functions

According to the declared functionality, there is the following division:

- engraving machines with a relatively weak light radiation, sufficient only for performing shallow operations, when changing the settings, entailing an increase in the wavelength, these mini-machines can be used to cut plywood, veneer;

- equipment with a high resource of laser radiation, suitable not only for cutting wood, but also for milling it, it has an engraving option, which is carried out by changing the power of the CO2 laser tube.

Control type

Models of laser cutting machines are divided into:

- manually operated machines, which belong to the category of the simplest, cheapest devices, despite this, they allow you to make original products;

- more expensive CNC machines guaranteeing excellent cutting and engraving quality;

- multifunctional machines - this type of equipment combines the potentials of manual and automatic control.

Power and size

- A small-sized desktop laser-engraving machine with an insignificant resource up to 80 W, it can be placed in a small workshop or at home. The machine is suitable for making small souvenirs, it is capable of engraving, sawing and cutting thin plywood.

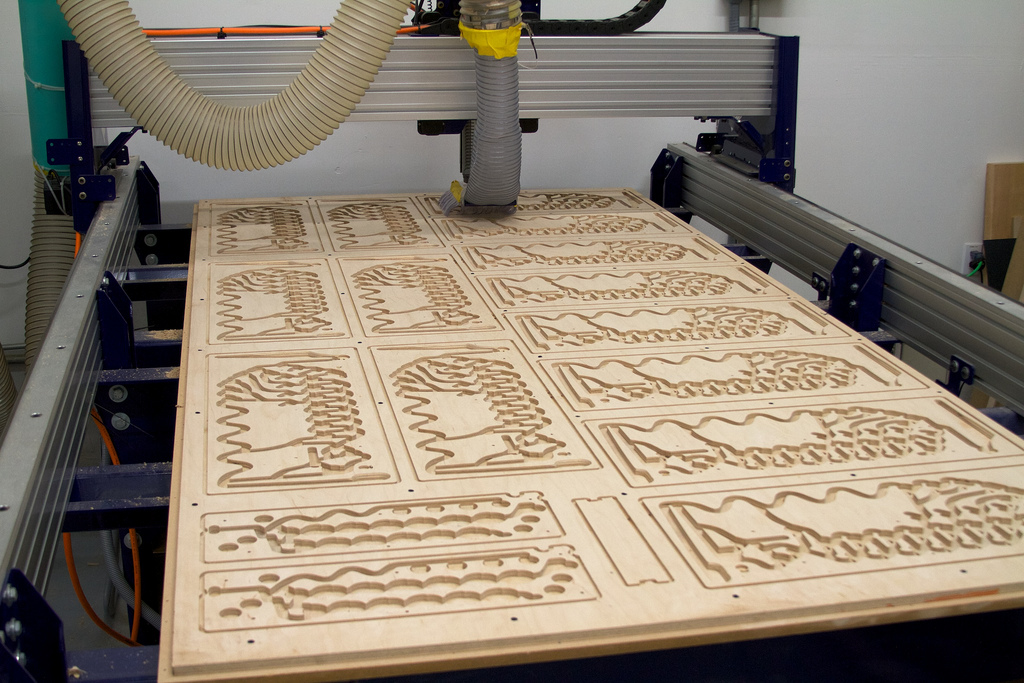

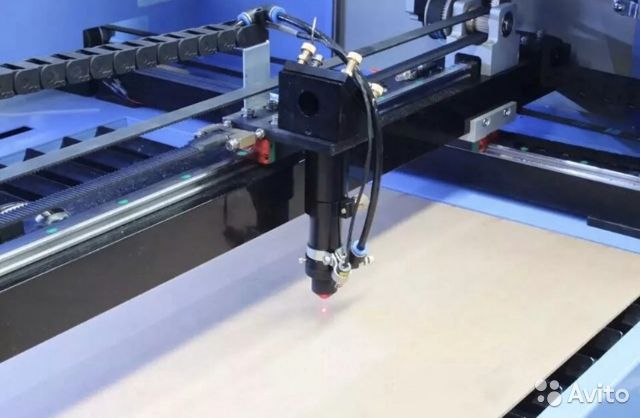

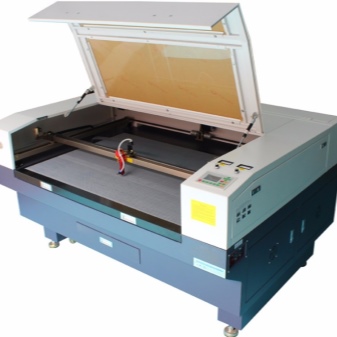

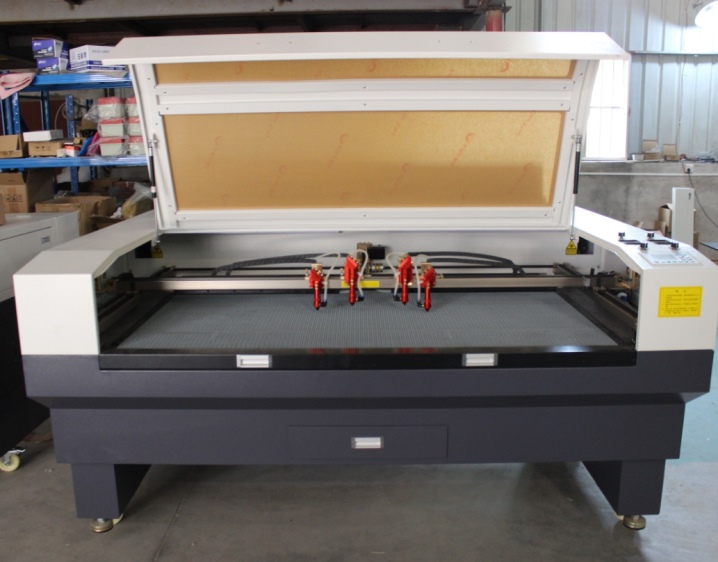

- A professional laser engraving unit has a resource of 80-195 watts. It is characterized by increased dimensions and is actively used in furniture production and woodworking for the manufacture of mass products and cutting out precise parts.

- The industrial wood laser machine can cut, sharpen, engrave and other operations. It has a decent size and is installed in large woodworking shops.

Manufacturers equip equipment with various options and auxiliary tools to simplify processing.

- Chiller is a device that cools CO2 tubes. It is needed in the case of long-term operation of the machine to equalize the temperature of the working elements of the equipment. It functions as an additional shell with a coolant connected to the pump.When the machine is not equipped with this device, it must be purchased separately.

- The air blowing system of the machine is required to lower the temperature of the cut and engraving area in order to prevent excessive burning of the seam.

The choice of a laser unit is determined by the requirements for its functional parameters and potential. For large-scale production, it makes no sense to purchase a miniature bench-type machine, as well as to install a production unit in an apartment.

There are multifunctional samples that can work with metals, wood, PVC and perform various operations: milling, sawing, cutting, engraving. The price of these devices is high, and it makes sense to buy them only for a large enterprise.

