Application of acrylic varnish.

Acrylic varnish, made on the basis of alkyd-urethane resin, is used for treating wooden surfaces both for interior and exterior decoration.

High resistance to mechanical stress and detergents allows the use of acrylic varnish for covering parquet floors and wood, provided that the operating load is not excessively high.

Varnish can also be used to process paper, wallpaper, cardboard, building structures, various materials from plaster, drywall, rolled metal, plastics, vinyl, fiberboard, fiberglass, brick, etc. as it gives transparent, high-strength, elastic coatings without changing the color of the substrate.

After drying, the acrylic lacquer forms a hard foam. You can wash off dried varnish only with a special solvent.

Application

The service life and quality of the coating largely depends on its application. Only taking into account all the nuances of creating a protective layer, you can create a high-quality design using varnish. First of all, you should remember about all the necessary tools for work.

These include:

- protective gloves;

- respirator;

- rollers;

- brushes;

- tools for grinding.

Preparation is an important step. Since water-based varnish is not suitable for outdoor work and for metal, it should only be used on wooden surfaces, preparing them in advance.

It includes the following steps:

- Removing the old coating (if any). This procedure can be carried out using a grinder.

- Next, you need to clean the wooden surface from dirt and let the material dry.

- Priming of the wood is an obligatory step. You can buy special types of primers, or you can significantly reduce the amount of work and purchase a self-priming solution. It contains both primer and varnish components. It is recommended to apply the primer mixture in several layers.

- Depending on the density and components of the varnish composition, it is applied in a certain number of layers. The less dense the coating, the more coats must be applied. Acrylic, for example, is sometimes applied to the surface 8 times.

Manufacturers

Many companies in Russia and abroad produce acrylic varnishes. In the modern market, products of various brands are offered to the attention of buyers. The most famous of them are presented below.

"Chief Technologist"

The line of paint and varnish materials "Chief Technologist" is produced by the enterprise from "NovBytKhim". A significant advantage of the manufacturer is its own research laboratory. Acrylate varnish for wood is suitable for indoor and outdoor work in the conditions of the average Russian climate. They can be used to coat already painted surfaces with water-borne paints.

The coating dries within 2 hours at room temperature and normal humidity (40-60%), it is consumed economically. Manufacturers recommend using paintwork materials at temperatures above 10 C. After applying each layer, it is necessary to let the previous one dry for an hour. In a closed state, the composition is stored for up to two years. The varnish is produced in buckets with packing of 0.5, 1, 2 and 10 kg. The color range is represented by 12 shades of the most popular tree species (maple, beech, pine and others).

VGT

VGT products receive good customer reviews. The two factories have their own laboratory and are engaged in the production of a wide range of materials. VGT varnish is intended for antiseptic surface treatment.Due to its composition, it penetrates deep into the base, ensuring the safety of the surface. It is applied in a thin layer in the form of an elastic film.

It can be applied with any tools, it has a low consumption (from 100 to 160 g / m2). The layer ceases to adhere within 1 hour. Complete drying takes place after 2 days. The composition is presented in 12 shades. It is recommended to apply it at a temperature of 7 degrees C and above, as well as sufficient air humidity. Stored under normal conditions for 24 months. Available in 0.9, 2.2 and 9 kg formats.

Tikkurila

Tikkurila is a well-known Finnish brand with a century and a half history. Since 1995 the company has been operating in Russia. The products have long gained popularity in the Russian and world market of paints and varnishes. Finnish quality makes Tikkurila varnishes popular in the construction market. Acrylic compounds are available in several versions.

There are glossy, matte, semi-glossy textures. The varieties have good protective properties, they are perfectly aligned when applied. Material consumption is moderate: from 8 to 14 sq. m / l. The brand varnish dries completely in 24 hours. On store shelves, it is sold in cans of 0.9, 2.7 and 9 liters. The only drawback of this product is the high price.

"Lacra"

The Lakra group of companies is one of the leaders in the Russian production of acrylic varnishes. Thanks to the manufacture of products in many European countries, their quality meets the highest standards. These compositions are applied with a brush or spray gun, they have a small consumption (from 8 to 14 sq. M / kg). The assortment includes all variants of textures, the products have an attractive price and are sold in two versions: 2.5 and 10 kg.