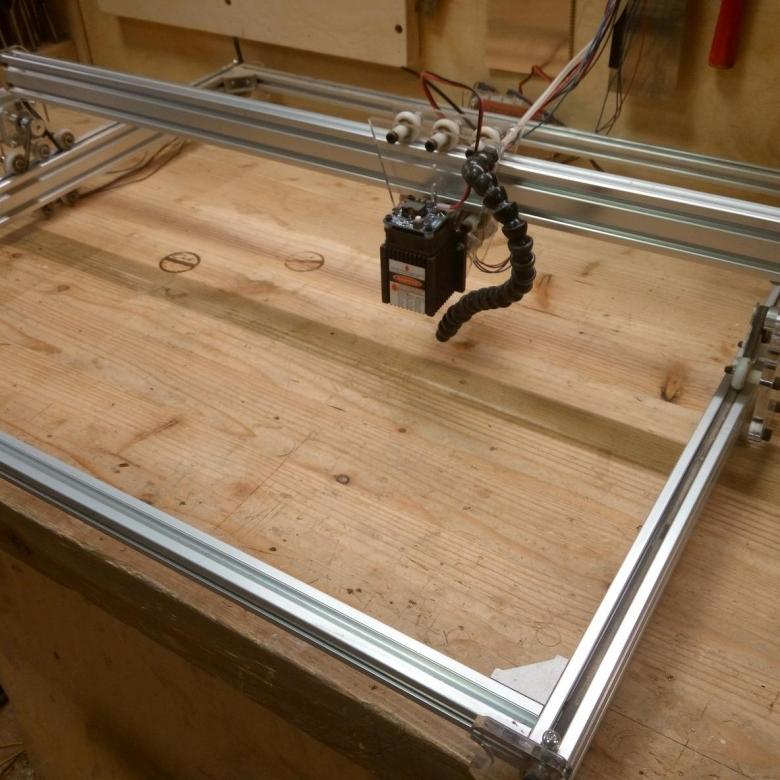

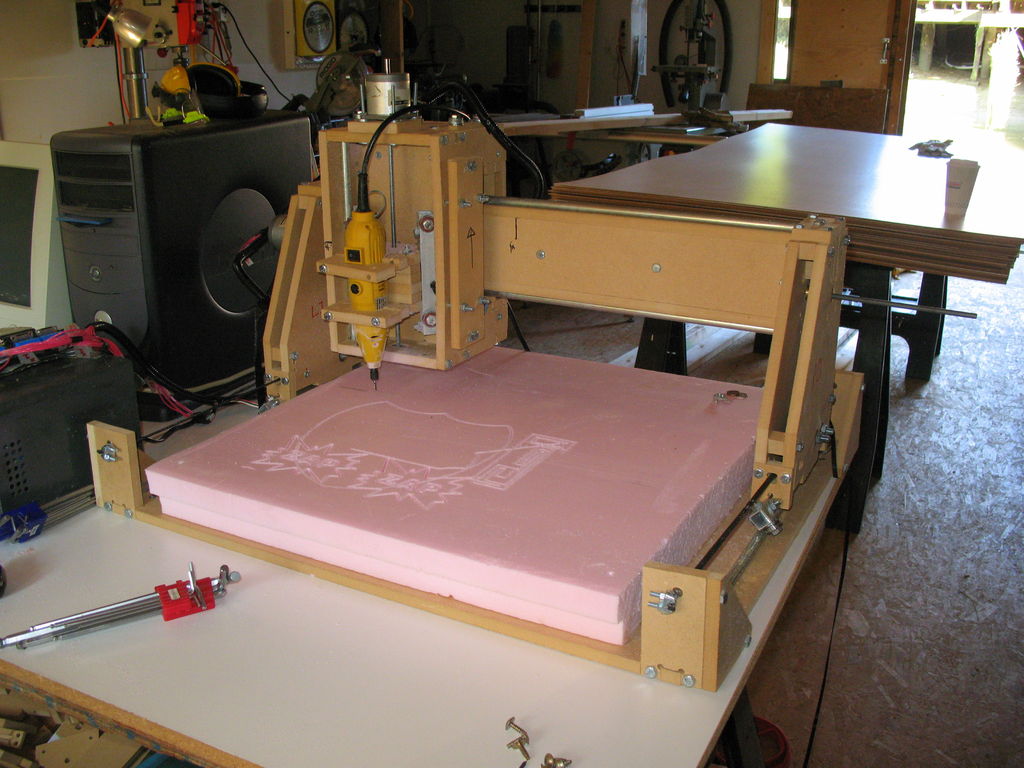

The ability to make your own hands

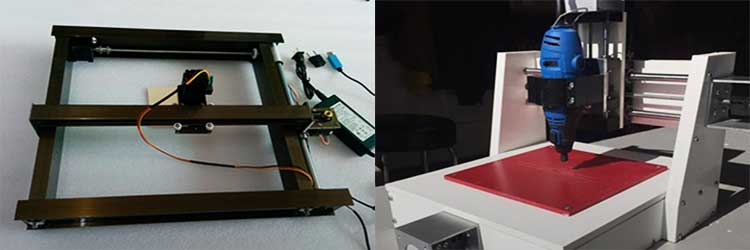

To independently make the simplest laser cutting device, you can use the tools at hand that can be found in the household of any thrifty master. When assembling such a device, it is allowed to use old parts from still working devices, such as, for example, a laser pointer, a lens and a disk drive with a working drive.

In addition, before assembling the laser machine, you should stock up on an electric soldering iron and a simple set of plumbing tools. The main functional element of a homemade laser cutter is a disk drive head with a write option.

The used laser emitter from the drive during assembly can be placed on its "native" carriage, which moves freely in both directions. To dismantle it, you will need to free the carriage body from many fasteners and detachable devices.

When self-made laser cutting machine for at home, you have to face certain technical difficulties. To eliminate them, you can use the advice of professionals with extensive experience in the manufacture of electronic devices based on old parts.

How to use?

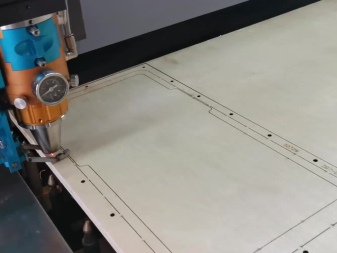

When cutting plywood on a laser machine, in order to avoid yellowish plaque along the cutting edge, it is necessary to use a more powerful compressor with an air supply of 1.5-2 atm to the nozzle.

When a cut is required without "shooting" from the back side, the material must be removed (raised) from the working surface by at least 1 centimeter. In this case, the beam will be scattered when "shooting" from the site, as a result of which there will be no traces on the plywood.

Perfectly flat plywood does not exist, any sheet turns out, leads. To prevent the laser radiation from shifting the focus when cutting uneven material, either practice a long-focus lens, or press the plywood against the table.

The most straightforward method of leveling plywood on the table with preventing "shots" on the back side involves installing Neo magnets on the table, placing a plywood sheet above them and fixing it on top with additional Neo magnets.

When cutting plywood continuously, clean the ventilation mesh often, as there is much more soot and burn from plywood glue than from organic glass. Because of this, ventilation clogs up quickly. For the same reason, mirrors and optics also need to be cleaned more often.

If you want to cut thick plywood, but the power of the emitter is not enough for this, then, according to the recommendations of experts, this can be done in two stages. First - you will need cut without supplying air, otherwise the laser machine will not cut it and will simply set fire to the plywood, because oxygen promotes combustion. At the second stage, it is necessary to supply air.

The following video explains how to choose a laser machine.