The hermetic product is stored for up to two years. Dries after application in 5 hours, hardness takes another 3 hours. The surface is completely ready for use after 7 days. The company's paint and varnish materials are distinguished by good performance characteristics.

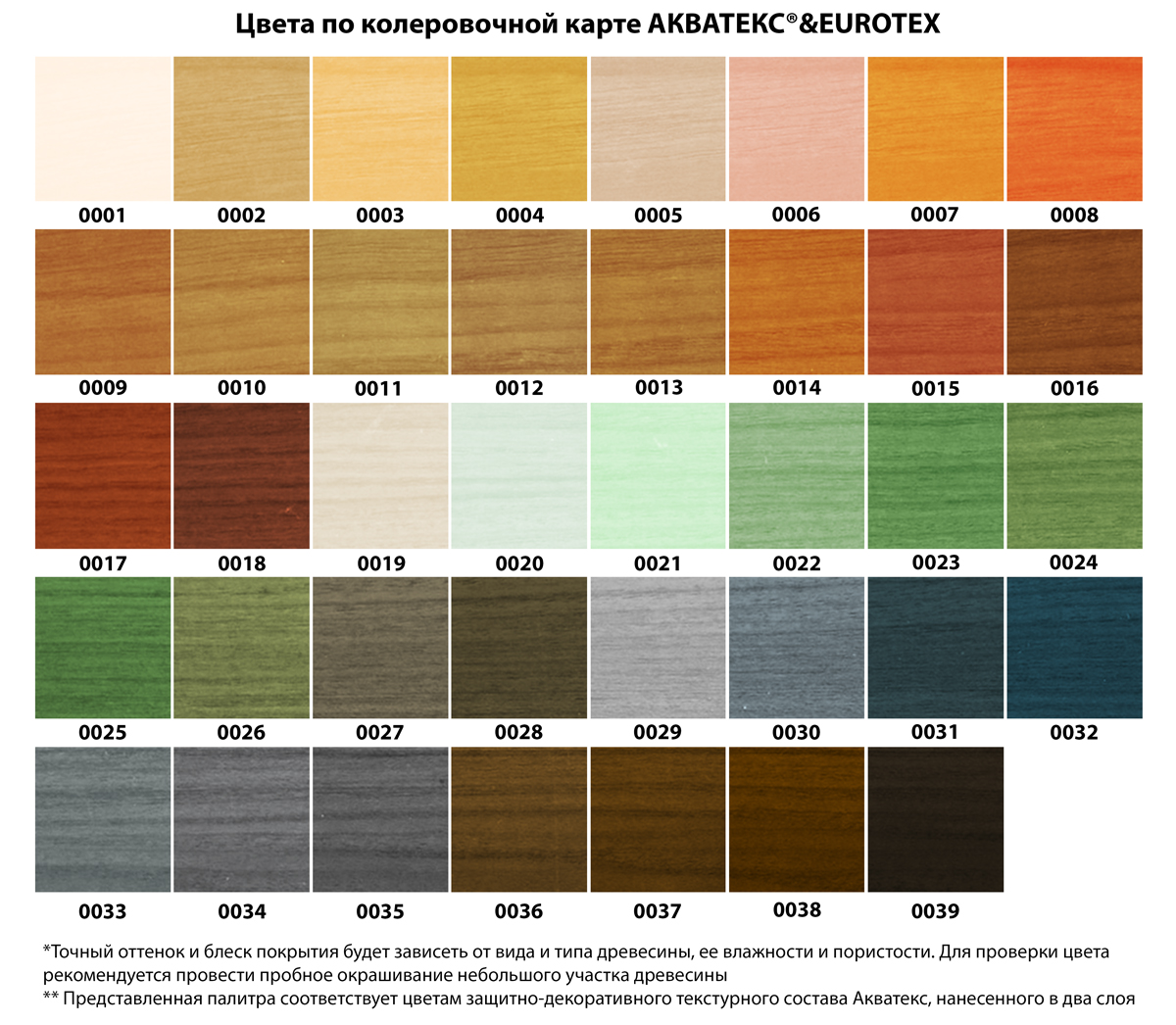

Eurotex

Eurotex acrylic varnish for wood is a product of a Russian brand. It guarantees the protection of the array from various kinds of microorganisms, moisture and temperature fluctuations. These products can be used for outdoor and indoor use. Paintwork materials are packaged in packages of 0.9, 2.5 and 9 kg. The trademark acrylic varnish is economically consumed: 1 kg is enough to process 20 sq. m of surface.