Principle of operation

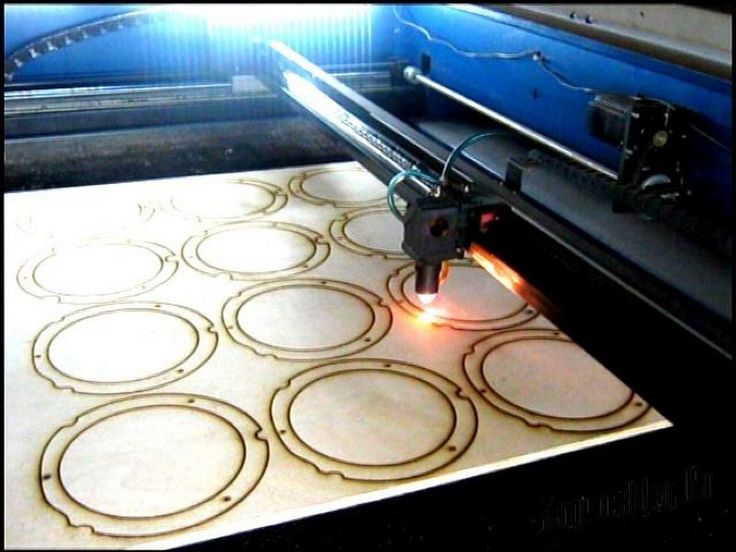

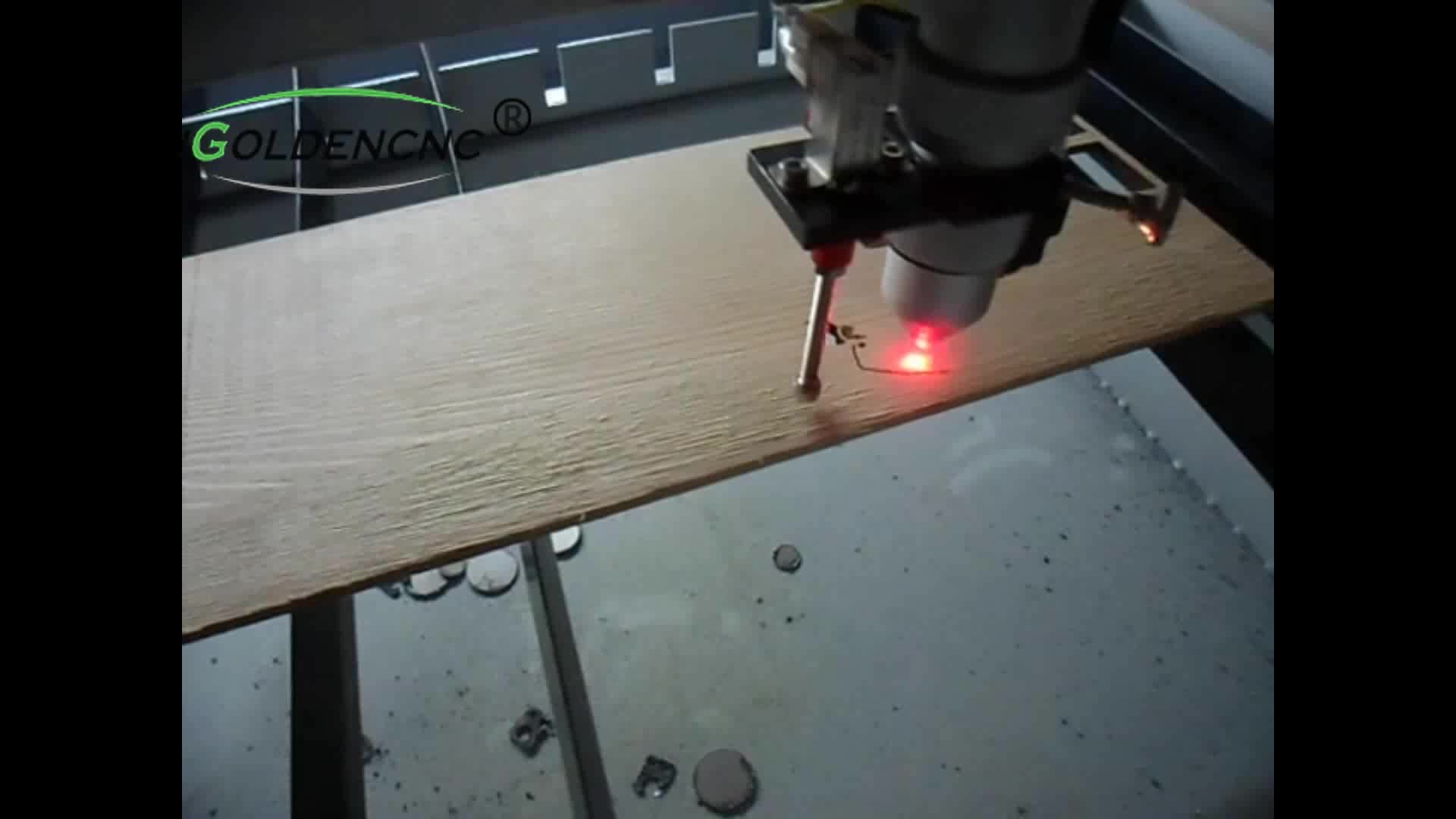

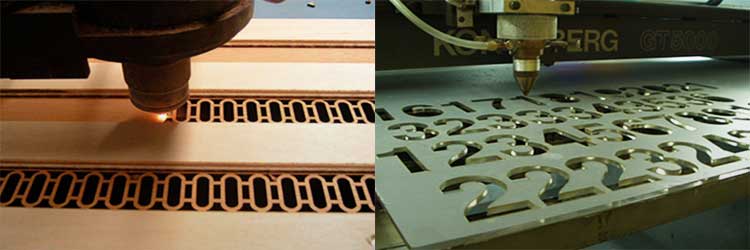

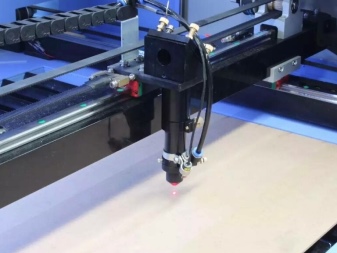

The main working tool of the apparatus is a laser, a high-power beam of light. When directed at a wood product, the contact area heats up strongly and the fibers of the material simply burn out. Thus, a non-contact laser thread occurs.Beam power may vary from model to model. The field of application of the device depends on this parameter:

- Low power laser machines are used for woodworking;

- More intense radiation is used to cut harder materials such as metals, natural and artificial stones.

The advantages of this processing method:

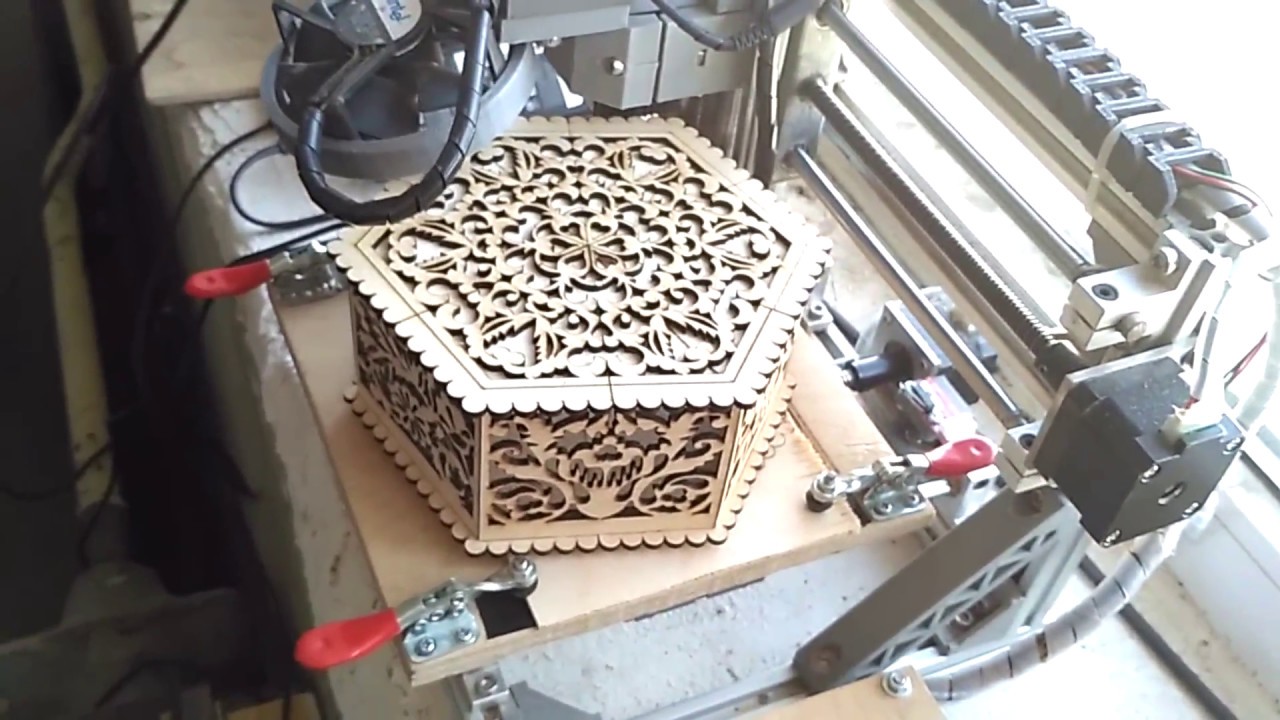

- The edges are perfectly smooth, do not require additional processing;

- Products of any size and shape can be processed;

- The devices are simple in manual and automatic control;

- Precise work down to small details and strokes.