The company's products receive a lot of positive feedback from buyers and craftsmen. Among other comments, the durability of the applied layer is noted.

Features and basic qualities

This paint and varnish material is sold ready-to-use. This allows you to start surface treatment immediately after purchase. However, if necessary, it can be diluted with water, but the amount of this solvent should not exceed 10% of the total. Thus, in most cases there is no problem with how to dilute acrylic varnish.

It should be borne in mind that there are acrylic varnishes that are suitable for coating interior surfaces, and there are options for outdoor use. Due to its special molecular structure, this material is highly penetrating and versatile, i.e. it can be applied to most types of surfaces, including:

- cardboard;

- wallpaper;

- wood;

- brick;

- glass;

- plastic;

- decorative plaster, etc.

In addition, this material is irreplaceable when the question arises of what varnish to cover acrylic paint with. Wood surfaces often have to be coated with acrylic varnish in several layers. This is due to the fact that the water contained in this material can be absorbed into the wood fibers, leading to their swelling. Because of this, after the first treatment, the surface may become slightly rough and unattractive.

Main characteristics

The varnish is made on the basis of a special plastic dispersion that can dissolve in water. The composition of this material directly includes acrylic and a plastic dispersion. This structure allows you to create a durable protective coating after drying. A layer of varnish provides protection not only from various negative environmental factors, but also from mechanical stress.

This paintwork is great for applying to a variety of wood products such as stairs, tables, countertops, chairs, floors, and so on. It has proven itself very well in parquet processing.

Parquet varnish with acrylic can create various decorative effects that emphasize the natural beauty of wood. Moreover, this paint and varnish coating is a reliable means for finishing wood products. Due to its ability to deeply penetrate into the pores located in the outer layer of the material, acrylic varnish creates a reliable film on wooden objects, which significantly increases the water resistance of the coating.

The main components of acrylic varnish:

- acrylic dispersion in the form of a liquid polymer;

- antiseptic solution to protect the tree from adverse effects;

- plasticizer, due to which the creation of a transparent layer on the wood is ensured, which protects it from the effects of mechanical factors.

The acrylic-based varnish composition has many positive qualities that distinguish it from other modern paintwork materials.

Key material qualities:

Advice

Experts recommend following a few tips when using water-based varnishes.

To obtain a flawless result, as well as to maintain the performance characteristics of the varnish, it is important to prepare the working bases in advance. They must be even, clean (free of grease stains and traces of the previous coating), dry.

Primer is applied first

You must not skip this stage of work, the primer should be applied in 2-3 layers, which will reduce the consumption of varnish, increase the strength of its layer.

It is recommended to use special primers intended for the surface to be finished, for example, for wooden surfaces, a wood primer should be used. It is important to choose compatible primers and varnishes. They both need to be water based.

- Water-based varnishes cannot be applied with brushes. For these purposes, only a roller is used; on large bases, a spray gun can be used. The use of a brush threatens the appearance of noticeable stripes on the varnished surface, therefore, rollers of appropriate sizes are used even in corners and in other hard-to-reach areas.

- Before applying each subsequent layer, you must wait until the previous one is completely dry. Otherwise, unevenness and roughness of the surface cannot be avoided. If this recommendation is followed, but the dried layer of varnish is rough, then this is due to the deposition of dust on the varnish. This problem can be eliminated by grinding the surface with a defect.

- Before use, acrylic and polyurethane varnishes must be thoroughly mixed or shaken for 2–8 minutes, depending on the volume of the container with the varnish.

- Water-based varnish application is permissible only at temperatures not lower than + 12 ° C and not higher than + 30 ° C. Experts believe that the optimal range is + 20-23 ° C. Failure to comply with this requirement is likely to reduce the adhesive properties of the product. Changes in temperature during the drying process of the varnish usually leads to an increase in drying time and curing.

- When painting furniture, it is recommended to disassemble it if possible. This will allow you to achieve a better varnish application.

- If, after mixing, the composition seems too thick and inconvenient for application, it is permissible to add water to it, but not more than 10-15% of the total volume.

- If it is necessary to tint or renew the surface, you can use the color scheme. It must be thoroughly mixed with varnish, otherwise more and less bright colored stripes cannot be avoided when painting.

- Water-based varnish can be tinted only by impregnation on a similar basis. First, the test part of the varnish is prepared - dye is added to a small amount by drops. After mixing, if the shade of the composition suits, it is checked on a separate area of the surface.

- The bases can be tinted with a spray gun or foam swab. This will allow for a more even layer. With different thicknesses of the applied layers, the shades in the thicker area will be darker. Experts recommend painting surfaces in 2-3 layers, applying them as thinly as possible.

- When varnishing the plastered walls, it is recommended to first wax them. This will reduce the consumption of varnish and will allow you to get a noble shimmering surface that changes its appearance depending on the angle of illumination.

- Before applying the finishing layer of varnish, it is worth walking over the surface with sandpaper, and then dust it off. This will avoid the formation of bubbles on the last layer.

- During work, as well as during the drying period, the windows should be closed. This will prevent dust from settling on the sticky surface.

In the next video, you will find a comparative test of water-based varnishes.

Lucky Lacra: overview and product advantages

To choose a decent coating, you need to know the entire product line.

To choose a decent coating, you need to know the entire product line. We invite you to familiarize yourself with the acrylic products of the Lakra company.

Parquet alkyd varnish PF-231

Suitable for wood or metal surfaces

It is a high-quality alkyd-based product that, when applied, forms a glossy, abrasion-resistant coating. Differs in transparency, good water-repellent and decorative properties.

Suitable for wood or metal surfaces, including parquet or oil-painted floors inside buildings. Before application requires preparation of the base: primer, sanding or sanding, as well as cleaning from rust and scale (metal).

Drying time - a day, storage is allowed up to a year in a tight closed container, the agent is used only for internal work, but the varnished coating can be put into operation no earlier than 48 hours after varnishing. If it comes to floors, then you can bring in and arrange interior items on the 5th day.

Varnish PF-283

When applied, it forms a particularly durable coating characterized by increased decorative properties

When applied, it forms a particularly durable coating with enhanced decorative properties. It is used for indoor work, metal and wooden surfaces can be varnished, including those already treated with antiseptics, enamels or oil-based paints.

A prerequisite is the processing of the base before applying varnishing: priming, sanding, cleaning from dust, flaking pieces, as well as churning off scale and rust.

VLP-1 acrylic parquet varnish

These Lacra products are made on the basis of an aqueous acrylic dispersion.

These Lacra products are made on the basis of an aqueous acrylic dispersion and therefore are distinguished by an exceptional aesthetics of the final result. At the same time, acrylic colorless varnish forms a durable, moisture-resistant and abrasion-resistant coating. With an increased drying rate, tinted or colorless varnish allows you to apply two layers per day, while the bottom layer does not wrinkle or warp.

The products are intended for varnishing parquet floors and other wooden surfaces only indoors. Tinted varnish Varnish has a wide range of shades, while retaining the natural beauty of the base, giving the wood a noble gloss.The degree of gloss can be selected: glossy, semi-matt, matte. Product price from $ 25 per 1 kg.

Acrylic tinted varnish with UV filter

Tinted acrylic varnish is resistant to sunlight

Ideal for wood surfaces. The basis of the product is a water-acrylic dispersion. This means that the product in its final form will not lose its aesthetics, while at the same time it will receive an additional shade. Tinted acrylic varnish is resistant to sunlight, does not fade or fade when hit by a directional light source. Operational in drying, the products can be applied in 2-3 layers while maintaining transparency, only the depth and density of the shade are added.

Scope of varnish Tinted lacquer - indoors. Not only the wooden surface is covered, but also mineral bases: stone, brick, concrete, ceramic tiles or natural stone compounds. Requirements for the surface to be coated are standard: dryness, evenness, and for mineral bases - priming with a mixture of varnish and water 1: 1.

Product price from $ 30 per 1 kg. Produced in packs up to 10 kg, when frozen, preliminary defrosting is shown at room temperature without the use of additional heating methods. Tinted varnish Lacra does not lose its qualities during deep freezing, correct subsequent defrosting and thorough stirring.