The disadvantage of laser cutting and engraving wood - the processing sites remain scorched, dark brown and black. For a natural material of a natural shade, this is not critical, often manufacturers do not process the ends because of their finished appearance, combined with the main background. Another nuance is not in favor of the equipment - its high cost, although it depends on the configuration, functionality, size and power of the machine.

Possibilities

What can be done using a laser machine:

- Cut various blanks and stencils from a single piece of wood or plywood;

- The device is used for and engraving on wood;

- A laser milling machine is used for milling parts of varying complexity, i.e. grooves, grooves, chamfers, etc .;

- Advanced models contain the function of cutting 3D products.

Depending on the filling of the equipment, the functions are present in different quantities, which, accordingly, is reflected in the cost.

Operating principle

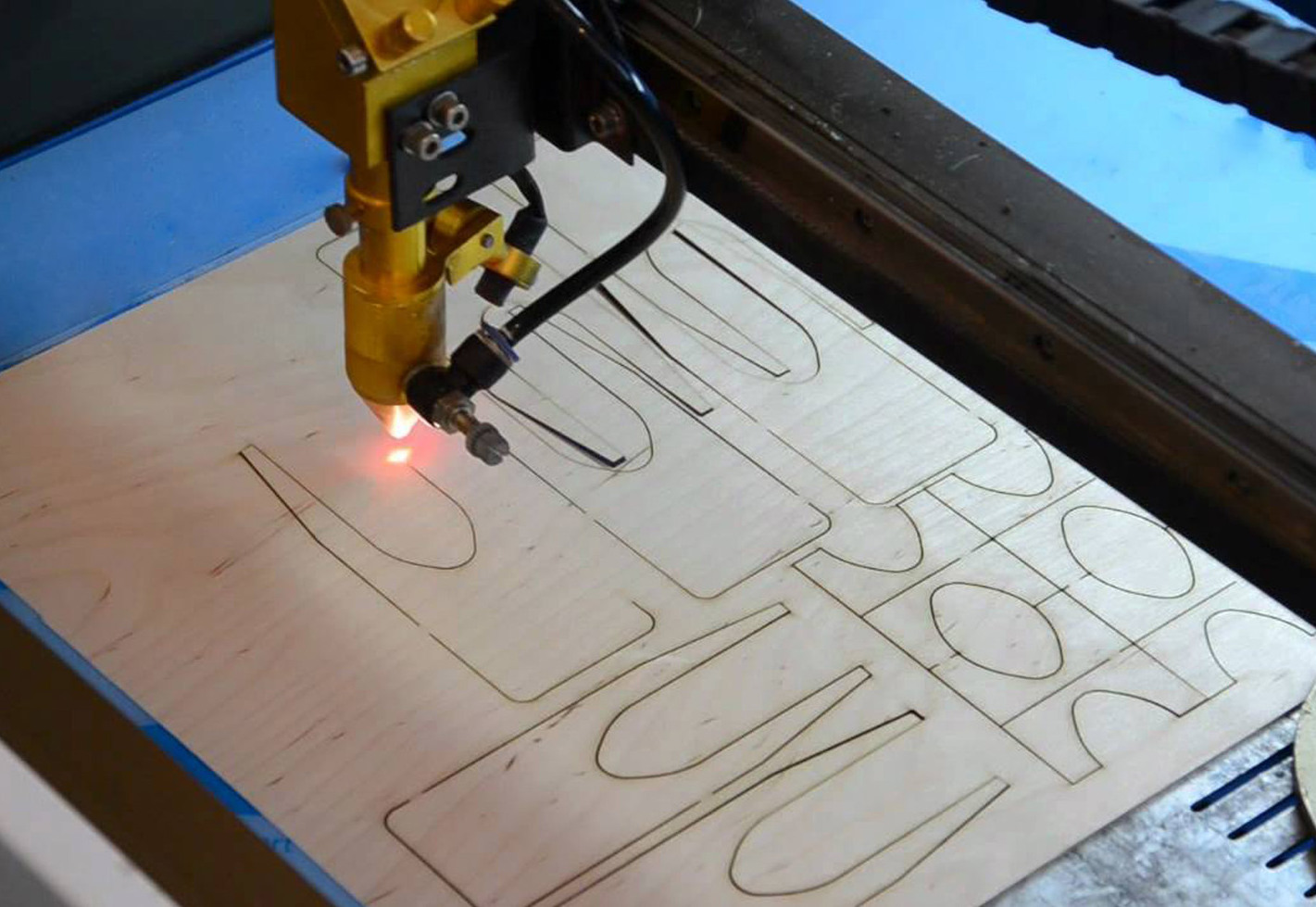

The main working tool of the plywood laser cutting machine is a high-power light beam, under the influence of which the processed area is thermally heated. As a result, part of the wood fibers burns out and forms a cut that cuts the workpiece into fragments of a given configuration.

For different models of machine tools, the power of a light laser can vary significantly, which affects not only their capabilities, but also the areas of application. In any case, the cut is smooth, there are no shavings, laser machines allow you to perform work quickly and as accurately as possible, to make original toys, furniture parts, souvenirs and much more.

2> Instrument selection

The more functions and power the plywood cutting machine has, the higher its cost. So, a small 40 W engraving tool can cost about 100 thousand rubles, and a more powerful device with the ability to process metal will cost 3-4 times more.

For cutting wood, plastic, leather, glass, mainly devices based on gas lasers (CO2) are used. If you need to process metals, then it is worth choosing machines with solid-state laser emitters (fiber and vanadates).

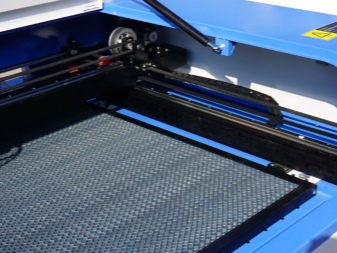

When choosing a laser tool for engraving, you should also take into account the height of the products to be processed and the area of the working field. Small-format laser cutters for plywood have a field size of 300 x 420 mm (you can process small products made of wood, acrylic, glass), and large-format laser cutters up to 2000 x 3000 (for furniture, parquet, advertising signs). There are also medium format models that occupy an intermediate position.

Equipment types

Various samples of laser machines may differ in their functionality, control method, power and dimensions.

By functionality

According to the declared functionality, there is the following division. Firstly, these are engraving machines with a relatively weak light beam, sufficient only for performing surface operations. In the case of their reconfiguration, accompanied by an increase in the wavelength, such mini-aggregates can be used to cut plywood sheet blanks, veneer.

And, secondly, this is equipment with an increased power of the laser beam, capable of not only cutting wood, but also milling it.They also have an engraving function, which is realized by reconfiguring the laser beam in terms of power.

3> By control type

According to this feature, all known samples of laser cutting machines are divided into the following classes:

- hand-operated woodworking machines belonging to the category of the simplest, cheapest and most affordable units. Despite this, unique products can be made with their help;

- more expensive devices with numerical control, providing high quality processing and engraving;

- universal machines.

The latter type of equipment combines the capabilities of manual and automatic control.

By power and size

According to these parameters, the following three types of plywood cutting equipment are distinguished.

The first type includes a compact desktop device for engraving work with a declared power of up to 80 watts. This machine is designed for the production of small-sized products from the category of souvenirs, it can also be used for cutting not very thick plywood sheets.

Professional models with a capacity from 80 to 195 watts and costing from 150 thousand rubles are intended for cutting wood and plywood. They have significant dimensions and are used for the production of serial products in the form of small batches.

And finally, samples of industrial woodworking equipment, capable of not only cutting plywood, but also boring blanks and engraving surfaces. These machines are quite impressive in size and can be installed in large woodworking industries.

> Individual rating samples of laser technology can combine several functions at once, which greatly facilitate the process of processing plywood products.