Acrylic varnish ХВ-784

One of the most popular products in the line

One of the most popular products in the line. It is used for indoor and outdoor work, dries quickly and is characterized by increased frost resistance. Possessing ideal fluidity, the colorless product is indicated for varnishing uneven surfaces, gives the base decorative properties and does not have a harmful effect on the human body.

Colors

Initially, acrylic varnish for wood is produced in a milky white color, but when it dries, it forms a colorless film that only emphasizes the texture of the wood without giving it any special shade. The transparent film only adds shine, due to which the original tone of the wood appears deeper and richer.

In recent years, new production and tinting technologies have appeared, which have significantly expanded the color range of varnishes. Now you can easily purchase a tinted acrylic sample, which can successfully replace the stain. So you can solve two problems at once, without resorting to complicated procedures: to give the boards the desired color and to protect them.

According to the level of gloss, five degrees are distinguished, each of which is characterized by the amount of light reflected in percentage by the surface covered with such varnish:

- high gloss - more than 90%;

- glossy - 80-90%;

- semi-glossy - 40-50%;

- semi-matte - 10-15%;

- matte - less than 10%.

When choosing, it is worth keeping in mind the features of shiny coatings. On glossy surfaces, all the flaws stand out strongly. Moreover, it is more often used to decorate modern interiors in hi-tech, futurism and the like. Matte varnish, on the contrary, allows you to partially hide blemishes, and the surface is velvety. Such an effect is needed when creating an atmosphere of comfort, for example, in the styles of Provence, country and others.

When choosing a varnish, decide what effect you want to achieve in the end. You may just need to emphasize the beauty of the wood or slightly change its shade, give the wood a shine or pearl shine. Remember that if you do not like how this or that varnish lay, you can partially dismantle the acrylic film by "walking" along the surface with a grinder with a special grinding disc

Useful Tips

- Before applying the coating, be sure to shake it well before opening and then mix thoroughly.

- To keep the compositions in proper quality, it is worth keeping it only in a room with a positive air temperature.

- It is also not recommended to carry out work on varnishing the surface in the cold season. Under the influence of low temperatures, the varnish often cracks, loses its aesthetic appearance and requires additional surface restoration.

- Do not use thinner instead of water to dilute the composition.

- Consider the interior features when choosing a varnish. Glossy varieties are not suitable for all styles.

- When applying varnish, be sure to wait until each previous coat is completely dry. If you reapply on a dry surface, then there is a risk of irregularities and irregularities in its relief.

- Many people prefer to tint wood. To do this, add the color of the desired shade to the varnish composition. Remember that you need to add such a component in small quantities.

To make the varnish coating a real decoration of your interior, follow the recommendations of the professionals and be careful when buying and applying the composition. Then the surfaces of walls, furniture or floors will delight you every day with their beautiful and laconic look.

How to varnish parquet with water-based varnish, see below.

Peculiarities

The list of positive properties of varnish is quite wide:

- It can be applied to almost any degreased surface.

- It dries very quickly. However, the formation of a completely cured strong film will occur in about a week.

- It tolerates ultraviolet radiation well, without changing color and without acquiring yellowness, while maintaining the color palette of the surface to be coated. Even the action of direct sunlight does not cause its destruction.

- The use of colorless varnish will keep the original color of the product, its saturation and brightness for a long time.

- Resistant to temperature extremes.

- Will add shine or matte if necessary.

- There is a huge assortment, any specialty store will provide a wide selection.

- Thanks to its water base, it penetrates deeply into wooden surfaces, protecting them from decay, mold, mildew and pests, giving additional strength.

- Provides water-repellent properties.

- Not subject to ignition.

- Protects against mechanical stress and damage.

- To obtain a certain tone on the product, any water-soluble paints can be added to the colorless composition.

- It has a high level of adhesion to the surface, due to which the surface film becomes especially durable.

- Chemically inactive, it is not affected by aggressive environments.

- Does not have a strong odor.

- Environmentally friendly, as it is made from harmless elements; does not emit into the environment substances that poison the human body, and therefore can be used to decorate rooms where children are often.

- It does not cause any difficulties in application.

- The acrylic lacquered surface is easy to care for - it tolerates household detergents well.

- Suitable for various types of work.

- Not subject to abrasion.

- Possesses high decorative qualities, shows the texture of wood.

- Used economically.

To obtain a stable finish, you must adhere to the following application conditions: